The Electrolux line of boilers is characterized by relatively high performance equipment that can operate at low room temperatures. The main advantage of such boilers is their high efficiency.

The protection system fully monitors the health of all processes, blocking the gas supply in the presence of malfunctions. Despite many advantages, this gas equipment cannot constantly operate without breakdowns. All faults are displayed on the display in the form of a code, the description of which helps in finding and fixing the problem.

E1

On different boiler models, this error may be displayed differently: 01, e01, E1.

In any case, the problem lies in the following:

- Lack of gas supply to the boiler or its insufficient level to maintain the combustion process in the boiler.

- A change in the angle of inclination of the electrode in the burner, which may be a factory defect or intentionally moving it away when setting up the equipment during installation of the heating system.

- The electrode is clogged with soot, which interferes with its normal operation.

- Lack of reliable contact between the electrode and the wire.

- Gas valve malfunction.

- Problems in the central control board, which inadequately evaluates processes and provokes an emergency shutdown of the boiler.

These problems can manifest themselves in the form of spontaneous extinguishing of the boiler. There will be difficulties with ignition, the boiler will go out immediately after the flame appears.

It can be difficult to fix the problem yourself if the cause is broken parts. The user of gas equipment needs to check the presence of gas in the system, as well as its supply to the boiler (if the valve is closed). After this, press the “Reset” button and check the operation of the boiler. The rest of the diagnostics and repairs will be performed by specialists.

Do not try to clear the error code by constantly restarting the boiler. This may help at first, but the problem will not go away. Be sure to consult with specialists and conduct unscheduled diagnostics.

Violations in working with code E4

Household gas equipment requires regular inspection and close attention from owners. After all, the slightest problem can turn into a serious disaster. From irretrievably lost equipment to various degrees of poisoning and explosions with fires - all these are the consequences of seemingly insignificant breakdowns.

Manufacturers of units for servicing private heating and hot water circuits were well aware that not all owners of the equipment would be prepared to operate them at a professional level. That is why a warning system was developed that appears on boiler displays.

In order for the user to be able to control and configure the new generation boilers without specialized education and training, the units are equipped with electronic control devices with displays. During setup, functions and parameters are displayed on the electronic screen of the gas boiler, making it much easier for the user to select the mode he needs. The owner of a gas boiler has the opportunity to constantly monitor the performance characteristics of gas equipment in order to take timely measures in the event of a breakdown or breakdown. If the gas appliance malfunctions, the user will immediately receive a signal in the form of a set of numbers and letters, which are essentially automatic self-diagnosis. New generation gas boilers. Simplifying the process of setting parameters. Demonstration of performance characteristics. Timely error signal

One thing is bad: almost all brands have their own alphanumeric designation of boiler failure. In some ways, the decryption systems have something in common, but mostly they differ. Equipment error codes with the Bosch logo, for example, are absolutely unacceptable for diagnosing breakdowns of Viessmann boilers or Ariston appliances.

What to do in a difficult situation if your gas water heater persistently beeps, displaying error E4? It’s as easy as shelling pears to analyze all the typical malfunctions in the operation of heating equipment, most often purchased by our compatriots.

As an example, consider Swedish-made wall-mounted models with the Elektrolux logo. More precisely, we will analyze violations in the functionality of units with the specified type of error.

The renowned supplier of high-quality and reliable equipment has developed a unified error reporting system for single-circuit devices with a closed combustion chamber (Basic S Fi), for double-circuit models with a closed (Basic Space Fi, Basic X Fi) and open (Basic Space i) combustion chamber.

Similar codes are used to notify and decipher errors on Electrolux units of the Magnum, Basic Duo, and Quantum series.

The reasons for displaying the E4 code on the electronic display in the listed models include:

- Low pressure in the heating circuit connected to the boiler.

- Lack of contact between the pressure sensor and the internal wiring of the boiler.

- Circulation pump failure.

In all of the above cases, the command to block the boiler operation was given by the pressure sensor. There are two options: either the coolant is poorly circulating through the circuit, or it itself took the readings incorrectly. Let's start looking for the cause with the most common violation - let's check the pressure in the heating circuit served by the boiler.

