| Figure 1. Sectional view of a plug valve |

Figure 1 shows a cross-section of a classic plug tap.

1 – space for the handle or steering wheel, 2 – cover, 3 – shutter element, 4 – body, 5 – connecting flanges, 6 – adjusting bolt.

Plug tap

, another name for conical or conical, is one of the types of shut-off valves designed to

lock

and regulate the flow of the working medium in a pipeline.

Locking

the element is made in the shape of

truncated

cone.

The plug tap has been known since ancient times. We all see such a tap in our kitchen if we drink tea from a samovar or when we buy kvass from a barrel.

Plug valve, straight through

Lined plug valve

Plug valve stuffing box

Some products from the catalog:

| Three-way plug valve (flange, cast steel, Dn125, Pn16) | Lined plug valve (flanged, cast steel, 1″, 150 lbs) | Plug valve straight through (cone, conical) (flanged, cast steel, 1/2″, 150 lbs) |

What it is

Schematic diagram and materials used

This is the name of a locking or regulating device, the main element of which - the plug - has the shape of a full or truncated cone with a through channel and is in contact with the body on all side surfaces. Impermeability to water, air, gas or other media transported by the pipeline is ensured by the absence of a gap between the plug and the walls of the housing.

The design of a plug valve involves a significant friction area and, as a result, a significant force required to turn. Obviously, with a large pipeline diameter it will become unacceptably large; Moreover, sticking of surfaces will additionally increase the resistance.

That is why corrosion-resistant materials with a low coefficient of friction - cast iron and brass - are traditionally used for the manufacture of plug valves.

Please note: due to the design features and low mechanical strength of the metals used, the diameter of plug valves rarely exceeds 100 mm, and the operating pressure is 16 atmospheres.

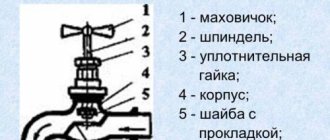

Before the reader is an assembly drawing of a plug valve.

There are no rules without exceptions: if you wish, you can find a plug-through tap with a diameter of up to 200 millimeters in a steel casing.

However, it has little relation to those valves that can be found in basements:

- To facilitate the rotation of the plug, a gearbox with a steering wheel is used.

- The plug is, after all, made of cast iron: if two steel elements stick to each other, even the gearbox will not help to tear them off.

Housing sealing

How a tap stops the movement of water or gas in a pipeline is not difficult to understand. How is it ensured that there are no leaks to the external environment?

Tension

The plug goes right through the valve body. Its threaded shank, when tightening the nut screwed onto it, presses the plug to the body with considerable force. The absence of a gap guarantees the absence of leaks both through the valve through the pipeline and into the external environment.

Valve with tension seal.

It’s interesting: when the valve operates, the quality of the surface grinding improves over time.

Spring

The gas plug cone valve, which can be seen on the supply line to the gas stove in most Russian apartments, is designed somewhat differently: the plug is pressed to the body not with a nut, but with a spring. A small clamping force, coupled with lubrication, ensures a moderate turning force of the plug; however, the maximum operating pressure of the structure is more than small.

Gas tap.

Stuffing box

Finally, the plug-stuffing valve was widely used for heating and water supply: the stuffing box around the stem ensured the absence of leaks. Typically, a braided graphite seal was used.

How the packing was clamped usually depended on the valve material:

- Brass products used crimping with a union nut.

- A cast-iron plug valve often used a pair of bolts to crimp the gland, which pulled the gland to the body lugs.

Here is an assembly drawing of a cast iron plug valve with a gland secured with bolts.

Methods for connecting the housing to the pipeline

There are actually only two of them:

- Flanged . Adjacent flanges are attracted to each other by four to eight bolts; tightness is ensured by a paronite or rubber gasket.

- Threaded or coupling . For sealing, sanitary flax and artificial sealing materials are used.

