Expanded clay concrete is one of the types of concrete. Recently, this material has become increasingly used for various works: construction of cottages, outbuildings, garages, etc.

d. Expanded clay concrete is also used to fill the frame of multi-story buildings built from reinforced concrete. Expanded clay concrete is so popular that it is used in almost all countries of the world, or rather, already made blocks of expanded clay concrete are used.

Order expanded clay concrete blocks on favorable terms by calling us at:

8-910-077-44-33

or send a request through the form on the website.

Those who have not yet been able to appreciate all the advantages of expanded clay concrete are already beginning to notice them. Those who decide to start building a house from this material should carefully study the issue regarding the thickness of the walls of expanded clay concrete blocks.

Let's figure out why this nuance is so important.

Dependence of thickness on type of masonry

The thickness of a wall built with expanded clay concrete blocks primarily depends on the choice of masonry type. In turn, each type depends on the weather and climate.

It is also necessary to consider how much the building will be used. During capital construction, other building materials can be used: brick, cinder blocks or foam blocks. The thickness of the walls of the future building will also depend on what kind of thermal insulation of the room will be needed.

In addition, you need to take into account the thermal conductivity and moisture-repellent properties of the material used. Depending on which masonry option is chosen, the thickness of the walls will be calculated. In this case, both the internal and external layers of plaster with which the walls are finished are also considered.

Laying options:

First option: the supporting wall is built from blocks measuring 390/190/200 mm.

In this case, the blocks are laid with a thickness of 400 mm, without taking into account the internal layers of plaster. Second option: the load-bearing wall is laid with blocks measuring 590 by 290 by 200 mm. In such a situation, the size of the wall should be 600 mm, and the resulting voids in the blocks are filled with insulation. Third option: when using expanded clay concrete blocks measuring 235 by 500 and 200 mm, the resulting wall will be equal to 500 mm. In addition, layers of plaster on both sides of the wall are added to the calculations.

Why is size and other indicators important?

Not only the speed of work, but also its quality depends on correctly selected dimensions and performance indicators. It is important to consider that some characteristics are directly related to each other. Below we will consider how thermal conductivity and vapor permeability depend on the density of the product.

| Density, kg/m3 | Thermal conductivity, W/(m×°C) |

| 1800 | 0,81-0,9 |

| 1600 | 0,66-0,78 |

| 1400 | 0,57-0,64 |

| 1200 | 0,45-0,53 |

| 1000 | 0,32-0,42 |

| 800 | 0,25-0,32 |

| 600 | 0,21-0,27 |

| 500 | 0,15-0,24 |

Here's how vapor permeability is related to density.

| Density, kg/m3 | Vapor permeability, mg/(m×h×Pa) |

| 1400 | 0,094 |

| 1200 | 0,108 |

| 1000 | 0,138 |

| 800 | 0,187 |

| 600 | 0,256 |

The larger the expanded clay concrete, the less mortar it will take to lay it.

Effect of thermal conductivity

Scheme of a block made of expanded clay concrete.

Before starting any construction work, you need to calculate the thermal conductivity coefficient, since it is of great importance for the durability of the structure. The resulting coefficient is necessary to calculate the thickness of walls made of expanded clay concrete blocks. Thermal conductivity is a characteristic of a material that indicates the ability to transfer heat from warm to cold objects.

In calculations, this characteristic of the material is shown through a certain coefficient, which takes into account the parameters of the objects between which heat exchange occurs, as well as the time and amount of heat.

From the coefficient you can find out how much heat can be transferred in one hour from one object to another, while the size of the objects is 1 m2 (area) by 1 m2 (thickness). Various characteristics have different effects on the thermal conductivity of a particular material. Such characteristics refers to: size, composition, type and presence of voids in the material. Thermal conductivity is also influenced by air temperature and humidity. For example, low thermal conductivity occurs in porous materials.

Construction of foundation and formwork

To do this you need: 1. Material for assembling formwork panels (edged inch board, plywood); 2. Sand, crushed stone and cement; 3. Ruberoid or other material (hydroglass insulation); At the beginning of any construction, we lay a reliable foundation. An excellent option would be a monolithic strip foundation.