If the boiler's electronic display shows a pressure of 0.5 bar, let's try restarting the boiler first. It is possible that there is no pressure sufficient for the normal movement of the coolant through the heat exchanger due to an electrical circuit failure or pump failure.

On the display of Electrolux brand boilers, code E04 appears if the circulation of heated water is difficult or data recording and control devices do not work correctly

The fact that the pump or the electrical wiring connected to it deserves attention and repair/replacement will be indicated by an increase in the pressure value after a restart by at least 0.1 bar. In both cases, you should contact gas suppliers with whom an agreement has been concluded for the supply of gaseous fuel and maintenance of the unit.

E2

This error, which in some models is marked as e02, indicates overheating of the coolant, which creates a reverse temperature difference in the system and, in turn, overheats the boiler itself, causing an emergency shutdown.

The reasons may be:

- Airiness of heating radiators - the heating system is sealed, but during operation air may enter, which is released from the water. It warms up faster than water, so the radiators will boil at relatively low boiler temperatures.

- Lack of the required water level in the system - if the water supply tap is closed or in the expansion tank, where water should be filled independently, the level has dropped sharply.

- Decrease in pressure on the boiler - if the mark drops to 1 bar, then you need to check the tightness of the system itself. There may be a leak in some radiators or at the joints, which is why the pressure is not maintained at the desired level.

- Thermostat malfunction - sudden voltage surges can lead to its inadequate operation. The sensor may need to be replaced with a new one.

- The pump does not work - there are two possible reasons: either there is no electricity, or the pump is set to the minimum operating mode. If it is used incorrectly, the device fails, as a result of which water stops circulating in the system, and is heated exclusively in the boiler, causing it to overheat and emergency shutdown.

In Electrolux boilers, problems with the pump occur quite often, or rather with the stator. In some models it cannot be repaired, so a complete replacement will be required.

You can resolve this error in the following ways:

- Check the airiness of the batteries by slightly opening the drain nuts on each - some of the water with oxygen bubbles should come out. The procedure should be performed only with the pump turned on, otherwise it will simply be ineffective.

- Add water to the expansion tank if its level is below the required level. Open the water supply valve when automatically recharging the system.

- Check radiators and joints for leaks if pressure in the system constantly drops.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

As for assessing the quality of the pump and thermostat, it is better to entrust everything to specialists in gas equipment. It is not recommended to interfere with the operation of the boiler yourself, since the consequences can be very unpredictable.

Basic error codes for Electrolux gas boilers

The digital LCD display is located on the front of the Electrolux gas boiler body. Displays the current coolant temperature, system operating parameters and a specific error code in the event of a malfunction.

Almost all problems can be fixed on your own, but if new problems and breakdowns continually occur, you should contact a specialist for repairs. Frequent faults:

- lack of flame supply or its instability (e1);

- coolant overheating (e2);

- poor smoke exhaust and malfunction of smoke removal components (error e 3).

Let's consider the reasons for the appearance of fault indicators and possible repair schemes.

e1:

The reasons for the appearance of error e1 on the panel lie in reduced pressure in the gas line or a malfunction of the ignition electrode, which is why the flame is not supplied. What can be done:

- Check the valve, turn it all the way.

- Restart the equipment by pressing the “reset” button. If the boiler does not start, contact the service center for help.

- Conduct diagnostics of the electrode: clean it of dirt, adjust its location.

- Check the wires for serviceability: inspect for defects, damage, etc.

- Inspect the gas valve; if it is faulty, replace the part with a new one.

- Diagnose the control board. If damaged, replace it.

- If, after diagnosing the above components, the gas boiler still does not work, you need to contact a specialist. A possible reason in this case is air locks in the gas line.

e2:

Error e2 detected on the display of the Electrolux device warns the user about the heating of the coolant, which occurs in the event of large airiness in the pipes, a breakdown of the circulation pump, or low pressure in the line. Also, the problem with this error may be a closed or not fully open gas valve.

Elimination methods:

- open the valve all the way to supply gas;

- eliminate airiness by opening air and smoke exhaust valves;

- restart the equipment when the corresponding parameter appears on the display. If the boiler is not

- turned on, then test the sensor with a multimeter;

- check the system for leaks by pouring water into the tank;

- diagnose the operation of the pump, call the contacts. If the voltage reading is different from the norm, install a stabilizer.

