Quite often, owners of apartments and individual houses independently carry out repair work in kitchen areas, install gas heating boilers, ovens and gas cookers. In almost all cases, during repair and construction work, homeowners have to deal with electrical networks that run close to gas pipelines, and for correct and safe installation they need to know the minimum distance established by the rules from the outlet to the gas pipe.

When laying electrical networks, they are guided by the norms and rules for the construction of electrical installations (PUE), which are mandatory for all public and private repair and construction organizations and ensure the safety of individual developers and finishers carrying out renovation work. The rules indicate the safe distances for placing group panels, internal and external electrical wiring relative to pipelines with liquid or gaseous neutral media passing through them, as well as flammable and explosive substances.

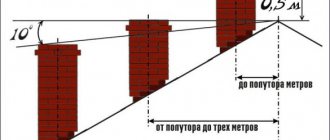

Fig. 1 Example of incorrect location of the socket in violation of the requirements of the PEC

Standards for private houses

According to the regulations, gas heating equipment can only be placed in rooms with good ventilation, which are located:

- On the first floor of the building;

- At the plinth level or in the basement;

- In the attic;

- In the kitchen (only boilers with a power of no more than 35 kW are suitable for installation in kitchens).

In the latter case, it is necessary to take into account not one standard, but two at once. The first of them allows you to install units with a power of up to 35 kW, and the second - up to 60 kW. These standards refer only to heating equipment - no requirements are imposed on any other devices using gas.

To know exactly what standard needs to be followed in a particular situation, you need to contact your local gas service - it is their employees who will put the equipment into operation after installation. Information about current standards can also be obtained from the designer - in the end, the source of information is not particularly important, only the result is important.

The result in this case is an understanding of the rules for installing gas boilers. In addition, you need to have an idea of what kind of room is needed for a gas boiler so that it can be installed and put into operation, having gone through the stage of coordination with the relevant services.

The placement of a gas boiler in a private house, depending on its total power, should be carried out as follows:

- Power up to 150 kW - installation is possible on any floor where there is a free separate room;

- Power from 150 to 350 kW - equipment can be installed in a separate room no higher than the first floor, as well as in extensions.

If the equipment power exceeds 350 kW, then it is prohibited to use it in private homes.

The average gas pressure in a gas pipeline is how much

To study the operating mode of gas pipelines, gas pressure is measured at least twice a year, during the period of highest flow (in winter) and lowest (in summer). Based on the measurement results, maps of pressures in gas networks are drawn up. Using these maps, those areas where there is the greatest gas pressure drop are determined.

On the approach to the city, gas distribution stations (GDS) are built, from which gas, after measuring its quantity and reducing the pressure, is supplied to the city's distribution networks. The gas distribution station is the final section of the main gas pipeline and is, as it were, the border between the city and main gas pipelines.

During the technical inspection, they monitor the oil level in the gearboxes, gearbox and counting mechanism, measure the pressure drop across the meters, and check for tight connections of the meters. Meters are installed on vertical sections of gas pipelines so that the gas flow is directed through the meter from top to bottom.

The gas arrives at the receiving point under a pressure of 0.15-0.35 MPa. Here, its quantity is first measured and then sent to receiving separators, where mechanical impurities (sand, dust, corrosion products of gas pipelines) and condensed moisture are separated from the gas. Next, the gas enters gas purification unit 2, where hydrogen sulfide and carbon dioxide are separated from it.

To check the operating mode of gas pipelines and identify areas with the greatest pressure drop, gas pressure measurements are taken. For measurements, gas control points, condensate collectors, inlets into houses or directly gas appliances are used. On average, one measuring point is selected for every 500 m of gas pipeline. All work on measuring gas pressure is carefully planned and carried out according to special instructions, which are approved by the chief engineer of the trust or office.

In Fig. Figure 125 shows a gas supply diagram for a large industrial enterprise. Gas from the high-pressure gas pipeline through a shut-off device / in the well is supplied to the central gas control point GRP 2. It measures gas flow and reduces it. In this case, high-pressure gas is supplied to workshops No. 1 and 2, medium pressure gas is supplied to workshops No. 3 and 4 and the boiler room, and low pressure gas is supplied to the canteen (through the GRU). If there are a larger number of workshops and they are located at a significant distance from the central gas distribution center, cabinet-mounted gas distribution units 7 can be installed in the workshops, ensuring stability of the gas pressure in front of the burners of the units. When gas consumption is high, gas flow metering units can be installed in workshops to monitor rational and economical gas combustion.

