Concrete floors without special treatment generate dust and are difficult to clean.

The concrete floor in the garage is familiar, but inconvenient. No abrasion resistance. As a result, constant dust and dirt. We assure those tired of endless cleaning: the best solution to the “dirty” problem is garage tiles. Let's try to figure out what types of facing materials are suitable for installation in such a specific place, and consider the nuances of designing floor slabs.

Laying tiles in a garage depends on two features of the latter:

- the room is often not heated;

- the floor experiences heavy loads;

Based on these factors, the range of materials is narrowed. The tile must be frost-resistant (we assume a hard, “unheated” version), resistant to abrasion and possible chemicals, fuels and lubricants. Installation also relies on these aspects; you need to choose glue and approach the cladding more carefully than in normal situations.

No. 1. What kind of tiles should be for a garage?

Naturally, ordinary tiles, which are used to furnish kitchens and bathrooms, are definitely not suitable for a garage due to their fragility and insufficient strength. What is needed here is more reliable material that will meet the following requirements:

- resistance to mechanical loads . A heavy vehicle will drive in the same place for a long time, but the floor covering should not deform or become cracked. The floor must maintain its integrity even if a heavy tool is dropped, one way or another connected with car repairs, therefore ordinary ceramic tiles used in apartment renovations will definitely not work;

- moisture resistance . Rainy and snowy weather is not uncommon in our country. When a car drives from the street, it brings with it a sufficient amount of moisture, which can negatively affect the floor covering. Some garages offer the possibility of washing cars, i.e. The humidity will very often be high. Floor finishes must have minimal pores and low absorbency to last in such conditions;

- resistance to aggressive chemicals . A garage is a place where substances such as gasoline, diesel fuel, motor oil, antifreeze and other auto cosmetics and household chemicals are constantly stored and used. If something accidentally spills on the floor (and sooner or later something will definitely spill), the coating should not be damaged. Wood, for example, will easily absorb spills, causing its appearance and many performance qualities to suffer. Some types of tiles are also highly porous, making them completely unsuitable for use in a garage;

- resistance to low temperatures . Garages are usually not heated, so in winter the temperature there will be almost the same as outside. If the floor covering is porous, then the accumulated moisture, turning into ice, will destroy the material, i.e. again, some types of tiles are definitely not suitable;

- fire safety . There are special requirements for the room where gasoline, diesel fuel and other flammable liquids are stored. As for the floor covering, it must not be flammable and not support combustion;

- ease of care . There should be no problems here, since almost any tile is easy to clean and wash. Difficulties can only arise with an excessively textured coating, which is chosen in order to create the most non-slip floor possible;

- the aesthetic qualities of the coating are of secondary importance for most car owners. The garage should be neat, and it is better to leave the unusual design for the apartment;

- price. High-quality coating is never cheap - you should come to terms with this and not try to save too much, but there are still more and less expensive materials, so everyone can make a choice according to their own budget.

Compared to other floor coverings used to furnish a garage, tiles seem to be almost the most ideal option. A concrete floor is dusty and needs constant sweeping, a wooden floor easily absorbs liquids and is afraid of fire, and a self-leveling floor suitable for all parameters is too expensive.

All, or almost all, of the above requirements are met by several types of tiles. Let us dwell on the properties and features of each of them.

Some tips

- When performing work on laying porcelain stoneware, it is necessary to take breaks.

- It should be taken into account that the tiles laid earlier will be located lower than those that are being installed now.

- As a rule, the adhesive for porcelain tiles hardens within 24 hours, after which you can begin grouting. At the same time, the floor cannot be used yet, otherwise it will become unusable.

- It is advisable to let the glue sit for two weeks.

Laying porcelain tiles is a complex and troublesome type of work and can only be carried out if the recommendations and advice of specialists are followed.

No. 2. Paving slabs

Paving slabs can be used not only to lay the area in front of the house and garden paths, but also the floor in the garage. This is a fairly budget and practical option. Concrete tiles are the most widely used. It is made from a concrete mixture that is used to fill molds. They are placed on a vibrating table, where the process of compacting the future tiles takes place (vibratory casting method). Additionally, a press can be used, which can significantly reduce compaction time (vibratory compaction method). Due to the presence of special additives in the concrete mixture, the finished material is resistant to moisture.

