Sooner or later, breakdowns happen with any equipment. The washing machine may not turn on, even if it was designed by the most experienced engineers.

Main symptoms:

- The indicators do not light up or they all light up at the same time,

- The washing suddenly stops

- I can't hear the engine running,

- It hums, but the wash does not start,

- The hatch door does not close completely, the lock clicks,

- The control panel reports errors.

All this is certainly scary. But the situation may not be as critical as it first seems. Let's figure out whether the problem is serious and how to fix the “washing machine” with your own hands, saving both time and money.

The manual is universal and is suitable for all vertical and horizontal models of the brands Ariston, Bosch, Candy, Gorenje, Indesit, Samsung, Siemens, Zanussi, Ariston, Bosch, Aeg, Beko, Electrolux, Haier and others.

The washing machine does not turn on: common causes of breakdowns

Before unscrewing the device or pressing the operating panel buttons, you should:

- Double-check, what if you simply forgot to plug it in?

- Double-check whether there is voltage in the network (by plugging in any other electrical appliance).

- Check if the cord and plug are damaged. There should be no creases, tears, or traces of burning.

Is everything okay with the cable, socket, plug? This means that the SMA does not work due to malfunctions in the “internals” of the unit itself.

Depending on the cause of the failure, the device may require:

- Simple repair. Problems can be easily eliminated without special knowledge and skills or special tools.

- Complex, expensive repairs, including comprehensive diagnostics of faults, replacement of individual parts and assemblies.

The most common reasons why the washing machine refuses to turn on:

- The hatch door for loading laundry is not closed. If the lock does not work (the latch does not click), the device will not give the command to start. The cause of the breakdown is obvious - a malfunction of the hatch locking device (UBL). There is only one way out - replace the faulty element with a new UBL.

- The “ON” button is broken. The malfunction can be determined by ringing the wires going to it and the entry and exit points (in working position). No ringing? The only correct solution is to buy and install a new button.

- The electronic module is broken. You can repair it if you have experience working with electrical engineering. Isn't there one? Contact the service center immediately. The specialist will determine the need for repairs and replace faulty elements.

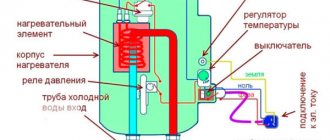

- The interference filter has failed. This part eliminates interference that appears during the start of the cycle, disrupting the operation of other equipment installed nearby. You can determine whether the filter is broken using a tester by ringing the contacts. The part does not work - you will have to replace the filter and the machine will work again.

- Internal wiring faults. The indicators blink, but the device itself does not function. Perhaps the lights were turned off for a short time when you were not at home. Visually inspect the wires and mounting sockets. Did any fall out? Paste in their original places. Replace burnt ones with new ones.

The washing machine does not spin

One of the useful functions of the machine is spinning. After all, in the process of alternating rotation of the drum, water is knocked out of the laundry, and we take the clothes out of the machine almost dry. The spin mode means that after rinsing, water stops flowing into the drum, rotation occurs first in one direction, then in the other. Spinning is completed by rotating the drum at high speeds in one direction. If the machine does not spin the laundry, then there is a failure in the nodes involved in the process: programmer, drive or winding switching relay.

When testing you should:

- turn off the machine from the network;

- remove the belt;

- turn off the motor;

- start the engine from the external network through the electrical circuit. Terminals 3 and 4, as well as 5 and 6, are responsible for the modes.

Important!

When starting the engine, there may be a jerk and the motor will begin to rotate. We recommend being extremely careful, as its rpm can exceed 10,000.

Troubleshooting Methods

Depending on the identified cause of the malfunction, the device may require:

- simple repairs - such faults can be fixed on your own without contacting a specialist;

- complex repairs - it includes complex diagnostics, replacement of individual components and, as a rule, is quite expensive.

If the Start button breaks, you need to purchase a new button and put it in place of the broken one. If the electronic unit fails, repairs can only be performed by a specialist with experience working with electricians.

