Most of us are accustomed to traditional toilets that are installed on the floor in bathrooms. Today you can find more modern offers from plumbing manufacturers. We are talking about built-in toilets. Due to the design, you can gain some free space in the room. Cleaning is much easier, and the sound when draining water is much quieter - these are several advantages of this plumbing.

Let's look at what these plumbing fixtures are, learn about their disadvantages and advantages, types, as well as installation.

general information

Built-in toilets are a design where only the bowl is located on the outside. The entire drainage system, along with the tank and fittings, is located behind the wall. On sale you can find wall-hung and floor-mounted built-in models. The specific choice depends on the characteristics of the bathroom, personal preferences and other factors.

The overall dimensions are much smaller, which makes cleaning much easier. Flooring solutions will always have areas that are difficult to access and where dirt cannot be washed off. A huge amount of it will accumulate in these places.

Even the most ordinary frame can withstand loads of up to 400 kilograms - this is more than enough. There are installations that allow you to mount a built-in toilet (photo in our article) in one of the corners. Manufacturers offer special rail systems - on these frames you can mount not only a toilet, but also other plumbing fixtures. For example, a bidet and a sink.

Materials

Toilets built into the wall are made using a variety of materials, differing in technical characteristics and appearance, which affects the final cost of the plumbing fixture:

- Earthenware models are deservedly popular and widespread in our country. The main advantage of this traditional design is its affordable cost, but the high level of porosity of the material can complicate the cleaning process. It is for this reason that it is recommended to purchase models with a special, modern dirt-repellent coating.

- Porcelain models, characterized by a smoother and easier-to-clean surface, are also produced not only in the classic monochromatic version, but also with a pattern or ornament. The most noticeable disadvantage of porcelain plumbing fixtures can only be attributed to the high price.

- Steel models , favorably distinguished by their original appearance, are easy to clean and very resistant to mechanical damage. Despite the rather high cost, such toilets are most often used when arranging a plumbing unit in a modern high-tech style.

Wall-hung toilet with hidden cistern

Plastic models are currently the best option for installation in suburban households, due to their small dimensions, affordable cost, ease of installation and ease of use.

Glass construction is the most impractical, fragile and expensive, but this option has recently been increasingly used by many designers when decorating the plumbing facilities of private households.

Features of frame installations

This is an assembled steel frame that allows you to attach it in a variety of ways. Installation of this design can be performed in any type of premises. Most often you can find models on sale that are installed on four fulcrum points. It is advisable to attach them to a load-bearing wall. That’s why it’s called a frame with wall fasteners. There are models that are fixed to the floor using special elements.

These frames have become very popular recently. For them, overall dimensions and installation location are not so important. The frame can be fixed exactly where the owner needs it. Since the wall does not always have the necessary strength, the presence of floor fasteners will help.

In compact bathrooms, many people install corner built-in toilets - as a result, you can gain a lot of free space.

Non-built-in built-in toilet

Often, ignorant users and some crazy experts call floor-mounted and wall-hung toilets, which are integrated with built-in tanks, “built-in”. Built-in tanks come in two types:

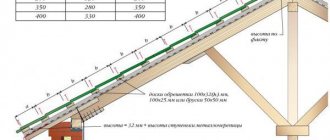

The tank is mounted on a durable steel frame, the so-called “installation”. First of all, the base is needed in order to attach a wall-hung toilet to it, secondly - for installing pipelines, and thirdly - as a frame for covering with plasterboard or other sheet material. For the most part, manufacturers offer installations of two types: some have a height of 115-120 cm, others 75-80 cm. The second allows you to install the lining flush with the washbasin built into the countertop. The frames are height adjustable by 4-8 cm.

A durable installation frame with a built-in cistern is designed for installing a wall-hung (not built-in!) toilet on it

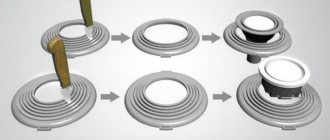

Tank installed separately. It is insulated, equipped with the necessary fittings and fastening elements, and costs significantly less than an installation kit. Designed for use with tankless floor-mounted toilets.

The frameless cistern integrates with any type of cisternless toilet, including conventional floor-mounted and in-floor Turkish

Whatever ceramic buddy you decide to install in an apartment or private house, the installation of pipelines, connection and installation of a built-in toilet, cistern, installation, wall-hung or floor-standing bowl should be carried out by people knowledgeable in plumbing. If the topic is familiar, you can do it yourself. If you don’t have the skills or necessary knowledge, it’s better to invite specialists to avoid trouble.

