Gutter systems made of metal attract with their undeniable strength and durability, due to the authoritative characteristics of the source materials. A considerable number of owners of country houses give them unconditional preference, despite the lightness and economic availability of polymer competitors.

Plus, installing metal roof gutters with your own hands is not difficult at all. However, for a successful result you need to know all the intricacies of the technological process.

Methods for draining water from the roof of a country house

The main goal that is pursued when organizing drainage for a country house is to drain water in such a way that walls and blind areas do not flood and puddles do not form on the site. A gutter for a dacha is chosen based on the structural features of the roof, aesthetic preferences and financial capabilities. There are three main ways to drain water

:

- organization of water drainage using pipes and gutters

; - using a chain

instead of a pipe to drain water;

Non-standard solution for drainage Source muratordom.com.ua

- use of overhead gutters

on the roof eaves.

The most widespread method of draining water is using pipes and gutters. Let's take a closer look at its features.

Roof mounting technology

Involves installing gutters on brackets:

- to the rafters;

- on the front board;

- to the edge of the roofing material;

- using additional brackets.

Let us examine in what cases it is advisable to use different types of installation.

To the rafters

Fixing the drainage to the rafters is carried out when the sheathing has already been covered with roofing material, but it is also allowed before laying corrugated sheets, slate and various soft flooring.

The fastening element is brackets with a long leg bent at a right angle.

When the roof is covered, you will have to tear off or unscrew the last row, if it is slate or metal tiles, in order to secure the drainage system to the last row of the sheathing, the rafters. When using soft tiles or ondulin, simply lift the last row to tighten the bracket.

This method is used if the cross-section of wooden rafters is from 180*50 mm.

When fastening, the roofing material must cover the gutters.

On the front board

The front board is mounted at the ends of the rafters. Width may vary.

Fastening is carried out with long brackets or hooks made of a guide metal profile and a bracket.

Special long planks with a groove are also produced. The plank is screwed to the board with self-tapping screws, and brackets fit into the grooves.

To the edge of the roof covering

In this way, the drainage system runs along the eaves of the roof. Used when a rigid material such as corrugated sheeting has been selected for the flooring.

To fasten the brackets (plastic or metal), you will need special clamps.

There are times when you cannot do without holes in the roof. Then it is recommended to put rubber gaskets under the metal clamps (if any). This way there will be less chance of damage to the roof.

Using an additional bracket

Installation is carried out when the roofing is completed. The risk of material damage is minimized. Also, additional brackets will be required if the main brackets for fastening the gutters are short.

Take a long bracket and simply bend it to the required length, fix it with a self-tapping screw to the wooden sheathing.

It is important to maintain the required distance from the center of the holder to the edge of the overhang. The recommended value is 30–40 mm. This will allow water from the roof to flow into the center of the gutter. Otherwise, water will overflow over the edges.

Types of drainage systems

There are a huge number of options for drainage systems, which differ in size, material from which they are made and the manufacturer. The choice of one option or another depends on financial capabilities. Let's look at the main types of drainage systems.

A drain made of metal in a polymer film is the most reliable, but at the same time the most expensive option. In the manufacture of its elements, steel with a thickness of 0.5-0.8 mm is used, which is coated on both sides with a special polymer. This ensures that the operation of this drainage system is possible in any climatic conditions; in addition, the wide range of possible shades of the film allows you to select the desired shade that is ideal for the building. The main advantages of such drainage systems are their following qualities:

- long service life

, during which the original shape is not deformed; - high strength

;

corrosion resistance

Metal with a polymer coating has increased resistance to corrosion Source arttn.ru

Another option for a drainage system is a system made of galvanized metal 1-2mm thick. The main advantages of this type are low price and ease of installation. It should also be noted that elements of this type are resistant to mechanical damage and temperature changes.

Plastic drainage systems have gained particular popularity recently. Installation of such a system is quite simple, in addition, it is resistant to corrosion and ultraviolet radiation, as well as a long service life.

Recently, homemade drainage systems have become common. Their main advantages are minimal cost, speed of assembly and the absence of any technology. Disadvantages include low quality, unpresentable appearance, low functionality and the need for periodic repairs.

Homemade metal gutters

It’s easy to make a gutter with your own hands from galvanized steel. However, difficulties arise if you try to make a gutter of the same length as in factory production (3-4 meters).

To manufacture a four-meter part, you will need appropriate technical equipment, which is usually not available in everyday conditions. Therefore, the standard length of homemade gutters, as a rule, is no more than 1 meter.

A clear example of making a simple drain for a private house from a galvanized steel sheet and steel brackets. The system is made by yourself

Oval gutter production technology:

- Take a sheet of tin 1 m long and 0.5 m wide.

- Place a piece of sheet on the bench.

- Take a metal pipe of suitable diameter.

- Bend a piece of sheet onto the pipe by straightening it with a wooden hammer to a semicircle.

- An indent of 10 mm is measured along the long front edge.