If you notice that some wires and mounting sockets have fallen out, then you need to replace the burnt ones with new ones, and put the fallen ones back in their places.

The device may not turn on if there is no voltage. Troubles of this kind are identified using a tester and immediately replaced with working ones. A broken socket needs to be repaired - most automatic machines do not start washing when plugged into a socket with loose contacts or in unstable sockets.

Constant heating of the device and rapid cooling lead to the door lock breaking - in this case, a complete replacement of the lock is required. To dismantle, you need to unscrew the screws that secure the lock to the machine body

After the part is released, it must be removed, carefully supporting it with your hand on the other side.

Replacing a faulty lock with UBL is not difficult at all:

- you need to unfasten all the connectors with wires from the old part, and then connect them to the new unit;

- install a new part and secure it with bolts;

- return the cuff to its original position and secure it with clamps.

After this, all that remains is to run a short test wash.

If a new machine does not start or if the equipment is under warranty, there is most likely a manufacturing defect. In this case, you should immediately contact a specialized service center, since any attempts to fix the breakdown on your own will lead to the fact that the warranty will cease to apply and you will have to carry out repairs at your own expense.

In order for the SMA to work properly and startup problems not to bother users, the following recommendations must be adhered to.

Give your equipment the opportunity to rest - do not use it intensively. If you plan to do a couple of washes a day, then you need to take a break of 2-4 hours between them. Otherwise, the unit will operate at the limit of its functionality, quickly wear out and fail.

Obviously, there are many reasons for the lack of SMA initiation. We looked at the most common ones.

The following video shows one of the possible breakdowns of the washing machine, in which it does not turn on.

Worn motor brushes

If the brushes on the motor are not changed in time, this may cause the washing machine motor to stop working. You can determine the problem yourself by inspecting the collector. If during operation it sparks strongly (not necessarily around the entire perimeter), then the problem is obvious. If parts are replaced, at first they may also spark, which is normal, it’s just that the new brushes have not yet gotten used to the commutator. Loss of power is also a wake-up call. Warped brushes may not produce enough current and the motor will not be able to turn the drum.

It is recommended to install original brushes, since analogues can cause many problems during installation for several reasons. Analog brushes have slightly different dimensions and shapes, so they will have to be pre-treated. Finding a brush of the required length can take a long time, since different brands of washing machines differ greatly in this component. A self-made brush requires additional verification of its smooth movement without lateral play, which can cause jamming.

How to choose motor brushes

The durability of the brush is affected by its hardness. The presence of a copper tip is mandatory if it was also installed on the old brush. Graphite brushes should not be used; they are designed for low voltage use. After installing the brush, you need to let the motor run at low speeds.

Source

We do it ourselves!

Before you start repairing your washing machine yourself, you need to make sure that the plug is connected to the outlet. Perhaps the reason is that the household appliances are simply de-energized. After all, we often forget to check the simplest option and immediately sound the alarm. Then we will check the presence of electricity in the network. To do this, you can connect any electrical appliance and check its functionality. If there is electricity, the machine is connected to the network, but it still does not turn on, then it’s time to start repairing.

Is the outlet working?

To check the health of various conductors that may break, it is best to use a tester. This device is also called a multimeter. Using it, we will look for faults by “ringing” various wires, etc. Brief video instructions on how to use a multimeter here:

In order to check the socket, you can also use an indicator screwdriver or some other electrical device. For clarity, it is better to use a lamp. If the lamp connected to this socket lights up, then the socket is working. If it doesn’t light up, then we have found our breakdown. And all that remains is to eliminate it.

To do this, we will turn off the power to the apartment. This is done in the shield. Then, using a screwdriver, remove the cover and repair or replace the socket. For clarity, we attach a video:

Is the network cable working?

If used carelessly, the washing machine's power cord may become damaged. Usually it frays or breaks

In order to check this type of malfunction, let's check the wires using a multimeter. If you find a break, it is better to replace the entire wire. As a last resort, you can find the break point and fix it with a twist or soldering iron. But we do not recommend this option.

