Failure of heating system units usually occurs at the most inopportune moment. At first glance, a gas boiler is a very complex device that can only be repaired by a trained gas service technician with experience, knowledge and manufacturer accreditations.

However, to quickly identify the cause, it is not necessary to study to become a gas technician. If an error occurs with an Ariston gas boiler, the system recognizes the problem and displays a fault code on the screen. In most cases, you can find a malfunction and adjust the heating yourself.

We will tell you how to promptly identify the maturation or occurrence of a breakdown. In the article we present you will find decoding of the codes and tips for correcting the situation. Our recommendations will be useful to those who decide to repair equipment with their own hands.

General characteristics of Ariston boilers

The description of Ariston gas units must begin with the characteristics of their main part - the burner. This element is used to burn fuel and release thermal energy into the heating system.

Types of boiler burner:

- regular

- modulation

The modulation burner is more convenient to use. It provides automatic power control depending on the temperature of the device.

According to the type of exhaust of combustion products, burners are divided into:

- closed type

- open type

Units with a closed burner are safer to use. In this case, natural gas combustion products do not enter the room. The use of a chimney is not required. A coaxial pipe is simply connected to the device and taken out.

The design of the coaxial pipe provides for the presence of two layers, which ensures the simultaneous removal of waste and the flow of air from the street into the burner.

Equipment with an open burner requires the use of a chimney to remove combustion products.

How everything should work

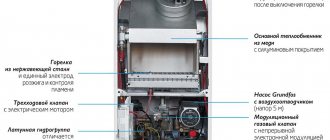

Inside the metal casing to which the motor is attached (position 14) there is an exhaust fan.

When it rotates, some of the air is drawn through a small outlet to which a tube is attached.

The second end of this tube is connected to an air pressure switch (position 2), which is activated when there is draft.

The exhaust turbine rotates, draft appears, the relay is activated and everything is OK. The processor sees that the sensor has triggered, which means there is traction, and you can give the command to ignite!

Features of Ariston boilers

Ariston gas boilers are the most in demand on the market, thanks to their time-tested reputation. They are distinguished by their compact size, convenient connection and maintenance system, reliable operation, and a variety of models. The company produces single-circuit and double-circuit units, wall-mounted and floor-mounted, with an open (chimney required) and closed combustion chamber (removal of combustion products through a coaxial pipe).

Ariston devices are equipped with an improved heat exchanger design, which allows reducing gas consumption, automatic protection, which increases the service life, and precise settings. If the water or gas supply is interrupted, an automatic blocking occurs, which eliminates the failure of the device.

How to determine the model of Ariston boilers?

The name and model number are indicated on the device itself, the packaging box or the operating instructions.

Problems with water heating

If during the washing mode the washing machine freezes for a long time, stops, does not heat up, or constantly drains water, the causes of the breakdown should be sought in the heating circuit. The device will signal these problems with codes F04, F07 or F08.

Failure of the heating element or pressure switch and codes F04, F07

In washing modes where heating is required, the error may appear immediately after startup, or after drawing water, but rinsing or washing in cold water will work normally. In this case, there are several options for solving the problem (besides the standard turn on/off the machine to reboot the controller).

If the code appears on the display during the washing phase or during startup (the machine does not even want to draw water), most likely the reason lies in the heating element itself. It can “pierce” onto the housing when the contacts come off or simply burn out.

To fix the problem, you need to get to the heating element, check all its connections, change the resistance with a multimeter (with a power of 1800 W it should produce about 25 Ohms).

To replace a faulty heating element, disconnect the cable with wires, unscrew the fastening nut (1), press on the pin (2) and pry off the sealing rubber (3), then install a new part and reassemble in the reverse order

If the device collects and then immediately drains water, the cause may be a breakdown of the pressure switch - the water level sensor. If there is a problem, this element can provide the controller with information that the heating element was not immersed in water, which is why the machine does not start heating.

In this case, it is necessary to check the water pressure sensor tube with the pressure switch (the hose may become clogged, kinked, frayed, or come off). At the same time, inspect the contacts of the sensor itself - they may need to be cleaned. But more precisely, code F04 “speaks” about the failure of the pressure switch - most likely, the part will require replacement.

