Quite often it happens that the coating of an old bathtub becomes unusable and it has to be restored. You can cover it with enamel or acrylic. Everyone knows the pros and cons of ordinary enamel since childhood, but the advantages and disadvantages of acrylic coating are not so well known. Often covering a bathtub with acrylic is the only possible solution, because many people cannot afford new expensive plumbing fixtures. With the help of this material, an old bathtub can be renewed in two hours, while all cracks and roughness are remarkably smoothed out, and the rust disappears.

What is acrylic

Previously, various materials were used to restore old bathtubs. Today, an innovative high-quality material that allows you to achieve a perfectly flat and smooth surface. Acrylic is a two-component substance that contains a large amount of non-volatile substances.

In addition, liquid acrylic is a wear-resistant and impact-resistant enamel, which is created on the basis of systemic cold polymerization technology. The work performed is effective due to the main property of the material - fluidity, as a result of which all cracks and chips are filled, and the bath receives a uniform and perfectly smooth coating.

Coating sanitary ware with acrylic allows you to turn an old bathtub with chips and scratches into a completely new and shiny one, as if it had just been brought from the store.

How to restore a bathtub

A new bathtub is not a cheap pleasure.

The cost of acrylic models starts from five thousand rubles, cast iron - from eight, and the upper price bar goes to infinity. Don't forget to add replacement costs: dismantling the old bathtub; paying movers to remove it from the house; delivery and installation of a new bath; repositioning side tiles. Renovating an old bathtub will cost an average of 2,000 to 5,000 rubles, depending on the size of the bathtub, type of restoration and material, so many people choose this method. During the last renovation, I myself did restoration, not replacement. My choice fell on poured acrylic, but we will consider other methods, because they all have their pros and cons.

Advantages of acrylic coating

Using an acrylic bathtub coating has the following advantages:

- By restoring a bathtub using this material, you get a bathtub that has all the characteristics of an acrylic one, without replacing it. This eliminates the work of removing the old bathtub and installing a new one. This also allows for significant savings.

- When pouring liquid acrylic onto the surface, the enamel is distributed evenly over the entire area without forming smudges. As a result, the surface of the bath is perfectly smooth.

- Due to the fact that acrylic does not allow air to pass through, air bubbles do not appear on the surface.

- Thanks to the high density of the enamel, all visible stains are successfully hidden . The restored bathtub has a smooth white color.

- This material does not have a pronounced odor. This makes it possible to carry out restoration work without special protective equipment.

- Acrylic is resistant to acids, alkalis and corrosion.

- If the acrylic coating is made with high quality and in compliance with all the necessary technologies, then such a bathtub will last at least 15 years. After this, the procedure is repeated.

- The acrylic surface is resistant to damage. If you accidentally drop any heavy object on it, this will not cause chipping or peeling of the acrylic.

- The acrylic coating is very pleasant to the touch, and although it is absolutely smooth, it is completely non-slip.

- This bathtub has a very attractive appearance, maintaining its whiteness for a long time, without turning yellow or darkening.

- Caring for a bathtub with an acrylic coating is very simple. It is enough to wipe its surface with a soft sponge. Under no circumstances should abrasive powders or aggressive chemicals be used for cleaning. They can cause damage to such a surface.

- The acrylic coating has good thermal insulation, which means that the water will cool in it for a long time.

Application technology

When choosing a product for restoring a bowl, people often wonder: painting the bathtub with acrylic or enamel, which is better and easier for use at home. Each material has different application rules and tools. Let's look at the features of application technologies.

Working with acrylic

You can restore the bowl with polymer material yourself. During work, be sure to use a respirator and mask, and open the windows in your home for ventilation. To avoid poisoning from toxic fumes, professionals recommend leaving the premises without residents or pets for a day.

