Nothing can withstand time. Even traditional Russian baths. No, they have not gone away - they just began to use much cheaper materials, but with similar performance characteristics. Surely you have already heard positive reviews from the owners of bathhouses made of foam blocks more than once: people build them themselves and note their amazing practicality and savings in the invested material resources. True, in order to get a result that is truly pleasing to the eye and heart, it is necessary to take into account all the details of the layout and draw up a high-quality project. We save your time and present in this material the best projects for building a bathhouse from foam blocks with your own hands.

Foam blocks: features and characteristics

Traditionally, a bathhouse is built from wood materials, such as timber, logs, etc. They are good for everyone, except perhaps the need for constant maintenance, since the wood begins to rot quite quickly under the influence of dampness. Without some care, a wooden bathhouse will very quickly lose its original appearance.

Foam block bath projects

But recently, bathhouses are often built from foam blocks. This material is an excellent alternative to traditional wood, as it has a lot of advantages and in some cases even surpasses wood in its characteristics. A foam block is a block of a certain size made from foam concrete or cellular concrete . It has not been a novelty on the construction market for a long time, but previously it was used much less frequently than now, due to the fact that its main disadvantage - hygroscopicity due to high porosity - has been overcome.

Foam block

However, the presence of porosity is the main feature of such materials. Thanks to it, foam blocks have an excellent level of thermal insulation, are able to perfectly retain heat in any structure, and are not too heavy materials. The pores inside the block can have different sizes and are located randomly throughout its entire interior.

Important! Due to the presence of pores, blocks absorb water very strongly. In the summer this is not scary, but in the winter the water, freezing, expands and can damage the blocks. That is why foam block buildings, and especially bathhouses, must be carefully insulated from water. Moreover, waterproofing work is carried out both inside and outside the building.

Foam concrete - production process

Interior wall decoration

A lot of questions arise with baths made of aerated concrete. Including interior decoration. We decided on the steam room - it definitely requires lining. In the sink, it is more advisable to lay tiles on the walls.

What remains is mainly a rest room, sometimes a vestibule. Many people would like to have wooden walls. Since the humidity will still be high, you can attach a vapor barrier film to the walls. The sheathing will already go on top, and the finishing board will go to it.

It is better to leave a ventilation gap of about 2-3 cm under the lining

If a good ventilation system is thought out in the bathhouse, then you can completely do without a vapor barrier: aerated concrete both absorbs vapors and releases them. The main thing is to provide him with this opportunity: to organize air movement along the walls. This is done using lathing, which provides a gap of 2-3 cm between the finishing material and the wall. As soon as the lathing is filled vertically, air circulates from bottom to top without problems. So the lining is packed horizontally.

Types of foam blocks

Foam blocks, depending on the manufacturing technology, may have different properties and some differences in appearance. The table below provides a description of the main varieties of this material.

Foam blocks are different

Table. Types of foam blocks.

| View | Description |

| Aerated concrete | This version of foam blocks is made from cement with the addition of aluminum powder. During the chemical reaction that occurs due to the addition of powder, pores are formed in the mixture. The future block is placed in an autoclave, where great pressure is applied to it, and the concrete hardens. The sizes of such blocks may differ from each other, this is due to the peculiarities of their manufacture. But deviations from the standards (average block dimensions 30x25x60 cm, weight - 30 kg) are, as a rule, insignificant, which makes it possible to obtain a minimal seam when laying blocks. Also, this version of foam blocks is called gas block or autoclaved foam concrete. The material is quite often used for the construction of baths and other structures. It is lightweight, conducts heat well, does not burn, and is not afraid of frost. It is also a fairly economical material and easy to process - it can be cut with a hacksaw. |

| Silica concrete | This type of block has a white color due to the addition of lime to the composition from which it is made. It is necessary to bind the mixture. This version of foam blocks has the highest hygroscopicity. There are a lot of pores in the structure of each block - 50% of the total volume. Due to the presence of a large number of voids, the blocks are very light and can be used for construction on light foundations. This material has excellent heat and sound insulation properties, so a bathhouse made from it will keep warm for a long time. |

