Due to its lightness, aerated concrete is an economical option when building a house. Construction planning includes an estimate in which the costs of all stages of construction of the building are calculated. It is worth considering materials, labor, transportation and installation costs, as well as the customer’s finishing and design requests. A correctly drawn up estimate allows you to control costs and not exceed the limits of the pledged capital.

Why is it needed?

A document containing labor costs, work schedules, and construction materials is called an estimate. Concluding an agreement with a developer company obliges to carry out all preliminary calculations and provide them to the customer for review, making corrections and subsequent control of construction work. A properly thought out and drawn up estimate is fully justified during the development process, and also helps to avoid bureaucratic misunderstandings with various authorities.

With the help of such a document, the customer will be able to obtain complete information about how much the construction of housing will cost him and how long it will take.

You can order a project from several organizations to compare quality and price characteristics.

Is it worth giving preference to this material at all?

Are you sure that this material is what you need? Let's take a look at the main set of advantages and disadvantages.

Advantages:

- High thermal efficiency will make the building truly warm. The coefficient is 0.08-0.33 W*mS. The material in question is one of the three leaders in this regard among representatives of lightweight concrete.

Compared to competitors

- High durability and frost resistance. In practice, this has not yet been verified. However, there is also no reason not to trust manufacturers.

The concept of frost resistance

- Strength and density allow the material to be used in many areas of construction. In the article we looked at the corresponding classification and were completely convinced of this.

Specifications

- Environmental friendliness is due to the composition of components that are not capable of causing harm. The foam block contains: water, cement, sand, lime and foaming agent. There are also additives that are individual for each manufacturing company.

Compound

- Fire resistance is substantiated by GOST.

Fire resistant

- Easy to process. The product can be easily split, sawed, sanded, and so on.

cutting

- Large dimensions will speed up the construction process.

Dimensions

- Low weight – reduced load on the foundation of the structure.

Weight

- Budget cost.

Low price

- Soundproofing ability and vapor permeability. The latter quality will help to establish the most comfortable climate in the building.

Soundproofing comparison

- A large assortment.

Range

- Biological stability. Fungus and mold are not scary.

How to calculate how many foam blocks are needed for a house

- Possibility of self-production.

Self-production

- Simplicity of installation technology.

Laying

Minuses:

- Fragility. Be careful and careful when transporting and carrying out work.

- Poor tear resistance.

- The need to purchase special hardware for fixation.

- Presence of handicraft industries. This fact increases the likelihood of purchasing products of inadequate quality.

- Hygroscopicity. Moisture absorption reaches 15%. And, despite the pore structure, which is closed, the value is relatively large.

This means that the developer must approach the cladding of the building as responsibly as possible. It must be performed technically correctly. If products are not protected from moisture, they will eventually be destroyed by moisture.

- Shrinkage. Walls may crack.

Types and composition

Universal

The document is drawn up to account for materials at their market value, transportation costs to the construction site. The chosen methodology allows the customer to control the process of building construction and monitor the movement of funds from the allocated budget. The estimate includes up to 60 items:

- materials (35-40 columns);

- additional expenses (7% of the deposited amount);

- invoices;

- workers' compensation;

- rented premises;

- taxation.

Such a document contains the basic data that is necessary to carry out the work without going into detail.

Labor-intensive

The estimate helps to summarize the work done over a certain time period. Based on the received calculations, the foreman negotiates with the customer about work issues of interest and requests the transfer of funds for wages. Low-budget construction is usually carried out precisely according to a labor-intensive estimate, since the accrual of money is given for 1 m2 of work performed.

Expanded

The document assumes a complete decoding of all waste for an aerated concrete house (frame, foundation). The estimate includes all packages of documents that are prescribed taking into account standards and legislation. During the compilation process, technological maps, calculations, technical conditions and types of work are taken into account. Cash costs for preliminary calculations will take from 50 to 200 dollars, but saving at this stage is not recommended.

In such a document everything should be described in as much detail as possible.

