Equipment types

Drilling begins with preparing tools for work. You can make holes using a screwdriver, drill or a special drilling machine.

To make a hole, you need to select the appropriate equipment. For metal workpieces, you need to choose specialized equipment that is suitable specifically for this material. This is due to the fact that equipment for wood, concrete or ceramic tiles have different sharpening and shape. Tooling for metal products is marked with the letters HSS.

The working part of the tool is coated with titanium nitride coating, which increases their strength and wear resistance. For hard steels, a different tooling is used, which is designated P18. The strength of the tool increases when cobalt is added to its composition. An example of marking is P6M5K5.

To drill alloy steel, drills with a tip made of carbide are used. With their help, you can drill any metal workpieces, however, due to the high price, this is not cost-effective.

When the hole is made, you can select a drill for the thread. Its diameter will depend on the previously used equipment. To make holes of different diameters in thin metal sheets, you can use cone drills.

Is it possible to drill with a drill in concrete?

Situations often arise when it is difficult to find a tool for drilling metal products at a construction site, but there is equipment for working with concrete. You cannot make holes of large diameter or in thick metal sheets with concrete drills. Otherwise, you may break the equipment or damage the surface being processed.

How to drill with a step drill?

On sale you can find stepped structures for creating holes in metal of various diameters. Several drills of different diameters are fixed on one axis. They are designed to create holes of various sizes in thin sheet metal. When working, do not rush or put too much pressure on the drill handle.

Is it possible to drill with a Pobedit drill?

Any master of finishing work will tell you that drilling metal with Pobedit equipment is unacceptable. Pobedite drills are designed for hard and, at the same time, brittle materials. These include natural stone, brick, concrete. When it hits metal, the drill will hit the surface and damage it, but there will be no hole.

How to drill large diameter holes?

Drilling large holes in metal requires the use of appropriate equipment. You can do the work in several ways:

- Crown for metal surfaces. It is a circle of the required diameter with sharpened edges. There is a drill in the center that pierces the metal. Next, at low engine speeds, the bit makes a hole of the selected diameter. During work, it is necessary to use forced cooling of the sharp edges of the crown and the surface being treated.

- Multi-stage operation. This implies the use of several metal drills of different diameters. Work begins with equipment of the smallest diameter and increases as drilling progresses.

- Cone-shaped equipment (stepped). Designed for working with thin sheet metal.

Builders recommend using crowns. However, when working with them, it is necessary not to increase the speed and ensure that all the teeth running around the circumference are intact.

How to avoid dulling a tool?

The tool becomes dull because it overheats during use. To maintain sharpness, drilling should be done at low speed. There is no need to press the power button all the way down. When drilling thick workpieces, you need to use coolants or pastes.

If there is no cooling lubricant, machine oil can be used instead. Coolant keeps the tool from overheating and reduces friction.

Bracket for receiving drilling machine

The multifunctional bracket will help you convert a standard hand drill (corded, with battery) into a stationary drilling machine. The body is made of heavy-duty aluminum alloy. Massive, allows you to securely install the drill for subsequent drilling. The fasteners are designed in such a way that they are suitable for all modern power tools.

The sole is equipped with a vice, which allows you to fix the workpieces in the desired position and avoid their displacement while drilling holes. The adjustable bracket allows you to set the desired height, taking into account the size of the tool itself. For convenient operation, there is a handle with a rubber pad that smoothly lowers the drill.

Multifunctional bracket for drill and screwdriver

| Price | 2,077.21 - 2,345.32 rub. |

| Rating | 4,6 |

| Reviews | 115 |

| Orders | 188 |

| Delivery to Russia | Free |

Drilling thick workpieces

Not many novice craftsmen know how to drill a hole in thick metal. Deep drilling is more difficult than usual. In production, it is carried out using lathes. In them, the workpiece is fixed in a movable spindle, which rotates it.

If it is not possible to use industrial equipment, you can drill a deep hole using a drill. To do this, you need to purchase special guides for power tools. Additionally, it is necessary to use machine oil for cooling. During operation, you need to stop periodically to clean out the chips and allow it to cool.

Battery power and types

An important question for builders is how to choose a cordless screwdriver tool? When choosing a cordless tool, be sure to look at the features of its charging. Drills and screwdrivers can be equipped with batteries with voltages from 7.2 to 36 volts. For home repairs, it is recommended to choose a tool with a voltage of 9 to 12 volts. Models with a power of more than 18 volts are suitable for professional builders.

One of the instruments from foreign manufacturers.

The power of the drill/driver depends on the type of electric battery selected. It can be nickel-cadmium, nickel-metal hydride and lithium-ion.

The most inexpensive batteries on this list are nickel-cadmium (NiCd). They are relatively heavy, but such batteries are inexpensive, can withstand about 1000 charge-discharge cycles and operate at sub-zero air temperatures. Such batteries provide stable power and do not overheat.

Nickel metal hydride (NiMh) batteries cost a little more, take longer to charge, are more compact and can also operate at low temperatures.

The lightest and fastest charging batteries presented are lithium-ion (Li-Ion). They charge quickly, and the charging and discharging of the battery is controlled by a special protection system. One of the disadvantages of such batteries is that it is problematic to work with them in winter frosts.

Thus, each type of battery has its own advantages and disadvantages, so it is impossible to say for sure which one is better.

It all depends on the time of year, the object and the type of work you are going to do. Expert opinion Sergey Pochtarev, master, Nizhny Novgorod.

If you are on a small budget, I would recommend purchasing a classic screwdriver with lithium batteries. They are lightweight, charge quickly and last a long time.