| Foam concrete | This version of the foam block is produced in almost the same way as conventional aerated concrete, but without the effects of temperature. Concrete hardens naturally, but a special foaming agent is added to the mixture from which the block is made, after which the finished mass is poured into molds, in which it hardens naturally. |

| Sand block | These are blocks made of cement, water and sand. This is the standard mixture for creating concrete. Such blocks are economical, resistant to external factors, and environmentally friendly. They also have voids, but the blocks almost do not absorb water. The main disadvantage of the material is its low thermal conductivity, so a bathhouse made from it will have to be additionally insulated. And their mass is large, so it is not recommended to lay them on a weak foundation. |

Structural and thermal insulation block

Note that each of these types of materials is suitable for building a bathhouse for any project. It’s just that some materials need to be well protected from moisture during the construction process.

Prices for gas blocks

Gas block

Floor installation

After the floor has been insulated, preparation of the base should begin. A reinforcing mesh is placed on the insulation. This is the time to remember to leave drain holes where they are provided.

Install the drains, seal the holes on them with tape so that the solution does not get inside. After installing the beacons, concrete is poured.

The concrete layer should be about 10 centimeters. As soon as it hardens, we make a screed up to five centimeters thick. This is necessary for the final leveling of the floor.

The last stage is decorative coating. Here everyone chooses according to their taste. You can put porcelain tiles, wooden floors, linoleum, quartz vinyl tiles.

Foam block bath projects

A bathhouse is not just a place where you can steam, although the steam room is perhaps the most important room in it. The bathhouse is also used to keep the body clean and for relaxation, so it must also have other rooms. That is, in one bath there must be a steam room, a wash room, and also a room where you can undress. In addition, the bathhouse can be equipped with a relaxation room, a terrace, and, if opportunities permit, even a swimming pool.

Design of a bathhouse with a relaxation room inside

The most common version of the foam block bathhouse project has a steam room, a wash room, as well as a relaxation room, which in this version also acts as a locker room. It usually has quite large dimensions, since, in addition to hangers, it contains a table and chairs. The most budget-friendly option for a bathhouse is a 4x6 m structure. This design allows you to place a partition in the bathhouse, leaving most of the room for a dressing room and a relaxation room. The second half of the building is divided into two more parts by a second partition, and a steam room and a washing room are organized in the resulting rooms. However, the premises can be made to the size that will be more convenient and relevant - for example, make a large steam room.

Advice! Even when building a small bathhouse, it is still recommended to make a small dressing room at the entrance. This room will allow you to keep the room warm in winter.

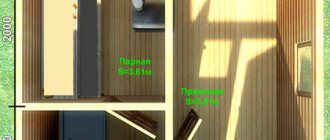

Bathhouse project 4 by 5 meters

The stove for the sauna must be selected taking into account the size of the steam room. As for the doors, they need to be positioned so that they do not interfere with anyone and do not take up much space. It is also important to consider that the steam room and washing room should have small windows. The top edge should be level with the door lintel.

The bathhouse will be a little more spacious if you build a bathhouse according to the 6x6 project. In this case, one of the options for distributing space is as follows: 5.3 m2 is occupied by the steam room, 7 m2 by the washing room, 1.7 m2 by the locker room, and 11.2 m by the relaxation room. The bathroom occupies 1.8 m2. In the steam room you can place two shelves on which you can lie, and the stove is installed so that it can be heated from the rest room. It is important to understand that, if you wish, all projects can be remade to suit yourself.

Layout of a bathhouse made of 6 by 3 foam blocks (several projects)

You can also organize a bathhouse according to a 6x3 m project. Moreover, there are no fewer arrangement options here than in other cases.

