Silicone sealant is a universal composition that you cannot do without during installation for interior and exterior work. Often the deadlines are extremely tight and commissioning of equipment does not require delay. But before the materials have fully gained maximum strength, it is not recommended to subject them to loads. Therefore, you need to clearly find out how long the silicone sealant takes to dry.

How many degrees does the sealant withstand: features, surface preparation for application

Like any other material, sealants should never be applied to an unprepared surface. This will not only disrupt the adhesive properties, but will also significantly reduce the temperature conditions that the material can withstand.

First of all, the object being treated is completely cleaned of any contaminants and any remaining old paintwork. But that is not all. It is also necessary to use special detergents and solvents. After this, you should use the following substances:

- solvent;

- gasoline;

- xylene;

- universal degreaser;

- solvent 646;

- acetone.

Should the operations be carried out outside the structure? Then you need to take care to protect the object from dust and dirt. To do this, you need to use masking tape and cover the entire surface to be treated with it.

When working with smooth materials, you should initially use sandpaper. Next, clean the surface of any remaining abrasive elements and then degrease with the above-mentioned substances.

Advantages and disadvantages

Fireproof sealants have a number of advantages that set them apart from materials with similar purposes:

- resistance to high temperature action, no burnout (for a number of products),

- high degree of adhesion to most building and finishing materials,

- absence of hazardous substances in the composition, release of toxins when heated,

- dielectric properties,

- absence of deformation, cracking due to elasticity,

- the ability to withstand vibration, UV radiation, radiation exposure, the influence of moisture, detergents, microbial activity,

- long period of operation (up to 40 years),

- Availability of convenient shapes and various volumes on sale.

The disadvantages include the increased cost of such products compared to conventional sealants, but this is compensated by a lot of advantages.

How to use silicone sealant

It is not recommended to carry out events in any order. Each action must be carried out gradually. Thanks to a responsible approach, you will not have to redo the entire range of work, and you will get exactly what you want.

Algorithm for using silicone sealant :

- Initially, the spout of the cartridge with the material is cut off and the nozzle is screwed on top. The cylinder itself is inserted into the gun, and the metal tube is pierced with the back of the cap. ;

- the place of contact of the sealant with the surface is wetted with water;

- the substance itself is evenly and slowly squeezed out of the container. At the same time, you need to ensure that the material lies evenly and completely fills the seam or crack;

- Remove any remaining sealant with a damp viscose cloth or other product. Alternatively, you can use a soft cloth.

It is worth noting that each type of sealant has its own polymerization period. For example, one hardens within a day, and the second only when used in a certain humidity range. Detailed information about the specifics of a particular type of product is indicated on the packaging.

Note: It is necessary to carry out work on filling the seam with sealant only in a certain temperature regime. Work is carried out in the range from +20 degrees, but in some cases the mixture can be used at lower temperatures - up to +5 inclusive.

How long does it take to dry?

Primary setting, that is, the period of film formation on the surface of the substance, for any chemical composition is 20–25 minutes. Further curing occurs in different ways, the speed depends on the components:

- Thus, the acidic version of the solution gains maximum strength within 5.5–7 hours.

- The neutral silicone mixture needs at least 24 hours.

The drying time of silicone sealant is influenced by the following factors:

- Layer thickness and depth. The thicker the seam, the longer it will take to dry. If you have applied a layer of sanitary agent and it begins to set, do not put another layer on it. It will not provide additional protection, and the layers will separate from each other.

- Humidity and temperature. The standard time for curing the solution is indicated by the manufacturer on the packaging. This indicator is determined during tests at temperatures from +18 to +25˚С and relative air humidity of 75%. If the temperature is lower and the humidity increases, the drying rate will be faster.

The temperature of the silicone substance itself also plays an important role in determining the drying time. If the solution was stored at sub-zero temperatures, then before application it must be kept at room temperature for 24 hours.

High-temperature sealant: characteristics, types of work

Immediately after polymerization, silicone creates a hard layer of material. However, it does not lose its elasticity. The consistency of this product resembles rubber.

