| Place | Name | Characteristics in the rating |

| Top 10 best pellet boilers |

| 1 | Svetlobor | Full automation, control via SMS |

| 2 | Froling P4 Pellet 25 | Highest quality |

| 3 | SOLARFOCUS pellettop | Stylish appearance |

| 4 | ZOTA PELLET 25S | The best adaptation to Russian winters |

| 5 | FACI Base 258 kW | High power, reliability |

| 6 | BUDERUS LOGANO S181-25 E | The most reliable |

| 7 | STROPUVA S30P | Best price |

| 8 | KITURAMI KRP 20A | Possibility of using pellets of different lengths and humidity |

| 9 | ACV TKAN 1 | Powerful boiler for a large house |

| 10 | KUPPER OK 20 WITH PELLET BURNER | Good price-quality ratio |

Pellet boilers appeared on the Russian heating market relatively recently, but have already become quite popular among owners of private houses. They differ from other solid fuel boilers in the type of fuel, efficiency, environmental friendliness and full automation. In addition, they are very reliable - with proper operation, such a boiler operates trouble-free for 20-25 years. A pellet boiler for a home will be a real salvation in cases where gas supply is impossible or impractical for financial reasons. Sometimes they are used by entrepreneurs to heat their facilities.

The boilers got their name due to the use of pellets – pressed wooden pellets from wood processing waste – as fuel. There is no glue in them, only pure wood; no harmful substances are released when burned. The boiler itself is a steel or cast iron structure with a fuel bunker. Pellets are loaded manually and enter the firebox automatically. Since the equipment is completely new and not widely used, it is difficult to make a choice in favor of any model - there are very few reviews about pellet boilers on the Internet. Therefore, we invite you to familiarize yourself with the selection of the best pellet boilers for home presented on the Russian market.

Review of imported manufacturers

“Termal” (Macedonia) - pellet fireplaces and boilers are very impressive, some models are suitable for installation directly in a living space. Production has also been established in our country.

"Termodinamik" (Turkey) - quality at an affordable price. In addition to pellets and other solid fuels with particle sizes up to 25 mm, boilers are fired with wood and coal.

“Froling” (Austria) - the manufacturer promises ideal performance and stable temperature, which is logical to expect for 700 thousand rubles. Includes all necessary heating systems and hot water supply. Wall-mounted models take up very little space.

Pellet boiler Termodinamik EKY/S

“Distand” (Austria) - budget equipment from a European manufacturer, equipped with dual-circuit weather automatics.

“Klover” (Italy) - presents a wide selection of pellet fireplaces and thermal kitchens for installation both in residential premises and in individual boiler rooms. Combination stoves for simultaneous combustion of wood and pellets.

Pellets are an inexpensive and efficient fuel. Build a pellet boiler with your own hands and see for yourself.

Read the link for tips on choosing a wall-mounted heating boiler. Main characteristics and prices.

In what cases should you choose a single-circuit gas boiler for heating a house and how to choose and install it correctly, read this article:. Detailed information about gas boilers.

Design Features

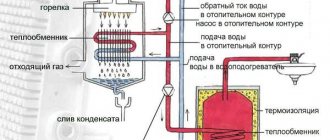

Main components:

- Combustion chamber - a combustion chamber with an installed burner, as well as two doors (inspection, cleaning).

- Convective - a built-in heat exchanger in the form of pipes or plates with a vertical, horizontal or combined arrangement for heating water (coolant) with hot air released during combustion.

- Ash pan is a container for collecting ash.

- Bunker – a container for storing pellets before feeding them into the firebox.

- Auger – for portion feeding into the firebox;

- Fan - to pump air in the absence of natural draft and maintain the combustion process.

- Control unit - for setting operating modes, combustion parameters, maintaining temperature.

Criterias of choice

Before purchasing, experts advise paying attention to:

- power - the simplest calculation is the ratio per 1 sq. meter 100 W, for example, for a room of 150 sq. meters, a floor-standing solid fuel pellet boiler with a power of 15 kW (100 W x 150 sq. m = 15,000 W) is suitable;

- Efficiency - as a rule, values are in the range of 85-95% with a direct dependence on the quality of the pellets;

- heat exchanger type – steel or cast iron;

- number of circuits - single-circuit or double-circuit if hot water supply is required;

- the volume of the bunker - depending on the needs of the user, as well as the characteristics of use;

- fuel supply - using a screw or vacuum with low noise level, but more expensive;

- additional functions: auto-ignition, self-cleaning, temperature sensors, GSM module.

Reviews

Without reviews from real customers, it is difficult to present a clear picture of the quality of operation of a particular unit.

