Every year the cost of utilities, be it electricity or hot water supply, is growing rapidly. Unfortunately, this is happening both due to the usual inflation and rising energy prices, and because of the banal greed of service providers. That is why today more and more people are looking for an alternative that allows them to reduce fees, which, apparently, will become simply unaffordable in a few years.

Autonomous boiler room in an apartment building

And many people find a solution to this problem. One boiler room per apartment building is able to fully satisfy the needs of all residents, providing them with high-quality heating, as well as supplying the required amount of hot water. However, installing your own autonomous boiler room is an extremely serious decision that cannot be made without thinking everything through and weighing the pros and cons a hundred times. And to do this, you should know both the pros and cons of this solution.

Main elements of the boiler

Many people who want to buy a water heater are wondering how the boiler works. The answer to this question is presented below.

So, the design of a water heater installed in houses and apartments includes the following elements:

- frame;

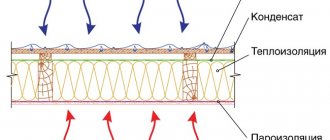

- insulating layer (responsible for ensuring that the liquid cools as slowly as possible);

- water tank (it is heated in it);

- FEC - a mechanism for heating water (the principle of operation is similar to a boiler);

- anode - the element on which all the scale remains;

- inlet pipe (it is connected to cold water);

- outlet pipe (connected to the tap from which hot water flows);

- safety and temperature control sensors;

- control panel, which includes control knobs and a display (not available in older boiler models).

Due to the fact that various kinds of microorganisms and mucus can form inside the water tank, it is recommended to select a model where the tank is made of stainless steel or has titanium coating.

For those who cannot afford a water heater in which the tank has the above coatings, they can buy a boiler in which the tank is made of glass porcelain. But the shelf life of this material varies from 1 to 3 years, since it very quickly becomes covered with microcracks.

Requirements for the boiler room (furnace) for a solid fuel boiler (wood, coal, pellets)

When designing and installing heating equipment, it is necessary to strictly follow the requirements of building codes and regulations for boiler and furnace rooms. Your peace of mind or even your life depends on it. Construction standards for the boiler room have been prepared for more than one year using the method of trial and error, fires and floods.

All solid fuel boilers (solid fuel) can only be installed in separate technical rooms - furnace rooms (for high-power boilers - in boiler rooms). Even before installing a heating system using wood or coal, you need to take care of how to build a boiler room (furnace room) for your home .

The requirements for a boiler room for solid fuel boilers (solid fuel boilers) influence construction decisions even before the design of the heating system, during the construction of the house, here are some of them:

- The volume of the boiler room is from 15 m3 + 0.2 m3 for every 1 kW of boiler power, but not less than 7 m².

- Naturally, the boiler room should be non-residential and separate with one entrance.

- A window is required for natural light at the rate of 0.03 m2 of glazing per 1 m3 of boiler room or furnace room.

If natural lighting cannot be provided, the boiler room must have electric lighting with illumination in accordance with SNiP II-4-79 “Natural and artificial lighting”. Additionally, there must be emergency electric lighting.

- The boiler room extension should be located near the blank part of the building wall with a horizontal and vertical distance from window and door openings of at least 1 m.

- The extension wall should not be connected to the wall of the residential building; these walls should have different foundations.

- The walls and floor of the boiler room must be sufficiently fire resistant. The boiler room is separated from adjacent rooms by fireproof ceilings and walls with a fire resistance limit of at least 0.75 hours, which means that the walls are left brick, or covered with ceramic tiles, or, in extreme cases, covered with a layer of mineral plaster.

- If the boiler room is on the ground floor, in the basement or basement, it must have direct access to the outside, and the doors should not have locks and not be locked while the boiler room is operating. The width of the entrance doors to the boiler room must be at least 80 cm. It is imperative to install a fire-resistant metal door with a fire resistance limit of 0.6 hours if an additional entrance to the boiler room leads into the house. The door from the boiler room to the house must be spring-loaded and open into the boiler room. The walls and doors are gas-tight (sealed). The door should open outwards.

- The ceiling height in the boiler room for solid fuel boilers must be at least 2.5 m.

- The construction of rooms and attic floors above boilers in a residential building is not allowed.

- The minimum distance from the front of the boiler (from the place where firewood is placed) to the wall is 2 m.