Dimensions and cost

The frame installation differs in its typical dimensions. So, in width it is approximately 50-60 centimeters, depending on the model. The depth ranges from 15 to 30 centimeters. Dimensions are standard except for height. It is selected strictly individually. If we take an average built-in toilet, the height dimensions are approximately 1.4 meters.

If we talk about the cost, it starts from 7.5 thousand rubles. As for corner structures, they are more affordable - from 3.6 thousand rubles.

How to choose?

We offer some tips to help when choosing equipment:

- We recommend purchasing products from well-known brands; the quality and reliability of such products are an order of magnitude higher than Chinese manufacturers. Considering the features listed above, cost savings can later turn into serious costs.

- Some models may have additional functions that increase comfort; an example is a microlift that ensures smooth lowering of the seat and lid. But it should be remembered that such additional piping significantly increases the cost of the equipment.

Example of a functional set to increase comfort - Pay attention to rimless models, their popularity rating has risen high in recent years.

A rimless toilet makes cleaning much easier - The circular flush system cleans thickets much more effectively than a horizontal flush.

Horizontal (A) and circular (B) drain - Pay attention to the mechanism of the drain fittings; they can be mechanical or pneumatic; the first is more reliable.

- Fittings that save water pay for themselves within a year or two. Now almost all well-known manufacturers install it on their products by default.

The two-button flush system has become almost standard for wall-hung toilets - Before purchasing, be sure to check the dimensions of the installation module; it may be larger or smaller than the required dimensions.

- Don’t rush to buy an additional bidet; some toilets support this function, so inquire about the availability of this model.

- Checking the availability of the appropriate certificate will help you avoid purchasing counterfeit products. Branded products (Roca, GaP, IFO, Laufen, etc.) must have technical documentation, which includes installation and connection instructions.

- Please check that the warranty card is filled out correctly.

Block installations

Unlike frame analogues, these structures are much cheaper. But it is important to take into account some features. If a frame installation for built-in toilets can be installed on any wall, here installation is only possible on a load-bearing wall. The system is a monoblock made of reinforcement. The dimensions are fixed - the width cannot be changed, the depth is most often from 10 to 15 centimeters. The height of the block installation will be no more than 1 meter.

The design consists of a plastic flush cistern and all the necessary fittings for it, plates for anchor fasteners, and studs for mounting the toilet bowl.

Types of cisterns

All drain tanks produced today differ in the location and method of installing the equipment. The main types are presented:

- An autonomous or “top” flush cistern, located on the top of the wall and connected to the toilet structure via a special pipe. Flushing is carried out by pulling the chain, which activates the mechanical part of the flush tank.

- A cistern equipped with a “compact toilet” and located on a specially equipped shelf, which is part of the toilet bowl. Flushing occurs when a special button is pressed or when a lever device is acted upon.

Compact toilet Rosa Orion Lux

Particularly convenient are built-in flush cisterns, which most often complement wall-hung toilet models, but are quite suitable for connecting to floor-standing attached models. This type of cistern is masked by a wall (built-in toilet cistern), so the structure is completely invisible, with the exception of the flush button.

The most modern and cost-effective models of built-in flush cisterns are equipped with two buttons that allow partial and complete drainage.

Baths with hydromassage are, perhaps, preferred by everyone. But massage is not for everyone, and you need to be aware of this. Hydromassage baths - benefits and harm to human health, the topic of this article.

We will consider the design options and rules for installing a floor-standing bidet here.

The design and principle of operation of a wall-hung toilet with a bidet function will be discussed in this article.

Myth No. 2

Another popular myth: since the toilet is built into the wall, if repair work is necessary, it will have to be destroyed. And this can be refuted. The manufacturers of this plumbing fixture have thought through everything carefully and long ago. The tank is made of very durable plastic.

It can last for a very long time - it will not need to be replaced during the entire service life of this plumbing fixture. Only the drain mechanism may need repairs - access to it is very easy. It is enough to remove the panel with the button. The tap that shuts off the water is designed with special features. It does not have the usual or traditional carvings. It is secured using a special plastic part. This element can be easily unscrewed if necessary. If some kind of malfunction occurs, the tap can be pulled out from the outside or left open altogether. The water can also be shut off from the outside.

Additional options

Very often, built-in toilets have additional functions. These include:

- Built-in bidet;

- Illuminated, allowing you to find the bowl even in complete darkness;

- Heated seat;

- Reservoirs for flavorings.