Broken button that turns on the machine

If your machine model is not new, then the breakdown may be related to the button that turns on the machine. There are two wires connected to the button. Using a tester, you need to make sure that these wires, as well as the button itself, are working properly. Let's check the button both in the off and on positions. If during the process of “ringing” with a multimeter you find a faulty button, then we order a new one and replace it.

Module and command apparatus

If all previous checks have shown that everything is in order, then we move on to the next possible reason - module failure. As in our other articles, we do not recommend repairing or changing the electronics module of a washing machine on their own for those people who do not have sufficient skills in solving similar problems.

But before you call a professional, you may want to check for other possible problems.

Interference filter malfunction

There is a possibility that the interference filter has failed. This part of the washing machine is needed only to ensure that various household appliances, such as a TV, radio and computer, do not interfere with the operation of the machine. It may break during long-term use of the washing machine or due to a short circuit. Three wires are connected to it at the input, and two at the output. We will also ring it using a tester and make sure that it is working properly. If it is faulty, then we buy a new one and replace it.

Lock failure

If the lock is faulty, then you may observe the following problem: when connected to the network, the indicator lights up. But even with the hatch closed, the washing does not start. In order to check if there is voltage at the lock when the washing machine is turned on. If there is voltage and it does not perform its functions, then it needs to be replaced.

Instructions for replacing the lock yourself in video format are here:

Violation of integrity and breakage of electrical circuit wires

During operation of the washing machine, some wires may come into contact with individual parts. This situation may cause friction and broken wires. Also, due to vibrations, they can become disconnected from the mounting sockets. In order to detect this malfunction, you must carefully examine all the wires. Such an inspection will make it possible to detect this malfunction. You can also “ring” suspicious places with a tester.

We hope this material will help you solve the problem. Happy renovation!

Carrying out disassembly

If you are wondering how to disassemble the Malyutka washing machine, then first you must remove the plug from the hole located in the back of the electric motor casing. The oblong hole of the impeller must be aligned with the hole in the casing. Through it, a screwdriver is inserted into the engine rotor. The activator is unscrewed.

You must insert a key into the hole in the activator housing and unscrew the housing. This will allow you to disconnect the tank. Disassembling the Malyutka washing machine at the next stage involves unscrewing six screws. Next, you can remove the flange and unscrew the locknut, as well as the rubber nut. They fix the switch. Now you can remove the washer and unscrew the screws that hold the casing halves together. Below it is an electric motor and other equipment elements.

Simple reasons that you can deal with yourself

Stopping and freezing are not always associated with global problems. It happens that due to inattention, the user chose the wrong cleaning mode, put things in the drum incorrectly, or the drain hose became bent/clogged. These and many other faults can be easily fixed with your own hands.

Program selection error

This problem is usually encountered in the middle of the wash cycle. The machine started working as usual: it heated the water, carried out a preliminary and main wash, and suddenly went silent. In this case, the door is blocked and the water does not drain.

In this case, you need to check which operating mode of the device is set. If it is a “delicate” or “hand wash”, then the drainage and spinning are automatically turned off. Simply turn the mode switch to the desired position and repeat the washing process. Some machines have an additional rinse and spin function. Using this option, you will be able to complete the wash.

Overload of laundry

Overloading a washing machine causes a lot of troubles, some of which will be noticeable immediately, while others will appear after some time. If the washing machine freezes immediately after turning on and selecting a program, you need to check whether there is too much laundry loaded into the spinner.

It is very important to ensure free rotation of the laundry in the drum of the machine. This is the only way to achieve uniform distribution of water and powder, and therefore better cleaning quality

An overloaded drum puts great force on the bearings of the device, which can result in failure or breakdown of the unit.

Before you start using a new appliance, you should read the instructions about the norms and rules for loading laundry. Each machine is equipped with a special sensor that monitors the weight of the drum with laundry and will not allow washing to start if it is overloaded.