When designing a bathhouse, it is important to understand that the steam room should be located in the farthest corner of the building , and not at the exit from the bathhouse. This is one of the most important rooms where the heat should be well maintained and maintained. But at the same time, the largest room should be the rest room, because no one will sit in the steam room for a long time. It’s nice to alternate steaming sessions with long sittings at the table in the relaxation room, so it’s best to make this room the most spacious. For the washing room, you can leave a small nook, but such that it is comfortable and not cramped to be in, and you can also install benches, place shelves for basins, etc.

Bathhouse project

If the bathhouse has a terrace, then you can organize a barbecue area on it. Also in the summer you can relax on the installed chairs. If desired, you can make a second floor in the bathhouse.

Bathhouse project 6 by 6

In general, it is worth noting that all standard bathhouse designs are similar to each other. If you want to do something original, then you need to come up with a new project yourself or together with a specialist and bring it to life.

Video – Bathhouse project

Subtleties of design

When developing a drawing of a future bathhouse, you must take into account its size. Only knowing the exact scale of the structure can you correctly draw up a project for such a room

In addition, additional buildings located nearby or under the same roof should be taken into account. Currently, you can find many bathhouse designs measuring 3x4, 4x4, 5x4, 4x6 m

This scale is small, so you need to be careful when designing these rooms. The design must simultaneously accommodate a steam room, a washing room, and often a shower room with a changing room. As a rule, in these cases, most of the space is set aside for the steam room. Often such baths have a window.

There may even be two openings (in the washing room and steam room). They act as necessary ventilation. Often, projects of such small rooms are combined with other residential buildings (garages, guest houses) to make the structures look more beautiful and solid.

In this case, many experts strongly recommend creating such areas outside the room. Today, a considerable number of projects for the design of larger baths have also been proposed. Their size is 6x6 m, some designs may be larger (+ 2-3 sq. m). Premises of this size can easily accommodate all the necessary rooms (shower, locker room, washing room, vestibule, steam room). In addition, such buildings often contain small recreation areas for the owners.

In these types of baths it is worth installing window openings. Their size must correspond to the dimensions of the room itself, since large structures require good ventilation. It is better to place windows in several rooms at once. Often such large-scale baths are made two-story. Moreover, the second tier is also made of a rather large size. Most often it is reserved for a swimming pool or a large recreation room.

The second floor of such premises does not necessarily need to be additionally insulated. Warm steam from the first tier will penetrate the room, warming it up. Due to the uniform distribution of heat, the temperature of the upper zone will not be too high, it will remain optimal. When building two-story bathhouses, experts and designers do not recommend combining them outside with other buildings. After all, they can completely ruin the beautiful appearance of the bathhouse and make the structure too overloaded. Therefore, it is better to place all other additional structures separately.

With swimming pool

Often, when building baths from foam blocks, swimming pools are placed in them. But it should be remembered that they should only be installed in structures with a large area. Otherwise, the design will be cumbersome and will cause significant inconvenience. If you are building a two-story building, it is better to place such an element on the second tier.

Today, on the building materials market, anyone can see various options for swimming pools for baths. They can be of various shapes (round, rectangular, square, semicircular). The choice of the appropriate option depends on the internal layout of the building. At the same time, we must not forget that the design of such premises with a swimming pool will cost the owners a lot.

With terrace

You can often find projects of bathhouses with a veranda. It can be included in projects of small buildings. According to some experts and designers, the terrace can fit perfectly into any type of design, regardless of size. If you are building your bathhouse from foam blocks, the veranda can be made from this material. But options are possible in which terraces are made from a different base (wood, metal, plastic, decorative stone).

Some designers advise placing small pieces of furniture (tables, sofas, chairs) on terraces. It is worth remembering that the veranda cannot be overloaded. Otherwise it will look ridiculous. If you are arranging a two-story bathhouse, then such structures should be placed on the upper tier.

Small buildings

Today, experts can offer designs for bathhouses made of foam blocks with dimensions smaller than standard ones. Such premises often include only a washing room and a steam room. Other zones in similar structures may be too small or cannot be accommodated there at all. Often, in order to increase the area of a small bathhouse, owners build a second floor of the same scale.

