Thermal insulation (insulation, heat insulator) is a structural element or material that provides resistance to heat transfer or its reduction. Its use is the main way to prevent the occurrence of condensation in ventilation systems. Insulation for proper operation of ventilation pipes (vent pipes, vent hoses) is a necessity. In addition to protecting against moisture, insulation has an additional function - it muffles wind noise.

Fig.1 Insulation of the ventilation system

In what places do pipes need to be insulated?

places for insulation of ventilation pipes

Insulation always remains mandatory for the surface of the air duct outside the heated volume. This is especially true for areas such as the cold attic and roof. Work is not required when passing through attics and heated second floors. These components require insulation inside heated rooms:

- Pipes through which air flows to devices.

- Fan installations.

- Supply ventilation ducts.

The action is mandatory for buffer zones, which include:

- Boiler rooms.

- Storage rooms.

- Cellars.

- Auxiliary objects.

All the pros and cons of interior and exterior insulation

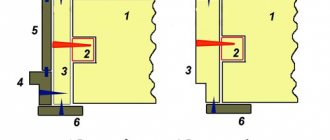

Insulation of pipes is usually carried out in one of the following ways: by internal lining or by installing insulation from the outside. Each of them has its own advantages and disadvantages.

Internal lining

- the installation process itself is more complex, but temperature and mechanical external influences do not harm such insulation;

- in order to avoid reducing the internal zone of the air duct, it will be necessary to carry out preliminary work to increase the original part;

- the selected insulator must be impenetrable to vapor and absolutely sealed, which will avoid the penetration of atmospheric moisture;

- It is better to choose a material with a smooth outer surface that will not prevent air from circulating freely.

Why is condensation dangerous?

ventilation system condensate

During exhaust ventilation, condensate has other consequences and composition when it comes to stove and fireplace pipes. The main composition is pure water, to which dust is mixed. Soot and acid-forming oxides are added to it when it comes to kitchen hoods. Such components are not highly aggressive, but increase the rate of destruction of internal parts.

Stainless steel pipes also corrode faster. But the total lifespan of such products reaches tens of years, so in practice it is difficult to establish exact figures. Galvanized steel structures are less resistant to acids. You shouldn’t focus too much on the condensation inside.

Sealed and correct installation is important for the pipes themselves. Acid solutions do not cause damage to plastic products.

Thermal insulation of ventilation ducts is selected according to three main criteria:

- Thermal conductivity.

- Fire safety.

- Material cost.

In the modern market, preference is most often given to a mineral base. Each variety has its own characteristics, negative and positive sides.

Moments of exhaust structures

The hood plays an important role in a finished house. It also serves as a chimney. Exhaust ventilation ducts should be installed in the kitchen. This arrangement of the channel is completely no coincidence because the air in the kitchen is the most polluted. The exhaust system channel should be shorter, unlike the supply system. This way you can significantly reduce the likelihood of condensation in unheated areas.

For the least resistance to air movement through the exhaust duct, in other words, to increase draft, the following conditions must be met: one duct size, without narrowing; the direction of the pipes is rectilinear without horizontal sections.

Exhaust duct with minimum length

You can achieve greater air extraction efficiency by installing a fan in the central air duct, which will subsequently extract air from the rooms.

For the hood above the gas stove, as well as for the heating boiler pipes, taps into the main duct are used, but only above the fan, otherwise it will quickly fail.

Mineral wool

thermal insulation of ventilation ducts with mineral wool

Manufacturers use the term to designate insulating materials based on basalt or slag, glass fibers. They are usually produced in the form of flexible mats or slabs that cover the air duct.

On the negative side:

- Gradually cakes, even if the rooms are completely dry.

- Constant contact with moisture leads to loss of some properties.

- Strongly absorbs water, it stays in the composition for a long time.

- The presence of phenol-formaldehyde resins in the composition.

- Lightweight and brittle material, even during installation it forms a large number of small fragments. The roof is no exception.

But there are also advantages:

- Low prices.

- Fire safety, ability to withstand temperatures up to +450 degrees.

- Strength.

- Elasticity.

- Noise and heat insulation at a high level.

Rolled insulation in the form of mats is most often used when it is necessary to insulate round-shaped structures.

Types of ventilation systems

Ventilation systems are divided according to the principle of operation into exhaust, supply, and supply and exhaust. There are no differences in the installation of thermal insulation for them. Depending on the location of installation, ventilation systems can be domestic or industrial. The area, air exchange of pipelines, and the volume of harmful fumes in production are many times higher than in residential, office or commercial premises - more powerful equipment is required. Another difference is that household ventilation systems often use plastic pipes, while industrial ones use galvanized metal pipes.