How to drill with a screwdriver?

You can drill metal workpieces not only using industrial equipment or an electric drill, but also using a cordless screwdriver. This power tool is low power. Because of this, it is suitable for drilling holes of small diameter and depth.

Drilling is performed using industrial equipment and power tools. It is important to choose the right equipment and take into account the depth and diameter of the hole. To ensure that your equipment lasts longer, you should use coolant. You need to drill perpendicularly to avoid damage to the workpiece or tool.

Subscribe to the channel, like, repost, and we will post useful information about metals for you! You can also visit our website, where you will find a lot of information about metals, alloys and their processing.

Source: zen.yandex.ru

Accessories for drills and screwdrivers - what can be done and how to choose attachments?

It seems that the task of a screwdriver is simple - drill and screw. But that's not all! There is a huge range of drills, bits, adapters and adapters that have turned drills and screwdrivers into multi-functional power tools. And here, for example, what.

What else can you do with a drill and screwdriver?

In some situations, drills and screwdrivers can replace hammer drills, angle grinders, jigsaws and even milling cutters. For example, using various equipment you can do the following:

- grind surfaces

- remove old paint and other construction debris

- mill wood or plastic

- stir building mixtures

- cut thread

Still, you should not expect the efficiency of specialized professional tools from drills and screwdrivers. They are suitable for solving local and specific problems that every home craftsman can do. And in order for them to cope even with a one-time job, it is fundamentally important to choose the right equipment.

Drills - holes in any material

Now you can drill everything - from stone and high-strength steel to fragile glass. When looking for suitable drills, pay attention to everything. Not only the area of application is important, but also the diameter, length, level of wear resistance, and shank diameter. For example, the reliability of fastening in the cutting tool chuck and the accuracy of drilling depend on the shape and diameter of the shank.

- Cylindrical . Classic! You need to make an effort to fix it even in self-clamping chucks, since the drills can rotate during operation.

- Triangular . They sit firmly in the chuck, do not rotate, but require attention during installation - the slightest misalignment leads to imbalance during operation.

- Hexagonal . They completely eliminate the rotation of drills in the chuck and are easier and faster to fix than triangular analogues.

- SDS MAX and Plus . Compatible with rotary hammer chucks and require the use of an adapter when installed on drills. Drills are installed instantly!

- M14 . Threaded shanks requiring the use of an adapter/adapter. Typical for diamond bits.

Also, when choosing drills, it is necessary to take into account compatibility with the chuck of a drill or screwdriver. All the necessary parameters can be found in the instructions for the power tool.

Working with metal

Metal tools are usually made of high-speed steel. The spiral design removes chips without interruption. The sharpening angle of drills varies between 118–135 degrees. Such cutting tools are used for processing alloyed or unalloyed steel, cast iron, and non-ferrous metals.

Using the equipment, you can drill holes with a diameter from 2 to 52 mm. Drills with a traditional spiral design are used to drill holes up to 20 mm, and when working with larger diameters, multi-stage models are used.

Wood and porous concrete

Drills for wood are structurally different from tools for metal. They have a pointed conical tip that prevents slipping. It also reduces the load on the cutting part and centers the tool.

The durability of these drills depends on the quality of the steel. When choosing, you need to pay attention to what materials they are intended for working with:

- softwood;

- laminated boards;

- hardwood;

- porous concrete;

- wet wood.

For example, the coating of laminated boards quickly dulls the cutting part. Therefore, carbide drills and special cutters are needed here.

In addition to spiral models, cutters and feathers are used for drilling holes in wood and panel materials (MDF, chipboard, plywood, OSB). They are structurally different from each other. Milling cutters are more reliable, durable and stable. In addition, spade drills are only suitable for through holes because they have a long tip for centering. Both cutters and feathers are used when drilling holes with a diameter of 15 mm or more.

Glass

For working with glass, drills with carbide tips or coating with diamond chips have been developed. The second type can be classified as crowns due to the peculiarities of their shape. Glass drills are either a solid rod with carbide tipping, or a hollow tube with a coating on the working part.

Brick, concrete and stone

These materials require a tool with a spiral shape and a carbide cutting part. The durability of the nozzle largely depends not only on the hardness of the material from which it is made, but also on its heat resistance. When working with particularly hard materials (concrete or stone), it is necessary to choose drills with a working part that has increased heat and wear resistance.

Also suitable for drilling stone are diamond bits/bits, which are used for glass processing. This cutting tool has increased resistance to deformation and leaves smooth, clean hole edges.

Ceramics

To work with hard tiles, the same cutting tools are generally used as when drilling concrete, stone and glass. They can also be used to accurately drill porcelain.

Crowns are the same drills, only bigger

A crown is needed where the drill is too narrow. For example, to drill holes with a diameter of 20 to 140 mm. An exception is diamond crowns for glass and tiles. They are classified as drills and crowns. They are hollow and oblong in shape and even at small diameters they look like crowns.

This type of drill is designed for working with wood, plasterboard, decorative and sandwich panels, metal, concrete, ceramics, stone, brick, foam concrete and wood slab materials. Like drills, bits have different shanks.

Cord brushes - grinding and cleaning

Another popular type of equipment is cord brushes, compatible with drills and screwdrivers. With their help, you can grind and clean metal, concrete, brick, stone or wooden surfaces, as well as remove varnish or paint from them, clean welds, and remove rust.

The working part of cord brushes is sandpaper or wire. The grain size and thickness of these materials differ from model to model. The cleanliness of the surface treatment depends on them. When choosing cord brushes, you need to pay attention to the following parameters:

- shape - round, radial, flat, wheel- and brush-shaped,

- rotation speed - from 3500 to 10000 rpm,

- shank type - triangular, cylindrical, hexagonal and threaded,

- outer diameter - from 17 to 200 mm.