To check the operation of the pressure switch, you need to put a small piece of hose with a diameter identical to the removed tube onto its inlet fitting and blow - characteristic clicks will be heard from a working part

In some cases, the problem may be in the board itself, faulty wiring or contact groups in the area from the board to the heating element or water level sensor. Therefore, you should ring all the elements of the control unit associated with the operation of the heating circuit, and if necessary, replace the burnt tracks or the controller itself.

Heating circuit faults and F08 symbol

If the water heating does not work correctly (or the machine “seems” to start when the tank is empty), error code F08 will appear on the display. The cause most often is a malfunction in the pressure switch circuit.

This problem can occur due to high humidity in the room, which negatively affects the controller. To make sure the board is in order, inspect it, wipe it dry, or blow it with a hairdryer.

Another simple solution to the issue could be the disconnected contacts of the heating element and the pressure switch, especially if the device was started for the first time after transportation. In other cases, a more professional inspection will be required with possible replacement of parts.

First, make sure that there is really no water in the tank, then remove the back panel of the machine and check the heating element with a tester

Possible malfunctions of Ariston machines, indicated by code F8:

- If the washing mode is interrupted immediately after starting or during the washing phase and the device does not heat the water, the heating element will most likely need to be replaced.

- If the machine stops after starting, when switching to the rinsing mode, or does not spin, it is possible that the contact group of the heating element relay is “stuck” on the controller when it is on. In this case, you can replace the failed elements of the microcircuit and, if necessary, reflash the board.

- If the device “freezes” in various modes (and this can be either washing, rinsing or spinning), the wiring or contacts in the heater circuit may be damaged, or the pressure switch may break down, which considers that not enough water is entering the machine.

But if, when checking all the connections of the circuit and separately the pressure switch, the heating element relay and the heating element itself, no damage is detected, you will have to change the controller.

The most common error codes and troubleshooting methods

The most popular among Ariston boilers are wall-mounted 24 kW models. During the operation of the Ariston gas boiler, failures and malfunctions may occur, like with any other equipment. The list of error codes is given in the instructions in the form of a table. Some of them are a malfunction of the automation (cause a protective shutdown of the device) and can be eliminated by clicking on “Reset”, and some signal malfunctions and interference in the operation of the boiler and require intervention (block the operation of the system).

All codes are divided into six groups according to the number of boiler components. The first value indicates the node in which the failure occurred, the rest indicate the error code. But it should be noted that if the protective error is repeated frequently, this indicates a malfunction.

The most common of them:

- error sp 3 (5p3) - refers to problems with ignition and means flame separation. Happens on Ariston Clas Evo models and indicates a problem with the gas block. Checking and adjusting the gas valve can solve the problem, but in some cases the reason lies in improper assembly of the coaxial pipe on devices with a closed combustion chamber;

Ariston Clas Evo boiler control panel

- error 501 - no ignition. Check whether the gas valve is closed; if there is supply, you should pay attention to the ionization electrode, it may get wet, dry it with a hairdryer. Look to see if it is bent; the distance from the electrode to the comb should be 8mm with a tolerance of 1mm; see if the connection between the electrode and the board is good;

- error 607 - stuck contacts of the fan control relay; replacing the relay, and sometimes the entire electronic control unit, will help.

Other breakdowns

In addition to those described above, the following codes may appear:

The reason lies in the NTSc sensor, there is no hot water at the outlet, the safety valve is leaking. If there is no hot water, but the heating system is working, most likely the water flow sensor is faulty or clogged with debris. Another reason may be that the turbine blades have worked too hard, stuck to the housing, this can interfere with rotation, replace the blades or the turbine itself.

The second reason in this situation may be the NTC sensor; to check its functionality, measure the resistance at its contacts with a multimeter; if it is unstable, replace the sensor with a new one. If the safety valve is leaking, the gaskets may be worn out, replace them.

NTC sensor

How to determine the error code if the device does not have a display or does not have a dial, such as on the Ariston BS II 24FF model? This device is equipped with indicator lights, thanks to which you can determine the breakdown. So, for example, if the 90 indicator and the crossed out water drop icon are on, this means that the boiler has overheated and is blocked. To eliminate this, you need to check the pressure switch and its connection to the board.

