No matter how zealous scientists and engineers are in searching for alternative heat storage and transmitters to liquid media from sources to end points of heat transfer, a worthy replacement for liquid media has not yet appeared. Water heating systems will remain the most common for a long time, as they are practical and quite efficient. They are called water-based, although it would be more correct to call them liquid, because they use not only water, but also other types of liquid substances as a coolant.

What is a coolant, requirements, properties

A coolant is a liquid substance that meets a number of operational requirements and is capable of effectively transferring thermal energy from the heating boiler circuit to the radiators in the room. In a simplified form, the principle of its operation is the following algorithm:

- The flow of substance washes the heating circuit of the heating boiler.

- Having acquired a given temperature, it then passes through pipes to receivers - radiators.

- In contact with the internal structures of the batteries, the thermal agent cools and transfers heat to the walls of the device, which in turn release it to the surrounding space.

- The cooled coolant, leaving the radiator, returns in the return line to the heating circuit and the cycle repeats.

Moreover, not every liquid can be used as a heat agent.

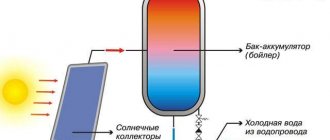

Scheme of autonomous heating at home Source survival.com.ua

Requirements

For successful and safe use, the liquid substance must meet the following series of requirements:

- The ability to quickly and fully absorb, transfer and release heat - which corresponds to a high value of heat capacity.

- Neutrality or the minimum possible chemical activity with contacting material - equipment, pipes, radiators and sealing elements.

- Wide range of operating temperatures – both in the heating and cooling zones. Ideally, the heating liquid should not boil quickly and turn into a vapor state at standard boiler operating rates. It should also not thicken or completely crystallize when cooled well below 0 °C and lead to destruction of system equipment in winter.

- The absence of dissolved components in the composition that can crystallize with constant heating of the liquid. Since they can be deposited in the form of insoluble growths on the walls of pipes, radiators and boiler circuits. This will lead to a narrowing of the working clearance and a deterioration in the heat transfer of the equipment, as well as a load on the pumping station.

Clogging of pipes with insoluble sediment Source ds-m.ru

- Absence or minimal corrosion activity on the metal surfaces of system elements.

- Chemical stability - the absence of processes of decomposition or transformation of coolant components into other compounds under the influence of heat, time of use and other factors.

- Constancy of performance characteristics - fluidity indicators, thermal capacity, chemical inertness, etc. - throughout the entire period of operation and under given conditions.

- Absolute safety for the residents of the house. Absence of toxic, flammable, explosive, radioactive and other components hazardous to life and health.

Important! Whatever the requirements, an ideal coolant does not exist in nature. Therefore, in each individual case, it is necessary to select a fluid that matches the nature of the application, equipment configuration, type of building, climate and other operating factors. Some boiler manufacturers directly recommend specific brands of products for filling the system.

Antifreeze supply system Source remont-book.com

Water as a coolant - pros and cons

Ordinary water is the most commonly used liquid for heating a private home. The main reason for this is accessibility. There are also a number of other advantages of its use:

- Natural prevalence . This makes water a free, accessible and easily replenished resource for any heating system. This not only reduces, but completely eliminates coolant costs for maintenance and repairs.

- Maximum heat capacity – high efficiency of heat transfer from the boiler to the radiator.

- Optimal technical indicators - fluidity, operating temperature, stability.

- Operational safety for people, animals, the environment and the equipment itself - does not burn, does not explode, does not poison.

However, the use of water in the heating system also has its disadvantages:

- High freezing point . When the ambient temperature drops below 0 °C, crystallization will occur with all the ensuing negative consequences - rupture of pipes, batteries, damage to equipment.

- Corrosivity . Water is easily and quickly saturated with oxygen, which, when in contact with metal surfaces of equipment, leads to rusting and destruction of its structure.

Pipes destroyed by corrosion Source gidpokraske.ru

- Formation of scale, growths, siltation. Due to the presence of dissolved impurities of various substances in ordinary water from natural sources, deposits of salts, silt and other components often form on the inner surface of pipes, circuits and batteries. As a result, the clearance narrows, heat transfer properties deteriorate and the service life of the equipment decreases.

Recommendation! Despite the obvious disadvantages, water is the most popular coolant for the heating system of a country house. However, in order to avoid the disadvantages associated with its use, some manipulations are carried out on it. For example, to get rid of impurities, it is boiled, distilled, passed through filters, or special additives are added to it.