To fix some types of cord brushes in a drill or screwdriver chuck, adapters are required. When looking for a suitable brush, you need to take into account that this is not an analogue of an angle grinder! Cord brushes are suitable for processing small areas, hard-to-reach areas and performing work that requires precision.

Bits - we tighten everything, from the self-tapping screw to the screw

For tightening self-tapping screws, screws, bolts using power tools, special attachments are used - bits. They come in single- and double-sided versions and usually have a hex shank. Bits are primarily classified by spline: cross, hex, PZ, sprocket, straight, end.

This is enough to select the right nozzle for any hardware. Many bit models have a magnetic tip - it helps to hold the screws. The durability of bits depends on the material from which they are made. Typically, hard alloys with resistance to both deformation and corrosion are used for these purposes.

Mixer - mixing construction mixtures

This mixer is definitely not for pancakes. Although, if you knead the dough in buckets, then a drill will do. But in general, a mixer attachment is needed for uniform mixing of building mixtures. They are suitable for dense, liquid or fluid masses.

It is better not to use screwdrivers at all for mixing dense masses, and drills - only for small volumes, being careful not to overload the engine. Different models of mixers differ from each other:

- load capacity - from 10 to 65 kg;

- length - from 400 to 600 mm;

- shank type - hexagonal, threaded and SDS.

When choosing, it is advisable to take into account the degree of corrosion protection, since you will be working with mixtures containing water.

Adapters - for cutting materials

To cut wood or metal, special attachments are provided. This is a mini-gearbox that transmits torque from a drill or screwdriver to the working part. With such attachments you can grind, mill, sharpen drills, tighten and drill in awkward places. You can even quickly make a portable compressor and inflate your car or bike tires.

Additional equipment

In addition to various drills and bits, there are other accessories for screwdrivers and drills:

Core sets . Designed for marking wood. Provide high precision drilling in the manufacture of furniture or carpentry.

Lock installation kits . The kit includes a crown and an auger drill. Door fittings are cut quickly and accurately.

Flexible extensions . Allows you to tighten self-tapping screws and screws in hard-to-reach places.

Extractors . Helps remove self-tapping screws with damaged slots.

Rigid extensions . Compatible with a variety of drill bits and help you drill deep holes.

Magnetic bit adapters. They allow you to quickly change attachments, so you don’t have to unscrew the cartridge every time.

There are also attachments for sawing - analogues of a jigsaw and a circular saw. You should not use them - it is very dangerous!

We recommend purchasing extractors, a flexible extension cord and a magnetic adapter - these items will be useful for every home craftsman. They allow you to quickly solve complex problems that often arise in emergency situations.

Can I drill with a screwdriver?

Manufacturers offer a variety of tools. Almost everyone can choose a tool to suit their financial capabilities and technical needs. A screwdriver is becoming increasingly common in the home workshop. Therefore, questions arise about what else can be done with its help. Today we’ll figure out whether it’s possible to drill with a screwdriver?

Experts do not recommend working with concrete. Even a drill with good technical characteristics may not be able to handle such hard material. But, if your model has an impact function, then you can try to overcome thin concrete, stone or brick.

As a rule, modern structures are built from aerated concrete or sand-lime brick. Such surfaces can be drilled with the most ordinary model, which does not contain an impact function. The main thing is to use the right drill. What can a screwdriver handle without problems? If you plan to work with wood, plaster, metal or plywood, then you can safely take out the tool. It will help not only tighten screws, but also be useful for drilling.

How to choose a tool?

To safely use a drilling device, you must choose it correctly. What should you pay attention to? If you want it to always be ready for use, then buy a network device or a battery-powered one, but with a spare battery.

The ability to drill various materials is affected by the rotation speed. For example, for tightening, 500 rpm is sufficient. For the drilling function, the speed should reach 1300 rpm. It is also important to pay attention to torque. If it is small, then such a screwdriver is only suitable for drilling wood.

Summing up, we can say with confidence that you can drill with a screwdriver. Modern models can cope with almost any surface. Even with thin concrete or brick. If you are just choosing a new instrument model, then listen to our advice.

Source: ecommercemarket.ru

How to use a screwdriver: useful operating tips

After purchasing a screwdriver, follow simple recommendations regarding use. And then the tool will work for a long time and efficiently:

- Before connecting and removing the battery, turn off the screwdriver;

- do not allow the instrument to overheat, take breaks;

- adjust the torque control clutch correctly;

- after using high speeds, set the minimum speed and idle the engine for several minutes to cool it down;

- Check the cable of the mains screwdriver, and the power cord of the charger for the battery. If a tool or charger periodically loses power, the wire must be replaced;

- Do not use the screwdriver in rain or snow. In humid environments, you can only work under a canopy.

Which screwdriver can handle drilling in steel pipes?

Task: drill holes in steel pipes (pillars for video surveillance) and drive self-tapping screws into them. productivity 10-15 holes with a diameter of 2-4 mm per hour. There is an outlet for recharging, but there is no way to drag the 220 to the poles.

Yes, almost everything. if the drills are sharpened correctly. And to be specific, announce the amount allocated for the instrument, otherwise lovers of DeFort, Bort, Packard Spence and other German-Swedish-Chinese brands will come running and trample on it. R. I apologize in advance if your famous company is not included in this list.

Shurik with two spare batteries, plus a conductor for the pipe, plus a supply of drills - and off he goes.