- Naturally, there should be free space around the boiler for free access, inspection and cleaning of the combustion chamber and smoke channels from ash and soot. The width of the passage between the boilers, or between the boiler and the wall of the boiler room is more than 1 m. The width of the passage between the protruding parts of the boilers and the protruding parts of the building is more than 0.7 m.

- It is also necessary to take into account the requirements for maintaining distances to the boiler from the manufacturer of these boilers (the manufacturer usually also takes into account the ease of installation, cleaning, operation and repair of their boilers.

- Periodically, the remains of fuel combustion (wood, coal, pellets, fuel brackets) - ash and slag - are raked out of the firebox, filled with water and taken out of the boiler room.

- Typically, the boiler takes air from the room, and not from the street, so the air in the boiler room is intended for combustion, and should not contain dust, chemically active or flammable materials with a strong odor (vapors of solvents, varnishes, paints). The appearance of dust in a working boiler room is unacceptable. Dust leads to soot deposits in the heat exchanger and reduces the efficiency of a solid fuel boiler.

Boiler design

In this diagram you can see the main elements of the boiler design.

A boiler is a device that heats and stores hot water. Structurally, it is a container of one volume or another, equipped with thermal insulation and a heating element. The water supplied to the tank is heated to a predetermined temperature, after which it can be used by consumers. The heating temperature is adjusted and maintained using a built-in thermostat. The maximum temperature reaches +70-80 degrees.

Most boilers have a pressure design. That is, the outlet water flows under the same pressure under which it is supplied to the unit’s tank. If the supply of cold water stops, then it will not be possible to get water from the storage water heater - it simply will not flow out of it. Thus, the water in the tank is under constant pressure (increasing with heating).

How does a boiler work and what components will we find in its interior?

- A tank with a protective coating is the basis of any storage water heater. Tanks are made of metal and coated with enamel or glass-ceramics to prevent corrosion. Tank capacity varies from 10 to 300 liters;

- Heating element – inside boilers we can find one or two heating elements. They are responsible for heating the water (in gas boilers this function is performed by the burner);

- Thermostat – provides support for the set temperature (mechanical or electronic adjustment is used);

- The control panel is hidden or open, it is used to set the temperature;

- Thermometer – provides control of the temperature of the water in the tank. The thermometer can be mechanical or electronic.

The design of boilers is extremely simple, and the main volume is occupied by massive tanks of varying capacities.

Varieties

Today, the Russian domestic market offers a very large selection of electric water heaters of different types and types with different price ranges, while the build quality and individual parts can vary greatly. The electric instantaneous water heater has long enjoyed well-deserved popularity among users in different regions of the Russian Federation due to its simple operation. They are divided into two main types:

- pressure or closed type;

- non-pressure - open type.

The first option is capable of supplying hot water to several points at once: a washbasin, a shower stall, a kitchen, but for this it is necessary to ensure a fairly high pressure in the home water supply line.

The second option functions normally at any pressure in the main line with a connection directly to the water intake point.

Boiler device for heating water, depending on the type

Such devices are of electric and gas type. As for the design features, the product consists of a tank into which water is collected, as well as thermal insulation and an external housing on which a control panel is installed.

Installed inside:

- Heating element or, in other words, heating element;

- Special magnesium anode;

- Thermostat;

- Special pipes.

An indirectly heated water heater is installed in an apartment building or private cottage, which has autonomous water heating, with permission to install a single-circuit boiler. The temperature inside the indirect heating tank increases not through exposure to the energy source, but as a result of heat exchange with the heating circuits.

The device has its own heat exchanger in the form of a coil.

It is located along the entire length of the tank or can be located in its lower part. Each of the two heat exchanger pipes is connected to the heating boiler. The coolant installed in the boiler moves through the heat exchanger, and due to this, the water in the tank is heated (due to a process such as heat transfer).

The removal is carried out through a special pipe that directs water into the boiler. As a rule, one heat exchanger is installed, but there are models with several heat exchangers. In this case, it is permissible to connect the equipment to a gas boiler and similar sources.

An indirectly heated boiler can be without a coil; such designs are called “tank in tank”. In other words, there is another tank installed inside the tank. Heating of water suitable for use occurs in a tank, which is located in the very center of the product.

Combined models are a combination of two previous models in one. They come with indirect heating, however, they have a heating element installed in the tank cavity, through which the product can be used as a storage electric boiler.