Main advantages :

- high resistance to mechanical loads, which is ensured by the significant thickness of the products;

- wear resistance;

- low level of slipping, which is important for a room where the floor will often get water and other liquids;

- durability;

- huge assortment. The garage can be decorated with either regular gray rectangular tiles or colored figured ones, creating an interesting pattern;

- easy installation;

- low cost, and if you take into account the combination of price and quality, then paving slabs can be considered almost the most optimal flooring option for a garage.

drawback :

- the material is hygroscopic, so it can absorb moisture. Of course, the level of hygroscopicity is not as crazy as that of wood, but not as low as that of porcelain stoneware. Manufacturers are trying to create tiles that are more and more moisture-resistant, but it is still impossible to completely get rid of porosity. This means that it is better not to use paving slabs if the garage is not heated and is located in a region with a cold climate. Also, paving slabs are not suitable for garages with constantly high levels of humidity. In addition, hygroscopicity will complicate the cleaning process.

Some types of tiles are quite expensive. If your budget is limited, then there is no point in spending money on the most expensive tiles, but it is also better not to take very cheap material, since it can be made in a handicraft industry without observing all the standards, and then you won’t have to talk about any of the advantages listed above.

Mandatory base treatment

Processing the base is a mandatory stage of preparatory work. Without this, the quality of installation will significantly decrease, and the performance characteristics of the material will deteriorate. To do this you need:

- Pits and potholes are covered with an adhesive mixture. All recesses must first be wetted with water.

- Removing oil stains.

- Repairing decaying areas and cleaning them.

After preparation, the floor should be allowed to dry. Only after this do they begin laying porcelain tiles. Dust and dirt must be removed before starting work.

No. 3. Clinker tiles

Clinker tiles meet all the requirements for garage flooring and could be considered an ideal option if not for their relatively high cost. The material is obtained from refractory types of clay, mainly shale clay is used. For glazing, glass chips are added to the raw material. The temperature in the melting furnaces reaches 1200-13000C, due to which the pre-well-pressed raw material is sintered so well that all pores and voids disappear - it is possible to obtain a monolithic product. It is thanks to this technology that the unique properties of clinker tiles are achieved.

Advantages:

- practically zero water absorption, therefore the material does not care about rainy weather, spilled liquids and frosts;

- a high level of resistance to mechanical stress and abrasion, and when heavy objects fall, chipping is unlikely;

- resistance to chemicals;

- fire resistance. If you remember at what temperatures the material is made, it is easy to guess that clinker is not afraid of fire. At temperatures up to 18000C there is no deformation or destruction;

- durability, measured in tens of years;

- ease of care. Dirt does not accumulate in the dense structure of the tile without pores, and any spilled liquids will be very easy to clean up.

Unfortunately , there were some downsides :

- price. You have to pay for a high-quality, reliable coating, but this can be considered an investment in the future, devoid of problems with repairing the flooring in the garage;

- complexity of installation. Minimal porosity complicates the process of choosing an adhesive composition for laying tiles. You will have to be as careful as possible when choosing glue, and it will not be cheap;

- A small range of colors and shapes could be considered a disadvantage when arranging a floor in a living room or when choosing a material for a front yard, but when it comes to a garage, performance comes to the fore. It is enough that clinker tiles look nice and on its basis you can create a neat, discreet and, most importantly, durable coating.

If your budget allows, then feel free to choose clinker tiles - they will faithfully serve for many years in a row. If finances are limited, then you will have to consider other options.

Facing materials

Porcelain tiles

Covering the floor in the garage with porcelain stoneware. The seams will darken in any case, so there is no need to make them light.

There are several types of ceramic granite, but they are united by high strength and resistance to mechanical and chemical damage. The low porosity of the material is positively reflected in the reaction to temperature changes - neither frost nor heat affects it. However, this same circumstance leads to poor adhesion of adhesive mixtures to tiles. Low water absorption works against adhesion, but the problem can be solved by choosing the right adhesive. Fortunately, today the line of tile compositions is large and varied.

Any oil stains can be easily removed from porcelain tiles in the garage.

Paving slabs

Many people associate the sidewalk with the street, but it also has a place in the garage. It is more hygroscopic than porcelain stoneware, which affects frost resistance, but widespread use has proven its operational reliability. High water absorption is compensated by the thickness of the paving slabs, dry laying and the width of the joints.

Paving slabs in the garage.

- availability;

- huge service life;

- variety of formats and shades;

- high slip resistance;

Clinker tiles

Clinker tiles in the garage.

- high price;

- small assortment;

If you are on a limited budget, it is better to pay attention to another material. But if the financial component is not a hindrance, a design problem may arise

Clinker tiles have their own tasks, and so far manufacturers have not indulged in a tonal and format range. The garage as a work of art is rare, so existing “collections” are sufficient.

Acid resistant tiles

Industrial acid-resistant tiles Stalotec from the Stroher factory (Germany).