Based on my recent experience. Recently I drilled a dozen holes with a 8-pointer in 2 mm steel (initially 4, then drilled 8), one with a 4-pointer in 10 mm steel, drilled out 3 stuck screws, 2 holes with a 4-pointer in several mm steel, and cut threads into them. Several 4-piece self-tapping screws into the wood, I drilled them for them. a hole for an 8-mm cable in the wood, 20 mm, then a few more screws into the dense plaster, the force is on the verge of breaking the slot (if you tighten it by hand, you will sweat a lot with a very powerful screwdriver). I did some other little things, twisted screws, small screws, one hole in the plastic with a blunt drill. I don’t remember everything. oh, yes, before that there was a telephone socket on the wall with a self-tapping screw, another in the traffic jam (it didn’t work), a hole in the brick for it. All this on one charge, I charged it a long time ago, in mid-November (that is, self-discharge must be taken into account), there is still a charge, I don’t know how much. I think this should cover the work you want it to do in an hour, and that hour charges the other battery. So everything is real.

But, IMHO, the mandatory requirements should be:

- two-speed

- two batteries

- charging 1 hour

not lower than 12 volts, but preferably 14-18

I have a Bosh GSR 14.4-2, blue, two speeds, two batteries, charging in an hour. Battery 14.4 V x 1.5 Ah. I don’t know what the index -2 means, I assume it’s due to the battery, because... The model without it has 1:1 parameters, but the battery capacity is 1.2 Ah. I bought it at the house for 3900, it’s cheap, I just happened to come across some promotion. Without a promotion, this costs at least about 4 with a few hundred. Good luck!

Source: www.mastergrad.com

"Cricket"

Efficient, reliable and popular attachment. Shaped like scissors. This cutting mechanism ensures an even cut. It cuts flat or profiled steel, aluminum, composite, copper, and zinc equally effectively. In addition to cutting steel, it can be used for cutting thin polymer materials.

The “cricket” cuts steel up to 1.5 mm, stainless steel up to 1.2 mm, and copper and aluminum sheets up to 2 mm without flaws or defects.

Its design makes it possible to saw in all planes. Make internal cuts without cutting through the workpiece. The comfortable handle provides a reliable and safe grip.

“Cricket” is ideal for processing metal tiles and corrugated sheets. The working part does not destroy the protective layer, preventing corrosion.

How to drill a hole in metal

Metal products, compared to parts made from other materials, have increased hardness and strength, so to successfully work with them requires adherence to the technological process and the use of high-quality cutting tools.

Tools for metal drilling:

- Electric or hand drill;

- Twist drill;

- Kerner;

- Hammer;

- Protective glasses.

Metal drills are selected based on the diameters of the holes and the properties of the material being processed. As a rule, they are made from high-speed steels, such as R6M5K5, R6M5, R4M2. Carbide drills are used to work with cast iron, carbon and alloy hardened steels, stainless steel, and other difficult-to-cut materials.

The power of the electric drill must be designed to drill a hole of the required diameter. Manufacturers of power tools indicate the corresponding technical specifications on the product. For example, for drills with a power of 500...700 W, the maximum drilling diameter for metal is 10...13 mm.

There are blind, incomplete, and through holes. They can be used to connect parts together using bolts, studs, pins and rivets. If a hole is drilled for the purpose of cutting threads, you should pay special attention to the choice of drill diameter. Due to its beating, a hole in the chuck occurs, which must be taken into account. Approximate data are presented in the table.

| Drill diameter | 5 | 10 | 15 | 20 |

| Hole layout | 0,08 | 0,12 | 0,20 | 0,28 |

| Result | 5,08 | 10,12 | 15,20 | 20,28 |

To reduce the breakdown, drilling is performed in two stages: first with a smaller diameter drill, and then with the main one. The same method of sequential drilling is used when it is necessary to make a hole of large diameter.

Classification of cutters by material

- hard alloys;

- carbon tool steels;

- high-speed steels;

- hard abrasives;

- diamond coated steel.

In addition, carbide cutters are coated with special materials based on nitrides and carbon to increase wear resistance.

Carbide

To improve the physical characteristics of the cutting edges of the cutters, special coatings are applied to their surfaces, reducing the cutting force and increasing the wear resistance of the tool. Currently, coatings based on titanium nitride are mainly used, each of which, among other things, paints the surface of the roller cutter in a certain color. The most common materials for such coatings:

- titanium nitride (yellow);

- titanium aluminum nitride (blue);

- titanium carbonitride (gray color).

To improve chip control when processing tough metals (aluminum alloys, brass, etc.), cutters with a carbon-based hard coating (LTE), which has a dark gray color, are used.

Made from carbon and high-speed steels

It should also be noted that high-speed steel has increased viscosity, and therefore is more resistant to vibration and changes in the hardness of the machined surface during processing. Unlike metals, soft materials are milled at low cutting speeds. In this case, the use of burrs made of tool and high-speed steels is preferable, including for economic reasons.

Abrasive

Abrasive grinding attachments are basically similar in shape to burrs, which is why in everyday life such a tool is called an abrasive cutter. They use ceramic, elastic and bakelite binders as a base, and abrasive fillers, as a rule, are aluminum oxide and silicon carbide. Solid nozzles are used for cleaning castings and welds, removing old coatings, oxides and scale, as well as direct and profile sampling of metal. Bakelite and elastic bits are used for cleaning, rough grinding and precise removal of allowances on metal and other materials. Structurally, such a tool consists of a head in the shape of a cylinder, sphere, cone, drop, etc., which is pressed onto a cylindrical metal shank.