Metal ventilation pipes especially need protection from condensation. In the process of cutting into pieces of the required length, the galvanization layer is broken. Contact with moisture causes the metal to quickly rust, and the pipe becomes unusable within 2 to 3 years.

Fig.3 Industrial ventilation system

Basalt wool

basalt wool for chimney insulation

Composition of rock fibers in molten form. Mineral group insulation whose properties have been improved. Sold in the form of slabs and mats, like other varieties. Installation also involves the same actions as in the case of mineral wool. The chimney can be reliably protected.

Some manufacturers produce ready-made basalt fiber cylinders, which speed up installation. There is a foil coating, or the products are made without it. The price is higher compared to mineral wool. Cheap brands can be dangerous to the health of others.

The material has more advantages:

- High thermal insulation coefficient.

- Durability.

- Fire safety.

Aluminum foil on one side and special water-repellent compounds provide additional protection. Even the roof sometimes allows such insulation.

Foamed polyethylene

Outwardly it resembles foam rubber, but its cells are larger. Available in several varieties:

- Pipe insulation.

- Self-adhesive.

- Foiled.

- Ordinary.

Allows dismantling and reuse if necessary. Elastic and durable material that retains its original characteristics for a long time. Lasts up to 10 years and is easy to install.

The only disadvantage is melting when and ambient temperatures

Foamed synthetic rubber

foamed synthetic rubber

A material whose main function is to insulate pipes. 90% of the structure is closed pores. It differs from PPE in increased flexibility, although in appearance the materials are very similar to each other. Available in the form of sheets and rolls, mats and tubes. There are brands to which glue is added on one side.

Foam rubber has the following positive aspects:

- Low prices.

- No secretions containing harmful substances.

- Self-extinguishing material of high flammability class.

- Mold resistance.

- Moisture protection.

Styrofoam

A type of foam mass, including polymers or plastic. But the main volume in this case is occupied by gas. Allows the option when one of the sides is covered with foil. Rigid material with a release form in the form of slabs or pipe insulation. The only disadvantages are that it burns too easily and attracts rodents. This foundation has many more advantages:

- Low prices.

- Rot protection.

- Easy cutting and installation.

- Light weight.

Installation of insulation can be carried out using the principle of brickwork. To connect the elements to each other, a special glue is used; its usual varieties are not suitable.

Expanded polystyrene

insulation with polystyrene foam.

A type of polystyrene foam, only with improved characteristics. Differs in the following characteristics:

- Service life up to 5 decades.

- Operating temperatures from -50 to +75.

- During static bending, a high strength limit is observed.

- Over 30 days, the water absorption coefficient is 0.4%.

- Thermal conductivity is at a high level.

The installation rules, advantages and disadvantages largely coincide with the information that has already been provided regarding polystyrene foam.

Requirements for material characteristics

In order for the insulation to serve for a long time, not to become damp before its time, not to become moldy, and to perform all the tasks assigned to it, it must have the following qualities.

One of the most important characteristics is the thermal conductivity coefficient , expressed in W/m•°C. The degree of cooling of the air in the pipes depends on it. Manufacturers, taking into account different installation conditions, produce thermal insulation materials of various thicknesses and densities.

The table shows popular building materials used for thermal insulation of air ducts. Using the given data, it is possible to determine the dependence of the thermal conductivity coefficient on the density and thickness of the material

The second important parameter is vapor permeability . If the air ducts are prone to condensation, it first penetrates into the insulation and increases its moisture content, which increases thermal conductivity.

If for insulation you have chosen porous, fibrous materials that easily absorb moisture, take care of additional vapor barrier. The simplest option is to wrap the insulated area with plastic film

The next characteristic is acoustic efficiency . Air moves inside the ducts, causing vibration and noise. A running fan also creates sound waves. They are transmitted through the air and through the rigid structure of the air duct into the surrounding space and create discomfort for the residents of the house.

To reduce the noise level as much as possible, you need to think through the design features of the air ducts, make them straight, with a minimum number of turns. Noise can be significantly reduced by using sound-absorbing insulation.

Do not lose sight of such quality as resistance to biological influences . The less suitable the material is for the formation of mold colonies and the proliferation of various microorganisms, the longer it will last, and along with it the structure of other building materials - for example, wood or concrete - will be preserved.

