A set of construction equipment is indispensable without a tool that allows you to tighten a screw, hang a shelf, assemble furniture or carry out minor home repairs. An automatic screwdriver greatly simplifies and speeds up these tasks.

There is a huge selection of drills and screwdrivers on the market: mobile, networked, of different power, weight and size. Impact drills are considered the most versatile option. How they work and how they differ from impactless models will be discussed further.

What is it and what is it for?

The impact screwdriver has already gained recognition in the professional community, but it is not yet so widely known in the mass market. In appearance, this tool is similar to a conventional electric drill, the difference lies in the principle of operation. Hammerless drills operate using a gearbox, while screwdrivers of this type are equipped with an impact mechanism that increases torque.

The shock mode does not have a constant tempo, but is triggered when colliding with an obstacle. This gives the device a noticeable advantage when working with hard and particularly hard materials, such as concrete.

The purchase of such a tool is relevant for both home use and professional construction. Craftsmen note that the impact principle of operation does not interfere with tightening fasteners and does not damage the elements.

Description of the screwdriver

The screwdriver is designed for screwing in or unscrewing a variety of threaded hardware, from screws and self-tapping screws to anchors or dowels. Thanks to the interchangeable bit attachments, they can work with slotted heads or hex heads. The tool is usually small in size and can be operated with one hand. It is suitable for assembling and fastening wooden parts, as well as other soft and moderately hard materials, both at home and in production.

Classic corded instrument

With additional attachments it can be used for sanding surfaces or drilling holes. Uses electricity, directly from the network or from a battery. There are also models with pneumatic, hydraulic, and even gasoline drives, but they are less common due to their bulkiness.

The classic scheme includes:

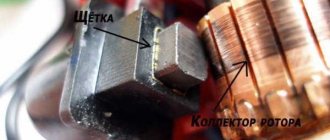

- the body is plastic or metal, there are often rubber inserts on the handle for grip;

- motor – it is the one that rotates the nozzle;

- planetary gearbox with adjustment clutch – for controlled transmission of rotation to the spindle with a chuck;

- cartridge - nozzles are placed in it;

- electronics unit - for starting the engine and using reverse;

- nozzles - as a rule, a hexagon-shaped shank, but round ones can be installed;

- if the model does not operate from the mains, then a battery is also added.

Disassembled

Before starting work, you need to select the degree of tightening using a coupling, which is attached to the mating part using spring-loaded balls. This allows you to screw in the screws exactly flush with the surface of the material being fastened. Stopping is achieved by slipping due to the increasing resistance of the screw. When drilling, the unrestricted mode should be used.

In a standard household version, the tool has a torque of about 10-60 Nm and is capable of spinning up to 600 rpm. For professional models, these figures can reach more than 100 Nm and 1300 rpm, respectively. The larger it is, the larger the screws that the tool can handle. There are also specialized models optimized for specific applications.

Electric screwdriver

The electric screwdriver is designed for repetitive operations of assembling and disassembling household appliances. It has modest dimensions, light weight and equally low power - about 10 Nm at about 200 rpm, without speed control. The impact wrench already produces up to 1000 Nm, plus it uses a square profile to fasten the wrench heads. Due to the pulsed action of tangential (transverse to the axis of rotation) impacts, it can unscrew even old connections. A screwdriver works in a similar way, only it has a holder for screws.

Kinds

Before classifying impact screwdrivers, you need to understand the division of tools into drills and screwdrivers. The former are equipped with drills for making holes, while the latter can additionally screw in fasteners. If a tool allows the use of different types of attachments, it receives a compound name, for example, “drill-driver.”

According to the method of power supply, electric and pneumatic tools are distinguished. But the latter are extremely rare and are used only in specialized enterprises (tire fitting, service stations). Therefore, we can assume that all screwdrivers are electric.

According to the type of connection, electric screwdrivers are divided into mains and cordless. The former are lightweight and convenient for use at home. Battery-powered models are indispensable when working on sites without the ability to connect to an electrical outlet.

Areas of application

The fundamental difference between impact models and standard ones is their compatibility with other devices. You can use a hole saw in parallel, and also replace the functions of a conventional drill to drill holes using special attachments.