How to drill metal correctly with a drill

The peculiarity of drilling metal with a drill is that it is necessary to manually hold the tool, give it the correct position, and also ensure the required cutting speed.

After marking the workpiece, you should mark the center of the future hole. This will prevent the drill from moving away from the specified point. For ease of work, the workpiece should be clamped in a bench vice or placed on a stand so that it takes a stable position. The drill is installed strictly perpendicular to the surface to be drilled. This is important to avoid it breaking.

When drilling metal, you do not need to apply much pressure to the drill. On the contrary, it should decrease as you progress. This will prevent the drill from breaking and will also reduce the formation of burrs on the exit edge of the through hole. Care must be taken to remove chips. If the cutting tool is jammed, it is released by returning it to reverse rotation.

Selecting cutting mode

When using a high-speed steel tool, you can focus on the rotation speed according to the data in the table. When working with carbide drills, the permissible values are 1.5...2 times higher.

| Drill diameter, mm | up to 5 | 6…10 | 11…15 | 16…20 |

| Rotation speed, rpm | 1300…2000 | 700…1300 | 400…700 | 300…400 |

Drilling of metal products must be carried out with cooling. If it is not used, there is a high probability that the tool will lose its cutting properties due to overheating. The cleanliness of the hole surface will be quite low. An emulsion is usually used as a coolant for hard steels. At home, machine oil is suitable. Cast iron and non-ferrous metals can be drilled without coolant.

Features of drilling deep holes

Holes are considered deep if their size is greater than five drill diameters. The peculiarity of the work here lies in the difficulties associated with cooling and chip removal. The length of the cutting part of the tool must be greater than the depth of the hole. Otherwise, the body of the part will block the screw grooves through which chips are removed and liquid for cooling and lubrication is supplied.

First, the hole is drilled with a rigid short drill to a shallow depth. This operation is necessary to set the direction and centering of the main tool. After this, a hole of the required length is made. As you progress, you need to remove metal shavings from time to time. For this purpose, use coolant, hooks, magnets, or turn the part over.

Source: tehnouzel.ru

Design and characteristics

Externally, as well as in mechanical action, a screwdriver resembles a drill. The difference is the low speed /high scrolling torque. In addition, screwdrivers have fixed speed settings (on drills they are self-adjustable). Control over speed is necessary for safe and high-quality operation of the tool. The chuck stops moving the moment the screw is fully tightened. Even though the chuck has stopped, the motor is still running.

A specific speed/mode of operation is designed for a particular type of work. There is a function for reverse, tightening, unscrewing screws (as well as nuts, screws, self-tapping screws, soft materials). Craftsmen use screwdrivers all the time. In some cases (working with drywall, assembling an interior, creating a partition), the tool increases the speed and productivity of work several times.

Diagram of a cordless screwdriver.

READ How to Cut Laminate Flooring at Home

Screwdrivers are designed on the same principle. Design basis:

- pistol-shaped handle (for working with the leading hand);

- little weight;

- a start key that starts/controls rotations;

- power source - mains or battery (note that the battery is more massive and more expensive than the tool itself);

- capacity is limited by the total weight of the tool;

- continuous operation time - about 3 hours;

- Spare battery available (depending on model).

Equipment types

Drilling begins with preparing tools for work. You can make holes using a screwdriver, drill or a special drilling machine.

To make a hole, you need to select the appropriate equipment. For metal workpieces, you need to choose specialized equipment that is suitable specifically for this material. This is due to the fact that equipment for wood, concrete or ceramic tiles have different sharpening and shape. Tooling for metal products is marked with the letters HSS.

The working part of the tool is coated with titanium nitride coating, which increases their strength and wear resistance. For hard steels, a different tooling is used, which is designated P18. The strength of the tool increases when cobalt is added to its composition. An example of marking is P6M5K5.

To drill alloy steel, drills with a tip made of carbide are used. With their help, you can drill any metal workpieces, however, due to the high price, this is not cost-effective.

When the hole is made, you can select a drill for the thread. Its diameter will depend on the previously used equipment. To make holes of different diameters in thin metal sheets, you can use cone drills.

Is it possible to drill with a drill in concrete?

Situations often arise when it is difficult to find a tool for drilling metal products at a construction site, but there is equipment for working with concrete. You cannot make holes of large diameter or in thick metal sheets with concrete drills. Otherwise, you may break the equipment or damage the surface being processed.

How to drill with a step drill?

On sale you can find stepped structures for creating holes in metal of various diameters. Several drills of different diameters are fixed on one axis. They are designed to create holes of various sizes in thin sheet metal. When working, do not rush or put too much pressure on the drill handle.

Is it possible to drill with a Pobedit drill?

Any master of finishing work will tell you that drilling metal with Pobedit equipment is unacceptable. Pobedite drills are designed for hard and, at the same time, brittle materials. These include natural stone, brick, concrete. When it hits metal, the drill will hit the surface and damage it, but there will be no hole.

How to drill large diameter holes?

Drilling large holes in metal requires the use of appropriate equipment. You can do the work in several ways:

- Crown for metal surfaces. It is a circle of the required diameter with sharpened edges. There is a drill in the center that pierces the metal. Next, at low engine speeds, the bit makes a hole of the selected diameter. During work, it is necessary to use forced cooling of the sharp edges of the crown and the surface being treated.

- Multi-stage operation. This implies the use of several metal drills of different diameters. Work begins with equipment of the smallest diameter and increases as drilling progresses.

- Cone-shaped equipment (stepped). Designed for working with thin sheet metal.