But it is not suitable for every type of soil. The next stage is the construction of formwork with your own hands from materials such as plywood, fasteners and boards. You can buy ready-made concrete, and to save a little on this you can prepare it yourself. The required amount of concrete is mixed in a concrete mixer. Based on experience: first we fill in a bucket of crushed stone and a bucket of water, and then add a bucket of cement. Crushed stone will break up all the lumps of cement and help it dissolve well in water. Mix until the required consistency is reached, then pour in all the sand and the rest of the crushed stone. Mix everything thoroughly again. It is necessary to adhere to the following proportion: 1: 1: 3: 4.5, respectively, water, cement, sand, crushed stone. These proportions are suitable for grade 400 cement. The solution should not be too thick, but also not too thin. The resulting solution is poured into the formwork, which then needs to be tapped thoroughly to allow air to escape from the concrete. After the solution has hardened, the foundation is waterproofed by laying roofing material on it, preferably in two layers.

Example of calculating wall thickness

The calculation must be made very accurately. It is necessary to take into account the best thickness of walls built from expanded clay concrete material. In order to make an accurate calculation, you need to use a special formula.

To do this, you need to know only two quantities: the coefficient of thermal conductivity and the coefficient of resistance to heat transfer. The first value is indicated by the symbol “λ”, and the second by “Rreg”. The value of the resistance coefficient is influenced by such factors as the weather conditions of the area where construction work will be carried out.

This coefficient can be determined according to building rules and regulations. The thickness of the future wall is indicated by the “δ” icon. And the formula for calculating it will look like this:

δ = Rreg x λ

For example, you can calculate the required wall thickness for building a building in Moscow or the Moscow region. The heat transfer resistance coefficient for this area has already been calculated and is approximately 3-3.1. The thickness of the block itself can be any, for example, let’s take 0.19 W. After making calculations using the above formula, we get the following:

δ = 3 x 0.19 = 0.57 m.

That is, the thickness of the walls should be 57 cm. Most experienced builders advise erecting walls with a thickness of 40 to 60 cm, provided that the building is located in the central regions of Russia.

Thus, by calculating a simple formula, you can build walls that will ensure not only the safety of the structure, but also its strength and durability. By completing this simple step, you can build a truly strong and reliable house.

The walls of private houses, cottages and other low-rise buildings are usually made of two or three layers with an insulating layer. The insulation layer is located on the load-bearing part of the wall made of bricks or small-format blocks. Developers often ask questions: “Is it possible to save on the thickness of the wall?” “Shouldn’t we make the load-bearing part of the wall of the house thinner than the neighbor’s or than provided for by the project?

On construction sites and in projects, you can see a load-bearing wall made of bricks with a thickness of 250 mm, and from blocks - even 200 mm. has become commonplace.

The wall turned out to be too thin for this house.

Advantages and disadvantages

The main advantages of expanded clay blocks in construction are considered:

- Strength, density and durability.

- Natural mineral composition.

- High frost resistance and sufficient thermal conductivity.

- Good sound and noise insulation.

- Easy to operate and install due to its low weight.

- Variety and large selection of blocks for walls.

- Good adhesion with cement and adhesive mortars.

- Compatible with reinforcement and finishing materials.

- Sufficient vapor barrier and creation of a “breathable” layer of the wall.

- High fire protection, no tendency to spontaneous combustion.

- Affordable cost (1 block costs from 24 to 36 rubles).

- Possibility of use in different climate zones.

- No shrinkage with a properly executed foundation.

- Resistance to mold and fungal microorganisms.

The disadvantages include the following::

- Not suitable for creating foundations.

- Requires high-quality waterproofing.

- Suitable for the construction of 1-2-story buildings.

- Without insulation, cold bridges can form.

Summarizing the above, it is worth noting that the benefits of using expanded clay concrete for a home or cottage are obvious. Even with the use of waterproofing and insulation, the cost of construction will be much cheaper than a house made of brick.

The strength of a house wall is determined by calculation

Design standards (SNiP II-22-81 “Stone and reinforced masonry structures”), regardless of the calculation results, limit the minimum thickness of load-bearing stone walls for masonry within the range from 1/20 to 1/25 of the floor height.

Thus, with a floor height of up to 3 m, the wall thickness in any case should be more than 120 - 150 mm.

The load-bearing wall is subject to a vertical compressive load from the weight of the wall itself and the overlying structures (walls, ceilings, roof, snow, operational load). The design compressive strength of brick and block masonry depends on the grade of brick or class of blocks for compressive strength and the grade of mortar.