- extremely small assortment (even smaller than clinker);

- complexity of installation;

No, it’s not that difficult to veneer with it; the point is in the peculiarities of the compositions that form the layer between the slabs and the base. Once you understand the issue, you will get a truly perfectly functioning floor. Even if it is not brilliant with aesthetics.

Rubber tiles

An unusual solution that, like other types, has pros and cons.

Rubber tiles are quick to install and easy to clean.

- Wear resistance. How difficult it is to “break” a rubber tire! Such tiles are not afraid of impacts, crowds of feet and wheels; this ensures high reliability of the floor and durability.

- Zero water absorption. The influence of water combined with temperature fluctuations is one of the most destructive. In this case it is minimized.

- Anti-slip surface.

- Depreciation. Anything can happen in a garage; it's a workplace. When you fall on a rubber tile, your chances of getting injured are dramatically reduced.

Rubber crumb tiles.

- Relatively high price.

- Fire hazard. Rubber burns well, so when purchasing, check the composition and properties of the material. There are boards on sale that contain fire-fighting additives.

- Inappropriate reaction to chemicals. This results in potentially difficult rubber tile maintenance.

The choice of material is left to the needs. Since ceramic tiles are popular, we will now consider the nuances regarding their installation.

No. 4. Porcelain tiles

Porcelain tiles are ideal for use in garages. It is possible to classify the material as tile only with a stretch, since porcelain stoneware is close in properties to natural stone, and in some characteristics even surpasses it. It is produced on the basis of clay, sand, mica, feldspar and granite chips. All components are mixed, pressed at high pressure and fired in an oven at a temperature of 1200-13000C. The result is a material that is almost completely devoid of pores (like clinker tiles). The unique composition allows us to achieve record strength: 3 mm thick tiles can withstand loads of up to 200 kg/cm2. It is not surprising that porcelain stoneware is considered almost the most suitable material for a garage.

Advantages:

- high strength and wear resistance. The material can easily withstand the load from a car constantly driving through the same place, and the fall of a heavy tool will not be fatal for it;

- almost complete absence of moisture absorption, therefore precipitation, car washing, spilled liquids are not dangerous for porcelain tiles;

- frost resistance. Due to the absence of pores, porcelain stoneware easily withstands low temperatures and temperature changes, maintaining its integrity;

- ease of care. There are no pores - there is no dirt in them, so maintaining cleanliness will be very simple;

- resistance to chemicals;

- fire safety;

- durability;

- wide variety and the ability to create an aesthetic coating to suit every taste.

There are disadvantages to porcelain stoneware:

- high price;

- difficulties during transportation due to the large weight and fragility of the material;

- difficulties during installation due to low porosity and resulting poor adhesion with many adhesive compositions, therefore the choice of adhesive should be approached with extreme caution. In addition, porcelain stoneware does not cut well, which further complicates installation;

- low thermal insulation qualities.

The range of porcelain tiles is impressive, but for a garage it is better to choose material with a matte surface - glazed specimens look nice, but in the garage scratches will quickly appear on the surface, and the coating will look sloppy.

Preparatory stage

At this stage, the surface is leveled. Height differences of more than 1.5 cm are eliminated using a concrete screed. Small differences are leveled out during installation of the floor covering by applying a thicker layer of adhesive.

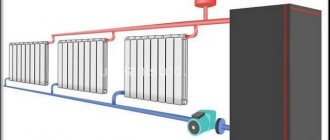

When installing a heated floor with porcelain stoneware, the preparatory stage includes:

- waterproofing material flooring;

- installation of heated floor elements;

- surface concreting;

- solidification of the solution;

- treating the floor with an antiseptic and primer;

- surface drying.

If the old floor was wooden, it should be dismantled and replaced with new boards. But a more expedient solution would be to replace the wooden flooring with a concrete base. You can either create a new concrete floor or pour expanded clay with concrete, which fills the space between the joists.

No. 5. Rubber tiles

Rubber tiles are inferior in popularity to other types of tiles, but in terms of their overall performance qualities they are excellent for use in the garage. The material is produced on the basis of rubber crumbs with the addition of dyes and modifiers. Rubber tiles are used for arranging industrial premises, and recently they have begun to be used for organizing flooring in garages.

Advantages:

- excellent resistance to mechanical and shock loads. Even a heavy tool, if it falls, will not split the coating, and the car will not leave any damage on it;

- high level of moisture resistance. Rubber tiles are an ideal solution for a garage where you will need to periodically wash your car. She is not afraid of frost and temperature changes;

- ease of installation. Individual tiles are connected to each other thanks to special grooves;

- good soundproofing qualities - if a heavy tool falls on the floor, the noise will be insignificant. There will definitely not be such a roar as when falling on clinker tiles or porcelain tiles;

- non-slip surface. Even if there is a puddle of water on the floor, it will be difficult to slip, and this is very important from a safety point of view;

- ease of care;

- wide choice of shapes, colors and sizes.