To select part of the main gas and transfer it through outlet gas pipelines under the required pressure to intermediate consumers, gas distribution stations (GDS) are built. The GDS is equipped with pressure regulators (spring or lever action), dust collectors, condensate collectors, installations for odorizing gas (i.e. giving it an odor) and measuring the amount of gas supplied to the consumer, shut-off valves, connecting pipelines and fittings. The mass of piping pipelines and fittings for gas distribution stations with a throughput capacity of 250–500 thousand m per hour reaches approximately 20–40 tons.

Standards for installing a gas boiler in the kitchen

If the kitchen is selected as a site for installing gas heating or water heating equipment with a power of no more than 60 kW, the room must meet several requirements:

- The total volume of the room for installing a gas boiler must exceed 15 m3, and another cubic meter is added for each kilowatt of boiler power;

- The height of the room must exceed 2.5 m;

- The ventilation system must provide exhaust volume three times the size of the room;

- The air flow through the ventilation system should also be three times the volume of the room, and this value does not include part of the air spent on the combustion process;

- The room under the gas boiler must have a window with a window (the area of the window is selected depending on the thickness of the glass);

- The room door should not be located close to the floor, but at such a distance that the total gap area exceeds 0.025 m2.

There is an additional rule that is not noted in the standards, but requires fulfillment - gas heating equipment can only be installed in those rooms that have a door. Failure to comply with this rule (as well as all others) always leads to refusal to put the boiler into operation.

Today, meeting the requirement for a door in a room with a gas boiler can be problematic. In modern construction there is a tendency to remove most partitions and form arches in doorways. The solution to the problem may be non-standard door options. Glass doors are also a good option, as they do not overload the interior, but still perform their function.

How to avoid problems?

First of all, following the rules is your health and safety for your life.

Therefore, if you combine gas and electric, use a few simple recommendations:

- Follow the rules of the PUE and SP exactly.

- At the entrance to your apartment, install a protective shutdown device that guarantees a power outage in case of problems with the neutral wire.

- Before installing the wiring, make sure that the new one will match the wiring of the old circuit (if it does not change).

- A gas stove cannot be grounded through a gas pipeline, just like ordinary household items that run on electricity.

And in addition, be sure to use the services of experienced electricians and enter into contracts when installing electrics for gas appliances.

Always check the license and documents of the gas workers whom you call to install gas-using equipment. In addition, be sure to conclude a bilateral agreement and check that the electrical installation of the devices is carried out in accordance with all the rules

All these recommendations will help you avoid problems with regulatory authorities and ensure a safe energy supply.

Requirements for individual premises

Boiler rooms located in separate rooms must meet a number of requirements, which are very similar to the previous ones:

- The ceiling must be at a height of over 2.5 m;

- The area and volume of the room are selected depending on individual preferences, but the minimum allowable volume is 15 m3;

- Each boiler room wall must have a fire resistance limit of 0.75 hours and no flame spread (brick, concrete and building blocks meet this requirement);

- Ventilation is subject to the same requirements as when installing a boiler in the kitchen - three times the outflow and the same amount of air intake, increased by the volume of oxygen consumed during the combustion process;

- The room must have at least one window with a glazing area of 0.03 m2 per 1 m3 of room volume.

When installing gas boilers with a power of over 150 kW, it must be possible to exit the boiler room directly onto the street. Placing a gas boiler in an individual residential building assumes that the equipment cannot be adjacent to living rooms. In any case, the boiler room must be equipped exclusively with fire doors.

An important point is that the room standards for installing a gas boiler take into account the glazing area, and not the size of the window itself. In some situations, it is regulated that the room must have at least one glass with an area of more than 0.8 m2. If necessary, such a window can even be placed in the door - there are no rules about its location in the regulations, and in this case there is no need to track the distance from the boiler to the window.

Cost of specialist work

Prices for assembly, installation and connection of the grounding loop depend on the specialist or company, region, and type of soil on the site. In Moscow and the Moscow region, the cost of work is about 4,500-6,000 rubles, in St. Petersburg - 3,900-5,500 rubles, in the regions - on average from 3,000 to 4,000 rubles. Please note that the price does not include the price of the grounding kit (another 6-10 thousand).

Most companies carry out turnkey installation and indicate prices taking into account the cost of the finished grounding kit.