How to choose equipment for a boiler room

People who at least once in their life are faced with the selection and purchase of heating equipment know very well how extensive and complex the complex a heating boiler is. So if you need a boiler room on the roof of a multi-storey building, it would be better to turn to specialists.

Experienced engineers will be able to carry out all the necessary calculations. This takes into account the average winter temperature, as well as monthly minimums, wind intensity and direction, insulation of apartments, wall material and thickness, type of fuel used and much more. As a result, they will select a boiler of suitable power, as well as the appropriate equipment, so that each of the apartments is warm and cozy all year round.

What is a furnace or boiler room?

It is not difficult to guess that a boiler room is a place where a boiler is installed to heat water. There are special requirements for this room. The finishing must be made of non-combustible material. There must be excellent ventilation. Heating radiators are installed in the boiler room. Connection of devices is carried out only according to the rules, so that safety is observed in all respects.

Electric water boilers are sold in a wide range and it is possible to purchase different equipment, choosing according to parameters such as:

- Dimensions;

- Power;

- Tank capacity;

- Type of location.

Electric types of heaters differ from gas ones. It is designed differently inside and does not work like a gas one. To be more precise, it has a different structure of the heating element, and this is a heating element.

Only he is responsible for how quickly a certain amount of water can heat up and to what temperature.

Tens come in dry and wet types. Dry ones are placed in an additional capsule, and heating by such an element takes much longer. A special temperature sensor must be installed near the heating element, which controls the operation of the electromechanical or electronic thermostat. This ensures that the water temperature is maintained at a given level. When the liquid cools, the temperature sensor is triggered and automatic heating of the contents of the tank begins.

Project

The requirements for installing a gas boiler room in a private house imply compliance with a number of standards. The project is carried out by a specialist who has permission to do so. When creating a project, a thermal engineering calculation of the room is carried out, equipment is selected and drawings are made, the solutions are described in a note. The result is submitted for approval.

Design requirements:

- room parameters, its placement;

- heating mode, possibility of installing program control;

- type of energy carrier and equipment.

The project is submitted for approval; additionally, a technical passport for the device, its certificate of technical requirements, instructions and a sanitary certificate are provided. If there are no requirements, then it is certified with a seal and then transferred to the customer, otherwise revision is required.

Option for heating and hot water supply scheme Source 3agorod.ru

Simple design of a gas boiler

The boiler is controlled by a temperature sensor and thermostat. They are responsible for fixing a certain level of water temperature, and as soon as the heating reaches the desired level, the system automatically turns off. Gas boilers are equipped with a safety group or, in other words, a special safety valve that relieves too high pressure. This prevents the product from exploding and similar consequences. To prevent scale formation on the product, a magnesium anode is also installed in it, which needs to be changed over time, as it is destroyed due to exposure to salts in hard water.

Boilers can be of different types, types, shapes and even installation methods, but the requirements for their purchase are on average the same, since you need:

Inspect the body for integrity; Pay attention to the availability of certificates for compliance with GOST; Buy products only at specialized sales points; Be sure to check the terms of the warranty.

DIY water heater installation

Diagram of the connected water heater.

Instantaneous water heaters are much easier to install yourself than storage water heaters. To do this, you just need to install a special machine and lay a powerful three-core cable directly from the switchboard. Installation is carried out in 2 options:

run the cable under the baseboard or groove the wall, and after laying the cable, seal it with cement or putty.

From the tool you may need:

- perforator;

- screwdriver;

- drill;

- spanners;

- pliers.

Installing a storage water heater with your own hands can take from 2 to several hours. First you need to calculate exactly how much tank volume you will need. This must be done to understand exactly how the water heater should be mounted.

Thus, tanks with a volume of up to 100 liters can be hung on the wall, but with a volume of more than 150 liters they must be placed on the floor.

According to the rules, the tank of a storage-type water heater must be located at least 30 cm above the floor. The most convenient mounting location in the apartment is above the toilet in the toilet.

Water heater design diagram.

Everyone chooses the specific height themselves, based on their height and the height of their family members. Installation of such a water heater may require several people (at least 2).

Tanks are supplied for sale with the necessary fastenings: anchor bolts - 2 or 4, depending on the type of water heater.

- Therefore, when installing it yourself, first be sure to attach the anchors to the wall according to the instructions. The required distance, if not specified, is calculated from the notch on the rear of the tank.