All things are taken out of the bathroom, leaving the bathtub and toilet. It is better to cover furniture and household appliances with polyethylene, and tiles with masking tape. Old enamel in the bowl is removed with sandpaper or a grinding machine. The roughness of the walls will ensure good adhesion and prevent delamination of the material. The debris is removed with a vacuum cleaner, washed with warm water and, after drying, degreased with acetone. The siphons are unscrewed and reservoirs are placed under the holes.

First stage of restoration Source master4-100.ucoz.ru

Correctly applied coating will last at least 15 years. It is more convenient to work with liquid acrylic at a room temperature of 21-26 C. Before the procedure, add hot water to the bathtub, drain it after 30 minutes and thoroughly wipe the walls.

Liquid acrylic is prepared before use. The hardener is added to the container with the substance according to the instructions and stirred carefully. If the connection is poor, areas will appear on the surface that do not harden. The stains will begin to peel off, so restoration will have to be done again.

Liquid acrylic is applied to the surface by pouring at home. For convenience, the composition is poured into a small container. The resulting solution is poured in a thin stream along the side of the bathtub, gradually moving along the perimeter of the plumbing. The width of the strip should be 5 cm. The thickness of the product is such that the mass slowly flows off the surface, leaving no streaks or bubbles.

Filling plumbing fixtures with liquid composition Source static.tildacdn.com

Cons of acrylic coating

This material also has some disadvantages:

- The filling technology must be followed very strictly. If even one point is violated, it can lead to rapid damage to the surface. Also, the pouring process itself presents certain difficulties for an inexperienced person in the construction business.

- Some types of acrylic in a liquid state can be poisonous , as a result of which safety precautions must be observed very strictly.

- If the bathroom has very large damage or it is necessary to close the hole, it will be impossible to level it all with acrylic without prior restoration.

- The poured layer takes quite a long time to dry. You can use the bathroom only after 2-4 days.

- If the acrylic coating was applied incorrectly, it will be very difficult to remove.

Self-leveling acrylic

This method uses the same material as an acrylic liner, but applies it in liquid form, which solves most problems with a bathtub insert. Suitable for all common types of bathtubs and shower trays. The price of restoration depends on the size of the bathtub and the material: acrylics are more durable, quick-drying and from Western manufacturers, the price will be higher.

The master works for about two hours: he prepares the bath, and then pours the composition from the sides. The acrylic flows down, creating a thin, uniform layer. If acrylic is quick-drying, then after 16 hours the bathtub can be used; other types of acrylic dry in 24-48 hours.

Pros:

- impact resistance;

- average price;

- high degree of restoration;

- long service life of 15-20 years;

- warm to the touch coating;

- no need to dismantle anything: neither drain nor tiles;

- does not smell;

- does not turn yellow over time.

Minuses:

- If you work carelessly, the surface may turn out to be uneven;

- if the bathtub is initially deformed, acrylic will repeat this shape and not remove it.

Caring for acrylic bathtub surfaces

Caring for an acrylic surface includes several simple rules:

- after use, it should be wiped with a dry cloth;

- Under no circumstances should you use abrasive cleaning products;

- It is not advisable to place metal basins and other heavy objects inside the bathtub;

- You should not take a bath using salts and cosmetics with a high content of dyes;

- Do not soak clothes with bleach in it;

- It is necessary to ensure that no aggressive chemicals come into contact with the acrylic coating.

Recommendations from experts

The service life of an acrylic bathtub, like any other sanitary product, directly depends on its quality. You should not purchase a model with very thin walls, with a rough or porous surface - in the future, microcracks, stains and other defects will likely appear on it.

To ensure that the product lasts a long time, choose a bathtub from a manufacturer that has proven itself in the market

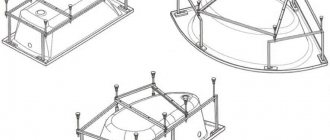

In order to purchase a truly high-quality product, experts in the field of construction work advise inspecting the product for:

- uniformity of acrylic throughout the bathtub body to ensure that there are no flimsy, see-through or thinned areas;

- wall thickness - durable products have sides with a thickness of 4 to 6 mm, cheaper ones are usually made of sheets 2–4 mm thick;

- pretentiousness of form - high-quality products usually do not contain a large number of ornate bends, but are characterized by simplicity of configuration;

- side cut - not only a layer of acrylic, but also resin should be visible on it, otherwise we are talking about cheap plastic;

- reinforcement - the reinforcement material must be of high quality, with layers of fiberglass.