Decoding boiler error codes

Numerical combinations are displayed on the screen instead of a clock, which is why not a letter designation was chosen, but a digital one.

So, the list of codes usually looks like this:

- 101 – boiler overheating.

- 102 – pressure sensor does not work.

- 103 – absence of water or its low pressure (rate of change in the temperature of the medium is over 7ºC per second).

- 104 – absence of water or its low pressure (rate of change in the temperature of the medium is over 20ºC per second). If error 104 occurs, the Ariston boiler must be reset to its original state using the Reset button.

- 105 – lack of water or low pressure (supply water temperature is higher than at the inlet by more than 55ºC).

- 106 – lack of water or low pressure (supply water temperature is lower than at the inlet by 10ºC or more).

- 107 – lack of water or low pressure (supply water temperature is lower than at the inlet by 30ºC or more).

- 108 – no water in the primary circuit. If error 108 occurs, the Ariston boiler cannot be reset using the Reset button; repair is required.

- 109 – excessive pressure in the primary circuit. If error 109 occurs, there is also no point in resetting the Ariston boiler; you need to check the water supply line.

- 110 – contact lost in NTC1 sensor.

- 111 – short circuit in NTC1 sensor.

- 112 – contact lost in the NTC2 sensor.

- 113 – short circuit in NTC2 sensor.

- 114 – external temperature sensor not detected.

- 115 – external temperature sensor has shorted.

- 1p1 – poor water circulation or its absence, determined by the following sign: the temperature of the carrier increases faster than 7ºC per second.

- 1p2 – poor water circulation or its absence, determined by the following criterion: when the temperature difference between the outlet and inlet is more than 55ºC.

- 1p3 – poor water circulation or its absence, determined by the following sign: when the temperature of the return water is 10ºC higher than the supply.

This list of codes applies exclusively to the heating circuit; other components also have their own set of codes. Depending on the model, additional signals may appear; their descriptions can be found in the operating instructions.

Rice. 2

Hot water supply circuit (DHW)

Is everything OK with the heating circuit, but there is no fault code shown on the display in the list above? Then it is quite possible that the problem is in the DHW circuit.

Error code 201 - DHW temperature sensor error

Short circuit or open circuit in the electrical circuit of the DHW temperature sensor (NTCs).

Error code 202 - Error in the lower temperature sensor of the boiler (solar heating system).

Short circuit or open circuit in the electrical circuit of the lower temperature sensor of the boiler.

Error code 203 - Boiler temperature sensor error (for boilers with a boiler)

Short circuit or break in the electrical circuit of the boiler temperature sensor (for boilers with a boiler).

Error code 204 - Solar temperature sensor error

Short circuit or open circuit in the electrical circuit of the solar collector temperature sensor.

Error code 205 - Sensor at the DHW inlet (solar)

Open circuit or short circuit.

Error code 207 - Solar heating circuit error

Overheating in the heating circuit of the solar collector (solar heating system).

Error code 208 - Antifreeze function error

Low temperature in the solar circuit (frost protection).

Error code 209 - Water overheating

Overheating of sanitary water in the boiler.

Error codes for other boiler components

A list of all possible errors, their digital designation, and decoding may take a long time. In order to more fully understand the significance of the various codes, it is worth giving a description of the most important, most frequently occurring problems with gas boilers.

- 501 - Ariston boiler error 501 indicates problems with ignition, the boiler must be reset with the RESET button. If there is no flame, the gas supply must also be checked.

- 6p1 - if error 6p1 occurs on the Ariston boiler, you need to check the exhaust system, it means that the contacts of the relay responsible for the operation of the fan have not closed in the normal way. Sometimes resetting with the Reset button helps.

- 5p3 - with error 5p3 in the Ariston boiler, flame separation from the burner was detected.

- 117 - if error 117 occurs, the Ariston boiler must be reset using the Reset button, and it should work.

- sp3 – no burner ignition. Found in models with the EGIS Plus index and the like. Sometimes it is interpreted as flame separation, which makes it possible to classify the sp3 code as the most critical error.