- The main thing to remember when installing a storage water heater with your own hands is that the wall must be load-bearing. If the wall crumbles when drilling, you need to take longer anchors.

- When a tank is not secured securely, there is a high probability of its collapse. Who wants to change the toilet with their own hands? So the installation should begin with checking the complete configuration of the storage water heater.

Connection diagram of the cold water line to the water heater.

Storage water heaters have 2 special outputs: red and blue. This is for cold and hot water respectively. The included safety valve is attached to the blue hole. It is necessary for the proper operation of the water heater: this valve is responsible for releasing excess pressure in the tank.

2 special ball shut-off valves are attached to the red outlet from the tank and to the check valve of the blue outlet. The tank can be attached to the water pipes and mixer using metal-plastic pipes or using a flexible line of the required length.

If, when installing with your own hands, you decide to go with metal-plastic pipes, you should remember 2 mandatory things:

- You cannot bend such pipes;

- you need to carefully select pipes. Thus, seamed metal-plastic pipes are suitable only for cold water, while seamless pipes are required for hot water.

- If you plan to install and use a flow-through heater in an apartment, then, as noted above, it will require a three-core cable.

- A gas instantaneous water heater is not yet the most common occurrence in a modern apartment. And since you will have to deal with the gas main, it is better to invite a specialist to properly install and connect the gas device.

Whatever option you choose, the main thing will be the uninterrupted availability of hot water, which will undoubtedly make the life of any person much easier.

We study the structure of the boiler: 4 internal elements.

Boiler design for heating water

The design of the boiler includes elements for heating water, which are divided into the following types:

- Located in water (they are called open or wet).

- Elements that do not have direct contact with water (they are called closed or dry).

Wet water heating elements are quite familiar to us and resemble tubes placed in a kettle. They are hollow and contain a heating coil. Empty space is usually filled with special magnesium oxide or sand. The substance can be anything, the main thing is that it has high heat conductivity.

Dry water heating elements are separated from contact with water by a special ceramic casing.

This type is considered safer due to the following points:

- no scale occurs;

- the risk of a short circuit is practically zero;

- accidentally turning on the device without liquid does not spoil this type of heating elements so much;

- the service life is much longer.

In addition, these elements differ depending on the type of fastening; they are nut and flange. In the second case, pressing occurs with a large number of small bolts.

Storage water heaters

Water heater installation diagram.

They are often designed in the form of a tank filled with water. Water is poured into it, after which it is heated to a preset temperature.

Such heaters are equipped with a special air layer that prevents the water in the tank from cooling quickly. So, having heated the water in the morning, you can use it throughout the day or until it runs out. Devices must be constantly connected to the network.

Due to the operation of the thermostat, the water in the tank always remains heated to a certain value: when the water cools down to a certain temperature, the heating element turns on.

The boiler of this device is usually installed either in the bathroom or in the toilet. Storage water heaters are attractive because they consume little electricity. However, you will have to rack your brains about where to place the volumetric tank, and wait at least 1-1.5 hours until the water in the tank heats up.

Using what criteria to choose

There are 3 main criteria for this process:

- Volume. You should not set the device to the maximum value for this value. This may lead to financial difficulties in the future. Since a container of sufficient volume will use more water, the bill for its consumption will be higher. It is worth remembering that the larger the volume of the installation, the more it will come into contact with the coil, which can lead to heating of the coolant.

- Power. This criterion affects water heating. For a full heating process, a water heater with an indicator of 8-12 kW is suitable.

- Diameter. This criterion depends on the area of the room where the device is installed.

What is an indirect heating boiler?

To heat water, indirect heating boilers use heat from the home's heating system.

A little higher we looked at the design of an electric water heater. Now we will talk about indirect heating boilers. What are they and how do they differ from electric models? Indirect heating boilers operate from heating systems, taking some of the heat from them. Inside them there are coils, characterized by a large area - they provide rapid heating of water. There are also thermostats and thermometers.

Indirect heating boilers are highly efficient and productive, since the area of the heating elements (coils) is quite large, and heating is carried out throughout the entire volume. How to get hot water in the warm season, when heating systems no longer work? To do this, you need to purchase or make an indirect heating boiler with a built-in heating element - it will provide water heating when the heat from the heating system is not enough.