In most cases, replacement of equipment components is required. You can purchase spare parts for gas boilers at the manufacturer’s service center or at a specialized auto parts store. You can also place an order through the store where the device was purchased.

e3:

The value of error parameter e3 is a malfunction of the chimney. The equipment is automatically blocked and turned off, since if there is a blockage in the chimney or sudden temperature changes, the security system sensor is triggered.

Causes and solutions to this problem:

- Check and clean the chimney. If it is of the coaxial type, then regular removal of accumulated ice or snow in winter is required.

- Check the sensor power contacts for possible defects. If the wires become oxidized, they must be cleaned and the connection restored.

- Check the temperature sensor for possible short circuit. If there is a malfunction, replace it.

- It is necessary to diagnose the contacts of the Electrolux gas boiler board. If the part does not work, replace it with a new one.

- Adjust the supply air draft in the room. Remember that running an air conditioner or fan interferes with the proper operation of the entire heating system. Better open a window or door.

- Incorrect assembly of the chimney system leads to such a malfunction. In some cases, it may be necessary to completely dismantle the structure and reassemble it following certain parameters.

e4:

Error value e4 – pressure drop in the line is below the norm of 1 bar. The reason may be that the heat exchanger is damaged by scale or the radiator is damaged by corrosion, after which a water leak appears. What can be done:

- turn off the device and open the fuel valve to drop the pressure parameter on the pressure gauge. After the procedure, turn on the equipment;

- if the error remains on the display, you need to descale the radiator using a citric acid solution;

- Using a soldering iron, you can independently eliminate holes that are leaking in the radiator.

e5:

The indicator of increased pressure in the line is above 2.5 Bar.

The error may have appeared due to improper operation of the pressure sensor. In another case, the cause is a defective safety valve. How to repair:

- restart the boiler using the “reset” button; if the indicators on the display do not change, then proceed to the next steps;

- wash the safety valve filter;

- check the expansion tank for damage;

- Check the sensor contacts for overvoltage or open circuit; if faulty, replace the part.

e6:

Damage to the hot water supply sensor. It is necessary to restart the device to determine exactly the problem:

- if the boiler does not start working, then it is necessary to replace the sensor;

- if the error code remains unchanged, you need to diagnose the contacts and connecting wires of the sensor; Check the system board; if faulty, replace it.

e9:

The reason is that the temperature in the boiler drops below 2 degrees. To eliminate further indicators of this code and eliminate possible freezing, it is necessary to install an additional thermometer outside to monitor the temperature. If the boiler will not be used during the winter, drain the water as indicated in the equipment operating instructions.

Additionally, the Electrolux “Basik” gas boiler is configured if there is a similar problem and after a long shutdown.

E3

This error is marked the same on all boilers and indicates problems with smoke removal, when the exhaust gas is not discharged outside as it should be, but remains in the combustion chamber or penetrates into the room.

There are several reasons for this:

- A blockage in the chimney can be the remains of burning and soot, and in the winter season - ice and icicles. You need to look into the chimney and check the draft level. If it is weak, then you should call a stove technician who will clean the ventilation duct.

- A malfunction of the gas control sensor gives a false signal that blocks the operation of the entire boiler.

- The supply draft in the room is disrupted - when the windows and doors are tightly closed, and there is no ventilation duct in the room itself. Often occurs in apartments where the chimney is clogged.

- Problems with the electronic board are less common, but it happens that this error appears for no apparent reason when the light is suddenly turned off and then turned on. The automation is under increased load, which it cannot cope with.

To fix the problem you need to:

- Check the draft in the chimney by holding a burning match to the hood. If the flame does not move, then there is a blockage and you need to clean it.

- Open a window or door to the room and try to restart the boiler.

- Call the experts if all else fails, so that they can conduct a comprehensive diagnosis and eliminate the identified cause.

If there is ice inside the chimney (parapet boilers), it should be carefully removed. If this happened due to prolonged non-use of the boiler, then it is started at minimum speed, after which it is gradually warmed up.