Gas boilersInstructionsBoilers

Extension of boiler rooms

Of course, it is very convenient to have a separate room for gas equipment, but this is not always possible, and you have to think about where to place a gas boiler in a private house under such conditions. The solution to the problem is to add a boiler room.

The standards in this case coincide with those described above, but there are a number of additional requirements:

- The boiler room can only be attached to a solid wall;

- The distance between the nearest window or door should be more than one meter;

- The boiler room can only be laid out using non-combustible materials that can last at least 0.75 hours before ignition;

- The walls of the boiler room itself must be erected separately from the main building - i.e. you will need your own foundation and four new walls.

In order for a gas line to be installed into an equipped boiler room, the building must be registered. In the absence of appropriate documents, representatives of the gas service will simply refuse to approve the equipment, even if all standards are met.

If the main building has not yet been built, then during the design process you need to find out what the room for the gas boiler should be like and comply with all the requirements, otherwise putting the boiler into operation will be impossible. When installing a boiler in an already constructed building, you can allow small deviations in some parameters, but they must be compensated for by others.

Replacing a faulty device

Gas meters rarely break down. This happens due to violation of operating conditions. For example, if you use a model with a lower throughput than the actual one, use a device without a dust filter, or use high humidity. Malfunctions can be different:

- the device stops recording gas consumption, works intermittently or freezes in place;

- on electronic meters, the numbers on the screen completely or partially disappear;

- there is a slight gas leak at the point where the device is connected to the pipe.

Such products must be replaced, regardless of the service life of the gas meter set by the manufacturer. Such products must be replaced, regardless of the service life of the gas meter set by the manufacturer.

If the owner discovers a problem, he must immediately notify the service organization about the problem. Any breakdown can be repaired only by the gas service; disassembling the device yourself is prohibited. The called technician will inspect the device, record the fact of the malfunction and take it away for inspection. Gas consumption will be calculated according to standard values from the moment the problem is detected until the installation of new equipment.

Much more serious consequences can occur when a technician identifies a breakdown during a routine inspection of the meter. In this case, the gas service may decide that the owner deliberately did not report an obvious malfunction and hid the fact of incorrect recording of gas consumption, and he will have to pay for the energy resource according to the standard for the last six months. Therefore, we recommend that you regularly check the equipment for possible malfunctions and, if any are identified, apply for a replacement gas meter.

Broken seal

It is prohibited to remove the seal from the meter yourself. If it is accidentally damaged, for example during cleaning, it is better to immediately notify the service organization. The company’s specialists will arrive as soon as possible and solve the problem on the spot.

Otherwise, the fact of the violation will be discovered during a scheduled inspection, which is fraught with suspicion on the part of the service of mechanical unwinding of the counting mechanism. In such situations, the device is immediately removed and sent for examination, about which a corresponding report is drawn up. All costs for dismantling and checking the device are borne by the homeowner. In addition, the owner may be held administratively liable and receive a considerable fine for damaging the seal. If, based on the results of the examination, the device is found unsuitable for further use, you will have to purchase a new meter.

How to replace a meter

Upon expiration of the meter's service life or confirmation of its breakdown, the device is replaced with a new one. The device itself must be purchased in advance. It is advisable to install a meter similar to the previous one, or a similar model from the same manufacturer. If such a device is not on the market, we recommend contacting the gas service to select new equipment. Before installation, the product is first checked for serviceability.

If it is necessary to replace the meter, you must notify the gas supply organization in advance, which will send a controller to take readings from the old device and check the integrity of its seals.

Installation of a new device is carried out by an organization with which the owner has an agreement. If welding work is required, it is also performed by company employees and paid for by the owner. Upon completion of installation, the equipment is sealed immediately or within 5 working days.

The purchase of a new meter and installation services are the responsibility of the home owner. Free replacement is possible only for low-income people, large families and WWII veterans.

Installation of a gas boiler in combined kitchens

In modern construction, the arrangement of studio apartments or layouts in which the living room and kitchen are combined into one large space is actively practiced. Of course, such a solution has a lot of advantages - for example, it opens up a large portion of free space, which is perfect for implementing all kinds of design ideas.

The problem is that gas services regard such layouts as residential, so the installation of any gas equipment in them is prohibited. In studios this problem cannot be solved, but when combining a living room with a kitchen, options are possible.