For low-rise buildings, as calculations show, the compressive strength of a wall with a thickness of 200-250 mm made of brick is provided with a large margin. For a wall made of blocks, with the appropriate choice of block class, there are usually no problems either.

In addition to vertical loads, the wall (wall section) is subject to horizontal loads caused, for example, by wind pressure or transmission of thrust from the roof rafter system.

In addition, torques act on the wall, which tend to rotate a section of the wall. These points are due to the fact that the load on the wall, for example, from floor slabs or a ventilated facade, is not applied in the center of the wall, but is shifted to the side edges. The walls themselves have deviations from the vertical and straightness of the masonry, which also leads to additional stresses in the wall material.

Horizontal loads and torques create a bending load in the material at each section of the load-bearing wall.

The strength and stability of walls with a thickness of 200-250 mm or less does not have a large margin for these bending loads. Therefore, the stability of walls of the specified thickness for a particular building must be confirmed by calculation.

To build a house with walls of this thickness, it is necessary to choose a ready-made project with the appropriate wall thickness and material. We always entrust the adjustment of the project with other parameters to the selected thickness and material of the walls to specialists.

The practice of designing and building low-rise residential buildings has shown that load-bearing walls are made of bricks or blocks with a thickness of more than 350 - 400 mm. have a good margin of strength and resistance to both compressive and bending loads in the vast majority of building designs.

The walls of the house, external and internal, resting on the foundation, together with the foundation and ceiling, form a single spatial structure (framework), which jointly resists loads and influences.

Creating a durable and economical building frame is an engineering task that requires high qualifications, pedantry and culture from construction participants.

A house with thin walls is more sensitive to deviations from the project, from construction norms and rules.

The developer needs to understand that the strength and stability of walls is reduced if:

- the thickness of the wall decreases; the height of the wall increases; the area of openings in the wall increases; the width of the partition between the openings decreases; the length of the free section of the wall that does not have support or interface with the transverse wall increases; channels or niches are installed in the wall;

The strength and stability of walls changes in one direction or another if:

- change the wall material; change the type of floor; change the type, size of the foundation;

Mistakes when building a house from expanded clay blocks

During the construction of an expanded clay concrete house, common mistakes are often made. In most cases, they are associated with unprofessionalism and the desire to save money on everything. Inexperienced developers choose low-quality blocks and fasteners, which is why the reliability of future construction is at risk.

Key errors include the following:

- The desire to reduce costs and not carry out a geodetic survey. This will entail such negative consequences as cracking of the foundation.

- Lack of competent design or work without diagrams. This approach will lead to the walls being thicker than the foundation or vice versa.

- Buying low quality blocks. This material has an irregular shape and insufficient performance properties.

- Failure to comply with roof and roof installation rules. The roofing pie is the most complex system of every home, so increased demands must be placed on its quality.

- Using the services of inexperienced workers.

Expanded clay concrete buildings are distinguished by high build quality, comfort and reliability. However, the listed properties are only possible if construction technology is followed and the step-by-step guide to building a house is carefully studied.

Therefore, in order for a home made from expanded clay concrete to be durable and comfortable, be prepared to devote a lot of time to all stages of construction.

Defects that reduce the strength and stability of walls

Violations and deviations from the requirements of the project, norms and construction rules, which are allowed by builders (in the absence of proper control on the part of the developer), reducing the strength and stability of the walls:

wall materials (bricks, blocks, mortar) with reduced strength compared to the requirements of the project are used.

anchoring of the floor (beams) with metal connections to the walls is not performed according to the design; deviations of the masonry from the vertical, displacement of the wall axis exceed the established technological standards; deviations in the straightness of the masonry surface exceed the established technological standards; the masonry seams are not filled completely enough with mortar. The thickness of the seams exceeds the established standards. excessive use of brick halves and chipped blocks in the masonry; insufficient bonding of the masonry of internal walls with external ones; omissions of mesh reinforcement of the masonry;

In all of the above cases of changes in the dimensions or materials of walls and ceilings, the developer must contact professional designers to make changes to the design documentation. Changes to the project must be certified by their signature.

Your foreman’s “let’s make it simpler” suggestions must be agreed upon with a professional designer. Control the quality of construction work done by contractors. When performing work on your own, avoid the above construction defects.

The norms of the rules for the production and acceptance of work (SNiP 3.03.01-87) allow: deviations of walls by displacement of axes (10 mm), deviation by one floor from the vertical (10 mm), displacement of supports of floor slabs in plan (6...8 mm ) etc.