It is worth noting that the peak temperature regime of high-temperature sealant is at around 250 degrees. However, some manufacturers strengthen their products and set them from 280 to 300 degrees.

Oven sealants, unlike automotive sealants, are chemically neutral and do not emit odors. Due to their elasticity, they are resistant to environmental influences. The peak thickness of the created layer, as well as other characteristics, is indicated on the packaging of the material.

It is worth noting that such products, due to their technical characteristics, have a limited range of applications. They are widely used for:

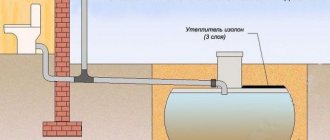

- sealing cracks in brick chimneys;

- effective sealing of connecting materials to the pipe;

- installation with further sealing of chimneys, including sandwich panels and boilers.

Sealants operating at high temperatures are divided into two classes. The first has heat-resistant characteristics, and the second is notable for its high-temperature products. The latter have a striking difference - red color. This is due to the high content of iron oxide.

Regarding the maintenance of stoves and chimneys (D), high-temperature silicone sealants are used to connect D and seal small external cracks. Like any silicone, the high temperature grade is different:

- increased elasticity;

- enhanced hydrophobicity;

- resistance to various chemicals.

They can also be either acidic or neutral. The first type has limited specific use, and the second is universal.

Requirements for fireproof sealing of seams

Any fireproof sealant is manufactured in accordance with existing state standards, technical specifications, norms and other documents regulating production. Each product must receive a certificate of conformity, which is awarded after passing tests for resistance to heat, fire, etc.

The list of requirements for fire-resistant sealants is specified in the PPB SP "Fire Protection", and additions to them are reflected in Art. 87, 88 Federal Law No. 123. The main requirement for water-gas-tight fireproof sealants is the ability to localize flames, limit the spread of fire, and maintain the integrity of fire partitions. As indicated in the regulatory documentation, fire-resistant sealants are used for fire protection purposes. Here are the main ones:

- sealing joints of pipes and ceilings,

- sealing seams between wood and metal structures,

- cable protection when laying electrical wiring,

- strengthening the tightness of fire-resistant double-glazed windows,

- installation of ventilation systems, air ducts,

- joining floor slabs together,

- sealing various seams in fire compartments,

- waterproofing of premises, roofs.

High-temperature sealant: specifics of use, characteristics

The main feature is its use for sealing furnaces. It is worth noting that the latter is a single mechanism, which is notable for the complete calculation of each element.

During operation and over time, various cracks and holes begin to appear in parts of the furnace. They violate the sealing of the walls and the combustion chamber. Because of this, there is a significant deterioration in draft, and the smoke, which is a by-product, passes into the room, poisoning it and harming the body.

Important : Depressurization has serious consequences. Carbon monoxide not only poisons the body, but can also cause a fire. Therefore, at the first appearance of cracks, it is necessary to carry out urgent repairs to the furnace.

Previously, discovered cracks were sealed with clay mortar. However, it gives only a temporary and far from the most reliable effect. That is why it is necessary to use specially designed products for this purpose - high-temperature sealants.

It is worth noting that self-extinguishing fire often occurs in metal or sandwich chimneys. This occurs due to a leak in the gas boiler. Also, this problem most often occurs in units that use gas as fuel. Subsequently, depressurization will cause irreparable harm not only to the unit itself, but also to the structure as a whole - a fire hazardous situation has arisen in which an emergency cannot be ruled out.

Application area

Quite diverse, because fire-resistant sealants are actively used:

- When finishing stoves, fireplaces, installing heat generating units;

- For sealing connections of parts, parts of engine units of various vehicles - from a car to a diesel locomotive, which is also facilitated by their resistance to contact with fuels and lubricants;

- For fire protection of electrical routes in places of cable penetrations through fire barriers, at entries into process equipment housings, into distribution cabinets;

- For sealing joints and leaks in the manufacture of fire-resistant windows, doors, transoms filled with fire-resistant glass;

- When installing ducts of ventilation units, including those included in smoke protection systems.