So, it is quite possible to call the room “kitchen-dining room” during the paperwork process. Thanks to this name, the combined room will not be considered residential, so you can safely install a gas boiler in it. Another option is the installation of a sliding partition between the rooms or a complete re-issuance of all certification papers.

Network load calculation

When deciding how to install an outlet for an air conditioner, you should take into account the power consumption of the electrical device. This is necessary to ensure reliable power supply to the cooling system and eliminate the possibility of an emergency. This information is contained in the technical data sheet of the device. To cool a larger area of the room, choose a more powerful air conditioner. The maximum load on the network when operating household air conditioning systems does not exceed 10A. Therefore, when installing them, you can use a standard plug socket with a rated load of 16A.

High power cooling devices are used for large areas. Their installation is carried out using special equipment for direct connection. The connection point, regardless of power, must have a grounding device. If other household appliances are connected to the line, the total power is taken into account in the calculations.

The distance from the gas pipeline to the electric cable is a distance determined by the need to comply with the security zone of both types of structures, their location and broadcast intensity.

Gas boiler location

A gas boiler in an apartment is usually placed in the kitchen, which is determined by the presence of all the necessary communications, and the distance from the gas pipe to the boiler is maintained without problems. As a rule, wall-mounted boilers are used for apartments, which are attached to the walls using special brackets that come with the equipment.

If the house has a staircase leading to the top floor, the owners have a desire to install a boiler under it. As a rule, the volume of space under the stairs is enough for a boiler, but there are problems with ventilation, so it has to be arranged separately using large-diameter pipes.

Deciding where to install a boiler in a private home depends on the format of the equipment and the requirements specified in the attached documentation. The passport for the boiler always indicates the required distances from the walls, ceiling and opposite wall, and you should definitely focus on these indicators.

What to do if the device breaks down

Any mechanical device can fail over time. Gas meters also do not escape this fate.

Breakdowns may vary depending on the type of meter:

- If we talk about electronic means of metering gas consumption, digital values are not reflected on the screen, or they are viewed, but only in fragments;

- for other types - the meter may freeze in place (this is noticeable visually), or there is a slight gas leak in the places where the meter is attached.

If, however, any problems are observed in the operation of the device, they can be eliminated in several ways. Regardless of when the specialist discovered a violation of the sealing of the accounting device, when he is called by the owner of the apartment or during the next medical examination, a report is drawn up.

In it, a representative of the organization indicates the identified fact of violation. When this happens, the owner of the equipment will be required by law to pay the company for the resource consumed, but according to the standards, this is an order of magnitude higher than payment according to indications.

Payment is calculated for the last six months of using the resource. By analogy with this technique, resource consumption is calculated when there is no metering device.

Please note! If the seal remains intact, but the gas engineer, during a routine inspection, discovers that the meter is faulty, you will also have to pay for gas according to the standard for the last 6 months.

It is believed that if the consumer did not report an obvious breakdown, he deliberately concealed the fact of incorrect recording of resource consumption.

A message about recalculation of the amount due to a violation will be sent to the consumer within 30 days. The company is obliged to notify about the recalculation and calculate the amount due.

If a malfunction of the device is discovered by the homeowner, and this is reported to the service company, a specialist arrives on site, determines that the seal is in place, and records the fact of the malfunction.

Here, calculation of consumption, based on approved standards, will be made only from the moment a malfunction is identified until the installation of another serviceable device.

Installation features according to SNIP

In the absence of specific recommendations in the documents attached to the boiler, it is worth using SNIP standards, according to which:

- Installation of gas boilers is only possible on walls made of non-combustible materials. The distance from the gas boiler to the wall must exceed 2 cm.

- If the walls are still subject to combustion, they must be protected with fireproof material. The most common options are a layer of asbestos with a metal sheet, plaster over 3 cm thick, ceramic tiles or mineral wool cardboard.

- On the sides, the distance from the boiler to the wall must be at least 10 cm. If the walls are made of flammable materials, this distance increases to 25 cm.

- A gas boiler can only be installed on a substrate made of non-combustible material. In the case of wooden coverings, special supports are made from tiles or bricks, which provide the necessary fire resistance. The base for floor-standing devices must be at least 10 cm wider than the dimensions of the boiler itself.

Types of gas meters and their characteristics

Gas meters are special devices designed to record the consumption of natural or liquefied gas. The types of such devices are presented in the table.

| Based on throughput | Based on the operating principle |

| Household | Turbine |

| Rotary | |

| Utilities | Diaphragm |

| Industrial | Membrane |

The main characteristic of gas meters is their throughput. This indicator allows you to determine how much of a resource can pass through the counter within a certain time. This number is indicated in the device labeling.