On the upper tier you can place a shower room, a relaxation room, and a small swimming pool. If you do not want to build another floor, remember that it is better not to load such structures with verandas and other additional elements. Even in small bath rooms it is necessary to place window openings. For these structures, two small windows are enough. In small-scale baths this will be enough for ventilation.

Construction of a bathhouse from foam blocks

After creating the project, you can calculate the required amount of materials and begin construction. It is important to take into account that the design of a bathhouse made of foam blocks for any of the projects is subject to certain requirements. So, as for external walls, it is better to take blocks with a thickness of about 25-30 cm for buildings in the central zone of the Russian Federation, and in the northern regions you need to take blocks with a thickness of 35 cm or more. Moreover, the lower the density of the blocks, the warmer the building will be, so this also needs to be taken into account. For partitions, you can take thinner blocks 15-20 cm thick, this will be enough.

Important! Walls made of foam blocks in every third row need to be reinforced. For this purpose, ribbed rods with a cross-section of 12 mm are used, which are laid in grooves. The groove must be located at least 3 cm from the edge of the block and have a depth of more than 12 mm.

DIY budget sauna

Insulation of the bathhouse is necessary if it needs to constantly maintain a positive temperature. Then the costs of maintaining the desired indicator will be lower. But if the bathhouse is used irregularly and periodically, then insulation can be neglected.

An important point is the hydro- and vapor barrier of the bath . Blocks can be prevented from being hygroscopic with special solutions that will help protect the material from moisture (the blocks will not absorb it). They just need to coat the walls. However, in the sink and steam room it is necessary to provide good protection from water. Vapor barrier in this case is done by laying a special film.

Bath building made of foam concrete

On a note! You can avoid impregnating the walls if you provide good ventilation in the bathhouse.

You can decorate the interior of the premises like this: cover the steam room with clapboard, make tiles in the sink. In the rest room, the walls can be decorated with wood. The main thing is not to forget about vapor barrier here too.

The roof is installed like this. First, a reinforced belt of reinforcement is made along the top row of wall blocks (with a cross-section of 8-14 mm for longitudinal reinforcement and 6-8 mm for transverse reinforcement) and filled with M200 concrete. The height of the belt should be about 20-30 cm. Then the roof is mounted on the finished armored belt.

Installation of a roof for a bathhouse

Prices for various types of timber

timber

Subtleties of design

When planning, it is necessary to take into account its expected size, the location of other buildings and premises nearby. You can find a number of ready-made projects of standard sizes. For a dacha plot of standard size, a bathhouse measuring 6x4 or 5x7 is suitable. These parameters are suitable so that everything you need can be placed in the future room.

The layout should accommodate:

- steam room;

- shower;

- washing room;

- recreation rooms.

Most of the space is usually taken up by the steam room. The presence of windows is permissible in the bathhouse.

A rest room, a vestibule (a kind of hallway) can be located in an object measuring 6x6 or more. In larger buildings it is possible to install additional windows. Large baths are often made with two tiers. One of them is set aside to accommodate a swimming pool or a large relaxation room.

It is not necessary to insulate the second floor, since it will be heated by heat from the first floor. The heat will be distributed evenly so it won't get too hot upstairs. A two-story bathhouse should not be combined with additional buildings.

DIY block bathhouse with terrace

To build a bathhouse from a foam block, the location of the terrace is chosen depending on the direction of the wind (if it is on the ground floor). This is done on purpose so that smoke does not flow onto the terrace and does not interfere with the enjoyment of fresh air by people relaxing on it. If a terrace is being built to shield people from the sun and create coolness, then you should not place it on the south side.

When placing it, you need to pay attention to the surrounding landscape. The terrace should not have a view of the street toilet or other pictures that are unpleasant to the eye

The terrace is suitable for any size bath. If the entire structure consists of foam blocks, then the base of the additional room may consist of them. But this is not necessary; the foundation can be made from:

- metal;

- wood;

- other building materials.

You can place furniture on the terrace: tables, chairs, sofas, armchairs.

Note! You should not install too many furnishings, it will look bulky and inappropriate.