Particular attention should be paid to problems such as flame separation. It occurs due to too powerful a gas flow and can lead to gas contamination inside the boiler. The same error in the Ariston 501 or 6p1 boiler does not cause any special problems, except for the inability to turn on the water heating. Error - flame separation in the Ariston boiler may indicate serious problems in the supply system; they cannot be solved on your own, you just need to call a specialist, having first turned off the gas supply.

When a flame breaks out, a fire hazard arises, so if it occurs frequently or at least systematically, you should consider checking the gas supply line. The accumulated gas in the boiler can flare up and cause mechanical damage to it or even create a health hazard for people living in the apartment.

In addition, heating efficiency decreases significantly and gas consumption for the same volume of water increases. The flame power should be adjusted smoothly, without popping inside the boiler and other abnormal phenomena and sound effects. Only then can you expect economical operation from the heater.

Rice. 3

Air supply/Smoke exhaust

If the air supply is disrupted or the exhaust of flue gases is difficult, this can also cause an error code to appear on the Ariston boiler display.

Error Code 601 - Traction Sensor Error (Open Chamber Models Only)

Triggering of the traction sensor.

Error code 602 - Smoke removal thermostat error (only in boilers with an open combustion chamber type VMC)

The smoke control thermostat has tripped.

Error Code 604 - Fan Error/Hall Sensor Failure

Fan operation at low speed (less than 1775 rpm - 100 rpm) or Hall sensor malfunction.

Error code 607 - Pneumatic relay error

The air relay is turned on before the fan starts.

Error code 6P1 - Pneumatic relay error

Pneumatic relay response delay.

Error code 501 - Error: No flame found at ignition

- There is no gas.

- There is no contact or grounding is not used. The voltage between neutral and ground is more than 10 V AC.

- Malfunction of the ionization electrode. Check the electrical contact and continuity of the circuit from the ionization electrode to the main board.

- Check or adjust the power of smooth ignition.

- Check the main board for damage.

Error 501, what it means and how to fix it

Error 501 means that the device does not start due to lack of ignition flame. The heating unit can be turned on by correcting the following causes of failure:

- lack of gas (you need to make sure it is present, open the gas valve);

- control board failure;

- violation of the electrode connection with the ignition control module;

- breakdown of the ionization electrode (it is necessary to clean the contacts, check the correct placement of the comb: a distance of eight millimeters must be maintained between the parts);

- reduction in the power of the smooth ignition system;

- leakage of electric current (remove the breakdown in the electrical network: the voltage should be 10 V).

Expert advice

- Before you begin repairing the Ariston boiler, you need to press the “RESET” button (translated as reset, playback, zero) and restart the heating installation. Often this helps restore its functionality. As a rule, the occurrence of an error is caused by voltage instability - a typical case in the private sector.

- If an Ariston boiler does not have a display and its indicator lights are blinking, it is not a fact that a malfunction has occurred. This happens when the Comfort mode is turned on. The heat generator is forced to adapt to the microclimate in the room, hence its periodic switching off/on

Sp3, 5p3 (flame break)

If the wall-mounted gas boiler Ariston 24 gives one of the indicated designations (error sp3 or 5p3), there may be a problem with the flame. Eliminating the error of flame separation from an Ariston gas boiler is associated with cleaning the chimney. It is too clogged with dust and soot or is not arranged correctly, so the fire is immediately blown out or the so-called flame separation occurs.

Temperature zones

It is also necessary to monitor temperature zones. If the display shows errors with codes 701-707, then this is probably overheating or a malfunction of the temperature sensor on one of the circuits.

Error code 701 - Supply temperature sensor error (zone 2)

Short circuit or open circuit in the electrical circuit of the flow temperature sensor (zone 2).

Error code 702 - Return temperature sensor error (zone 2)

Short circuit or open circuit in the electrical circuit of the return temperature sensor (zone 2).

Error code 703 - Supply temperature sensor error (zone 3)

Short circuit or open flow temperature sensor (zone 3).

Error code 704 - Return temperature sensor error (zone 3)

Short circuit or open return temperature sensor (zone 3).

Error code 705 - Water temperature sensor error

Short circuit or break in the electrical circuit of the hydraulic temperature sensor.

Error code 706 - Overheating error in zone 2

Overheating in temperature zone 2.

Error code 707 - Overheating error in zone 3

Overheating in temperature zone 3.