- Bend the edge line at an angle of 90º.

Then a second fold is made on the trailing edge, cutting off the excess sheet.

To make tin gutters yourself, you need a long, wide bench and a set of simple tools. Tinsmith skills preferred

Rectangular gutters are made in approximately the same way. Only for straightening use an angular metal blank.

Scheme for making a rectangular gutter for a drainage system for independent practice. An example of a product made by hand at home

It is even easier to make rectangular gutters, as well as to prepare shaped parts for them. Therefore, it makes sense when choosing a technology to focus on rectangular gutters.

Video description

How to organize drainage in a country house from sewer pipes is shown in the video:

See also: Catalog of companies that specialize in the installation of water supply, sewerage, drainage and drainage systems

Drainage systems differ in the shape of the pipe section: round and square. Round ones have a more aesthetic appearance and are easier to install. Square ones are cheaper and are used in buildings that have a complex shape and contain a large number of corners and turns.

Depending on the placement of the drainage system, the following types are distinguished:

- Organized external water drainage

. The most common type of drainage, in which water is drained through a system located on the outside of the building. - Organized internal drainage

. Most common in multi-story construction. A peculiarity of this type is the placement of elements of the drainage system inside the object, next to the external walls. - Unorganized water flow

. It is used only in buildings of simple construction with a pitched roof and provides for water drainage directly to the ground.

External and internal drains Source swtor-guild.com

Let's prepare the tool

Before starting installation, you need to think about what tool you will need at each stage of the work and prepare it. This will significantly reduce the installation time of the drainage structure.

When using mains powered equipment, prepare an extension cord of the required length.

Mounting equipment:

- scaffolding or ladder for carrying out work at the edge of the roof;

- marking equipment: pencil, marker, level, tapping cord, tape measure;

- power tools (you can get by with a manual equivalent): grinder (hacksaw), screwdriver (screwdriver);

- additional equipment: metal scissors, hammer, straight and corner pliers, clamps or holders;

- personal protective equipment: gloves and goggles are required, a protective suit and special shoes are optional.

Types of drainage system organization

When organizing a drainage system at your dacha, you can use several options for collecting water from gutters (that is, organizing drainage elements on the ground):

- Open drainage system

- involves the use of ditches for collecting water located on the surface of the summer cottage. - Closed system

- drainage pipes are used for drainage in the ground, located around the entire perimeter of the house or site. Most often, perforated plastic pipes or cross-linked polyethylene pipes are used for these purposes.

Closed drainage system Source vseogarage.ru

- Backfill drainage

is carried out using bricks and crushed stone. This type of drainage is short-lived and therefore not used often. - Surface drainage system

is a water drainage system using trays with grates to collect water. Water flows into the trays through special storm inlets. - Combined drainage system

. Provides for the simultaneous use of surface and closed drainage systems (drains on the ground and in the ground).

A properly organized drainage system will not only solve the problem of water drainage during rain, but can also contribute to a significant decrease in the groundwater level in a summer cottage.

From plastic bottles

A lightweight and cheap material is plastic. Having a sufficient number of plastic bottles, you can make a drain out of them. Dark beer or kvass bottles are suitable for this so that debris is not visible.

As in the first case, we draw a diagram of the future drain. Find the perimeter of the roof and calculate the number of bottles. From 1 bottle there will be 2 halves of 12-15 cm each.

We cut off the bottom and neck of the bottle, cut the remaining part in half and model the gutter using a stapler.

Overlap the bottles by 2 cm. The gutter is attached to the roof using a screwdriver and wire.

Drainage is made from cut, but not sawn, parts, inserting one into the other. The funnel is made from a bottle with the bottom cut off and inserted into the drain. The drainage pipe can be placed in a container or brought to the ground.

Elements of the drainage system

The main elements of the drainage system are:

- Gutters

. Their main function is to collect water from the roof slopes and direct it into the pipes. - Funnels

. Serve to connect the gutter to the pipe. - Connectors (couplings)

. Necessary for connecting gutters or pipes to each other. - Pipes for drainage

. Designed to drain water into a drainage or drainage system. - Turns and angles (knees and bends)

. With their help, you can bypass all protruding elements when installing a solid drain. - Plugs and fastenings (clamps, brackets)

.

Elements of the drainage system Source bydlokoder.ru

Useful tips and tricks

To prevent the drainage structure from clogging, nets are installed on the gutters. They do not interfere with the collection of precipitation, but protect the pipes from leaves.

Correct installation of drainage systems is the key to proper operation of the system Source sense-life.com

In ready-made drainage systems, such protection is included in the kit, but when making drains yourself, you need to do it yourself:

- you will need a metal mesh;

- Having cut it into strips slightly wider than the dimensions of the gutter, it is attached to the drainage elements using clamps.

The drainage system must be constantly cleaned of dirt and debris. Even a mesh will not provide reliable protection. Accumulated debris can make it difficult to remove precipitation, causing blockages to appear in the pipes. Water will begin to flow onto the facade of the building and wash away the foundation.