Carefully read the quality characteristics of acrylic bathtubs.

Before going to the store, be sure to take all the necessary measurements in order to determine exactly what bathtub configuration will be needed in the bathroom.

Disadvantages of the product

- instability to elevated temperatures;

- if you regularly add almost boiling water to the bath, the coating will deform over time;

- without additional fastening, the bottom bends slightly;

- acrylic bathtubs are considered fragile. If you drop a heavy object, a dent, crack or hole may remain on the surface;

- An acrylic bathtub requires proper daily care. For these purposes, only those products that do not contain abrasives or aggressive acids are suitable. You will also have to give up metal brushes and hard sponges.

Cast iron, steel and acrylic bathtubs - comparative table of characteristics

| Characteristic | Cast iron | Steel | Acrylic |

| Ease | Heavy | Heavy | Lungs |

| Noisiness | Noisy | Extremely noisy | Almost silent |

| Design variety | Variety of domestic models | Unpretentious appearance | A wide range of |

| Price | Average | Low | Average |

| Enamel strength | Small | High | Average |

| Thermal insulation | Average | Small | High |

What to consider when choosing?

First of all, you need to make sure the quality of the product. To do this, you need to carefully inspect the bathtub and check for the appropriate certificates.

You should look at the light through the bowl. High-quality products do not show through.

When you press your finger on the wall, you will definitely feel rigidity, since the bathtub is necessarily reinforced.

It is important to pay attention to the cut of the bathroom. There should be a layer of acrylic and resin. If plastic is also present, this indicates low quality products.

Methods for making acrylic bathtubs

Acrylic baths are made by thermoforming using two main types of sheet material: polymethyl methacrylate (PMMA) or acrylonitrile butadiene styrene (ABS) coextruded with polymethyl methacrylate (PMMA).

The advent of ABS/PMMA technology has made it possible to significantly increase the impact resistance of bathtubs compared to brittle acrylic, and to increase the adhesion of the formed sheet with a reinforced fiberglass coating thanks to the outer ABS layer. Due to the high plastic properties of co-extruded ABS/PMMA sheets, which have lower viscosity compared to acrylic, it was possible to obtain smaller radii of curvature with their use - this made it possible to significantly expand the design boundaries.

The basic technology for the production of acrylic bathtubs consists of the following steps:

- Using a given template, a mold for casting a bathtub is made (a 3D printer is often used).

- A sheet of cast sanitary PMMA or ABS/PMMA acrylic 4-5 mm thick is placed on its surface, to which electrodes are connected along the perimeter, heating it with electric current.

- When the temperature reaches about 200 °C, the acrylic sheet becomes soft, plastic and falls into a mold in which many tiny holes are made - air is pumped out through them.

- Thanks to the vacuum, the sheet fits tightly to the form, accurately repeating all its contours.

- After cooling by fans, the finished product is removed from the mold and sent for reinforcement.

- A sheet of chipboard is placed under the bottom of the bathtub, and individual wood fragments are placed around the perimeter of the side to strengthen it.

- Then the back surface of the bath is covered with fiberglass thread mixed with resin, after which the body hardens and becomes highly durable.

- The final stage is trimming the outer plastic around the perimeter and processing the edges of the bathtub, then drilling holes in the right places and installing equipment for expensive Jacuzzis.

Finished products

Brand overview

TRITON : Russian company working with Austrian acrylic sheet “SENOSAN” (4 mm thick). Antibacterial coating “ANTIBAK” is used.

- Advantages: ease of cleaning, long-term heat retention and silent filling with water. The models have non-standard sizes, which allows them to be placed in a designer bathroom.