How to calculate how many blocks are needed to build a house

Content:

- To calculate the number of foam blocks for construction

- Calculation of wall lengths

- Calculation of the amount of material for construction in pieces

- Calculation of the number of foam blocks for construction video tutorial

To calculate foam blocks, you need to divide the walls into groups according to thickness. For example, the first group is external walls, the second is internal load-bearing (the thickness may differ or be equal to the thickness of external walls), the third is internal non-load-bearing. There is one more parameter that must be taken into account when calculating the number of foam blocks. This is the percentage of blocks cracked after transportation. And although this percentage depends on many factors (including the condition of the road and car), the manufacturer usually has some average figures.

What is included in the estimate?

Preparation for construction

An important step in the construction of a building is the selection of a suitable area and its cleaning. The material is lightweight, so any type of foundation is suitable. However, preference is given to the tape and monolithic type, with basement waterproofing. At this stage, the estimate takes into account the study of the geological and climatic features of the area.

Pouring the foundation

The construction of the foundation involves entering into the document the costs of planning and marking the territory for the sketch of the future building. After this, excavation work is planned, which involves mechanized and manual digging of trenches, laying a sand base and an additional crushed stone layer. Installing formwork and laying a reinforcing layer allows you to strengthen the structure and prevent concrete from spreading beyond the boundaries of the trench. After all the work has been completed, the builders begin the actual pouring of the future foundation. The estimate necessarily includes the cost of renting formwork and materials (concrete, reinforcement, waterproofing, sand and crushed stone).

Installation of formwork is one of the stages of work that must be taken into account in the document.

Features of wall construction

The construction plan must include the costs of laying, delivering and unloading the material. When constructing a 10X10 building, monolithic construction of load-bearing columns became relevant. A house of such dimensions will require only 4 structures 3 meters high, which are erected using specialized formwork options. Taking into account the data obtained, it can be calculated that the area of the supporting structure will be 120 square meters. meters. The walls are laid with D500 gas blocks with a thickness of 375 mm.

Floor installation

The reliability and strength of a building is determined not only by the foundation and load-bearing walls. Properly arranged floors, which are carried out in a monolithic manner, help to increase endurance and distribute the load. This approach is justified not only in private construction, but also in the construction of multi-story buildings. The estimate should include costs for the following materials:

To fill a monolithic floor, it is important to take into account all the costs of purchasing material and working with it.

- formwork;

- reinforcement complex and fastening parts;

- concrete solution;

- insulating layer covering the perimeter of the building.

How is the roof laid?

A labor-intensive and critical stage of construction is the construction of the roof. Depending on the previously agreed upon type, the required raw materials and components are calculated. The contract specifies the cost of the following components:

The document must indicate everything necessary for arranging the rafter system.

- material (tiles, slate);

- rafter system;

- drainage and additional installations;

- ventilation and chimney structures;

- nails, screws.

Finishing and cladding

Gas silicate blocks are susceptible to rapid absorption of moisture from the air, so it is recommended that finishing work be carried out immediately. The work is carried out using insulating blocks or facing tiles. A simple way is to plaster and paint the walls. The work plan includes financial costs:

- facing material;

- installation of floor coverings;

- installation of windows and doors;

- stairs.

The costs received at each stage of construction of the building are summed up, and the total estimated cost is obtained. It is not always possible to invest in the initially pledged capital, so experienced craftsmen try to squeeze it in and adjust the budget in those moments where technology allows. If necessary, the estimate is revised and increased with the consent of the customer.

Pros of foam concrete

It has a number of positive and negative qualities:

- Environmentally friendly - in this respect it is similar to natural materials such as wood.

- The presence of pores (cells) in the structure allows air to pass through, which means the house “breathes.”

- Resistant to high temperatures - when heated, its structure does not change, the stone does not burst.

- Good sound insulation - this allows you to save on finishing the house.

- The weight is a very light material, you don’t need a powerful foundation, it’s enough to build a strip foundation.

- Fire resistance - in the components from which the foam block is made, there is not a single one that is subject to combustion, so it has the highest class of fire resistance.

- Does not collect moisture - because the pore structure is closed.

- The size is large enough that it allows you to build a house quickly, in one season.

- The shape is geometrically accurate, the ability to build a perfectly level structure of any complexity, and also allows you to erect walls and build a house yourself, no professional experience is needed.

- Good thermal insulation allows you to save on heating your home.