To correct the situation, you need to turn off the machine and take out some of the things, postponing cleaning them until next time.

Imbalance

When loading laundry into the machine, you must not only follow the weight recommendations, but also ensure that the items are evenly distributed in the drum. If the machine has filled with water, turned the drum several times, but is not going to start washing, you can suspect the presence of an imbalance.

The cause of this problem may be improper loading of clothes and other things into the machine. Before washing, buttons and zippers on the products are fastened, items with Velcro are placed in special bags, and bulky rugs, pillows and blankets are washed separately.

You can deal with the problem as follows:

- disconnect the device from the network;

- drain the water using the drain filter located at the bottom of the unit;

- open the hatch;

- sort out the laundry, arrange things evenly in the centrifuge.

After this, you can set the desired program and restart the device.

Clogged water supply or drainage system

If the washing machine does not switch from wash to rinse mode, it can be assumed that the drain filter, pipe or drain pump is clogged. Waste water carries with it threads and lint, particles of dust and dirt, and sometimes much larger debris, such as coins, pins, paper clips that have fallen out of pockets.

To prevent this “wealth” from entering the sewer pipe, a drain filter is provided. Over time, it becomes so clogged that it is unable to pass water. As a result, the unit does not switch to rinse and spin mode, and the washing cycle stops.

In this case, you need to determine where exactly the fault is hidden: in the machine, the drain hose or the general sewer.

- Inspect the drain hose and straighten any kinks.

- Eliminate the possibility of blockage in the sewer. To do this, the end of the drain hose must be disconnected from the sewer pipe and directed into a bathtub or bucket. Start draining the water. If the water still does not drain, then there is a problem with the machine. Otherwise, you need to clean the sewer pipe.

- Remove and clean the filter located in the lower right corner of the device.

This simple procedure will bring the device back to life. If you empty your clothing pockets of debris and small items before washing, you will need to clean the filter no more than once a year.

Closing sensor on the “vertical”

On top-loading washing machines, problems with starting are often caused by a loading hatch blocker. This is a limit switch that prevents the control board from starting the wash when the drum is open. Also, on some models, this device is also responsible for collecting water into the tank.

If the limit switch is broken, the module does not receive an enabling signal and the machine does not start. To correct the situation, it is necessary to remove the “blocking”. To do this, we check the device for faults.

The switch is located under the top panel of the washing machine. The blocker is activated by a special pin, which is located on the loading hatch cover. If the drum is closed, then the protection is triggered. If there is no start, you need to check:

- is there any mechanical damage to the sensor device;

- are the levers and other mechanisms of the “locker” in good working order;

- Is the contact group of the switch stuck?

When the switch is activated, but the collection of water into the drum does not begin and the engine is “silent”, then there is a breakdown of the “blocker”. This means you need to remove the device and check its functionality. We proceed like this:

- disconnect the washing machine from the power supply;

- release the wiring from the switch terminals;

- We connect a multimeter to the blocker and measure the indicators.

If the malfunction is confirmed, you should dismantle the old device and install a new one. It is strongly not recommended to repair the switch by closing the contact group with a jumper. Such manipulations violate the conditions for safe operation of the washing machine and can lead to spontaneous combustion.

Possible actions and repairs

High-tech and structurally complex equipment requires detailed diagnostics, some knowledge and special tools. Therefore, an adequate assessment of your capabilities is the first mandatory point before any manipulation with such equipment.

The locking device needs to be replaced

The reason for its failure may be a long service life. The reason is the deformation of the bimetallic plate due to a constant temperature difference. Replacing an element requires disassembling the locking device (UBL).

- Unscrew the two screws securing the lock to the body. The element is removed by supporting it with your hand from the back.

- The wires with connectors are disconnected from the faulty part, then they are connected to a new spare part. It is again fixed in its rightful place with screws, the cuff is returned to its previous position, and secured with a clamp.

