According to statistics in Russia, about 90% of houses do not meet modern heat saving standards. To improve the situation, a number of legislative acts and industry regulations have recently been adopted to ensure the performance of buildings taking into account the requirements; all new buildings are being built using modern heat-saving technologies. What to do with old buildings? It is necessary to insulate the facade walls, due to this, losses are reduced to 40%. There are quite a lot of insulation materials; in this article we will consider only one type of them - liquid.

Insulation with liquid thermal insulation

Liquid thermal insulation: what is it?

Liquid thermal insulation is one of the types of insulation that is used to insulate facades, walls, pipes, etc. This material can be compared to sour cream or mastic in consistency. Liquid thermal insulation is usually applied in 2-3 thin layers. Moreover, it is important to wait until each of them dries. Only after this can a new layer be applied.

Most often, the base of thermal paint consists of acrylic. In addition, silicone, glass or ceramic microsphere are added.

Liquid thermal insulation for walls

Video description

The video tells more about the Corundum thermal paint:

The coating is formed thin with a porous structure. Technically, the dry residue has high strength and ductility, which explains its resistance to cracking.

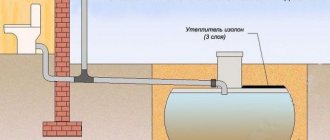

More often the material is used for thermal insulation of cold water pipelines. The protective layer prevents the formation of condensation and corrosion on metal lines.

Akterm and Astratek

The Akterm series is represented by 15 positions. 7 of them have thermal insulation properties. The table provides a brief description of the samples.

Application of Akterm thermal paint Source akterm.ru

| Standard | used as a waterproofing agent in the residential and industrial sectors. |

| Volcano | exhibits resistance to heating up to +500 degrees Celsius; applied to metal, penoizol, mineral base (concrete, brick, cinder block). |

| North | The paint is made on an organic basis; operating temperature from -35 degrees Celsius; has high adhesion to most substrates; shows inertness to aggressive environments; resistant to corrosion. |

| Facade | resistant to natural phenomena; used for external insulation of mineral bases. |

| Anti-condensation | base – aqueous dispersion; prevents the formation of condensation; Contains antifungal additives. |

| Metal | withstands heating up to +190 degrees Celsius; protects metal from corrosion; prevents freezing and condensation. |

| Concrete | used for interior work; suitable for painting concrete; contains antifungal additives; the coating is suitable for decorative painting and wallpapering; a 1 mm layer does not allow heat and cold to pass through. |

How to apply liquid thermal insulation

To insulate walls, it is recommended to buy insulation with a ceramic component. External facades are finished with varnish-based materials.

Before you start working, surface preparation is required. Try to get rid of all the unevenness and plaster some places with gypsum mixture. Next you need to apply a primer. Then mix the liquid insulation. Usually the manufacturer writes on the can how to do it correctly.

Thermal paint is applied in several layers. Each of them should be no more than 1 millimeter. How many layers you get depends on the thickness of the wall and the material. Typically the product is applied with a spray or foam roller.

If we talk about pipe insulation, then special liquid thermal insulation is used for this. Before you start working, you need to remove rust and dirt. Then prime the pipe. When the primer is completely dry, begin the insulation process. The paint is applied with a special sprayer or brush. On average, you will need to make 5-6 layers. Each will take about 5 hours to dry. Then you can coat the pipe with special enamel.

Video - Applying liquid thermal insulation mechanically

Description of insulation

To increase the energy efficiency of buildings, manufacturers offer a choice of materials in the form of slabs, rolled sheets or sprayed compounds. The last option differs from the others in that the insulating coating is formed monolithic, relatively thin and is suitable for decorative finishing in almost any way.

According to the application method, materials can be divided into 2 groups: sprayed insulation in cylinders and paintable ones. The latter are applied by painting and spraying. The former are characterized by foaming, while the latter form a relatively thin-layer coating.

Application area

The composition of liquid insulation for walls differs from each other, so the application also varies. The material is mostly used in construction for insulating pipelines, walls, floors, ceilings inside buildings, roofs and facades. The products are also relevant in the automotive industry, as some insulators have anti-corrosion properties.