Depending on the nominal diameter of the connected pipeline, the DN (nominal size) of the valve is indicated. Domestic documentation uses the metric system; DN approximately corresponds to the internal diameter of the pipeline in millimeters. Imported goods are often marked in inches:

| DU | Size in inches |

| 15 | 1/2 |

| 20 | 3/4 |

| 25 | 1 |

| 32 | 1 1/4 |

| 40 | 1 1/2 |

| 50 | 2 |

The cost of carrying out work by specialists

Malfunctions occur suddenly and require quick fixes, especially when a gas stove breaks down. However, not all home appliance owners have the necessary skills. When it is impossible to carry out repairs yourself, you have to call a specialist to your home. What expenses await the owner:

- replacement or repair of a gas supply valve - from 300 to 1,200 rubles;

- nozzle cleaning - from 400 rubles;

- replacing the oven lamp - from 400 rubles;

- gas adjustment - from 500 to 900 rubles;

- lubrication and cleaning of rods on the feed lever - 900 rubles;

- replacement of rods - 1200 rubles;

- thermocouple replacement - 900 rubles;

- replacement of the ignition unit - 900 rubles;

- cleaning of supply contacts - from 900 to 1,100 rubles;

- change of sealing gum - from 500 rubles;

- replacement or repair of a spark plug - 800 rubles.

Prices depend on the stove model and the region where household appliances are serviced and repaired.

Application

Here are a few examples of the use of plug taps in their various designs.

- The most obvious example is the samovar faucet. The plug in it is held in the valve body only by its own weight.

Stopper of the samovar tap.

- Soviet-style faucets with a lever switch were not very convenient to use and often leaked; but they were practically indestructible. Breaking a lever or a plug was not a trivial task.

- Three-way plug valves were used to regulate the temperature in apartments: depending on the position, they allowed the flow of coolant through the radiator, through the jumper, or completely blocked it.

By the way: the last function of the crane was the reason for the fierce hatred of the mechanics who served the microdistricts built up by Khrushchev. It was not immediately possible to find out which of the residents turned off the tap on the riser.

- We have already mentioned Soviet-style gas taps. Compared to the then common screw valves, the plug valve really looked much more reliable and guaranteed no leaks.

- Finally, along with the screw valve, the plug valve was the most common element of shut-off valves for heating and water supply systems in the 60s - 80s of the last century. It was there, in particular, that the 11B6BK DU50 valve mentioned at the beginning of our material was widely used: it was mounted on hot water and heating connections in elevator units.

The photo shows a brass valve 11B6BK DU50.

Differences from plumbing fittings

The water tap is painted red.

The gas valve differs from the water tap in the appearance of the lever, which is yellow instead of red, as well as in a number of design features:

- long connecting thread;

- more durable housing and locking mechanism;

- ability to withstand high pressure;

- the presence of strong and sealed rings.

Despite the fact that a standard gas faucet is more expensive, it cannot be replaced with water fittings, since such savings may lead to the replacement of the main elements of the system as a result of an accident.

Advantages and disadvantages

How do plug taps compare to alternatives when it comes to plumbing?

Let's start with praise for them.

pros

- Unlike screw valves, they do not need to be oriented in a specific way in the direction of water flow. There is no risk of valve rupture simply due to its absence.

- The straight and wide through channel in the plug creates a fairly moderate hydraulic resistance - again, in contrast to the tortuous passages in a screw valve.

- For the same reason, plug valves never become clogged with scale, sand and rust. There is simply no place for garbage to stay in them.

- Plug valves differ from modern ball valves in their greater resistance to high temperatures.

However: 150 C, the maximum for a ball valve, is the temperature limit on the supply line of the heating main at the peak of winter cold. Higher values are only achievable in steam heating systems, which are currently used only in a few industrial enterprises.

Heating temperature chart. As you can easily see, there are no temperatures above 150C.

Minuses

The author’s experience with plug valves in heating and water supply systems allows us to formulate the following main complaints about them:

- Both cast iron and brass valves boil when left inactive for a long time. To turn them after five years of inactivity requires an effort quite capable of breaking the threads on the drive.