Household indirect heating boilers are highly economical, since in the winter they do not consume electricity, but are powered by heating systems. At the same time, connecting them to heating does not lead to noticeable gas consumption, which is a big plus.

Reasons prompting the developer to choose an autonomous heating system for the house:

- Lack of engineering infrastructure for the development site;

- The distance of the object from city heating plants, but the presence of a gas pipeline nearby;

- Capacity shortages and inefficiency of the central heating system;

- Difficulty and/or high cost of coordinating technological connection to existing networks;

- The density of buildings in the central regions interferes with the work on laying heating networks;

- The development area, free of heating mains, allows for the creation of attractive recreation areas, parking spaces, and children's playgrounds.

In addition, the presence of an individual boiler room is presented by developers as an additional advantage for potential clients and allows them to position the property as comfort-class housing.

Some characteristics

So, before you start installing water heating devices with your own hands, you need to figure out which one is right for you in terms of all its characteristics.

Today there are several types of water heaters on the market:

- accumulative;

- electric flow;

- flow gas type.

Of these, each buyer chooses solely according to his preferences. As a rule, a big role is played by how often and how many people will use a particular water heater during the period when hot water is turned off.

If it’s just one person and not very often, then you can install a flow element for yourself. But if at this time there will be 3 or more family members living in the apartment, then the storage accessory will be the best choice.

For final heat consumers

Advantages of apartment heating:

- Ability to regulate the temperature in the apartment;

- With constant attention to gas equipment, compliance with all operating rules and clear accounting, savings are possible.

Disadvantages of apartment heating:

- High costs for repairing gas equipment or replacing the boiler after the warranty period expires;

- The need for constant monitoring of the serviceability of the gas equipment used;

- The need to independently organize repair and maintenance work related to the operation of gas equipment and chimneys;

- Unheated driveways and basements;

- In the absence of permanently living neighbors, their apartments are not heated, and accordingly increased heat loss;

- Increased risks of accidents due to improper operation of equipment (by any of the residents).

Advantages of a modular boiler room:

- Guarantee of stable heat supply;

- Complete absence of operational concerns related to heat generation and gas facilities;

- Low cost of repairing boiler room equipment, per apartment;

- Heat in common areas;

- Increased safety guarantees due to the planned routine maintenance work.

Disadvantages of a modular boiler room:

Inability to completely turn off the heating in the apartment (eliminate heating fees).

Principle of operation

How does an instantaneous water heater work? A stream of water passes through a relatively small product, heating it to the desired temperature. The heating element is used of a standard type or in the form of a heating coil. In volumetric devices, the first option is always used, and in miniature ones, the second option, because there is simply nowhere to insert the heating element.

As soon as the tap opens, the heating element turns on, the water flow heats up, and when the tap is closed, the power supply to the product is turned off. The principle of operation of an instantaneous water heater is based on the fact that the temperature of the water flow set by the user is gained in a short time, and then only with the help of the heating element is kept constant. Externally, an ordinary electric instantaneous water heater looks like a small plastic container with a connection to the home water supply.

When an instantaneous electric water heater is used as a separate hot water tap, its operating principle becomes even simpler: the water flow is instantly heated by a powerful spiral enclosed in a copper housing.

Features of the boiler video

Having studied the above, you can be sure that the equipment is in good working order and will last for a long time, without causing problems, much less consequences in the form of an explosion of pipes and a tank, which can cause the destruction of an entire room and entail far from small expenses.

4 questions about placing a water heater in the interior.

Choosing a location for a water heater in your home depends on your hot water needs, the layout and size of the room. This is a responsible matter that requires an engineering approach and correct calculations.

1 Floor or wall? If the volume of a storage water heater exceeds 200 liters, it is better to consider a floor-standing option. In such tanks, thicker steel is used and a copper heating element is installed, which is not subject to corrosion. Floor heaters, as a rule, are used in country houses, where both the needs and possibilities (at least in terms of placement) are higher than in a city apartment. Small wall-mounted water heaters with a volume of 50-80 liters are usually installed in apartments to compensate for the shutdown of hot water.

Horizontal or vertical? There is an opinion that in horizontal water heaters the water warms up worse: due to convection, it is warmer at the top than at the bottom. However, experts reassure us that we are talking about fractions of a degree. But the horizontal model can be built into small rooms where it is not possible to place a vertical water heater, and almost anywhere - for example, hung above a doorway. Some manufacturers produce universal water heaters that can be hung both vertically and horizontally. The heating element in such systems is located at an angle, so that the water will warm up evenly in any case.