Liquid heat insulator is very effective when it is necessary to insulate surfaces of complex shapes - for example, in cars Source kursk.poliuretan-ppu.ru

Advantages and disadvantages

Builders prefer painting and sprayed thermal insulation due to a number of positive aspects. These include:

- ease of working with structures of any complexity;

- high efficiency of products with low coating thickness;

- resistance to various operating conditions, including physical stress;

- fire resistance;

- vapor permeability, water resistance for most samples;

- inertness to certain chemical reagents, biological activity;

- light weight, which is especially important for old foundations, since there is practically no load on the foundation.

However, the materials also have drawbacks. If some compositions are made as sprayed thermal insulation in cylinders, then the rest are applied using special equipment. Devices are rarely purchased for home use due to their high cost. Therefore, you have to turn to the services of specialists, which is reflected in an increase in the amount of the overall estimate.

Special installation for working with liquid insulators Source penoglass.ru

Tips and recommendations when choosing liquid thermal insulation for walls

First, decide where to apply the heat paint. Most often, the manufacturer labels the jar with the product. Look carefully at what surface you will apply this product to.

Also take a closer look at the contents of the jar. It must be uniform, without plaques or any inclusions. It is better if the color is white, but beige and gray shades are possible.

Do not ignore the density of the product. Low values will give greater heat transfer. Also find out the service life and interaction with various environmental indicators.

Not every liquid thermal insulation has an easy application method. The tool should be easy to use. Give preference to trusted companies.

Video - Liquid thermal insulation Armor: do-it-yourself insulation of a balcony, loggia, walls, ceiling, floor

Video description

The video talks about SHUTTLE liquid thermal insulation:

Ecowool

An environmentally friendly product stands out against the background of thermal insulation materials. This is the only material that cannot be classified as a liquid insulation material in an unambiguous sense. But one of the methods involves using a ready-made mixture to prepare a working solution.

Spraying Ecowool Source myuspehlife.ru

Initially, the heat insulator consists of cellulose fibers in loose form:

- rejected products from printing factories;

- waste from the pulp and woodworking industries, from the production of corrugated and cardboard packaging;

- heterogeneous raw materials from recycled waste paper.

The raw materials are pre-treated with antiseptic drugs and fire retardants. Boric acid can make up up to 12% of the total volume. It provides resistance to moisture, fungi and mold. As a result, the insulation has a capillary structure, and not porous, unlike its analogues. About 8% is sodium tetraborate, a fire retardant substance that improves the fire resistance of the finished product. It also works as an insecticide that resists the appearance of settlements of certain insects.

The preparation of the solution for spraying is based on the lignin contained in the raw material. This natural substance becomes sticky when in contact with water. Spraying and simultaneously compacting natural fibers occurs using a special installation. Floors, walls, ceilings inside the building, and roof structures on sides protected from moisture can serve as a working base.

Industrial insulation with Ecowool Source stroyportal.ru

Voting for the best liquid thermal insulation for walls

Which liquid thermal insulation for walls would you choose or recommend?

Teplomet Nord

20.00 % ( 1 )

Isollat-02

0.00 % ( 0 )

AKTERM Vulcan

20.00 % ( 1 )

Astratek facade

0.00 % ( 0 )

RE-THERM

0.00 % ( 0 )

Corundum Classic

0.00 % ( 0 )

Armor Nord

0.00 % ( 0 )

AKTERM Concrete

0.00 % ( 0 )

Termion Finish NG

0.00 % ( 0 )

Termion Standard NG

20.00 % ( 1 )

Magniterm Standard

0.00 % ( 0 )

VIOTERM Metal ALLUMA

0.00 % ( 0 )

ThermoColor "Facade"

0.00 % ( 0 )

HeatPlus

20.00 % ( 1 )

Armor Station Wagon

0.00 % ( 0 )

TERMION Winter

0.00 % ( 0 )

Work technology

Sprayed insulation and thermal paint are applied to a clean, durable base without corrosion or areas of biological damage. Painting is carried out in the same way as with traditional compositions: priming, forming a layer-by-layer coating with intermediate drying of each. The manufacturer writes on the packaging about the intricacies of the work.