Of course, all (or only part) of such capabilities are installed in expensive models and are not really needed in the everyday life of an ordinary person.

But a rimless toilet or a lift mechanism for lowering the lid will appeal to any housewife due to the ease of cleaning and maintaining the integrity of the bowl.

Myth No. 3

Sellers of traditional plumbing fixtures claim that in the event of a breakdown, it will be difficult to buy the necessary spare parts for a toilet built into a cabinet or a false wall.

In fact, the kit already contains everything necessary for the toilet to operate; all spare parts and elements can be easily found on sale. The button for the tank is selected by the buyer.

Review of manufacturers

Below is a table that contains the best manufacturers taking into account various criteria.

Rating of manufacturers based on several criteria

We hope this table will answer the question of which manufacturer is better. It should be taken into account that new models are entering the market, therefore, the objectivity and relevance of the sample may not be reliable.

Installation without installation

The installation is not used in all cases when installing this plumbing fixture. Installation can also be carried out directly to the wall. The tank and drain coupling will be mounted in a monolithic concrete base. In addition, this monolithic concrete structure will support the toilet from below. What is good about this installation? In terms of reliability, it is no worse than with installation, and in terms of cost, it is more profitable.

For work, you should prepare studs with a diameter of 20 millimeters and a length of 60 to 80 millimeters. You will also need four nuts to match the thread size on the stud. To create a monolithic concrete structure you need approximately 50 liters of concrete and formwork materials.

The holes must be drilled with a hammer drill or drill. Measurements are made using a tape measure and a building level.

The first step is to prepare the sewer system - install a drain coupling. Then mark on the wall the place where the studs will be mounted. A gap of 200 millimeters is made between the studs. Then the wall is drilled through, the studs are passed into the holes, and they are secured on the back side with nuts.

One panel and two panels on the sides are used as formwork. Holes will also need to be made in the shields. To hold the formwork, the nuts on the studs are tightened. Then check the correct installation. The formwork is filled with concrete. In this case, you must not forget about the location of the tank. It can be made using polystyrene foam or other material. The concrete is left to gain strength for 7 days.

When hanging the toilet, carefully coat the drain hole with sealing materials, allow them to dry completely and connect the plumbing fixture to the system. After this, you can start using it.

Drain

It would also be a good idea to purchase a modern flushing system. The drain button can have the most unusual shape that attracts attention, or it can be a minimalist option.

Good solutions include:

- Stop the flow of water by pressing again;

- Use a double button that allows you to use either the entire tank or only half of it;

- Installation of a touch sensor that performs automatic flushing.

Modern devices can be equipped with an anti-splash system or a circular movement of water in the bowl. The first option helps to avoid splashes and makes cleaning easier, the second saves water and helps to better deal with dirt and bacteria.

Reinforcement: invisible but important components

Fittings are attached to the installation: tank, pipes and other parts.

Despite the fact that some parts are hidden behind the false panel, they are also important for the long, reliable service of the wall-hung toilet

All components must be made of especially durable polymers or metal with an anti-corrosion coating. The button can be connected to the sewer fittings using a pneumatic device, a lever or a cable, with preference given to the first two mechanical methods.

Image gallery

Photo from

Drainage cisterns are part of the installation

Cisterns fittings for hidden installation

Covering a false installation with a plasterboard wall

Technological hatch for equipment maintenance

Device

Design of the installation system on which wall-hung toilets are mounted

To figure out how to install a wall-hung toilet, you first need to understand its structure.

- The base for the toilet is a rigid frame made of steel. It's called an installation. The manufacturer provides the possibility of adjusting the frame in height, that is, selecting the optimal position of the plumbing fixtures for each user. The installation is attached to the wall and floor. Please note that the wall must be load-bearing, or made of brick or concrete. Plasterboard partitions will not work, know right away. The wall-hung toilet itself is hung on pins located in the installation.

- The next element is the drain tank, which is also located in a steel frame. There is a special hole in the tank through which installation is carried out and the operation of the system is checked, so there will be no problems with access during operation.

- The composition also includes a bowl, which remains, in fact, the only visible element of the toilet after its installation.

- Another component of such plumbing are fasteners and sometimes tools.

Before installing the wall-hung toilet, carefully study the contents of the package, especially look at the package with spare parts. Now take the assembly instructions provided by the manufacturer. Most likely, the kit will not include a number of elements necessary for installation. Check what is missing, and then go to the store to buy the missing components. Do this in advance so that you don’t have to rush out and run to the shops in the middle of the work process.