An impact screwdriver is needed for minor repairs, fastening parts, and for drilling particularly durable surfaces. Many professional workers appreciate the lightness and compactness of impact models. At high rotation speeds of the drill, there is no damage to either the screws themselves or the fasteners. Manufacturers and stores offer a wide range of models, which allows you to choose a tool at a low price, which will help out both with minor household repairs and with active use in the workshop.

Distinctive features

When choosing between an impact and hammerless drill, it is important to understand the pros and cons of each option:

- Scope of application. Hammerless models are suitable for drilling metal, wood or plastic. When working with more durable materials (brick, concrete, stone), preference is given to impact tools.

- Operating mode. A non-impact screwdriver works only in two modes: drilling and tightening. The percussion model provides the ability to enable a third mode - percussion. It allows you to cope with particularly difficult areas.

- Accuracy of the result. According to this criterion, hammerless drills win. The spindle of the impact model is designed for work with heavy loads. Plus, most tools of this type do not have stops, which can lead to damage to the material.

- Weight. Impactless models are much lighter than impact models, which is more convenient for long-term work. At the same time, the presence of a striking mechanism helps reduce the load on the operator’s hand.

- Specifications. The main parameters are power and rotation speed. High twisting speed is typical for non-impact operation. Impact tools increase torque, making it easier to drill into surfaces.

Drill

The main function of a drill is drilling. However, if there is speed and reverse adjustment (and most models now have them), it can also be used as a screwdriver.

However, they lack any mechanism to automatically prevent the bat from falling off.

Often, when tightening a self-tapping screw with a drill, its head may be excessively sunk into the material, or the slots of the bit will rotate in the head, which can cause them to be torn off.

Therefore, here you have to rely only on your hands and head.

According to the drill, the verdict will be as follows. Buy it if you plan to mainly drill. But keep in mind that sometimes it can also be used as a screwdriver - after all, this is in any case more convenient than turning with a screwdriver.

How to choose?

An important selection criterion is the type of cartridge and its opening diameter. The chucks come in quick-release and key chucks. In the first case, the attachments are fastened automatically, and in the second, a special key is required for replacement.

The opening diameter affects the functionality of the tool: the higher it is, the greater the number of attachments available for installation.

Special attention should be paid to the maximum torque value. The higher the indicator, the faster and easier the drilling will be. Models with continuously adjustable torque are preferable, as this option helps avoid damage to materials.

Another useful feature is reverse rotation. It allows you to switch to twisting mode without changing the attachment.

When choosing a cordless tool, you need to decide on the type of battery. They produce models with lithium-ion and nickel-cadmium batteries. The first ones are the most popular in modern equipment. They are light, capacious, and can be recharged at any time. Disadvantages include high cost and rapid wear during operation at low temperatures.

Nickel-cadmium batteries have completely opposite properties. They are inexpensive, can withstand frost, are heavy, and require complete discharge before charging to extend their service life.

The choice is also influenced by the manufacturer and cost of the tool. The best brands include Metabo, Bosch, Makita, DeWALT and Zubr.

Specifications

Looking at the impact screwdrivers on sale today. You should familiarize yourself with the basic technical characteristics of household and professional models.

The power of network devices for home use ranges from 200 to 500 W. The same figure for professional equipment is over 500 W. If the master purchases a battery device for household purposes. A device with an operating voltage of 9.6 to 14.4 V is suitable. This figure for a screwdriver that works frequently and for a long time is from 14.4 to 18 V.

The battery capacity of a household appliance is 2 Ah, and that of a professional one is 4 Ah. Conventional screwdrivers usually do not have the ability to change speed. Professional equipment has a wider range of functions. Therefore, in such devices there are 2-3 speeds. Their torque is 20 Nm or even more. Household screwdrivers have this indicator at 15 Nm.

In addition, specialists purchase a tool that is not afraid of loads, mechanical shocks and even falls from a height. The cost of such devices is quite high. Therefore, more fragile but cheaper power tools are used for home use.

READ Which Trimmer Is Best For Tall Grass

Operating rules

Before starting work, be sure to read the instructions. It describes all possible modes of using the tool. Remember to follow safety precautions:

- Setting the maximum torque increases the risk of injury.