E 02

Electrolux boiler error E2

The error indicates a sharp increase in temperature in the circuit (overheating). This happens when the rate of fluid circulation decreases or the channel is blocked. The Electrolux boiler is not always to blame - troubleshooting should begin with diagnosing the heating system.

Probable Causes

Recommendation : a good owner always has a backup heat source at hand (an alternative to a boiler). The optimal solution is to remove the heat exchange device and send it to a workshop: maintenance will take no more than 3 days. It’s better not to do it on your own, following advice from the Internet. The internal part of the product has a complex configuration, and we are not talking about a perfectly smooth surface. Just clean it and put it in Electrolux - delay the appearance of the error for two to three weeks. The technology of competent maintenance involves stage-by-stage processing of the heat exchanger: pouring a special reagent/holding (to soften deposits)/rinsing under pressure. Can't do it at home.

If the measures taken do not help eliminate the error, you need to change the thermostat of the extract air circuit. In all Electrolux boilers, its function is performed by a thermal resistance. A regular continuity check for a break does not give the true picture: the defect may be an interturn short circuit - only replacement.

E4

This error code indicates a sharp decrease in pressure in the circuit. May also be designated 04.

Occurs for the following reasons:

- Water from the circuit has gone into the water supply system - this is appropriate if the make-up tap is not closed and the water in the general water supply has been turned off.

- Contamination of the heat exchanger with scale occurs when using tap water saturated with oxygen, as well as when operating the boiler at maximum temperatures. The preceding factor is the lack of annual preventive cleaning, which completely dissolves scale on the heat exchanger.

- Depressurization of the heating system - leaks in radiators or at joints.

When error E4 appears, it is necessary to check the presence of the required water level in the system, fill the deficiency if necessary, and also look for a leak. If all this does not help, then you should call the experts. The cause may be a faulty pressure gauge or a problem with the board.

Other faults

On Electrolux 24 Basic Space Duo devices, error f4 may appear if the circulation pump is faulty. The code appears if, after 30 seconds from the moment the pump starts, the pressure has not increased by 0.1 bar. Check the operation of the pump; if it malfunctions, purchase a new one.

Error l01

This means that the heat exchanger is clogged. Remove it and descale it according to the instructions for the device.

Code E7

Appears when a malfunction occurs in the coolant thermostat. In this case, measure the resistance of the thermostat and see if the sensor wires are disconnected or oxidized. If the problem is in the wires, strip and connect the wires; if the sensor is faulty, replace it. If the sensor is OK, check the electronic board.

Thermostat

If noise occurs when the boiler beeps, you should check the system for airiness, the operation of the fan and pump.

When the boiler does not produce hot water, check the flow sensor for short circuit and open circuit, electronic control board. If the board or sensor is faulty, replace it with new ones.

If the room does not heat up when the boiler is running, check whether the heating tap is closed, the condition of the dirt filter, rinse it if necessary, check whether the heating circuit is airy.

E5

Occurs when the pressure on the pressure gauge rises rapidly and shows critically high levels.

The reasons may be the following:

- Failure or airiness of the expansion tank - in those models where the expansion tank is mounted directly into the boiler itself.

- The safety valve is clogged when using low-quality water, as well as a large amount of scale and rust, which clog the small cells of the filtration grid.

- Pressure sensor malfunction - possible short circuit or break.

It is impossible to diagnose this problem yourself. You should call specialists who can check all possible causes and eliminate them. If this error is detected on the display, you must turn off the boiler and shut off the gas supply. Using gas equipment that displays critical values in a heating system is extremely dangerous.

E9

The error code signals a critically low temperature of the coolant in the system, which is fraught with freezing. This happens when the boiler has not been used for a long time, and the temperature in the room drops to 0 degrees. In an apartment this error is less common than in private houses.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

If you need to leave, and you decide to turn off the heating, and it’s severely cold outside, it makes sense to drain the water from the system. It’s easier to ask someone you know to look after the house than to then warm it up from scratch.

E 03

Electrolux boiler error E3

The error indicates that the smoke removal system is not operating correctly. Mainly due to a narrowing of the diameter of the canal or its blockage. This could be caused by foliage, or a bird caught in the pipe - checking the draft and cleaning it is not difficult.