- They check the performance of the machine and do a test wash.

Testing and repair of the command device

If the results of checking the remaining nodes are zero, then there is only one potential culprit left - the programmer (command device). In this case, quite painstaking and careful work remains. The unit is disassembled into small parts, then the “patient” is examined.

- to gain access to the command device, first disassemble and remove the front panel of the washing machine;

- remove the electronic module and begin disassembling it;

- remove the cover by pressing the latches located on the sides;

- remove the board, inspect it for burning, if there are such places, solder them;

- The resistance at the contacts is tested with a multimeter;

- check (clean) the central gear, then all elements, including the core, are removed;

- test the electric motor winding, replace the wire if burns are detected;

- the parts are treated with alcohol and placed back, observing the reverse assembly order.

Not all washing machine models have relatively simple programmers; some are quite complex. In this case, no one can guarantee a successful repair, so it is more logical to replace the unit with a new module.

New cars - problems with the button

The latest generations of washing units are capable of presenting another “surprise”. This is a problem with the “Start” button, since the current supply to it comes directly from the power cord. To check the potential source of problems, do the following:

- disconnect equipment from the network;

- remove the upper part of the body;

- dismantle the control panel;

- disconnect the wires from the button;

- connect the multimeter, plug the device into the network;

- test the presence of current when in the on position.

If the button functions normally, then the search for the culprit devices continues. Otherwise, the faulty part is replaced. Some washing machines have a different operating principle, where the voltage is supplied to the electronic module/programmer. It all depends on the manufacturer and the specific model.

What to do to make your machine last longer

To avoid all kinds of damage, it is important to use the washing machine carefully. For proper operation you must:

For proper operation you must:

Strictly follow the instructions. Give the washing machine a rest. It is recommended to take breaks during continuous washing. So, the machine will last longer. After unloading clean laundry, the hatch should be left slightly open, which will prevent the appearance of mold and unpleasant odors. It is also necessary from time to time to wipe the cuff, wash the dispenser tray and run the machine in cleaning mode

It is important to prevent scale using special cleaning products. In order not to damage the machine, it is recommended to use special washing powders and gels.

Therefore, before purchasing cleaning products, you should familiarize yourself with the composition indicated on the bottle.

If you follow all these simple rules, your equipment will last a long time.

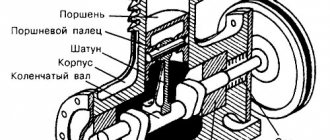

Kinds

The first thing you should do before starting diagnostics is to determine what type of motor is installed in your washing machine. There are several types of motors that manufacturers use to equip washing machines. Let us present brief information about them in the form of a table.

Asynchronous washing machine motor

Commutator motor of a washing machine

Brushless washing machine motor

| View | Main design elements | Advantages | Flaws |

| Asynchronous | starter and rotor |

|

|

| Collector | starter, rotor, tachogenerator, electric brushes |

|

|

| Brushless (direct drive) | starter and rotor |

|

|

When turned on, the washing machine shows no signs of life, does not turn on at all

Why doesn't the washing machine turn on? There can be no clear answer to this question. There are many reasons:

- The socket is faulty.

- Overvoltage in the power system and, as a result, knocks out the machine.

- The device's network cable is not working.

- The power button is faulty.

- The FPS interference filter needs repair.

- The control module is not functioning.

These and other reasons affect the performance of the washing machine. What to do in each specific case should be decided by a highly qualified specialist after a comprehensive diagnosis of the device: visual inspection and, if necessary, hardware testing. Independent unprofessional actions to restore the functionality of the device can cause harm and lead to complete failure of the washing machine.

Check if the electricity in the apartment is turned off

When the washing machine does not start, the first thing that comes to mind is the lack of electricity in the apartment or part of it. Of course, checking whether other devices turn on is easy. However, if only the machine does not respond, then the machine may have been knocked out due to overvoltage in the system. That is why household appliances with high energy consumption should be separated into different sockets. You should also carefully monitor the electrical wiring of the entire apartment to avoid short circuits.