- Do not change settings while the chuck is rotating. All changes are made before turning on the device.

- Keep track of continuous operation time. Severe overheating of working elements leads to rapid wear.

- Do not touch the working parts immediately after turning off the tool.

- Do not use the device for other purposes.

- When working, be sure to use protective glasses and gloves.

Function difference

Most screwdrivers on the power tool market today belong to the semi-professional class. This means that the equipment has improved qualities, but does not meet the requirements for professional devices.

Almost all manufacturers produce both powerful and simple models. The most popular impact driver is Makita. Bosch, Metabo, and among domestic brands - Interskol, Zubr.

A professional tool is distinguished by its ability to work without interruptions for a long time, high power, and quick replacement of equipment. This type of device does not require too careful handling and is distinguished by its endurance and durability.

Home screwdrivers are characterized by a more modest set of qualities. It should be said that in professional series of equipment there are also low-power types of products. For example, this is a Bosch Professional impact screwdriver with a 10.8 V battery. However, they are included in this group due to their high build quality, thoughtful ergonomics, and long working life. Such devices are indispensable, for example, in furniture assembly plants.

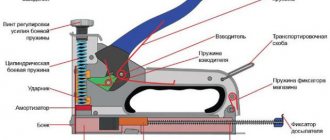

Differences in the design of impact mechanisms

Both devices have an impact

mode, but the mechanism of reproduction into bits is radically different. The hammer drill has an electro-pneumatic mechanism to produce the impact. The engine rotates a shaft, the movement of which turns into reciprocating movements of the piston. Compression is created between him and the striker, under the influence of which the striker transfers the blow to the working attachment (drill, chisel, drill or crown). Thanks to this performance, the impact force is quite impressive and the device can easily crush even hard concrete.

The impact mechanism of the drill has a completely different design. It consists of two ratchets (gears), one of which is movable and the other. No. While the engine is running and the shaft is rotating, a rigidly fixed ratchet forces the movable movement to move back and forth with a certain amplitude. Thus, the influence is transferred to the working nozzle.

However, unlike a hammer drill, it is the drill that transmits the impact

impulse of the chuck itself, so the harder we press the drill against the concrete, the stronger the impact will be. However, no matter how we press the drill into the concrete (even with our whole body on it), we will not be able to achieve the same impact force as an impact drill, since the amplitude at contact of the ratchets is too small. Thus, for hammer drills, the impact force can range from 1.5 J for weak ones to 20 J for powerful, heavy models. For example, the Bosch GBH 240 has an impact force of 2.7 J. This is a common indicator for domestic rotary hammers, but this is also unattainable for a drill.

Examples of models for different tasks

The following models of screwdrivers are suitable for professional work:

- DeWALT DCD 790 P2 - for construction and repair work;

- Bosch GSR 14.4-2-LI 0.601.9A4.400 - drilling and working with fasteners in the professional field.

For home use you can use:

- Metabo PowerMaxx BS Basic 600080500 - furniture assembly, working with drywall, drilling;

- STURM CD3012LP - minor repairs, shallow drilling in wood and soft metal.

To make the final choice of a tool, you can read reviews. Based on their results, choose a screwdriver that will serve for a long time and will not fail at the wrong time.

Definition

A screwdriver is needed to tighten and loosen screws and small bolts. The power tool has a built-in mechanism that stops the rotation of the chuck at the moment when the resistance to this rotation reaches its maximum. This is a very important point because the mechanism prevents damage to the screwdriver mount. By the way, you should definitely take into account that the above mechanism is adjustable. Today there are two main types of devices: screwdrivers that run on electricity and models that run on a battery. Of course, the price of power tools varies.

DeWALT Cordless Screwdriver

To drill holes on various surfaces, you need a drill. It is widely used in construction, decoration, carpentry and installation work. An interesting fact is that the first electric tool for drilling holes appeared in the mid-19th century, and since then it has been constantly improved. A modern drill has two operating modes: normal and impact

. If in the first case everything is more or less clear. With a drill you need to drill regular holes in walls and wood surfaces, then in the second you should clarify a little. Impact mode is activated when you need to drill holes in stone or concrete, that is, on harder surfaces.

The influence of the BOSCH drill on