Builders recommend using crowns. However, when working with them, it is necessary not to increase the speed and ensure that all the teeth running around the circumference are intact.

How to avoid dulling a tool?

The tool becomes dull because it overheats during use. To maintain sharpness, drilling should be done at low speed. There is no need to press the power button all the way down. When drilling thick workpieces, you need to use coolants or pastes.

If there is no cooling lubricant, machine oil can be used instead. Coolant keeps the tool from overheating and reduces friction.

Drill attachment for cutting sheet metal: scope of application

The main purpose of such an accessory is the processing of metal blanks, mainly sheet iron. The variety of options and types available on the market makes it possible, with proper practice, to produce not only straight cutting, but also shaped cuts, which is necessary when:

- roof installation;

- installation of air ducts;

- manufacturing a drainage system.

When choosing a specific type, you need to decide on the scope of future work. There are commercially available tools for cutting round holes, which resemble a milling machine in operation.

Also, using the nozzle, you can obtain devices for grinding metal, which is important when it is necessary to process edges or seams, especially after welding or cutting work.

All models of devices on the market are divided into certain types according to their area of application. They are:

- for performing corner drilling;

- performing grinding work;

- for drilling;

- allowing surface polishing;

- used for sharpening;

- used directly for cutting.

The difference in accessories for power tools for cutting metal lies not so much in the functional features, but in the permissible thickness of the sheet being processed, which also needs to be taken into account when choosing the optimal option.

- https://prosto-instrumenty.ru/nasadki-na-drel-dlya-rezki-metalla/

- https://moiinstrumentu.ru/nasadka-dlja-razrezanija-metalla-na-drel-zachem-nuzhna-i-kak-polzovatsja.html

- https://stroyday.ru/stroitelstvo-doma/instrumenty-i-oborudovanie/nasadka-na-drel-dlya-rezki-metalla-kak-vybrat.html

- https://remoo.ru/instrumentyi/nasadki-na-shurupovert

- https://proinstrumentinfo.ru/nasadka-na-drel-dlya-rezki-metalla-sverchok-tsena-nozhnitsy-video/

- https://homius.ru/nasadka-na-drel-dlja-rezki-metalla.html

Drilling thick workpieces

Not many novice craftsmen know how to drill a hole in thick metal. Deep drilling is more difficult than usual. In production, it is carried out using lathes. In them, the workpiece is fixed in a movable spindle, which rotates it.

If it is not possible to use industrial equipment, you can drill a deep hole using a drill. To do this, you need to purchase special guides for power tools. Additionally, it is necessary to use machine oil for cooling. During operation, you need to stop periodically to clean out the chips and allow it to cool.

Advantages and disadvantages

Cutting metal with a screwdriver has many advantages.

- The result of working with a screwdriver is a high-quality and even cut.

- Economical. When purchasing a nozzle, there is no need to purchase additional consumables.

- Greater device performance.

- The versatility of such attachments.

- Thanks to the presence of a special handle, the work process is easy, convenient, and efficient.

- Some models are applicable to any screwdrivers and drills, electric or pneumatic.

- Special attachments are quite easy to maintain.

- This method makes it possible to make cuts of almost any configuration.

The disadvantages of this method of cutting metal include some inconvenience in the work for novice craftsmen. You first need to adapt to the process, acquire some skill, even art. Experienced craftsmen will not need this - they will easily cope with the task. Another disadvantage of the product is the difficulty when working on the roof, since both hands are used when cutting metal.

How to drill with a drill?

Drilling metal with a drill requires following some recommendations:

- To make a hole you will need an electric drill, a core punch, a hammer, machine oil and safety glasses.

- Initially make markings.

- Wear safety glasses.

- When the pressure on the drill is low, you need to select the low speed position and start working.

- Don’t forget to water the area being treated with coolant.

If you follow the technology and use high-quality tools, you can make holes of different diameters and depths. To drill straight holes or accurately select the depth, you can use a device called a “depth stop.” It is attached to an electric drill and adjusted to the desired depth.

Torque: how much is needed for construction

Another parameter that affects the functions of the tool is torque. It is measured in Newton meters (N*m). Thanks to the torque, you can determine the degree of load for which the drill/driver is ready. The higher the torque, the greater the range of work the tool can perform.

For home work, a drill-driver with a torque of 10-15 N*m is suitable, when working with dense materials (for example, when screwing a 100 mm self-tapping screw into wood) - 30-40 N*m. Professional builders are recommended to use a drill/driver with a torque of more than 120 N*m.

How to drill with a screwdriver?

You can drill metal workpieces not only using industrial equipment or an electric drill, but also using a cordless screwdriver. This power tool is low power. Because of this, it is suitable for drilling holes of small diameter and depth.

Drilling is performed using industrial equipment and power tools. It is important to choose the right equipment and take into account the depth and diameter of the hole. To ensure that your equipment lasts longer, you should use coolant. You need to drill perpendicularly to avoid damage to the workpiece or tool.

Source: xn—-ntbhhmr6g.xn--p1ai

Care and storage

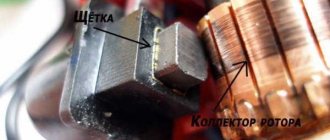

- regularly disassemble and clean the internal elements of the screwdriver from carbon deposits, dust and dirt;

- If unstable operation occurs, carry out diagnostics. Check the wear of the brushes so that you do not have to change the motor armature;

- Do not leave the instrument in areas with high humidity or under the sun. The same goes for the battery;

- Do not keep the battery near keys, coins or other short metal objects. In case of accidental contact with the poles, the battery will short circuit. As a result, a fire may occur;

- At the end of the working day, take a clean rag and wipe the instrument. The cloth can be slightly moistened with water without using detergents;

- The screwdriver should be stored in a dry environment with positive temperatures. Use a case or other packaging to prevent the instrument from becoming covered in dust.