6p1

This code indicates incorrect air intake and an incorrect smoke removal process.

Causes of error 6р1

- Signal circuit defects. Error 6р1 occurs when there is no “visibility” between the EPU and the traction sensor. Check the lines for reliable contacts, absence of short circuits, breaks, or melted insulation.

Clean your Ariston boiler

- The tubes are clogged. Condensation or dust that came from the street through the filter. Blow it out, and error 6р1 will disappear.

- Loose fitting of tubes on signal ports. Weakening and cracks in the polymer that appear during operation of the Ariston boiler lead to error 6p1. The problem is eliminated by heat-shrinkable material, a high-temperature sealant.

- Deformation of plastic. Microcracks and tube breaks (CONDENSATE TRAP according to Ariston specifications) are reflected in the traction. The code is cleared by replacing the problematic part.

- Condensate collector overflowing. A miniature cylindrical container where moisture entering the chimney accumulates. Emptying will remove error 6р1.

- Venturi device deformation. Under the influence of high temperatures, the plastic bends, cracks, melts, and the hole is blocked.

Venturi boiler ariston

The air flow to the draft sensor weakens (stops), the pressure drops, the microswitch does not work, error 6p1 is displayed. Replacing the device is a matter of a few minutes; the services of a professional are not needed.

- Damage to the condensate trap. It is located above the combustion chamber and is exposed to thermal effects. Touching its upper part leads to melting of the plastic, the tightness of the air supply channel to the draft relay of the Ariston boiler is lost. As a result, error 6р1.

- Sensor malfunction. Burning of the MV contacts leads to a break in the signal circuit - the ED will not see the message that the boiler is ready for ignition and generates error 6р1. The solution is to replace the traction relay. The loss of elasticity of the membrane is not critical - it is not difficult to revive the device: remove it, tap it on a hard surface. The microparticles adhering to the rubber products will fall and the Ariston boiler will start. This method of eliminating the error is a temporary measure: the relay should be replaced.

- Fan problem. It turns on, but does not develop speed. The forced draft is insufficient, error 6р1 is displayed. Reasons: contamination of the blades, making it difficult to rotate the shaft (cleaning is required) or interturn short circuit of the winding. The malfunction cannot be eliminated - the fan must be replaced.

If the measures taken do not remove error 6р1, the reason is in the “brain” of the Ariston boiler (EPU).

Ariston boiler control board

Diagnostics of the board is carried out in a hospital setting, on a simulator stand. In everyday life, even a professional will not be able to determine the ECU malfunction that caused code 6p1: contact a service technician. When submitting an application, indicate the marking of the control unit of your boiler (marked on the board with symbols of numbers and letters). Replacement during diagnostics - and the problem with the Ariston emergency lock is solved.

Conclusion:

Taking into account the cost of the Ariston boiler, it is not advisable to take excessive initiative in identifying and eliminating the flame separation error on your own. Everything that is recommended for the user to check and perform is indicated in the article. There is no result - call a representative of the service organization.

Practical advice

- A one-time visit from a technician due to a problem with the boiler is expensive. On thematic forums you can find the following data: 5000 rubles for eliminating the flame separation error. It is more expedient to conclude an annual maintenance agreement with a service center (cost about 2500). The benefit is double – significant money savings and professional service.

- Experts recommend mitigating the risk of electrical interference on the gas main. For this reason, the control circuit of Ariston boilers often gives failures and errors. In some cases, the program is broken, and the board has to be reflashed. This problem can be avoided by installing dielectric inserts on the pipe (in several places); with professional installation this is done immediately.

- When connecting an Ariston boiler to a gas tank, you need to choose the right supplier of “blue fuel” and conclude an agreement with him. If the flame separation error is caused by low quality LPG, there will be someone to file a formal claim and compensate for possible damage (both moral and material). And one-time calls to fill the reservoir of representatives of little-known organizations, even those offering a low price, should not be practiced. Solving possible problems with the operation of the Ariston boiler will ultimately cost more.

Hardware problems that can lead to error 104

Fault code 104, according to the manufacturer's instructions, indicates poor circulation or insufficient coolant.

Ariston boilers have an automatic system for checking the circulation and heating of the coolant at the moment of release from the heat exchanger, which protects the device from overheating.