The thinner the walls, the more they are loaded, the less their safety margin. The load on the wall multiplied by the “mistakes” of designers and builders may turn out to be excessive (pictured).

The processes of wall destruction do not always appear immediately, but sometimes years after the completion of construction.

Manufacturers

Many domestic factories are engaged in the production of various types of expanded clay blocks. Let's list the most popular ones.

- Kstovo expanded clay concrete plant. Produces modules using expanded clay fraction 5-10 mm. The material is manufactured on the Rifey-Polyus automated line. The company produces solid and four-slot blocks.

- "Teplostroy IM" The company was founded in Cheboksary. It has been producing expanded clay concrete modules since 2005. Productivity is 1500 blocks per day. For the production of building materials, the company purchases expanded clay 10-20 mm, which is subsequently crushed into smaller fractions - 5-7 mm.

- Ishleysky building materials plant. One of the first producers of expanded clay blocks in Chuvashia. The company was founded in 2000. In the first years of operation, modules were manufactured using homemade equipment. Today, the Rifey-Universal automatic line is used for their production. The daily production capacity of the plant is 1200 products.

- Bloks 21. The company produces hollow expanded clay blocks in Novocheboksarsk. Maximum productivity reaches 1500 products per day. Bloks 21 company offers its customers delivery and unloading.

- "EcoBlock". Manufacturer of large format blocks. The plant is located on the territory of Naberezhnye Chelny. Offers modules of non-standard sizes, as well as decorative solutions for cladding work. The company produces sand-free blocks. Expanded clay, cement and water are used to prepare the solution.

Popular manufacturers of block expanded clay materials also include PF Veles, GK Mercury, and Forward.

Tips for the developer

It is certainly advisable to choose a wall thickness of 200-250 mm made of brick or blocks for a one-story house or for the top floor of a multi-story house.

A house of two or three floors with a wall thickness of 200-250 mm. Build if you have at your disposal a ready-made project tied to the ground conditions of the construction site, qualified builders, and independent technical supervision of construction.

In other conditions, for the lower floors of two- or three-story houses, walls with a thickness of at least 350 mm are more reliable.

Read about how to make load-bearing walls only 190 mm thick here.

Next article:

Previous article:

Expanded clay concrete is one type of concrete. It has recently become quite often used in construction work: the construction of cottages, outbuildings, garages.

It is also used to fill the frame for multi-story buildings that are built of reinforced concrete. This material has become so popular that it is difficult to imagine a country in which it would not be used by builders. More precisely, pre-made expanded clay concrete wall blocks are used.

Many who have not yet had time to appreciate the benefits of this material are beginning to notice them. Those who decide to use it for their construction must carefully consider such a characteristic as the thickness of the wall made of expanded clay concrete blocks. This is all for good reason, because having studied all the nuances, you will be able to get the most out of this insulation.

Areas of use in construction

Expanded clay concrete blocks have been used in the construction industry around the world for several decades. By using such material, you can significantly save on construction costs.

Various building elements and structures are erected from expanded clay blocks.

- Foundation. For this purpose, the most durable solid modules are used - they are able to withstand heavy loads. The foundation will last for a long time, since the blocks do not shrink and are not afraid of groundwater.

- Base. This is the “foot” of the building, lying on the foundation.

- Load-bearing walls, partitions and ceilings. They are widely used in low-rise construction when constructing buildings of no more than 3 floors.

- Baths. In order for a building exposed to high temperatures and humidity to last for a long time, it is important to provide it with good waterproofing and insulation.

- Garages, cellars and basements.

- Gazebos, verandas and terraces, various extensions to a residential building or cottage. Both open and closed structures are erected from expanded clay blocks.

- Fences. Such structures are often erected from several building materials, for example, expanded clay modules, wood, and wrought iron elements. With the right approach to design, the fences will look original.

Every year, non-standard use of expanded clay blocks is becoming more and more common. Garden benches are built from them - they often become an original and inexpensive solution for landscaping a place to relax. You can build a porch, staircase, or well from expanded clay modules.

Flower beds are also made from blocks with large voids - they will add elegance and brightness to the space. For a more colorful design, the blocks can be painted in the desired colors.

Dependence of thickness on type of masonry

The thickness of the surface finished with expanded clay concrete block mainly depends on which masonry option you choose.