Among the disadvantages we note:

- rubber tiles are relatively easy to ignite and burn. For the garage, you need to take those products that contain substances that impede combustion;

- price. Rubber tiles are not the most expensive, but not the cheapest coating either;

- instability to some chemicals;

- Although the process of installing tiles is relatively simple, it is necessary to prepare a perfectly flat and durable base for the coating.

Rules for laying the coating

The instructions for installing tiles of any type are the same. A standard tiled floor is installed. The only significant difference is the freezing time. It will take several days for the floor to rise and be ready to withstand heavy loads.

Floor preparation

Before laying the tiles on the floor, treat it with a primer to improve adhesion. If necessary, level the surface and make a screed. To prevent water from accumulating in the garage, make a natural slope from the far wall to the gate. Storm gratings are installed at the entrance. If there are severe frosts in winter, a heating cable is placed under the gate.

Installation

Start laying tiles from whole blocks, from the gate or from the inspection hole, if there is one. During the process, they try to evenly distribute the adhesive solution so that there are no voids. Otherwise, the tile may crack in this place. The glue layer should be thin.

No. 6. Acid resistant tiles

This material makes sense to use if the garage is not only a place to park a car, but also a space where various types of repair processes often and actively take place. Tiles are made from fire-resistant clays with the addition of substances that increase the material’s resistance to various types of negative influences.

Pros:

- wear resistance and strength, resistance to mechanical loads. If the material can withstand the weight of factory machines and their vibration, then it can easily withstand the weight of a car;

- the material practically does not absorb moisture;

- resistance to aggressive substances;

- frost resistance and resistance to temperature changes due to low porosity;

- easy to maintain, because the non-porous surface of the tile does not absorb dirt and grease.

Minuses:

- simple design and small range;

- difficulties in choosing an adhesive composition.

General recommendations for work

Any finishing material, including porcelain tiles for the garage, no matter how good it is in itself, requires proper installation and the use of good special compounds. For proper operation, the garage floor must be flat and free of voids before installation. Many owners turn a blind eye to this stage. In vain - a slab laid over an empty bubble will break at the first opportunity! High-quality cement, glue and grout will definitely help to avoid such an outcome. It is better to add a plasticizer to the cement mixture for laying tiles for greater reliability. Especially if the garage is unheated. Be sure to choose mixtures created specifically for your finishing materials and operating conditions! Contact trusted manufacturers of glue and grout, for example – ]Mapei[/anchor], which has an ideal price-quality ratio.

Characteristics of paving stones and the degree of their compliance with the requirements

The properties of paving slabs are based on the characteristics of concrete products, but are superior to them in a number of ways. Let's consider these properties from the perspective of suitability for use as garage floor cladding.

Paving slabs are durable and easy to install

- Strength – paving slabs have high compressive strength due to the material used – concrete. Paving stones are a non-reinforced material, so their resistance to other types of load (tension, bending, shearing) is less, but tiles laid on a preparatory screed are only exposed to compression (the weight of a car, a jack, a workbench, etc.).

- Resistance to impact loads - paving stones can withstand significant impact loads without collapsing, but shells form on its surface from impacts.

- Frost resistance - depending on the manufacturing technology, the water absorption of paving stones is less than 5%, as a result of which it can withstand 200 - 300 freeze-thaw cycles, which guarantees the floor covering, even in harsh climates, at least ten years of operation.

- High resistance to temperature changes - paving stones retain their characteristics even in areas with seasonal temperature fluctuations of 80 - 90 degrees.

- Resistance to chemicals - during operation, paving slabs are exposed to detergents, oils, and in winter - road chemicals from car wheels, partially losing their aesthetics, but keeping their strength characteristics unchanged.

- Friction-slip coefficient - dry paving stones have a friction coefficient of 0.9, wet - 0.75, so the material meets the safety requirements for floor coverings.

- Safety - paving stones are a hard surface, so if a person falls on it, like on any other hard base, it is fraught with injury, but the tiles do not release toxins into the environment, are antistatic and fireproof.

- Simplicity of installation, routine maintenance and spot repairs are the undeniable advantages of paving slabs, which contribute to the growing popularity of its use as a garage floor covering.

The listed characteristics of paving stones meet the requirements for finishing a garage floor, so its use as a floor covering is an advantageous alternative to concrete screed.