Voltage surges are not a problem for modern models of automatic machines, since they are equipped with RCDs and residual current devices. In the absence of such an element, interruptions in the supply of electricity disable large household appliances. If there are frequent power surges, we recommend installing stabilizers that control the amount of voltage entering the panel. If the value exceeds 260 W, then blocking occurs and the consumer is disconnected from the network. Such control is important not only for a washing machine, but also for other large household appliances, such as a refrigerator or stove, and especially electronic devices.

If the washing machine shows no signs of life, it is worth checking the functionality of the outlet. This can be done using a multimeter or by connecting another device.

Network cable fault

So, electricity is supplied to the device, we continue checking. The power cord comes into view: if a part malfunctions, the machine does not turn on at all. You need to check the household appliance using a multimeter. Is there no voltage? Is there a cable break detected? It's time to change the cord. Home craftsmen often solve the problem using regular electrical tape. This method is extremely unreliable; we recommend calling a specialist to your home. The technician will quickly replace the cable and the equipment will continue to operate reliably.

The power button is broken

Is the power button broken? Don't worry, the problem is small. It's not time to choose a new car yet. Invite our technician at a time convenient for you, who will first diagnose the breakdown using a multimeter. If the device makes a squeaking sound, it means there is current. Otherwise, the problem is really in the power button and requires replacement. Our company employees always have the necessary spare parts on hand for urgent repairs. The problem most often occurs with washing machine models from the Beko and Candy brands.

FPS noise filter failure

If during diagnostics the FPS interference filter turns out to be faulty, then it needs to be replaced. The part is responsible for ensuring that the control module, motor and other electronic equipment do not experience interference during operation of the washing machine. The filter is located immediately under the top cover, in the corner. In the event of a malfunction, the part does not pass electronic current, so the machine does not work.

On the Internet you can read that the machine will perform its functions without this filter. However, remember, the machine will not work for very long, as it will not be protected from power surges.

Control module malfunction

If the machine does not function and the display does not light up, then the electronic module may have malfunctioned. Only a highly qualified technician can diagnose the problem. The breakdown is typical for machines from Ardo, LG and other brands. You won’t be able to solve the problem yourself without special knowledge and skills. It is better to contact our service center and get professional help at attractive prices.

Precautionary measures

To prevent the causes of breakdowns of this nature, you need to follow several recommendations from experts:

In conclusion, I would like to add that despite the independent actions of your main assistants when washing things, you should not leave them unattended while working.

Modern units are also equipped with timers to delay the turn-on time of devices, but you should not trust them again, and not because of their unreliability; a short-term power surge, for example, during a lightning strike, can also cause a breakdown.

Source

Other reasons

It is worth considering other reasons why the machine turns on itself. The problem is not considered widespread, but still causes inconvenience. Sometimes even a master cannot accurately answer the question of what could cause this. In this case, people may decide to leave everything as is, because they do not experience any particular inconvenience.

Other reasons:

- You need to immediately check whether everything is in order with the outlet. The electrical socket may have broken, causing voltage surges. They, in turn, provoke the LG washing machine to turn on randomly. If possible, you should try connecting the unit to a different outlet. If the problem does not go away, then you will have to look for other reasons.

- There is also a situation when a malfunction occurs due to a broken plug. In this case, it is this element that supplies current incorrectly. It is better to contact a specialist, because as soon as he can definitely say whether the plug is really broken. It may become damaged over long service life or mechanical stress. In this case, the washing machine turns on by itself, which worries people.

When the question arises of what to do if a problem occurs, you need to find out exactly the cause. Only in this situation will it be possible to unambiguously decide how to fix the device. It is likely that a software glitch occurred or the button failed. In any case, such assumptions will have to be tested.

Sometimes an error code appears on the washing machine screen. All that remains is to remember it and find out what exactly it means. Then you will be able to quickly understand the situation and understand how to fix the breakdown. If everything is done correctly, then the LG washing machine will no longer fail.