- After the notorious period of inactivity, the slightest turn of the valve leads to water leakage through the seal. Yes, this is a problem - common to all products with stuffing box packing; however, in the case of a screw valve, it is solved by completely opening it. Here you have to refill the oil seal.

- By the way, about the oil seal: you can fill it only by first shutting off and dumping the water. What is the instruction related to? If you open the valve under pressure, the disturbed plug will most likely fly into your face at the front of the water flow. At best it’s cold, at worst it’s scorching hot.

The plug is held in the housing only by the oil seal cover.

For comparison: a valve with lapped cheeks for packing the stuffing box with your own hands is enough to simply close.

- Glandless (tension) valves must be loosened before opening or closing, which is accompanied by water leakage. It is especially touching when you are under the valve. If you do not loosen the tension nut, there is a real chance of tearing the thread off the plug.

- To turn the rod you have to use an adjustable wrench, an open-end wrench, or (most often) a gas wrench. As a result, frequently used taps are easily recognized by their rounded, or even practically absent, stems above the gland.

- With all this, the price of a plug valve is not lower, and often higher, than a ball valve of the same size.

Features of replacing a gas valve

Ball valves of any type are not immune to breakdowns, so if a fault is detected, the element must be urgently replaced. It is better to entrust this work to gas service specialists. A new tap is purchased based on the diameter of the gas pipeline, which must correspond exactly to it.

Before the expert arrives, you need to light the gas on the stove and close the valve, directing the burner and waiting for it to completely extinguish to allow the remaining fuel to exit the gas pipeline. After completing the work, the specialist must definitely test the shut-off valves for leaks and enter information about replacing the element in the technical passport.

We stock up on tools to carry out repairs

To repair gas stoves at home, you will need a minimum number of tools, first of all:

- A universal screwdriver with interchangeable bits - a cross and a standard straight slot, pliers;

- Small adjustable wrench with side lip extension of 15-20 mm;

- Fum tape for gas appliances;

- Solid gas lubricant;

- Soft brush and highly effective detergent.

You can take “CIF”, “Cleaner” or any other liquid gel used to clean gas stoves with a stainless base from burnt-on fat. Sometimes, in extremely rare cases, you have to use a multimeter to repair a stove.

And, of course, you will need good health, at least there should be no runny nose, otherwise it will be difficult to detect a gas leak, and when working with gas appliances, the main condition for success is work safety. For the most serious work with coupling joints in a gas stove, you will need a watercolor brush and diluted liquid soap.

Operating rules

A dielectric coupling is necessary to reduce the impact of stray currents.

In order for a ball valve for domestic gas to last as long as possible, standard recommendations must be followed during its maintenance. The element is designed to quickly shut off the gas flow inside the pipeline. It can only be opened and closed using the factory handle; it is prohibited to use any tools for this purpose.

The design of the valve itself is not intended for flow control; the element has only two operating positions: open and closed. If it is half-open, the rapid flow of pumped fuel can cause deformation of the sealing rings, as a result of which the valve will quickly become unusable and will have to be replaced. The element must not be used in environments with contaminants that could cause mechanical damage to the gaskets. Sometimes the fastenings of the rotary handles become loose, in such cases it is necessary to tighten the screws securing them. If there are leaks in the stuffing box seals of the rods, adjust the nuts located under the valve handles.

According to instructions from crane manufacturers, any repair work, including replacement of the device, is prohibited from being carried out independently without the necessary skills.

Manufacturers of household gas taps

When choosing shut-off valves, you need to pay attention to all the details and purchase only high-quality products from well-known manufacturers. Products from Italian companies FIV, Valtec and Bugatti have proven themselves best. Devices from the German brands Dungs and Profactor, the Polish brands Broen Ballomax and Efar, as well as the Russian concern LD are also of good quality.

It is not recommended to save money and give preference to Chinese manufacturers, since such fittings do not meet international standards and requirements.