Zota “ Pellet ” - users note the unpretentious nature of the burner installed on this model. Pellets can be of different quality and humidity, but it copes; in some cases it is necessary to change the settings.

“In the first year, it was necessary to replace the heating element with an automatic ignition, but this is a consumable item.”

“I turn on the boiler through the phone, even in winter or summer, if I need to heat water. Informs remotely about operating modes.”

“Peresvet” - Those who bought a burner separately and installed it on their boiler note that with the original boiler, the pellet consumption is up to two times less.

“Some imported boilers look more aesthetically pleasing, but this one is easy and straightforward to set up yourself.”

“Firing with pellets is of course convenient, but 10 thousand rubles. per month for 140 square meters of house - a little expensive.”

“Our boiler goes out at low combustion temperatures; another disadvantage is the high price of spare parts.”

Boiler “ Faci Big ” (24 kW) Unpretentious to fuel quality. Some users are disappointed by the high consumption of the boiler; they consume 50 rubles worth of pellets per hour.

“I work in a non-residential building, I burn about 1 ton of pellets per month, the temperature stays around +14 degrees. Over the two years of operation, I have not noticed any shortcomings, I just carry out regular maintenance - cleaning and replenishing the bunker.”

How to install

You can try to install a pellet boiler at home with your own hands if you have special knowledge or by using the Internet, where step-by-step instructions are provided. However, it is better to entrust the solution to this issue to professionals from a specialized organization that has a construction license, who will reliably install the unit during repair or construction.

Design must be completed before installation can begin.

Main stages

1. Preparatory:

- preparation of the premises;

- strengthening and leveling a fireproof base capable of supporting the unit;

- electrical wiring;

- installation of ventilation and chimney.

2. Installation and piping:

- installation on a hill, connection to the chimney of the gas-air duct;

- bunker installation, auger connection;

- control panel assembly;

- circulation pump piping;

- installation of an expansion tank;

- installation of automation for return control;

- wiring of backup power supply, installation of stabilizer;

- connecting the coolant and return circuits.

3. Commissioning activities:

- control of compliance with the project;

- leak testing;

- automation check;

- crimping;

- control start-up and parameter measurement;

- adjustment work.

4. First launch:

- filling the container with pellets;

- checking water pressure, replenishing it to the standard if necessary;

- opening the smoke damper;

- ignition - by control panel or manually;

- checking the compliance of the parameters with the project;

- stopping after burnout;

- control of coolant temperature to prevent condensation formation.

Common mistakes

- Lack of return temperature control.

- Unsatisfactory tightness of the gas circuit, decreased efficiency due to leakage of pyrolysis gas;

- Poor thermal insulation of the base, causing condensation and the release of harmful substances.

- The size of the boiler room does not comply with fire safety requirements, which does not allow servicing the bunker or auger.

Pellet boilers are characterized by efficiency, ease of operation, and long battery life. But optimal parameters can only be achieved if the equipment is correctly selected, installed and configured.

Enjoy the shopping! Take care of yourself and your loved ones!

Types and classification

By fuel

1. Pellet - only compressed granules are used.

2. Combined - the use of other raw materials as backup fuel (wood, coal).

By burner type

1. Retort - feeding pellets into a bowl “from the bottom up”, where air is pumped and where combustion occurs.

2. Flare - dosed supply into a horizontal tray, where the fire is inflated by injected air to form a powerful torch.

According to heat exchanger material

1. Cast iron - with a long service life and resistance to overheating, but heavy weight and poor impact resistance.

2. Steel - with a shorter service life, but more durable.

By download

- Automatic – pellet loading is regulated by programming by specialists;

- Semi-automatic – with manual adjustment;

- Mechanical – manual filling of the bunker.

By number of circuits

1. Single-circuit – only for operation in heating mode.

2. Double-circuit – the possibility of additional production of hot water.

Equipment design

Pellet boilers are designed to consist of 3 main parts. This:

- The device itself, the body of which is standardly made of high-temperature resistant steel. It is equipped with a special burner for igniting fuel.

- A bunker where raw materials are stored.

- Mechanism for feeding pellets into the combustion chamber. Most models use a screw device. However, there are also those where the fuel enters the chamber under the influence of gravity.

Some units are equipped with automation that controls operation. The devices are characterized by reliability, but correspondingly high prices. Devices can be programmed for the desired turn-on time, support specified temperature parameters, etc.

What it is

A pellet boiler is a type of solid fuel heating device, where pellets are used as fuel - cylindrical granules from agricultural or woodworking waste, pressed on a granulator (special press).

Main types of pellets:

- white - made of high quality wood, low ash content up to 0.5%, but expensive;

- agropellets – agricultural waste (straw, sunflower husks) with a high ash content, as well as the need for regular cleaning of the boiler from slag;

- industrial - gray-brown in color with a high bark content, ash content greater than 0.7%, not recommended for domestic use.