Each option, in turn, depends on weather and climatic conditions. It also takes into account how much the building is used. When construction is major, often more than just one block of expanded clay concrete can be used.

In addition, bricks, foam and cinder blocks are used. The thickness of the future masonry will depend on what kind of thermal insulation is required for a particular building. The various thermal conductivity and moisture-repellent characteristics of the insulation will also be taken into account.

Depending on the choice of masonry, you will calculate the thickness of the walls, which are made with ceramic blocks. Moreover, the outer and inner layers of finishing plaster applied to the wall will be taken into account:

- The first option: if the supporting wall is laid out in blocks of 390:190:200 millimeters, then the masonry must be laid with a thickness of 400 millimeters, not counting the layers of internal plaster and insulation that is located outside. The second option: if the structure of the load-bearing wall consists of blocks measuring 590:290: 200 millimeters, then the wall should be exactly 600 millimeters. In this case, it is worth filling special voids in the blocks between the walls with insulation. Third option: if you decide to use an expanded clay concrete block measuring 235:500:200 millimeters, then the wall thickness will be 500 millimeters. Plus add layers of plaster on both sides of the wall to your calculations.

Return to contents

Disadvantages of the material

In addition to the advantages, expanded clay concrete blocks have certain disadvantages:

- The exterior may require further cladding.

- When building large structures, it is necessary to correctly calculate the strength and grade of material.

- A large number of handicraft industries with products that do not comply with GOSTs and specifications.

- Due to the high porosity of expanded clay concrete, the blocks are inferior in strength to heavy concrete.

- Ventilation of the walls is more difficult than in the brick version.

These disadvantages can be minimized if you choose the right type of blocks for construction, which should only be purchased from a reliable manufacturer.

Effect of thermal conductivity

Scheme of expanded clay concrete block.

In construction work, it is important to calculate the thermal conductivity coefficient, since it has an impact on the durability of the entire structure. The coefficient is important when calculating the thickness of walls that consist of expanded clay concrete blocks. Thermal conductivity is a property of a material that characterizes the process of heat transfer from warm objects to cool ones. Everyone knows this from physics lessons.

Thermal conductivity in calculations is expressed through a special coefficient. It takes into account the parameters of the bodies between which heat is transferred, the amount of heat, and time. This coefficient shows how much heat can be transferred in one hour from one body to another, which has dimensions of one meter in thickness and one square meter in area.

Different characteristics have their influence on the thermal conductivity of each material.

These include the size, type, presence of voids of the material or substance, and its chemical composition. Humidity and air temperature also affect this process. For example, low thermal conductivity is observed in porous materials and substances.

Return to contents

Pros and cons of one-story and two-story buildings

The light weight of the blocks reduces the load on the foundation, which has a positive effect on the lifespan of buildings. In addition, the low shrinkage rates of expanded clay concrete will help avoid the appearance of cracks in the walls of the building.

It is worth noting that expanded clay blocks are susceptible to impact loads, but are resistant to compression. The porous surface of the blocks requires the walls to be finished to protect them from moisture. The same measure, as a rule, at the same time neutralizes the insufficient strength to impact loads.

Compressive strength allows you to build buildings with several floors , however, for such construction it is important to choose the right brand of expanded clay concrete blocks.

Pros and cons of a house made of expanded clay concrete blocks relative to houses made of other materials

Let's start with the pros:

- A house made of KBB has better sound insulation compared to brick or gas silicate houses.

- Buildings made from KBB almost do not shrink, which avoids the appearance of cracks.

- In terms of compressive strength, KBB exceeds gas silicate blocks, and therefore, the walls can withstand greater loads.

- The water absorption of KBB is 2 times lower than that of gas silicate blocks, which prevents the appearance of dampness in the house.

- KBB blocks are much cheaper than gas silicate ones.

- To build a house from expanded clay concrete blocks, one construction season is enough.

Minuses:

- Compared to gas silicate blocks, structural KBBs are slightly inferior in thermal insulation properties.

- KKB blocks do not have perfectly even shapes; it is difficult to give them the desired shape.

Recommended thickness for a residential building

For each specific building, its own wall thickness is measured. It varies depending on the purpose of the building. For a residential building, the standard thickness will be exactly 64 centimeters. This is all prescribed in special building codes and regulations.