Mold not only causes the destruction of natural materials, but also negatively affects your well-being. If you plan to place a living room in the attic, ensure normal temperature and humidity levels

For thermal insulation material, such a parameter as operating temperature . It differs for different insulation materials, but the average range is from -35°C to +60°C.

And one more characteristic - sanitary and hygienic properties . Thermal insulation should not distribute toxic gases harmful to health. From this point of view, materials that contain components of natural origin are valued - for example, felt or mineral wool.

PIR boards

PIR boards – ventilation duct insulation

New generation insulation, which is characterized by a rigid cellular structure. Both sides of the materials are covered with foil.

The positive aspects and characteristics are described as follows:

- Rot resistant.

- No risk of damage during installation.

- Low- and moderately flammable material.

- Service life up to 5 decades.

- 120 kPa is an indicator of compressive strength.

- No more than 1% water absorption.

- High thermal conductivity coefficient.

The question of choice is always decided in favor of external insulation. The reason is that the technology for carrying out work is too complex in the case of analogues.

thermal insulation of air ducts

Theoretically, work can be carried out inside and outside the system equally. But the outdoor option is chosen more often. The final quality of the material depends on the thickness of the layer. When choosing, you need to rely on several indicators at once:

- Temperature regime.

- Aggressiveness of the environment.

- Humidity, and so on.

The calculations are carried out by specialists, the formulas are given in the current SNiPs. The final result depends on a large number of factors, so it is not recommended to deal with the issue yourself.

Recommendations from experts

When choosing a suitable material for thermal insulation of a ventilation system, consider:

- The thermal conductivity coefficient should be as low as possible.

- Moisture resistance. The loss of insulating properties due to moisture absorption can nullify all the advantages of the material, including the low price.

- Difficult to install. The cost of specialist services depends on the danger of the material and the characteristics of its fastening. Insulating with cheap insulation can end up costing more than the highest quality insulation. If the work is supposed to be done independently, then the investment of time and effort is important.

- Fire safety class. This indicator can be decisive when choosing between two insulation materials with similar characteristics, if we are talking about a room with a high risk of fire.

According to experts, the best option for insulating vent pipes is foamed polyethylene. Foam rubber surpasses it in all characteristics and has no disadvantages.

Methods for insulating street air ducts

The thermal insulation design in this case must necessarily include the following components:

- Fastening elements.

- A covering layer that often requires additional UV protection.

- Thermal insulation layer.

The materials and operating rules repeat much of what is used inside.

If the installation is carried out outdoors, then you cannot do without waterproofing for mineral wool. An acceptable choice is roofing felt.

Special attention is paid to the place where the air duct passes through the roof. Master flash is the best option for isolation in this case. When passing through the attic floor, thermal insulation is also considered a mandatory requirement.

How is indoor air duct insulation performed?

insulation of air ducts indoors

Air ducts are often placed indoors, in this case insulation is also indispensable. The technology is not much different from projects that are carried out outside. The only difference is the absence of a mandatory requirement for the installation of an external protective layer. An exception is made only for aggressive operating environments and additional conditions that make the situation more complicated.

Most often, the materials are similar to those used for floors and walls. The air ducts are covered with a special membrane to provide waterproofing. Next comes the insulation, to which foil is added in another layer or a membrane. The first option is preferable; it helps create a kind of vapor barrier.

How to calculate the required thickness of insulation?

Surface heat transfer and thermal conductivity are the main indicators that need to be taken into account. Each material in this regard has its own characteristics that distinguish it from existing analogues. The lower the thermal conductivity, the thinner the layer required for installation.

Making the right choice of materials in accordance with the standards is not as difficult as it seems at first glance. But the installation of thermal insulation itself also requires a competent approach, otherwise it will not be possible to fulfill all the requirements. Before carrying out construction work, it is recommended to check the ventilation and its operation - is full power maintained, is there any contamination? No amount of insulation helps even if the pipes themselves were initially installed incorrectly. Then it is worth correcting the existing problems.

Advantages and disadvantages of ready-made insulated pipes

The main disadvantages are the price and a limited range of standard sizes. For large production systems, pipes may not be suitable. But in a private house, factory-insulated pipes make work much easier. The big advantage is quick and easy installation.

The considerable price is also a moot point: if you count the cost of installing a conventional pipe, its thermal insulation and labor costs, it will be more expensive. Another drawback is that such products are sold only in large stores, while penofol and shells made of PPU or PPS lie literally on every corner.