Advantages of pellet boilers

- high degree of automation with programming of operating modes, as well as long-term operation without operator participation;

- equipping with remote sensors;

- simple maintenance;

- remote control from mobile applications or via GSM module;

- high efficiency;

- economical consumption of pellets compared to diesel fuel, liquefied gas or electricity;

- long service life;

- minimal emissions of harmful substances.

Flaws

- high cost of pellets;

- sensitivity to their quality;

- the need for dry storage;

- dependence on electricity supply;

- impressive dimensions.

Content

- Principle of operation

- Rating TOP 7 best pellet heating boilers ZOTA Pellet 25S

- Sunsystem V2 25KW/PLB25 – P

- Kostrzewa Pellets Fuzzy Logic 2 25 kV

- Kiturami KRP 20A

- ACV ECO Comfort 25

- Cooper OK 20 with pellet burner

- Pelletron 40 CT

- Best price - Stropuva S30P

Installation Rules

Pellet boilers are installed only in a separate room. For such purposes, a basement with a special floor covering - durable and made of non-combustible material - is suitable. Simple options are poured concrete or a base lined with metal sheets. The device itself is installed at a height within 10-20 cm.

The boiler room should be heated and have moderate humidity. The unit is installed in accordance with the manufacturer's instructions (so that there is free access for cleaning, repair and maintenance).

Where can I buy

It is better to buy popular models of pellet boilers in specialized stores of heating equipment for the home, as well as in representative offices of manufacturers of such equipment or their dealers. The best units offered by the best manufacturers, where you can not only visually inspect them, but also twirl them or listen to practical advice and recommendations - which company is better to buy, what they are, how much they cost, how to choose, what to pay attention to in order to avoid mistakes when choosing .

In addition, budget new items can be ordered online in an online store specializing in the sale of such products. In this case, help will be provided by popular aggregators, such as E-catalog or Yandex.Market, where product cards with the necessary information are posted - description, parameters and their comparison, photos.

What to look for when choosing

What parameters will make the purchase the most profitable? Please note the following:

- Certificate. Be sure to purchase a product with a certificate - it indicates the safety of the device.

- Type of granules. Pay attention to the pellets that are used in certain types of boiler. Some models have specific instructions for the type of granules.

- Power. The more powerful the device, the better – this model will work longer in autonomous mode.

- Container volume. This parameter affects the frequency of boiler maintenance. The smaller the volume, the more often you will have to change fuel.

- Principle of operation. There are two options here: either a boiler with automatic regulation or a manual one. Choose the one that is more convenient for you personally.

Maintenance

Heating a home using pellet boilers requires little maintenance . They usually have an open heating system, so you need to monitor the water level in the system. You can automatically supply water replenishment to the heating system.

The boiler itself must be cleaned of soot, especially the heat exchanger jacket, as this affects the consumption of pellets. Smoke exhaust pipes need to be cleaned. This does not take much time, and the moment when cleaning is necessary can be determined visually by looking at the water jacket, or if the consumption of pellets has increased. The deadline is when the boiler begins to smoke into the room.

If pellets are supplied using a rigid auger, then it is necessary to periodically clean this system from dust that accumulates in the air supply channels.

If you are interested in industrial boilers in Aktobe operating on all types of fuel, follow the link.

Operating principle of boilers

After pellets are loaded into the chamber, the ignition is turned on. The fuel burns and releases energy, which goes through the air to heat the water. Further from the coolant, radiators throughout the house are heated.

The operating principle differs little from the functioning of other solid fuel equipment. However, the efficiency of pellet models is higher than that of wood-burning appliances (on average 90%). This is due to the design of the combustion chamber, in which energy is directed to the heat exchanger under pressure.

Exhaust gases from the system are removed through the chimney. In high-quality models, fuel burns almost completely. The mixture of carbon dioxide and steam is removed using a smoke exhauster.

View from the outside

Pellets need to be loaded into the receiver and this also requires time and effort. This is why many owners create their own storage bin and feeding conveyor. You can order a feed hopper yourself, which will minimize labor costs. In addition, every 2 weeks it is necessary to remove ash from pellets , and if you burned with coal, then it accumulates every day. This is also a significant disadvantage. The high cost of the boiler is relative. In any case, it is cheaper than a gas boiler; in addition, such a boiler is safer to operate.

The boiler requires a hole in the wall, but does not require a special chimney. In addition, when the power is turned off, the fan will automatically stop, so some of the smoke may enter the house. This can also be considered a disadvantage.

The consumption of pellets depends on the volume of the boiler, its power and the temperature outside the house.