True, some people think differently: that the load-bearing wall of a residential building can be 39 centimeters thick. In fact, such calculations are more suitable for a summer house, country house, garage, and buildings for household purposes. It is possible to build interior decoration with a wall of this thickness.

Return to contents

What influences price formation

Building a reliable house from bioblocks is not very expensive. The main price will be: building materials, total area, number of floors, interior and exterior decoration, utilities, heated floors and their covering, windows, doors, decorative elements, complexity and total scope of work.

To discuss the details of the desired project, call the following numbers:

+375 33 383-09-09, +375 29 383-09-09

We will call you back and discuss with you the project, the estimate and all the nuances of our cooperation. We will take into account all the wishes of the customer!

Return to the page “CONSTRUCTION OF COTTAGES AND HOUSES”

Having decided to build a house with your own hands, you should be prepared for difficulties and weigh all the positive and negative aspects of the project. The project cost very often differs greatly from the actual one, since it is impossible to take into account all the contingencies. There are often cases when, upon completion of construction, the actual price exceeded the design price by more than twice.

Scheme of ligation of expanded clay concrete blocks.

The very first stage of construction is the selection and preparation of a land plot.

Then you need to obtain a building permit. There is no point in going into detail at these stages, since each region has its own rules and procedures. A permit for the construction of auxiliary structures on the site is not required, only for the house itself.

Only when these stages have been completed can we begin the zero stage of construction - drawing up an estimate.

It is needed in order to find out the approximate cost of future construction and the amount of building materials. An experienced architect will also advise on the best material for the house in this case. When drawing up a design estimate, it is best to work with the architect privately, as it will be more convenient to discuss all controversial issues that arise.

Calculation example

Table of reduced heat transfer resistance for various wall designs.

The moment of making an accurate calculation is very important. It is necessary to take into account the optimal thickness of the walls, which are made of expanded clay concrete blocks. To achieve results, use a very simple one-step formula.

Builders, to solve this formula, must know two quantities. First you need to find out the thermal conductivity coefficient, which was mentioned earlier.

In the formula it is written through the sign “λ”. The second value that needs to be taken into account is the heat transfer resistance coefficient. This value depends on many factors, for example, on the weather conditions of the area where the building is located.

The area in which the building will then be used is also an important factor. This value in the formula will look like “Rreg”. It can be determined by building codes and regulations.

The value in the formula that we need to find, namely the thickness of the wall being built, we denote by the “δ” icon. As a result, the formula will look like this:

δ = Rreg x λ

To give an example, you can calculate the thickness of a wall under construction in the city of Moscow and its region. The value of Rreg for this region of the country has already been calculated and officially established in special rules and regulations for construction. Thus, it is 3-3.1.

And you can take any wall size as an example, since you will already be calculating yours on the spot. The thickness of the block can be completely different. For example, it will be possible to take 0.19 W/(m*⁰С).

As a result, after solving this formula:

δ = 3 x 0.19 = 0.57 m.

We understand that the thickness of the walls should be 57 centimeters.

Experienced builders and experts recommend making the wall thickness from forty to sixty centimeters if the building is located in such central regions of Russia as Moscow and St. Petersburg.

This is how, by calculating a simple formula, you can build such walls near your house to ensure the safety of the building, its stability and durability. Just by performing a simple action, you will build a truly good and reliable house.

One of the most important purposes of the external walls of any house is to protect it from external natural influences, weather conditions and create the strength of load-bearing structures.

The construction material expanded clay concrete is inexpensive and quite simple to install.

Advantages of cooperation with our company

Our cooperation with factories that manufacture building materials, plumbing fixtures, windows, doors and all components allows us to build durable and comfortable homes. Place an order with us and you can make all your dreams come true by getting cozy and reliable housing.

We provide a guarantee of up to 20 years and are responsible for the quality of our construction. Our professionals will find the best design solution for you and select a house project that will satisfy all members of your family. Our specialists will develop an individual estimate and agree on the terms of reference with you. Once construction is completed and the house is put into operation, you can safely move in.

What kind of material is this?

Expanded clay concrete contains expanded clay in the bulk - this is a special clay foamed and subject to firing with cement and water.

With a fairly high level of strength, this material is relatively light in weight. Walls built from expanded clay concrete, in contrast to structures made from concrete, have good heat and sound insulation properties and are much lighter, which makes it possible to build a house on a lighter foundation.