For example: if the meter says G4, this means that its throughput is 4 m3/h. The installation of the device must be carried out in a system within which the total demand for “blue fuel” of all household devices located there does not exceed the indicated figure.

Another important feature of each device is the total duration of its operational period. The average service life is 20 years or more. The countdown is carried out not from the moment the meter is installed, but from the date of manufacture at the factory.

Glazing material

When installing a window for a gasified boiler room, special requirements are also imposed on the frame material. They must be resistant to high temperatures and made from environmentally friendly materials.

Aluminum or metal-plastic is used to construct the window structure. The aluminum profile protects the heated compartment from adverse climatic conditions. It provides reliable sealing that prevents the formation of drafts and prevents the fire in the boiler from going out even with strong gusts of wind outside.

Metal-plastic frames are no less reliable and help retain heat in the furnace room.

Plain sheet glass is used as a glazing material. It is also allowed to install double-glazed windows that meet the requirements of GOST and act as easily removable structures.

Do you need to follow the rules?

Laying a gas pipeline to the boiler room and connecting gas to the unit is possible only after concluding an agreement with the gas service. To do this, the design for the placement of the heating system must be agreed upon with the supervised services (fire inspection, sanitary-epidemiological station, urban planning department).

If you ignore the requirements of SNiP, obtaining permits will become impossible. If the construction has not been approved by the relevant authorities, its operation will be prohibited. As a result, the boiler room will have to be re-equipped in accordance with the rules, which will entail additional costs.

In addition, failure to comply with safety standards can cause an accident, resulting in the destruction of the building and, possibly, the death of loved ones.

Before starting construction of a boiler room, you should carefully study all legislative acts. Supervisory authorities pay most attention to the area of the boiler room, the size of the window, the presence of ventilation and exhaust hood. Therefore, when developing project documentation, it is better to consult with specialists who are familiar with the current SNiP standards.

Easily removable window structures

An easily removable building envelope (ELS) is window glass that easily breaks under excessive pressure in the event of an emergency. The window opening is completely freed, while all the supporting structures of the building maintain their integrity.

The use of reinforced glass for glazing LSC is prohibited, since it is too strong and does not collapse under the influence of loads. The same goes for polycarbonate, triplex and stalinite.

According to GOST standards, special elements can be used instead of simple glass in light-removable structures.

It could be:

- a rotating flap, which, in the event of a gas explosion, even with a slight excess of pressure, swings outward or rotates around the fastening elements;

- a displaceable element that includes a window frame with a double-glazed window - in the event of an emergency, the structure falls apart and flies out onto the street.

To equip window units with a combustion chamber operating on gas, safety locking mechanisms, latches and self-destructive fasteners are used. Their function is to ensure the smooth release of the displacing or rotating device under the influence of excessive pressure.

Thus, it is not only the size of the window unit that matters. With its help, an opening is cleared for the release of the energy generated during the explosion of the combustion equipment.

Calculation of parameters to achieve the required resistance

To determine the resistance, it is necessary to assemble the components into a single circuit and take measurements. If the parameter is within 4–8 ohms, then you can begin installing the structure in the soil. Otherwise, the resistance must be brought up to normal by adding or removing conductors or changing the cross-section of the rods used. It is possible to calculate the parameter by a specialized company. When determining, the air temperature and soil type are taken into account, which increases the accuracy of determining the resistance.

Scheme of arrangement of power supply and ventilation

According to regulations and technical conditions, the gas boiler must also be connected to the electrical network. Run a cable with a cross section of 1.5x3 mm from the meter. Don't forget to install a circuit breaker that will protect against power surges.

Be sure to ground the equipment. The minimum distance from the nearest outlet to the gas appliance should not be less than 10-12 cm.

To ensure maximum productivity of a gas boiler, good ventilation must be provided. To do this, install a special grille, which should be placed at a distance of 25-30 cm from the ceiling. The minimum size of the hole should be 10x10 cm. Fresh air may be taken from non-residential premises, the street or the corridor.

Important! Calculate the ventilation area based on government regulations. For 10 kW of boiler power, 0.001 m2 will be required.

If you connect a heating device to a coaxial chimney, it can be discharged through an external wall. In this case, fresh air enters through the pipe from the street, and smoke and combustion products are freely removed outside.