When building a steam room with two floors, the terrace should be located on the top, then it will be a large balcony. You can choose a very interesting project for a two-story bathhouse made of foam blocks.

With swimming pool

Nowadays, swimming pools are being installed more and more often, but for its use the area must be large. If the bathhouse has two floors, then the pool is located on the second.

House layout 6 by 6: features, projects with photos

In the room in which the swimming area is located, you need to place one or more windows for ventilation. Swimming pools come in different shapes, the choice depends on your taste. The choice of shape depends on the overall layout.

The cost of installing a swimming pool and decorating such a room will be quite high. Building a bathhouse from foam blocks with your own hands will be problematic.

Design of small buildings

Building a bathhouse from foam blocks with your own hands requires drawing up a preliminary project. In small rooms there is usually only a washing room and a steam room. The remaining zones may be redundant, since there is not enough space for them.

Tip! The area of a small bathhouse can be increased by building a second floor above the first floor, which will be of a similar size.

On the top floor of the foam block bathhouse project there may be:

- shower;

- rest room.

If we are building a bathhouse with our own hands from foam blocks, and there is no desire to add a second floor, then there is no point in overloading a small building with a terrace. In a small sauna it is worth installing windows; two windows will be enough to ventilate the room.

Generalized instructions for constructing a bathhouse from foam blocks

Step 1. First of all, you need to create a bathhouse project, describing in detail all the dimensions and parameters of the structure. You should also select a suitable site on the site where the bathhouse will be built. Thus, the site, according to SNiP 30-02-97 , must be located at a distance of 1 m from the fence, 8 m from the neighbors’ house and at least 5 m from the border of the site. Also, the bath area itself must be dry.

First, a bathhouse design is drawn up

Step 2. Next, you can decide on the type of foundation and start building it. Foam concrete is lightweight, which means you can make a simple foundation (for example, a strip foundation).

Foundation arrangement

Step 3. After creation, the foundation must be covered with waterproofing, after which you can begin laying the first rows of blocks.

Laying the first rows of blocks

Step 4. The blocks need to be placed on top of each other in a checkerboard pattern, that is, so that the joints between adjacent blocks in one row do not coincide with the joints of blocks in the row below. It is recommended to fasten the blocks with special glue rather than standard cement mortar. It is important to ensure that the masonry is level and even, and do not forget about the presence of doors and windows. Every three rows the walls should be reinforced.

To fix the blocks it is better to use special glue

Step 5. When the frame of the bathhouse is ready, you can begin installing the roof. In this case, a simple gable roof is being built. The rafters rest on tie rods installed and secured to the load-bearing walls.

In this case, a simple gable roof is being erected

Step 6. The roof can be covered with metal tiles or corrugated sheets. The main thing is to install materials according to the rules.

Now you can start laying the roofing material

The roof is covered with corrugated sheets

Step 7. After this, you can move on to the interior decoration of the bathhouse - creating a floor, covering walls, etc. It is important not to forget to carry out waterproofing work!

Interior arrangement of the bathhouse

Insulation

If the bathhouse constantly maintains a positive temperature, then insulation from the outside is desirable: the costs of maintaining that “+” are lower. If the bathhouse is heated only periodically, then there is no point in external insulation. It’s already warm in the summer, but in the winter it will still be minus in an unheated room.

In an unheated bathhouse you need to have good internal thermal insulation. Then it will be possible to heat the room without touching the walls. The insulation layers are discussed in more detail below, since without a vapor barrier they do not work as they should.

Roof

The roof has one peculiarity: the roofing material must be light. It could be:

- soft roofing - made of rolled materials or soft bitumen tiles;

- corrugated sheeting;

- metal tiles;

- wooden roof.

The entire system is attached to the Mauerlat, and it is attached to the upper armored belt with long pins. When attaching the rafter system, everything is attached only to the beam. It is not worth attaching to the walls - there is no sense in it: gas silicate cannot withstand long-term point loads, it crumbles and cracks. That’s why an armored belt is needed.