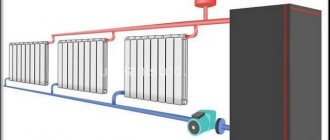

Insulation of walls using insulating foam occurs in the following order:

- installation of sheathing made of lumber, metal or plastic profiles;

- spraying a heat insulator onto the working surface across the entire width of the opening in the direction from bottom to top (it may be possible to repeat the procedure to increase the thickness of the coating);

- protection and decorative finishing of the formed layer.

The sheathing serves as a reinforcing material and a guide to the thickness of the insulation. After the foam has dried, the excess foam composition is cut off along the sheathing. This results in a smooth surface, which is easier to work with later at the finishing stage.

Foam insulation Source ytimg.com

Briefly about the main thing

The group of liquid insulation materials includes thermal paints and polymer foaming compounds. This also includes moistened ecowool, as it is applied by spraying.

The main advantage of the materials: high energy efficiency of thin-layer coating. The main disadvantage is the total cost according to the estimate. More often, spraying is carried out using special equipment that is not purchased for home use. Therefore, we have to hire craftsmen. If you purchase the material in gun cylinders, you can do the work yourself. But here there is a large consumption of expensive foam.

The insulation technology consists of 3 stages: surface preparation, application of insulation, decorative finishing. The base must be clean, strong and “healthy”. A sheathing is installed under the sprayed compositions. The finish can be anything: painting, paneling, plastering, cladding. Less commonly, thermal insulation coating is used as an independent coating.

Ratings 0

Where is Isollat used?

Thanks to its unique properties and packaging in containers of various sizes, the use of liquid insulation is available in all kinds of areas where thermal insulation is required, including:

- roofs of buildings, garages, hangars;

- walls of metal structures;

- oil and gas pipeline systems;

- pipelines supplying cold water;

- protruding elements of buildings such as slopes, loggias, cornices and others to prevent the formation of “cold bridges”;

- prevention and elimination of freezing of walls in cottages, low-rise construction sites, basements and utility rooms;

- slate and tile roofs;

- internal wall and ceiling surfaces, including residential and industrial premises;

- house facades;

- containers for drinking water;

- equipment for chemical plants;

- cold water and hot water pipes;

- air conditioning systems;

- heating mains;

- roofs of refrigerated vehicles;

- steam pipelines;

- oil tanks;

- industrial freezing units;

- oxygen pumping pipelines;

- other objects requiring insulation.

About the features of “Isollat”

Unique technical properties distinguish liquid insulation “Izollat” from similar thermal insulation products:

- a durable elastic coating with a thickness of 0.5-3.0 mm creates reliable protection against freezing and UV rays, and reduces heat loss;

- a painted base, facade, or other object takes on a neat appearance;

- to apply thermos paint, you can use a spatula, brush or airless spray;

- no scaffolding is required to process facades;

- processing is carried out at a rapid pace, which depends on the area where the insulation is applied;

- “Isollat” can be used for restoration work on architectural monuments and buildings of complex shapes and sizes;

- the paint is environmentally friendly, clean, neutral for people;

- costs for heating, air conditioning and ventilation of premises are reduced;

- “Isollat” is able to prevent freezing of walls, the formation of condensation, mold and fungal formations;

- guarantees comfortable temperature and humidity conditions indoors;

- saves energy costs by a third;

- guaranteed service life of the coating – over 10 years;

- due to the small thickness of the layer, the coating will not become an additional load for the walls and foundation, which significantly distinguishes Isollat from traditional insulation materials such as mineral wool and expanded polystyrene;

- in-line costs for maintaining any decorative façade coatings are reduced;

- prevents the formation of “cold bridges”;

- resistant to large temperature changes from -60 to +600°C, depending on the brand of insulation;

- has anti-corrosion, moisture-proof and sound-proofing properties;

- Izollat coating can be tinted while simultaneously carrying out external thermal insulation and finishing of the facade.

Please note: To apply Isollat liquid insulation, you can use a spatula, brush or airless spray equipment. When processing facades, no scaffolding is required.