The main causes of leaks and their locations

The most common reason for damage to any steel heating pipe is caused by oxidation of the material, when a fistula appears in the pipe. From the inside, water is almost constantly in motion, but from the outside, the metal is often exposed to moisture, air and temperature fluctuations, which contributes to the rusting of the pipe. This is the reason for the appearance of a leak in the most vulnerable place of the heating system.

Many of you may be wondering whether polyethylene pipes leak, because they do not oxidize like steel pipes. Naturally, in this case, the chance of leaks occurring is much less - the reasons for their occurrence will be of a slightly different nature. For example, heating pipes made of polypropylene and polyethylene may leak if they are incorrectly selected, that is, if they are used for other purposes.

This problem often arises among people who, for a number of reasons, decided to save money when building a heating system. Quite often, people buy PP pipes for cold water, which is a gross violation. The fact is that under the influence of high temperature, pipes undergo deformation, swell or burst. This in turn can greatly damage your home and your neighbors. As a result, there is no need to talk about any savings; on the contrary, at the end of the heating period, a significant part of the system will need to be replaced.

However, such a problem can arise even for those craftsmen who decide to use metal-plastic pipes for heating systems. In fact, even such heating pipes leak, and again the problems will need to be solved quickly so as not to harm anyone.

As a rule, the heating pipe leaks in the following places:

on a flat section of the pipeline;

Based on where the heating pipe leaked, the sealing method will be determined.

Antifreeze, types, features

Water purified from harmful impurities and inhibited by special additives still does not become an ideal coolant. Since it is impossible to get rid of the main drawback - freezing at 0 degrees. Therefore, today special antifreeze liquid is widely used everywhere.

Antifreeze antifreeze down to -30 degrees Source antifreez.ru

Properties and features of antifreeze

The main feature of using such a liquid is the operating temperature range suitable for winter operating conditions. Antifreeze for heating freezes at a much lower temperature than ordinary water. Besides this, it has other obvious advantages:

- The structure of antifreeze does not allow it to completely crystallize when the temperature drops, but only to transition from a liquid to a gel state. This essential property preserves the integrity and performance of pipes, circuits and batteries. Therefore, even if the temperature drops below critical due to an unexpected shutdown of the system in cold weather, the equipment will not defrost.

- Economical use due to the possibility of diluting the concentrate with distilled water. Most formulations are sold in concentrated form. The lower limit of their operating temperature is -60-70 °C. However, in most regions the ambient temperature rarely drops below -40-30 degrees. Therefore, the liquid can be diluted without loss of properties according to the factory instructions.

Antifreeze and distilled water for dilution Source koffkindom.ru

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

- Chemical stability and inertness. Antifreeze contains components that do not decompose when heated within the performance parameters and are inert with respect to the equipment material. In this case, the liquid lasts for at least 5 years.

With all the obvious advantages and superiority over ordinary water, however, antifreezes also have a number of specific disadvantages:

- High viscosity values. For normal circulation through the antifreeze fluid system, it is necessary to provide greater pressure, which means using a more powerful pump. At the same time, it is unacceptable to use antifreeze in variations with natural circulation.

- Up to 15% lower heat capacity than water. For this reason, the overall efficiency of the system will be reduced. Consequently, greater energy consumption, the use of radiators with an increased area and an increase in their number will be required in order to achieve a normal heating effect.

- The high degree of fluidity of the substance forces a more careful approach to the selection of sealing elements and more frequent procedures for their maintenance, repair and replacement in all connecting units.

Replacing seals in the radiator Source stroy-podskazka.ru

- Toxic components in many coolants pose a direct threat to all living things in the surrounding space.

- The need to install a larger expansion tank is due to the increased expansion coefficient.

Important! It is unacceptable to use inexpensive options for an open-type expansion tank with antifreeze for two reasons - loss of the substance through evaporation and contamination of indoor air with toxic fumes.

Varieties

Non-freezing heating fluid can have a different chemical basis. On this basis, antifreezes are divided into the following categories:

- Ethylene glycol.

- Propylene glycol.

- Glycerol.

- Bishofite.

There are also compositions specifically used in electrode-type heating boilers. In addition, many users recommend using regular antifreeze as an alternative to modern antifreeze. Let's look at the features of each option in detail.

Ethylene glycol coolant Source dialrus.com

Ethylene glycol

This is the most common, accessible and cheap antifreeze for the heating system of a country house. Available in two forms - concentrated and diluted. The second option is applicable at temperatures down to -30 °C, concentrate - up to -65 degrees. Among the main features of its operation are the following:

- Foaming under strong heating and, as a result, the formation of gas plugs. Eliminated by adding additives and temperature control.