3 Why is a flat water heater convenient? Another solution to the problem of limited space is to choose a flat-mount water heater, which takes up less space than conventional storage units and is sleeker in appearance. Alas, energy efficiency is often sacrificed for aesthetics: the size of the tank can be reduced due to the thermal insulation layer. To understand whether the tank is sufficiently insulated, place your hand on the body - if it is warm, then the thermal insulation is not working, if it is cold, everything is in order. Good thermal insulation cannot be less than 40 mm thick, and better - from 60 mm.

4 Where to install the water heater? General rule: the distance from the body to the disassembly points (taps) should be minimal. Firstly, it reduces heat loss, and secondly, you will have to wait less for hot water. In a city apartment, the water heater is usually installed in the same room where the disassembly takes place: in the bathroom or kitchen. Another thing is a big house. In this case, the system must be designed by a specialist who will find a location taking into account the layout, calculate the length of the pipes and the required volume of the tank. If water heating is not “tied up” to the operation of boiler equipment, it may be advisable to place the heater in the attic. If the house has boiler rooms where all communications are located, it is also convenient to install a water heater there. It will be out of sight, but at the same time available for preventative maintenance and repair.

Disadvantages of modern heating systems

As with any heating system, an autonomous one has its drawbacks. Although there are much fewer of them compared to the centralized one. Due to the fact that gas autonomous boiler houses are not widespread, it is quite problematic to obtain reliable equipment and all the components adjacent to it.

Therefore, boiler room elements will cost customers a tidy sum. Despite the high level of comfort that the systems in question provide, not all developers are willing to pay a lot of money for it.

In the event of an emergency, the entire heat supply system completely fails. There is up to five cubic meters of boiling water above people's heads. If the pipes burst, the water will flow down. That is why there are so many requirements for gas equipment

In addition, gas boiler rooms must be located in separate rooms or buildings. To do this, you need to allocate an area near the house, bring the roof to the required technical conditions, or install a block structure on the roof. All of these solutions require an infusion of additional resources either from the developer or from a common fund created by residents.

Gas heating systems release polluting decay products into the environment. Therefore, when installing boiler rooms, it is necessary to provide for the installation of filtration systems. Cleaning devices must perform their functions sufficiently to comply with SNiP standards. This further increases the cost of purchasing equipment.

When building a new house, the developer has a choice: to build an autonomous heating system or connect to the central highway. In order to crash into a highway, you need to obtain a number of permits. Often, resolving a problem requires a large sum of money. In addition, you will need to wait more than one month until the papers are checked by all authorities.

The high cost of connecting to existing networks, difficulties in coordinating this procedure, as well as the presence of many obstacles that impede the rapid and efficient installation of heating networks reduce the attractiveness of autonomous systems for developers.

Often the installation of gas boilers on the upper enclosing structure entails the need to strengthen the ceiling. The total load created by the heating system can reach 15 tons. Such values can be avoided by installing flow-through equipment instead of capacitive

Installing autonomous heating is also associated with a number of bureaucratic procedures. Both the initial implementation of systems and reconstruction with redevelopment have their own characteristic features. This is mainly due to the fact that you are going to use gas as a heating resource. All work with gas is strictly regulated by law.

Modern engineering developments effectively combat a number of shortcomings. If you need to heat just one house, an excellent option would be to place a block boiler room in the attic of the house. The attic becomes heated, and residents of the top floor do not experience discomfort.

Such structures are developed in detail by engineers, are lightweight and are installed on load-bearing walls. For such options, a flat roof option is required. This subtlety is usually taken into account at the design stage. Designers carry out calculations and determine in advance the location for the boiler room on the roof of the house.

The law sets a limit on the power of equipment on the roofs of 3 MW. Some regions have a 5 MW limit. If such power is not enough to fully heat the entire house, then additional permits must be requested

However, despite all the shortcomings, ultimately, the residents of the house will significantly improve their living conditions and get rid of discomfort. In addition to all the obvious advantages, autonomous systems have an increased level of security.

The new systems are equipped with threat and emergency alarms. A variety of sensors for gas boilers monitor many indicators. In the event of a breakdown, the backup boiler and additional pumps are activated.