- Disadvantages - wears out quickly, gets scratched. If you accidentally drop pumice on the surface, there is a risk of leaving marks.

Triston

ROCA : a Spanish company specializing in the production of inexpensive and elegant models.

- Advantages – can withstand up to two years of use in its original form. It is very mobile, its small size makes it easy to transport if you move.

- Disadvantages - since the bathtub is covered with an anti-slip coating, the surface appears dirty.

Roca

RADOMIR : Russian manufacturer using premium Austrian acrylic from Senoplast and European fittings.

- Advantages - the bath is stable, its assembly is neat. There are no glue or silicone stains on the seams. The hydromassage engine is installed on rubber shock absorbers, therefore it practically does not vibrate. There is a protective device against power surges.

- Disadvantages - high price.

Radomir

KOLO : Polish company practicing unusual product design. Any bathtubs are on sale: corner, sector-shaped, barrier-free.

- Advantages: Seven-year warranty on all products. The models are designed to meet the needs of different population groups.

- Disadvantages - not noticed.

Kolo

JACOB DELAFON : French manufacturers of elegant bathtubs are successfully experimenting with Flight material.

- Advantages: ease of bathing and mobility. Coating with antibacterial properties.

- Disadvantages - delicate coating, the bathtub quickly becomes covered with scratches.

Jacob Delafon

Restoring a bathtub with enamel: pros and cons

Another way to repair a bowl is with an enamel base. This is an older and proven method.

Advantages:

- economical method;

- chemical resistance;

- low level of wear;

- the mixture can be applied in several layers for greater strength and whiteness.

Flaws:

- short service life: after 5 years you will have to renovate the bathtub again;

- When working, it is imperative to observe safety precautions, since the material is toxic.

On the left is a crack in the acrylic bathtub, on the right is a chip in the enamel coating.

Production of acrylic structures

How are acrylic bathtubs made? Of particular interest is the production process, which comes in two types:

- direct casting of the product;

- by combining organic glass with acrylonitrile, butadiene, and styrene (the so-called ABS plastic).

The first type of manufacturing is considered more reliable, since the acrylic cast bathtub is less subject to wear and tear and is quite durable. To create a hot tub, a sheet of plastic is heated until it becomes soft and viscous. From the resulting substance, the manufacturer makes acrylic bathtubs of the required size, stretching them over the entire surface of the original shape.

The necessary conditions for the process of creating a container model are direct vacuum pressure and the addition of fiberglass. When casting, the latter material can be used in several layers.

Disadvantages: why cast iron is abandoned

- The first minus is the other side of the plus and is a consequence of the large weight of the cast iron bathtub. Due to the massive structure, considerable difficulties arise during transportation and installation. In addition, for some buildings the additional load acting on the floors must be taken into account. This is especially true for large-volume baths.

- Another disadvantage of cast iron bathtubs is also directly related to their advantages. Enamel, for all its strength and hardness, is a rather fragile material, and in the event of an impact, chips may form on its surface. Such a chip cannot be eliminated with improvised means; it is necessary to call a specialist with special tools, materials and appropriate skills for the restoration of enamel coatings.

- In addition, even with external integrity, over time the upper smooth layer of enamel is destroyed, and the coating acquires a porous, rough structure. Housewives who use products based on oxalic or orthophosphoric acid to maintain cleanliness especially often encounter this problem. Subsequently, the damaged enamel, like a sponge, absorbs iron salts contained in tap water, turning yellow and practically impossible to clean with mild means, so to maintain the whiteness of a bathtub with damaged enamel, you again have to resort to acidic preparations.

- And finally, the third disadvantage of cast iron bathtubs is the conservatism of the form. Cast iron is not malleable enough to allow designers to experiment with fancy configurations. Therefore, the strict classical form of cast iron baths remains unchanged. However, for some, this disadvantage turns into an advantage, because strict classics never go out of fashion.