Recommendation : the appearance of a code during the initial startup of the boiler is caused by errors in calculations (wrong length, diameter), an illiterate diagram or a violation of the chimney installation technology. The same thing applies if the code is displayed periodically when the wind direction changes. We will have to correct the mistakes made.

E6

Malfunction of the hot water control sensor, which happens after 10-12 years of operation of the boiler. The cause is usually oxide compounds, which you can either try to clean or completely replace the sensor with a new one.

The board itself can also give an E6 error. This happens when there is a power outage in the network. You can try to reboot the boiler using the “Reset” button. If this does not help, call the experts.

E 09

Electrolux boiler error E9

An error is generated by the anti-freeze system. Happens when the water in the pipes cools down (t 0 < +2).

Probable Causes

Recommendation : when installing an Electrolux boiler in an unheated room, raise the temperature with another heater. If, when the value reaches +5, the boiler does not start, call a specialist.

I01

This error can appear either independently or in combination with errors E5 and E6. Indicates contamination of the coolant, which is causing the heater to suffer. The problem is solved by dismantling and cleaning it using special means.

Some models have the ability to pour a cleaner into the system and drain it after a certain time. All manipulations are performed only by a specialist. Dismantling without skill and experience is strictly prohibited.

General tips and tricks

Error codes do not always appear when there is a particular breakdown.

Be sure to check these points:

- Is the gas turned on (is the supply valve open) and is there any gas in the system at all?

- Is water supplied to the heating system and is its level sufficient? The standards are specified in the technical operation manual.

- Is the chimney duct clogged and is there adequate ventilation in the room where the boiler is located?

- Is the pump functioning? Do the heating radiators heat up after turning on the boiler?

- Is the boiler plugged in?

For some, this seems funny, but a third of all calls to technicians occur precisely because of the user’s carelessness.

To reduce the risk of serious damage, you must follow 2 important rules:

- Every year, monitor the serviceability of gas equipment and clean the water heating element from scale.

- Call specialists immediately as soon as a malfunction appears or an error appears on the display.

This will protect the boiler from costly repairs, and your life from possible danger.

Violations in working with code E4

Household gas equipment requires regular inspection and close attention from owners. After all, the slightest problem can turn into a serious disaster. From irretrievably lost equipment to various degrees of poisoning and explosions with fires - all these are the consequences of seemingly insignificant breakdowns.

Manufacturers of units for servicing private heating and hot water circuits were well aware that not all owners of the equipment would be prepared to operate them at a professional level. That is why a warning system was developed that appears on boiler displays.

One thing is bad: almost all brands have their own alphanumeric designation of boiler failure. In some ways, the decryption systems have something in common, but mostly they differ. Equipment error codes with the Bosch logo, for example, are absolutely unacceptable for diagnosing breakdowns of Viessmann boilers or Ariston appliances.

What to do in a difficult situation if your gas water heater persistently beeps, displaying error E4? It’s as easy as shelling pears to analyze all the typical malfunctions in the operation of heating equipment, most often purchased by our compatriots.

Sources

- https://WyseDevice.ru/uborka/elektrolyuks-oshibka-e4.html

- https://m-strana.ru/articles/kotel-baksi-oshibka-e01/

- https://kuban-stan.ru/kak-chinit/kotel-elektrolyuks-oshibka-e2.html

- https://KTexnika.ru/uborka/oshibka-e2-elektrolyuks.html

- https://sovet-ingenera.com/otoplenie/kotly/oshibka-e4-v-gazovom-kotle.html

- https://megavat116.ru/kotel-elektrolyuks-oshibka-e3-chto-delat/

Questions and answers

Sometimes I see error E2 appear. I do a forced reboot and everything disappears. A few days later everything follows the same scenario. What to do?

In this case, it is better to call specialists, since there are many reasons for overheating of the coolant, and this is not necessarily airiness in the heating system.

I often see error E2 flashing on the boiler as soon as I increase the boiler power. With what it can be connected?

The most obvious reason lies in the airiness of the system. In theory this shouldn’t happen, but in practice this happens. You need to drain a little water from each radiator one by one and add a new portion to the expansion tank.

It shows that I have problems with ventilation, but I try to bring a match - the craving is crazy. What is the reason?