The period of preservation of the operational properties of such walls can be close to 75 years.

Why expanded clay concrete may be better than other building blocks

- Durability, environmental friendliness, non-flammability of brick. Like brick, expanded clay concrete contains natural calcined clay – these are expanded clay granules. Expanded clay is granules of baked clay. This indicates the environmental friendliness of the material and durability. The granules are already baked, that is, hardened at the highest possible temperature, which means that expanded clay concrete is not flammable. In terms of durability, expanded clay concrete is higher than brick. Basements are even built from it, but this is not recommended due to a number of features of expanded clay.

- Strength and reliability of cinder block. Like cinder block, the bonding material of the block is concrete. Expanded clay concrete block combines all the properties of high-quality concrete - high strength, hardness, wear resistance. But expanded clay concrete does not have the two main disadvantages of cinder block - heavy weight and dubious radiation background of slag.

- Light weight, ease of processing, and high thermal conductivity of foam blocks and gas blocks. Porous expanded clay granules make expanded clay concrete lightweight and thermally conductive.

- Breathing effect of shell rock and heat saving of sippanels. Expanded clay concrete block can be classified as a breathable wall material with minimal heat loss, due to the porosity of expanded clay granules. Expanded clay is not blown away by the wind like shell rock, even without special finishing and does not create the effect of a thermos like foam sippanel.

- Another bonus of an expanded clay concrete block is that, like a cinder block, you can make it with your own hands in artisanal conditions. This fact also speaks about the relative affordability of the material.

What should be the thickness of a wall made of expanded clay concrete blocks?

The thickness of expanded clay concrete walls depends on several factors:

Firstly, it is necessary to understand what functions the building will perform: residential or industrial. Based on this, it is important to determine the degree of use of the building. It is equally important to take into account climatic conditions.

The choice of masonry blocks is of great importance, depending on the functional significance of the building. The thickness also depends on the moisture-resistant and heat-conducting properties of the insulation. A layer of finishing plaster on both sides will also increase the thickness of the expanded clay concrete wall being built.

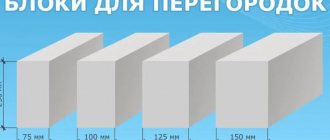

If we take into account natural conditions, then for the central region it is enough to erect single-layer block walls with a thickness of 400 mm to 600 mm. For regions with colder climates, the walls are insulated with heat-insulating materials.

Recommendations for building walls

The surface of the foundation of a house made of expanded clay concrete must be leveled with a solution and be sure to check the level. Then insulate it in two or three layers of roofing material glued to bitumen or bitumen mastic. It is recommended to start the masonry process from the corner, lay the entire first row, and be sure to check the accuracy of the masonry by level and plumb.

Then build the corners in several rows, pull the cord and continue building the walls. Expanded clay concrete blocks must be laid with ligation of vertical seams 15-20 cm from the previous row. Reinforcement of masonry should be done every 3-4 rows.

For this purpose, metal reinforcement with a diameter of up to 10 mm, metal masonry mesh or fiberglass mesh is used. It is advisable to remove external walls together with partitions and internal walls. If this is not possible, then make a groove by releasing the reinforcement in those places where the partitions will pass.

It is possible to lay walls simultaneously with laying finishing bricks. With this method, it is mandatory to bandage the brick and load-bearing walls using reinforcing mesh or fiberglass rods. The last row should be laid from a solid block.

The construction of walls can be done in several ways, it all depends on the thickness of the wall and the type of facing material:

If the thickness of the wall is equal to the width of one block and is approximately 20 cm, then the internal surfaces of the walls are treated with plaster, and the external ones are lined, with mandatory thermal insulation, the thickness of which must be at least 10 cm. If the wall has a thickness equal to the length of the block, that is, 40 cm , then the blocks must be bandaged, and the thickness of the thermal insulation can be much less. Bandaging of the blocks should be carried out in such a way that small voids are formed inside the wall, where the thermal insulation material is laid. The thickness of the walls in this case will be about 60 cm.

There are no differences in the laying of multi-slit block and brick. For this, cement mortar is used, reinforcement occurs in the same way as for the rest of the laying of expanded clay concrete blocks, but leaving voids for this type of blocks is not necessary. Since the slots are placed perpendicular to heat flows, the block also acts as a heat-insulating material.