Calculation of required drainage elements

Installation of a turnkey drainage system begins with calculating the number of required elements. This process consists of several stages.

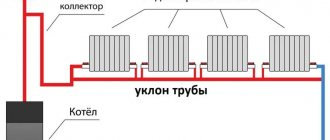

Drawing up a drainage diagram

To correctly calculate the drainage system, use a roof plan, on the basis of which the horizontal lines along which water will be collected are determined, the vertical lines are the places where water is drained from the trays and the water drainage lines are water receivers connected to the drainage system.

Determining the diameter of pipes and gutters

In order for the drainage system to fulfill its functions, it is necessary to correctly determine the required diameter of pipes and gutters. To do this, two indicators are taken into account: the area of the roof slope and the average amount of precipitation. Practice shows that for roof slopes with an area of up to 50 m2, the diameter of the pipe should be 75 mm, and the gutter should be 100 mm. For an area of up to 100 m2 – diameter 87mm, gutter cross-section -125mm. If the area exceeds 100 m2, the cross-section of the gutter should be 150 mm, and the diameter of the drain pipe should be 100 mm.

Installation of vertical drainage systems

The complexity of the work is that the vertical bends have several angles for connecting to the funnel. The number of different turns depends on the architectural features of the building.

Step 1. Measure the distance from the funnel to the wall of the house, select two corners and measure the length of the coupling sections. The missing distance should be increased with a piece of straight pipe. It is cut with a hacksaw or grinder; the edges must be cleaned of burrs.

Pre-assembly of parts without glue

Measurements

Step 2. Glue the top elbow to the funnel, the rest should only be inserted. The upper elbow is made non-separable for one reason - it is impossible to fasten the clamp in this place, the elbow is only supported by the funnel.

Applying glue

Connected elements

Step 3: Mark the locations where the pipe clamps will be attached. There are two ways to do this. The first is to mark a vertical line along the entire height of the house and drill holes for clamps on it at the required distance. The second is to use a level to mark the installation points of the elements one by one for each clamp, and maintain the vertical position with the level. Both methods have their advantages and disadvantages, make your decision on the spot based on your qualifications.

Marking the position of pipe clamps

Step 4. Drill a hole for the plastic dowel and secure the base of the clamp. Work carefully; if you use excessive force, the plastic may crack and you will have to replace the element with a new one.

Drilling a hole for a dowel

If the wall of the house has a layer of insulation made of foam plastic or mineral wool, then the length of the dowel should be increased so that there is a hole in the solid wall with a depth of at least 3 cm.

Step 5. Insert the pipe into the corner and secure its position with a clamp. Manufacturers recommend installing at least two clamps on one whole section of pipe; you will get two on each side near each coupling.

There are letter designations on the plastic clamps. The top clamp is screwed so that the arrow points to the letter “A” on the stand.

Position "A"

The lower clamp is fixed in position “B”, the arrow should point to this letter. The fact is that the clamp holders have different thicknesses of the thrust surfaces, the arrow points to a reinforced one, it is in this direction that the main forces will act.

Fastener installation process

Position "B"

If, due to the size of the building, it is necessary to connect two pipes, then a gap must be left in the coupling for their free movement. The gap width is at least two centimeters.

Gap width

The installation work ends with gluing the elbow to supply water to the blind area, to the receiver of the reclamation system or to a container for collecting rainwater. Then it is used for irrigation or other economic purposes.

Elbow for supplying water to the blind area

Current prices for installation of a drainage system

Despite the fact that the prices for installing a drainage system offered by various firms and construction companies differ from each other, you can determine their average level and focus on it when calculating the cost of work. Thus, the price for installing a drainage system in Moscow starts from 450 rubles per 1 linear meter.

Installation of gutters Source savalotsiding.com

If we consider the cost in the context of individual works, the average figures are as follows:

- installation of drainpipes -

from 300 rubles per linear meter; - installation holders

- from 150 rubles per linear meter; - installation of elbows and bends

- from 230 rubles per linear meter; - gutter

installation – from 200 rubles per linear meter; - installation brackets

- from 100 rubles per linear meter; - installation funnel

– from 200 rubles per linear meter; - turnkey

installation of a drainage system – from 450 rubles per linear meter.

Important technical points

The drainage of rain and melt water from the pitched roof is designed to significantly improve the finishing of the facade and the general condition of the external walls. After all, over time, water can damage even the foundation of a house. That is why there are special regulatory documents SNiP 2.04.01-85, which are responsible for the rules and regulations for drainage construction.

If you want to purchase a ready-made drainage system, then the calculations will be easy for you: almost all modern manufacturers publish special tables on their websites that help determine the relationship between the catchment area and the required parameters of the drainage system. If you are making a gutter for a pitched roof with your own hands, then the graphs and illustrations that we have prepared for you below will help you.