Such an error may also indicate the creation of reverse draft if your chimney is installed incorrectly or there is no deflector. It is better to call a stove-maker and a gas equipment specialist, as there is always a risk of malfunctions in the board itself.

In conclusion, it is worth noting that Electrolux gas boilers have excellent characteristics and cope with their work in the most unfavorable conditions. Breakdowns and malfunctions are marked with codes that indicate the need for repair of a particular part. The instruction manual contains all the explanations specific to a particular boiler model. Repairs and maintenance are carried out exclusively by specialists who have the appropriate permit.

Electrolux boiler error E3 Leave

Electrolux boiler E3 error

The lack of factory instructions for imported equipment is the minimum information in the “Diagnostics” section that is useful for the user. After indicating the probable cause of the fault code, the general recommendation is to contact a service technician.

Error E3 of the Electrolux boiler is not the most difficult, and in most cases it can be eliminated on your own. The reader will learn what you can do yourself from this article.

On a note! The search for the causes of any boiler error should begin with a reset (REZET button on the Electrolux front panel). When the power supply voltage surges, the automation displays a false code, although in reality there is no problem with the boiler or heating system. But if the error does not disappear, you need to deal with the reasons that caused it. And they are not always associated with breakdowns of the heating installation.

Reset button on the Electorlux Biasi boiler control panel

Code e3 of the Electrolux boiler informs the user about problems in the smoke removal system.

Consequently, the search range is narrowed - there is no need to test the heating circuit with such an error.

Testing is simple - for the presence/absence of traction. Control is carried out by the flame tongue: candles, lighters, matches. The degree of blockage and a specific area can be determined using a mirror. If the chimney head is not properly equipped, the channel gradually becomes clogged with dust, leaves, and sometimes small birds flying in. Anyone can clean it themselves, thereby eliminating the boiler error E3.

Coaxial chimney with protection from the external environment

It is somewhat more difficult for Electrolux with a coaxial chimney. In winter, if the rules for installing a smoke removal system are violated, icing of the channel is observed. You will have to warm it up, but with what exactly, it will be decided on the spot.

First of all, the condition of signal lines and power circuits is assessed. The most likely causes of any of the boiler errors: breaks, short circuits, insulation melting

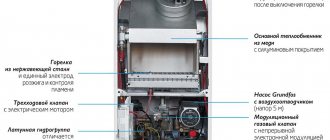

Electrolux Atmo series

In boilers of this modification, combustion products are removed naturally. And if there are no problems with the smoke exhaust duct, you need to look at the draft sensor. Its sensitive element is a bimetallic plate. The probable cause of error e3 is the lack of a signal to the electronic board due to a problem with the contacts (NC type) or wires (break, short circuit). The sensor cannot be repaired, only replaced.

The sensor is designed to control draft in Electrolux gas boilers

Electrolux Turbo series

- Fan. The mechanical part is checked by lightly touching the impeller: it should rotate freely. The condition of the winding can be easily assessed by directly applying the supply voltage.

- Venturi device. Its purpose is to control the flow of flue gases. Consists of a silicone tube that works in conjunction with a pressure switch sensor. It transmits pressure to its membrane, which causes the microswitch to operate. First of all, you need to carefully inspect the plastic housing of the sensor and the polymer tube. Temperature deformation is a reason to replace. Next, the tube is checked: it often becomes clogged with soot and dust, and the channel is blocked.

- Pressostat. In the documentation it is also designated as a smoke sensor, differential pressure switch. When the fan is turned on, its NO (normally open) contacts close due to the influence of the membrane (it bends), and a signal is sent to the electronic board of the boiler that there are no problems with the hood. The pressure switch cannot be repaired, it is replaced.

If the measures taken do not give a positive result, there are two reasons for the appearance of the E3 Electrolux code: a malfunction in the boiler control board and errors in calculating the parameters of the chimney.

In the latter case, the diameter, the total length of the highway, the number of turns, and the length of the vertical, “accelerating” section (for Electrolux Atmo) may be incorrectly determined. Only a specialized specialist can find out where the problem is.

Periodic display of error e3 with the boiler stopping, observed only during strong gusts of wind or a change in direction, is a clear sign of miscalculations made when drawing up the chimney diagram and its installation.