Control is performed by temperature sensors NTC1 (supply to the central heating circuit) and NTC2 (input from the central heating circuit). NTC devices are thermistors, the resistance of which decreases with increasing degree of heat of the coolant.

When the rate of increase in readings on NTC1 or NTC2 is more than 20 degrees per second, and fault code 104 occurs.

In real life, this breakdown looks like this: after switching on, the burner ignites, after a few seconds the gas boiler makes the characteristic crackling sounds of rapidly evaporating water, then the boiler clicks, the installation turns off and switches to emergency mode with error code 104.

In models BS 24 ff, cf the red light 90 gr is on. together with the indicator (crossed out flame), this indicates overheating of the equipment. When the yellow indicator (chimney) in the 24 ff heater flashes simultaneously with the 40 or 50 g indicators, this means a lack of coolant or insufficient circulation.

When trouble code 104 appears, the manufacturer recommends that you first reboot the equipment to make sure that it is not a system self-diagnosis failure.

Let's find out how to enable restart - to do this, press the "Reset" or "Reset" button on the control panel.

If after a reset the boiler does not function normally, then the self-diagnosis indicates a real defect.

The most likely causes of equipment damage: either problems in the heating pipes, or problems in the device itself - clogged coarse filter, damage to the pump, electronic board, sensors, heat exchanger.

If the pressure meter transmits inflated data, or heat transfer decreases, this demonstrates problems in the heating structure: blockage in the pipeline, the formation of air locks, a violation of the tightness.

Blockages appear due to the penetration of dirt into the pipes, layers of rust and scale. Detecting the location of a blockage is a very labor-intensive task; for this, methods of measuring the heat of pipes and an acoustic method are used, in which the pipeline is tapped and listened to.

To flush pipes, a hydraulic method is used, or the blockage is broken through using a wire with a brush attached to the end.

Air jams are formed as a result of air entering the pipeline for the following reasons: when water is heated, air dissolved in it creates air bubbles; air accumulation occurs due to a decrease in pressure, leaks, and repair processes.

After finding the plug by tapping (the sound increases in the problem area), the air space is eliminated using air collectors or air bleed valves.

Air locks also lead to a decrease in pressure in the heat exchanger, which will result in error code 108.

In most cases, leaks occur due to corrosion, which leads to both leaks and complete rupture. If you do not have the skills to properly install heating pipes, you should contact a specialist.

Ariston CLAS, GENUS, ALTEAS models have a built-in mesh filter. It is advisable to monitor its condition on a regular basis; if it becomes clogged, the bearings quickly wear out and cooling deteriorates.

To verify the cause of the breakdown, you should perform several manipulations:

- Turn off the power supply; you must completely remove the power, since after pressing the on/off button, the mechanism continues to function for some time; you will have to wait several minutes to stop completely.

- Let's see what pressure the built-in pressure gauge shows.

- Turn on the power and note the pressure gauge readings with the device in operation. If the pressure drop exceeds 0.2 bar, the structure is clogged.

- We open the front cover, fold out the control panel with the board and find the mechanism we need. It is located at the coolant inlet from the central heating circuit (bottom right), and a pressure gauge capillary is connected to it.

- Having previously shut off the heater, drain the water and remove the clamps.

- We first take out the capillary, and then the part we need, prying it off with a screwdriver.

- We wash the device and clean it of deposits, then install all the elements in the reverse order.

To check the circulation mechanism, unscrew the release screw on it, after placing rags or rags under it to prevent moisture from getting on the board. This will make it possible to see whether the shaft rotates after starting the equipment.

You can also turn off the power and try to turn the shaft manually with a screwdriver by inserting it into a special wide slot. If the shaft rotates manually but does not start when the device is turned on, check the supply voltage of the mechanism. If there is 220 watts on the chip, most likely the cause of the heater defect is damage to the part.

Ariston installs 2 types of pumps, with modulation and two-speed WILO: if the modulated one has become unusable, then only replacing the element will help, but the two-speed one can be repaired by changing the rotor and impeller assembly. A rotor from WILO RS25/6 is suitable for these purposes.

The circulation pump has two rotation speeds: V2 (55 W) – central heating mode and V3 (80 W) – hot water supply mode. Consequently, it is activated by 2 relays, the first supplies 220 V power, the second regulates the speed of rotation of the shaft.