At -30, the flow rate can reach 60 kg for a 25 kW boiler, at -5 the flow rate will be 30 kg, at 0 degrees – 22 kg.

You also need to remember that the heating season in the country is on average 5 months, from this you can calculate exactly how much fuel is needed for your home. In addition, we take into account the area of construction and the need for water heating if the boiler is double-circuit.

Some owners, having switched from diesel heating to pellet heating, believe that the costs are recouped in a year. However, we must not forget that the pellets themselves must also be purchased somewhere and delivered to your home, so purchase and transportation costs must also be taken into account. You also need to create a warehouse for storing pellets, which have special requirements for humidity, so you will have to allocate a special room for them.

Whether it makes sense to install this equipment or not, the buyers themselves decide, but many reviews are positive, which means that pellet boilers are quite satisfactory for the owners. Sometimes it’s easier to find firewood than to bring gas cylinders to a village where there is no main gas pipeline, so if you buy a universal boiler, you don’t have to worry about being left without heat for the winter. In addition, a distinctive feature of pellet boilers is complete fire safety , which is why they are in great demand among buyers. Moreover, this design does not depend on electricity or consumes it in a minimal amount, which can be solved with the help of a generator.

Such a pellet boiler can be installed in a house in the middle of nowhere and without having to worry about having to go for gas in winter.

Pellets

The compressed pellets, 6–8mm in diameter and up to 50mm in length, are made primarily from waste wood and are considered an environmentally friendly, renewable and carbon-neutral fuel. The granules are made without any kind of chemical additives. When burned, pellets emit more heat than wood, gas or diesel fuel. And at the same time, the price for them does not rise as catastrophically as for other types of fuel.

Pellets differ in their raw materials and the method of processing, which determine the color of the finished product. White pellets are obtained from wood waste. Gray - from a mixture of wood with bark and peat or seed husks. Black pellets are produced from the same raw materials, but by oxygen-free firing at high temperatures; their calorific characteristics are similar to coal, do not rot and are water-repellent.

Many boiler owners speak negatively about the quality of domestic pellets. Although it is difficult to rely only on reviews. Each region has its own producers of this type of solid fuel, and you can only find out what quality the pellets were after burning them. Even clean seed husks burn well and provide enough heat with the correct granule manufacturing technology. It is recommended to determine the approximate quality of granules by their appearance. They should be shiny, without cracks, at least 10 mm long, and not crumble into dust in your hands.

Comparison table of the presented models

Basic information on the technical parameters of each of today's models is presented in a brief table.

| Model | P (kW) | Efficiency % | S heating (m²) | Weight, kg) |

| ZOTA Pellet 25S | 25 | 90 | 250 | 395 |

| Sunsystem V2 25KW/PLB25 – P | 27 | 96 | 250 | 488 |

| Kostrzewa Pellets Fuzzy Logic 2 | 25 | 92 | 250 | 430 |

| Kiturami KRP 20A | 24 | 92 | 330 | 210 |

| ACV ECO Comfort 25 | 25 | 88 | 250 | 428 |

| Cooper OK 20 | 20 | 95 | 200 | 99 |

| Pelletron 40 CT | 40 | 92 | 400 | 120 |

Review of Russian manufacturers

Let's look at Russian pellet boilers:

Obschemash supplies the market with Russian-made Valdai and Peresvet boilers and burners that can be installed on an already operating heating system. Boilers are supplied to the market with different capacities. Devices controlled via wi-fi cost 10-20 thousand more.

“Valdai” was designed specifically for pellets, but heating with wood is also possible, as an emergency option.

Pellet boiler Pelletron

“Peresvet” accommodates three times more firewood in the combustion chamber and can be considered universal.

“Zota Pellet” - Domestic boilers with the ability to control remotely via SMS. Unpretentious to the quality of fuel, it can consume both firewood and fuel briquettes and pellets.

Some pros and cons

- Combustion is supported by pellets, a fairly inexpensive type of fuel.

- They have a high level of efficiency, which brings their characteristics closer to gas boilers.

- Fuel is supplied to the burner and the temperature is maintained automatically.

- Storing pellets is not difficult, since they are packaged in bags (often thirty kilograms each) and only need a dry room.

- When burned, they leave behind small amounts of environmentally friendly ash.

- The pellet appliance provides the house with both hot water and a comfortable, constant temperature regime.

- They have a smart control system; some system models are designed for remote control.

- Pellet equipment for autonomous home heating is safe and does not require registration with regulatory authorities.

When deciding to buy a good pellet boiler, it is worth paying attention to some disadvantages .

- Installation and connection to the home heating system must be carried out by qualified specialists.

- Pellet production is not yet well organized, which may result in fuel shortages.

Pallet boiler