System error codes

Modern devices are equipped with digital control modules. They provide the display of a code corresponding to the malfunction. Here are some of them and possible causes of failure.

On an LG machine the following codes will appear:

- DE – the washing machine door does not lock;

- PF – power failure;

- SE – the drum shaft does not rotate.

Bosch equipment signals an error with the following codes:

- E67, F67 – programmer or control module error;

- F01, F16, E16, F34 – hatch malfunction;

- F21 – the drum does not rotate.

Examples of Samsung brand error codes:

- 5E, 5C, E2 - water does not drain from the machine;

- 4E, 4C, E1 - water does not fill into the machine;

- LE, LC, E9 - water spontaneously drains from the machine;

- UC, 9C - unstable voltage in the mains (too low or high)

Indesit brand error codes:

- F01, F02 - electric motor problems;

- F03, F04, F07, F13 - sensor failure;

- F05, F10, F11, H2O - incorrect draining and filling.

Only a specialist can carry out an accurate diagnosis. Knowing the error codes can help the client collect as much information as possible before the specialist arrives. This will speed up the process and make the task easier for a professional.

If the indicators on the Indesit washing machine are blinking

It happens that during the washing process, all the indicators on the front panel of the washing machine suddenly begin to flash, a buzzer sounds warning of a breakdown, and the operation of the unit stops. The lights can light up alternately, in different combinations, or all at the same time. In any case, such blinking indicates abnormal operation of the washing machine.

There are many reasons for the appearance of cheerful illumination. Only sometimes are they associated with serious breakdowns; often they are the result of simple carelessness.

Causes

The instructions supplied with the machine by the manufacturer describe in detail common problems and how to fix them. Here are some normal situations in which the washing machine blinks all the buttons, and solutions.

- Water is not pouring. Check if there is water in the water supply; is the tap on the pipe leading to the machine open? Is the inlet hose kinked?

- Program crash. The unit is disconnected from the network for a few minutes and started again.

- Water does not drain. Check the drain hose and the connection point with the sewer hole; If necessary, clear the blockage.

- The power cable, plug or socket is damaged. Replace damaged elements.

- Incorrect download. They control the amount of laundry in the machine, remove excess, and distribute things evenly throughout the drum.

- Incorrect installation of the unit. The drain hose is located above the level of the machine drum.

If all of the above problems are corrected, and the blinking does not stop, it is better to seek help from professionals.

Error code

A modern automatic machine is equipped with special devices that allow you to control washing, rinsing and spinning, and in case of a problem, they report this using LED lights. To understand the system messages, you need to guess the error code based on the set of indicators involved. A list of all possible codes can be found in the instructions for the model.

The new generation of Indesit washing machines has a display on which an error code is displayed. All that remains is to read what exactly the malfunction has occurred and whether you can deal with it yourself.

Malfunctions of the collector lamellas

During prolonged operation, the lamellas begin to overheat, as a result of which they peel off and may lose contact with the rotor winding module. The lamellas are fixed to the collector using a special adhesive. And with the rotor winding, electrical contact is created due to the presence of hooks. One of the reasons for overheating is a broken cord at the junction of the rotor section with the lamella.

Also, the problem may arise due to a short circuit in a section of the winding, this leads to an increased supply of electricity that the lamellas cannot withstand. This is facilitated by jamming of bearings, which occurs due to unfixed drum flaps during washing. That is, a defect with lamellas indicates the presence of another breakdown in the electric motor or in the washing machine. Incorrect operation of the machine by the user also leads to deformation of the lamellas.

It is easy to identify a defect; just perform a visual inspection. When the motor rotor is manually rotated, the lamellas will make a loud cracking sound. If the peeling of the surface of the lamellas is insignificant (0.5 mm or less), then the problem can be solved by turning the commutator on a machine. After performing this procedure, it is necessary to clean the surface from copper shavings, dust and burrs.