Operate a screwdriver, observing safety precautions and the rules described in the instructions. Choose the right equipment. And then the tool will serve you for a long time.

Is it possible to drill a hole in a brick wall with a screwdriver? Suddenly it burns out or shorts out.

You can use a drill for concrete: a drill with a pobedite tip.

drill for a long time, stop periodically (often, every 5 seconds), wet the drill with water (dip it in a glass of water)

here is a drill for concrete - carbide brazed on the end

You can drill a couple of holes in the brick. But for a long time.

For larger volumes of work a hammer drill is required

Other answers Because of the wall? It’s possible, why not, you just need to take a good drill for concrete. Is it possible to break oak with a forge? -It is possible if the oak is forged and the oak is oak. LarisaStudent (199) 5 years ago I am a woman and am asking for help. I was hoping for an adequate answer. Laverna Manyakovna (self-isolated) Enlightened (33518) The answer is more than adequate because neither your screwdriver, nor the drill you are going to use, nor the type of bricks in the wall are known. Can. But not for long. take a hammer drill - why bother torturing Shurik? you can easily, if it’s normal, I personally saw how sandwich panels were attached to a square steel pipe 300 * 300 * 15 with a cordless professional Milwaukee drill, and it’s not a problem to drill through a brick, or with Duvalt, it’s brick and not concrete

I'm reporting. As a regular TV viewer of the Beaver TV channel (there is one in Tricolor), I report: only one Ikhny aunt (I don’t remember her name, but in all red and the smile of her ears goes on) is making holes in the wall (she says so herself, yeah!). The rest of their people are drilling holes.

I’m reporting again: It’s quite possible to drill holes in a brick wall (damn, how sticky it is). Yes, it’s labor-intensive, and a bit dirty, but if you have some kind of newspaper on hand to hold on to (to collect dust and crumbs), let the wall give way, let the brick bend, and let the battery not die out! Gee! Well, she’s the one from that “Beaver” and all in red, she manages to drill in the opposite direction, then invites a special guy to correct the situation, but then-oh! Then she lectures all the TV viewers - they say, holes should be made on the right, and not on the left.

And again I report: And if there is any broken drill, then it, with the end broken, will go where the brick will go sooner than a drill that is simply dull.

Hurray for Beaver! ————————— Found her, yeah! There will be a hole right now!

Impact-free drilling of brick/concrete

Hi all. I want to ask a professional, is it possible to drill concrete/brick with a hammerless screwdriver?

This is why I have a question: I want to buy a screwdriver, and I’m wondering if it will be possible to drill a couple of holes in a brick/concrete wall every couple of months to hang a shelf. When I started Googling, I found a bunch of uncompromising statements like “nowhere without a hammer drill.” But at the same time, I myself have been living well for decades with the simplest Makita impact drill, and I have already drilled hundreds of holes into it. I have never wanted to buy a hammer drill. As I already said, I’m not a pro, so whether it takes me 10 seconds per hole or 60 doesn’t matter, the main thing is that it’s not 10 minutes.

I came across the attached video and was amazed: either the guy is embellishing there, or what for then are all these hammer drills/impact drills/small pobedite drills? I’ve never tried drilling walls with a pen myself, but I think it will work? And if so, would a two-speed screwdriver be suitable for my needs?

Screwdrivers - recommendations for selection

Can the tool be used in drill mode?

Not every corded screwdriver can be used as a drill with conventional drills. For drilling, the tool must be equipped with an appropriate chuck, for example, a quick-release chuck. In addition, the screwdriver must have significant torque and high speed. If you are deciding whether to choose a corded or cordless screwdriver, choose the latter. Cordless drills/drivers are better suited for universal use. Corded screwdrivers with a drill function are not common. But for everyday use, we can recommend you the Caliber DE 300 w tool, equipped with a quick-release chuck. In other cases, drilling with a corded screwdriver will require drills with a hex shank.

What should you pay attention to when choosing a corded screwdriver?

Some corded screwdrivers have a narrow specialization; in particular, certain models are recommended for working with drywall. Having understood the scope of application, you should pay attention to the power. For screwing self-tapping screws into drywall, 450-600 W is sufficient. If you need to make threaded connections in parts made of wood, chipboard, and the same drywall, you will need a screwdriver with a power of 700 W or more. A tool with the same power is needed to drive screws with a washer into metal. The second important characteristic is the number of revolutions. If you want to drill holes, then this indicator should be high. We can draw the following conclusion: the best screwdriver for professionals should be chosen in accordance with its purpose.

How are network models used for working with drywall?

Thanks to the popularity of materials such as drywall, the use of screwdrivers in construction has increased significantly. You can screw screws into drywall with any tool, but the best results can be obtained with a special corded screwdriver. When using it, you do not need to pre-drill holes to install fasteners. The tool guarantees high installation speed, works with drywall screws, and some models are even equipped with a device that reduces noise levels. When tightening screws, do not apply force or put pressure on the tool. During work, you just need to make sure that the bit and the screw slot are aligned so that there is no misalignment.

Do I need to pre-drill holes to drive screws?

A corded screwdriver is a really convenient tool that allows you to get the job done quickly. It is an indispensable tool in construction and finishing work, as it allows you to tighten screws without first drilling holes for them. Moreover, this feature applies to almost all materials. It is recommended to drill holes only in certain cases, in particular when working with wood. But this should only be done to reduce the likelihood of cracks appearing in the material. Network tools are in good demand. We sell screwdrivers at a discount for many models in our store.