And also in other situations during assembly, repair of equipment, in construction, when an elastic, tight connection of joints and seams is required, resistant to high operating temperatures and contact with fire.

Tools for careful use of high temperature sealant

For the most effective application, use the following products:

- mounting gun or medical syringe;

- a special spatula made of rubber;

- knife;

- gas burner;

- masking tape – it must be used when interacting with any type of sealant;

- personal protective equipment – rubber gloves.

If the material is in a tube, then there is no need to use a construction gun, and if it is in a tube, there is no need to prepare a burner.

Sealing between bricks requires maximum responsibility and care. To avoid the product getting on the surface of the brick, the object being processed must be sealed with masking tape. For the best possible work, the following recommendations must be taken into account:

- regarding the placement of masking tape, it must be installed in such a way that it is located completely along the seam line;

After this, you should carefully and completely fill the seam with sealing paste. A rubber spatula is used as necessary to level the layer.

After the material has polymerized, the masking tape is removed. The latter allows you to maintain the original width of the joints without spoiling the neat appearance of the brickwork.

- it is not necessary to use masking tape;

In principle, this problem can be solved in another way. When preparing the tube, you do not need to immediately cut its nose. It is enough to make a small cut at an angle - the size should be 3 mm smaller than the width of the seam. However, this method requires maximum qualifications as there is always a possibility that the sealant will stain the object.

Is the composition harmful after drying?

Since the silicone solution contains solvents in the form of alcohol or acid, a chemical odor will be felt when working with the mixture. The neutral type of insulation ceases to smell of alcohol after complete drying.

The acidic solution will smell depending on the size of the room and ventilation. If the room is small and there is no constant flow of fresh air, the vinegar smell can be felt for 2-3 weeks.

When applied in liquid form, the mass can cause irritation and allergies if it comes into contact with the skin. You may also experience dizziness, nausea, or headaches if you work without a respirator in a closed room without ventilation.

After the substance has completely dried, it becomes harmless to human and animal health. When the temperature or humidity rises, it does not release harmful chemicals onto surfaces or into the air.

High temperature sealant application process

First of all, you need to cut off the sealed cap from the cartridge with a sharp knife - this is what closes the tube. In this case, it must be cut across its entire width. Then the following range of activities is carried out:

- the spout is screwed on - it must be pre-cut, as indicated above in the article;

- then the tube with the material is installed in a construction gun - its preparation should be carried out based on the features of its design;

- after all of the above, proper preparation of the surface for further work begins;

The object is thoroughly degreased, cleaned of dust, dirt and residues of building materials. If the surface is extremely smooth, then it is pre-treated with sandpaper. This step will provide enhanced adhesive properties. After sanding, you need to clean the surface from any remaining abrasive material.

Then the surface is degreased and dried. At this stage, it is advisable to use a hair dryer as it will speed up the work.

- after the surface has dried and additional checks, you can begin applying the sealant;

- When using high-temperature sealant, the latter must be allowed to harden. As a rule, the time required for complete hardening is around 24 hours.

After application, it is necessary to burn the material with a gas burner. By implementing all of the above measures, you will ensure sealing that can withstand high temperatures up to +1500 degrees inclusive.

Now you can safely use the stove and not be afraid of the risk of an emergency - it is completely eliminated by high-quality sealing.

Purpose

Fire-resistant are considered types of sealants that, due to their physical properties, are able to withstand operating temperatures exceeding 200℃ for a long time; short-term – up to 1300℃, including direct contact with an open flame; at the same time thermally swelling, maintaining the tightness and elasticity of the compounds they protect.

The purpose of thermally resistant materials is to ensure the tightness of connections under harsh conditions of prolonged high-temperature exposure, short-term contact with open fire, and often simultaneously with an aggressive chemical environment.

Application of fire-resistant sealant