- It can be glued - the consumption of the adhesive composition is several times less than the consumption of cement mortar.

- It’s easy to work with – it’s easy to cut, grind, etc., no special tools or equipment are needed.

- The price is several times less than the cost of brick and other natural materials.

Before you start calculating the number of foam blocks, you need to understand how much building material you need to buy to build a house, so that you don’t have to buy more during the construction process. You still need to decide what type of stone masonry to choose so that the house is warm and save on material. It's time to talk about how to calculate the number of foam blocks taking into account different types of masonry.

Conclusion

In this material, we tried to show the phased construction, indicating the necessary key points to which special attention should be paid. You should have understood that experts consider the best foundation to be a reinforced concrete slab, and the laying solution is glue (see also the article “Service life of concrete: extending the service life of a concrete structure”)

They also talked about reinforcement and the properties of the material to absorb moisture, which must be taken into account when finishing buildings. The video in this article will help you find additional information on this topic.

Method 2 – by area

The second method is to calculate the number of foam concrete blocks of a standard size for a building 10x10x3m with a wall thickness of 20, 30 or 40 cm for double-row masonry. For this example, we will place the block in one row with a wall thickness of 300 mm. The calculation technology is as follows:

- calculate the length of all walls, the outer perimeter is 4x10 = 40 m;

- determine the area of the walls – 40x3=120 m2;

- subtract the area of doorways and windows from the area - it is not difficult to calculate, but let’s take 10 m2 as an example, for a total of 110 m2;

- calculate the number of blocks per 1 m2 - area of one block = 0.12 m2, total 1/0.12 = 8.33 pieces;

- We will find out how many blocks will go to the whole house by multiplying the total area by the area of one block, total - 110x8.33 = 916.3 pieces.

In this simple way, we learned that we would need 917 foam concrete blocks. To make corrections caused by differences in the sizes of foam concrete from different manufacturers, we will use the tables above.

Sources

- https://openoblokah.ru/raschyet/72-kalkulyator-kak-rasschitat-kolichestvo-penoblokov-na-dom

- https://zen.yandex.ru/media/id/5bf9734e414f1b00a938b7c0/raschet-kolichestva-penoblokov-5c219638b5e90c00aa78941a

- https://stroy-calc.ru/raschet-penoblokov

- https://stroyew.ru/how-to-count-the-cubature-of-the-house-from-the-foam-blocks-how-many-foam-blocks-are-needed-per-house-calculation- and-quantity.html

- https://openoblokah.ru/raschyet/75-raschitat-kolichestvo-penobloka-na-dom

[collapse]

Similar posts:

- Aerated concrete block GOST 31360-2007: structure…

- Which blocks are best for building a house?

- FBS GOST blocks: foundation blocks 13579 78

- Aerated blocks - sizes and prices per piece, characteristics...

- The thickness of the brick wall (with and without insulation),…

- Aerated concrete construction technology - a guide

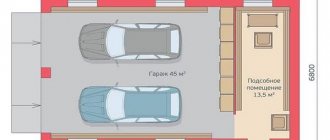

The simplest layout

The layout is extremely simple. In this case, the kitchen is separated from the room.

Sometimes an architect will draw a gorgeous layout, everything is functional, bright corridors, large rooms, a huge number of windows. It is very difficult to do this from the point of view of engineering solutions because large spans are always powerful floor structures, this is an unnecessary increase in cost.

In this project everything is different: it’s simple, cheap and can be built by almost any builder with minimal qualifications.

We have a vestibule that cuts off cold air when entering the house from the street. He's the hallway. It contains a wardrobe which is a wardrobe.

Then we find ourselves in a corridor from which we can go into a room with a kitchen and a combined bathroom.

The design solutions used in this house are the simplest and most affordable.

Foundation for a house made of aerated concrete, prices

Approximate cost of foundations for a house 10x10 m.

- Monolithic (slab) – 400 – 600 tr.

- Belt recessed – 200 – 300 tr.

- Shallow belt – 170 t.r.

- Pile-grillage – 200t.r.

The most expensive is monolithic, for example, a 10 by 10 meter slab will cost approximately 500 rubles. This includes all work and materials. If you do all the work yourself, it will cost about 200-250 rubles for materials.