Is it possible to regulate the speed of tightening screws?

Each corded screwdriver has adjustable speed. It changes depending on the force of pressing the trigger, and is also set using an adjustment wheel. By changing the number of revolutions, you can tighten the screws at different speeds. If you want to increase your productivity, choose a reliable screwdriver - an electric one with the highest possible speed. For example, the Makita 6825 screwdriver has an idle speed of 6000 rpm. In addition, we can offer you a large selection of models from different manufacturers with a rotation speed of 4000-4500 rpm.

Do all screwdrivers have a reverse function?

In the places of sale where you can find a screwdriver: the VseInstrumenty.ru online store, which is an official dealer of dozens of manufacturers, in our retail sales centers - you will not find a similar tool without a reverse function. Due to this, the fasteners can be turned out. Without reverse, a screwdriver will not be complete. After all, even when screwing self-tapping screws into drywall, it is possible that they will need to be turned back out, for example, when it is necessary to disassemble the structure. Usually, when choosing a particular model, buyers pay attention to how convenient the reverse button is for use.

How does the depth limiter work?

The depth stop is a sleeve that is made in the form of a ring and is placed around the bit. This is used to adjust the depth of screw tightening. As soon as the stopper touches the material, screwing stops. The manufacturer produces tools with a limiter preset to a certain value. To change the depth of twist, you need to turn the limiter. At the same time, clicks will be heard. Each click means a change in screw depth by a fraction of a millimeter (0.4 mm). If your tasks include performing large quantities of the same type of screwdriver work, then, of course, you need to order electric screwdrivers with adjustable screw depth.

Why do you need speed control?

To tighten the screws, it is enough that the number of revolutions is 500 per minute. High speeds are needed mainly for drilling. Almost all screwdrivers have a speed exceeding 2500 rpm and can be adjusted. By increasing or decreasing the pressure on the trigger, the user can select the appropriate mode for working with a particular material and size of fastener. It should also be noted that there is a locking button that locks the trigger at the selected speed, so you can relax your hand. Thus, the network tool for tightening fasteners is effective and convenient to use. Considering the low prices for a mains-powered screwdriver, many people buy this particular tool instead of an expensive battery-powered one.

I want to buy a screwdriver for my home, help me choose a network one.

For home use, you can choose an inexpensive electric screwdriver. Pay attention to tools from the Caliber and Interskol brands. Corded screwdrivers, which are offered by domestic companies, can be used to work with metal sheets, corrugated iron, and for driving screws into wood. Thus, they can be used for metalwork and carpentry work. These tools have a reliable design, in particular, they have a metal gearbox, so they are recommended for use not only in domestic, but also in industrial conditions. The screwdrivers are equipped with a rubberized handle, which guarantees comfortable operation.

How easy are network models to use?

If you want to choose a good screwdriver, then among the network tools you will definitely find a suitable tool. Each model is designed so that it is convenient to hold the screwdriver with one hand. In this case, all control buttons are located next to the handle. Corded screwdrivers are characterized by good balance; the tool lies confidently in the hand, without deviating to one side or another. The handles of most models are finished with soft pads or have a special coating; in any case, such tools are especially popular among buyers.

What are the advantages of online tools?

The advantages of corded screwdrivers are the possibility of long-term, continuous operation. This mode is in demand in production and construction. These tools are actively used when installing drywall, as they do an excellent job of tightening screws. Another important advantage that can be obtained by working only with a corded screwdriver is the ability to screw in a large number of screws to the same depth. Comparing the full characteristics of corded and cordless screwdrivers, it is not difficult to see that corded tools are better at processing hard materials.

What does ¼" cartridge mean in the description?

The ¼" chuck is designed for standard hex shank bits. This chuck is used on almost all corded screwdrivers. The ability to use ordinary work tools provides a definite advantage, especially if you decide to choose a screwdriver for your home. The cartridge is easy to use as it has a magnetic holder. The bit inserted into the chuck is also magnetized, and as a result the self-tapping screw easily fits onto the bit. The ¼" chuck allows the use of hex shank drills. True, the cost of such equipment is much higher than that of conventional equipment, and the range of diameters is small.

Drill and hammer icons

If you have an impact drill, then on its body you can see the “drill” and “hammer” icons. If you are just drilling, for example, wood, choose a “drill”. This will prevent the cartridge from turning under any force. If you need to drill a concrete wall, place it on the “hammer” to start the impact mechanism.

ATTENTION!!!

These modes are not used when tightening screws! Because if there is a lot of resistance, the cartridge will get stuck. And the drill itself will spin, grabbing your hand. And this is fraught with serious injuries.

Battery life

At the same time, it was checked how long the screwdriver would work under conditions close to real ones. As a kind of average task, we took the procedure of screwing 19 mm plywood to concrete wall blocks - similar to those used for timed drilling. The blocks were laid on the floor and covered with plywood. Concrete screws ~5x75 mm were used as fasteners, which required pre-drilling with a drill with a diameter of 4 mm. The procedure was as follows: first, one hole was drilled, then a screw was screwed into it. And so on until the battery charge is exhausted. Thanks to the quick-change chuck, alternating drill and bit took literally a couple of seconds, so the total time of this almost continuous process was also measured. As a result, the following results were obtained: on one battery charge it was possible to completely tighten 36 screws and half the depth of the hole for the 37th was drilled. The whole process took just over 23 minutes, which we consider to be a very good indicator for this cordless tool!