To check the functioning of both relays, the heater should be started in the “Purge” mode; this mode is configured by pressing the ESC button for more than 5 seconds. Next, we measure the alternating voltage: at the 3rd and 4th terminals there should be 220 V, and at the 5th and 6th - 0 V or 145 V. If the required voltage is not available, the corresponding relay should be replaced. When there is voltage at the 3rd and 4th terminals, but the unit does not turn on, try making a jumper between pins 5 and 6.

If power is supplied to all terminals, a possible cause of the defect may be an interturn short circuit. This problem can only be eliminated by completely replacing the component part.

What is this ? Firmware Schematics References Case markings Programmers Abbreviations Frequently asked questions

- This is an information block for repairs. It contains basic technical recommendations and search tips for sections of the site necessary for repairs - circuit diagrams, firmware files, programs, component markings, links to databases. Pay attention to other topics where the tips and secrets of the masters, measurements, operating principles and diagnostic methods are located. Intended for those who accidentally came to this page, it is periodically updated and displayed only to guests.

- Firmware in sections: TV firmware (requests) TV firmware (storage) Monitor firmware (storage) Various firmware (requests)

- Schemes in sections: TV schemes (queries) TV schemes (storage) Monitor schemes (queries) Various schemes (queries)

- Directories in the sections: Handbook on TDKS transistors - pinout, repair, etc. Termomax gas boilers Handbooks on microcircuits

- Marking (marking) - designation on electronic components Directories on SMD components Identify an element in a TV (questions) Directories on SMD component codes Marking of SMD transistors from PHILIPS

- Package (housing) - type of electronic component housing • SOT-89 - plastic housing for surface mounting • SOT-23 - miniature plastic housing for surface mounting • TO-220 - housing for mounting (soldering) through holes • SOP (SOIC, SO, TSSOP) - miniature surface mount packages

- Programmer (programmer) - a device for writing (reading) information into memory or another device Below is a list of some programmers: • Postal-2,3 - universal programmer for I2C, SPI, MW, ICSP and UART protocols. In detail - Postal - assembly, configuration • TL866 (TL866A, TL866CS) - universal programmer via USB interface • CH341A - the cheapest (not expensive) universal programmer via USB interface

- • PWM (Pulse Width Modulation) - Pulse Width Modulation • SPI (Serial Peripheral Interface Protocol) - Serial Peripheral Interface Protocol • TSOP (Thin Small Outline Package) - Thin package with reduced pin spacing • USB (Universal Serial Bus) - Universal serial bus • DMA (Direct Memory Access) - Module for reading and writing RAM without using the processor

- How can I ask my question?

After registering an account on the site, you can publish your question or answer in existing topics. Participation is absolutely free.Who answers the questions?

The answer to the topic Ariston MATIS 24 FF error “EEPROM failure”, like all other tips, is published by the entire community. Most of the participants are professional repairmen and electronics specialists.

How to find the information you need?

The ability to search the entire site and file archive will appear after registration. A site search form will be displayed in the upper right corner.

What brands can I ask?

For any reason. The most frequent answers for popular brands are LG, Samsung, Philips, Toshiba, Sony, Panasonic, Xiaomi, Sharp, JVC, DEXP, TCL, Hisense, and many others, including Chinese models.

What else can I download here?

If you actively participate in the forum, you will have access to additional files and sections that are not displayed to guests - diagrams, firmware, reference books, repair methods and secrets, typical faults, service information.

- Would you like your link here?

No problem. Reading the page: Your link will be posted in all forum messages. Welcome! - Replacing LED backlights for TV matrices. Replacing LEDs in the backlight strips of LED TVs. Replacing backlight lamps with LEDs. Photo report. Disassembly of large diagonal LCD matrices 47 inches and more Autonomous mode of PDP and LCD panels

The instructions for heating installations with a self-diagnosis function contain a table of faults with code designations and a brief explanation. There is little information, and the recommendations end with the words: contact specialists. This is of little use, although the user can fix a number of problems on his own. The article explains in clear language the meaning of error 6p1 Ariston and gives practical advice on solving the problem that has arisen with the boiler.