It should be noted separately that there is a novelty in the production of multi-slotted blocks - these are the so-called longitudinal and groove-transverse slotted blocks. Due to the presence of protrusions on the end and longitudinal sides, such blocks are connected vertically without the use of mortar. The patent for this invention was issued less than ten years ago and information about the quality of its work, unfortunately, is not yet available.

Upon completion of the construction of the walls, it is necessary to immediately install the roof, covering it with a pre-selected roofing material. After this, you can begin finishing work on the external and internal walls.

Masonry options

The size of the expanded clay concrete blocks determines how to produce masonry for residential premises:

- If the blocks have a size of 590:290:200 mm, then the width of the wall should be 600 mm. In this case, only the voids in the blocks are insulated. If the blocks have a size of 390: 190: 200 mm, then the masonry should be 400 mm thick without external finishing layers and insulation. If the blocks have a size of 235: 500: 200 mm, then the thickness of the wall being erected is 500 mm plus external and internal finishing of plaster.

The laying of walls made of expanded clay concrete blocks also depends on the purpose of the structure itself:

During the construction of warehouses and utility rooms that do not require special insulation. The wall is laid in one layer along the width of the block (200 mm).

The inner surface of the wall is plastered, and the outside surface is covered with insulation (mineral wool, polystyrene foam, or polystyrene foam) with a layer of 100 mm. If a small structure is being erected, for example, a bathhouse, then the principle of masonry is similar to the option of masonry for utility rooms, only the insulating layer will be 50 mm. Three-layer masonry is carried out mainly in residential buildings. A small gap is left between the blocks. The total wall thickness is 60 cm.

Its interior is covered with a layer of plaster, and insulation is placed in the spaces between the blocks. Laying expanded clay concrete blocks for regions with cold climates. When installing an external wall, two partitions are built parallel to each other, which are connected with reinforcement. Then insulation is laid between the partitions, then they are plastered on both sides.

Expanded clay concrete blocks can be solid or hollow. Full-bodied ones are stronger and more suitable for load-bearing structures.

Composition and production technology

The main raw material in expanded clay concrete is expanded clay of various fractions. In addition to it, the composition includes such elements as cement, sand, water and other additives designed to improve the quality of the material. And pumice or slag gravel, crushed stone, and sand are used as the main filler.

The use of expanded clay in the composition makes the blocks light, and cement gives them the necessary strength.

The production of expanded clay concrete blocks consists of the following stages:

- mixing all ingredients;

- pouring the prepared solution into molds;

- hardening and hardening;

- drying - takes two days;

- warehousing and preparation for shipment.

Construction stages

One of the most important stages is the construction of the foundation.

The strength and reliability of the structure depends on it. Assessment of soil quality. To do this, dig a hole 1.5-2 meters deep and look at the result. The best options are sandy, gravel or sandy-rocky soil types. The worst is peat or forest soil; construction on these types of soil is undesirable. At this stage, the amount of moisture in the soil is determined.

The hole is left for a day, and if no water has accumulated there during this period, the soil is considered normal. The depth of the foundation can be 30-50 cm in this case, the type of foundation can be strip. If water appears in the hole, the foundation is required deep, 0.5-1.5 m. In northern regions with deep freezing of the soil, the depth of the foundation is sometimes is up to 2 m, this is the only way to avoid deformation in the first winter.

The main condition is that the foundation line is at least 20 cm below the freezing level. Preparation, clearing the site. When marking, remove the top layer of soil over the entire area of the foundation. A trench is dug along the perimeter of the foundation to a depth determined by the manipulations of the first stage. The bottom is covered with a layer of sand. Laying the foundation begins. The foundation should be 20-25 cm thicker than the walls. It should be remembered that expanded clay concrete is a fragile material and is not used in construction for foundations.

For wet and forest soil, additional formwork is made from boards. When the height of the foundation reaches ground level, waterproofing is carried out. It is placed not only on top of the masonry, but also on the sides. The easiest and fastest way is to fill it with bitumen. Before continuing to build on a fresh layer of bitumen, the foundation must be leveled.

This is achieved by laying a leveling layer of cement-concrete mortar on top of the bitumen and expanded clay concrete blocks. But its thickness should not exceed 3 cm. The above-ground part of the expanded clay concrete blocks continues to be laid to the floor level. Here, holes are made near the walls of the house for ventilation and moisture removal. The last stage is another layer of waterproofing for the above-ground part of the foundation. It is better to use roofing material for it.