- Oxidation of zinc-coated surfaces despite the use of inhibitors.

- Chemical decomposition when heated above 110 °C. The problem is eliminated by automatic control of the boiler temperature.

- Possibility of insoluble precipitate formation due to overheating. As a result, the entire pipeline system becomes clogged.

Ethylene glycol is poisonous. Therefore, it can only be poured into closed-loop systems.

Closed heating Source ytimg.com

Propylene glycol

A non-freezing liquid for the heating system based on propylene glycol is at least twice as expensive as the analogue considered. However, despite this, he is in great demand. The reason is complete harmlessness to humans. In purified form, the compound is often added even to confectionery products as a flavoring additive. When used in heating systems, antifreeze exhibits the following series of properties:

- Increased fluidity, which implies strict control over the tightness of the system and places high demands on the sealing elements.

- Oxidation of zinc surfaces.

- Easy flammability - at 421 degrees.

- Service life – up to 10 years.

- Operating temperature – up to -50 °C.

Propylene glycol antifreeze can be used in open systems, as well as double-circuit junctions, when there is a risk of coolant getting into household water.

Glycerol

Glycerin coolant for heating is actually an analogue of the antifreeze discussed above. At the same time, it is 25% cheaper and is characterized by the following number of advantages:

- Non-toxic.

- Wide range of operating temperatures – from -30 to +110 degrees.

- Does not destroy pipes when frozen.

Glycerin-based coolant Source fabrikatepla.ru

Should I dilute with water or not?

The origin of this issue is due to the fact that equipment manufacturers set the same requirements, worrying about the safest and most efficient operation possible. Buyers stick to their line, driven by the need to save money. And coolant manufacturers maneuver between the requirements of manufacturers, buyers and sales practices. As always, the truth is somewhere in the middle.

Manufacturers of antifreeze liquids mainly offer “-65C” or “-30C” coolants to the market. Firstly, this is due to established demand, and secondly, such a coolant is guaranteed not to be frozen at the time of sale.

Equipment manufacturers have their own truth. Thus, the density of non-freezing liquid marked “-25C”, mainly recommended by equipment manufacturers for reasons of optimal fluidity, is 1.03 g/cm3, and that of liquid “-30C” is 1.04 g/cm3.

The fact that the content of the main substance in the coolant will be several percent higher is not an “exorbitant” deviation, but taking into account the fact that water can be “added” to the coolant either when recharging the circuit, or if water is not completely drained from the system after flushing , a “reserve” of concentration is simply necessary.

On the other hand, diluting the coolant from “-30C” to “-25C” - and this value is 3-4% - will not bring tangible savings to the buyer, but will increase the risk of losing other necessary properties. But in the case when the buyer plans to use concentrated coolant “-65C” and dilute it, the savings can already be up to 20%.

Rules for choosing antifreeze

An objective concept of which coolant is best to use in the heating system of a private house under specific conditions arises when taking into account the following series of criteria:

- Type of base and its applicability to equipment and operating conditions.

- Freezing and boiling points, optimal operating heating range - taking into account the dilution of the concentrate.

- Possibility of reducing concentration by adding water.

- Life time.

Note! Antifreeze is not recommended for use in open systems and with natural circulation. In addition, the antifreeze liquid should not come into contact with an unprotected galvanized surface and rubber, silicone seals, as well as oiled tow. In addition, only reliable automation can provide accurate control over compliance with its heating parameters.

Pouring antifreeze into the heating system Source hstream.ru

Ethylene glycol products

Ethylene glycol has a slightly oily texture, comes in several colors, and is odorless. The disadvantage of this type of antifreeze is its high toxicity. Avoid direct inhalation or contact with unprotected skin. This can lead to serious consequences, including death.

For this reason, its use for a heating system is limited - it cannot be used if there is a risk that the coolant may get into the hot water supply pipeline.

A red dye is added to antifreeze to alert people to the properties of the product and allow them to instantly see the leak. Such antifreezes are used up to temperatures of minus 65 degrees. It is noteworthy that ethylene glycol-based antifreezes are prohibited for use in some countries.

Tips for use

Before you start pouring antifreeze into the heating system of a private home, you must consider the following set of recommendations:

- It is almost impossible to make a fairly accurate calculation of what concentration and corresponding physicochemical parameters an antifreeze liquid will require. Therefore, after filling, it may be necessary to increase the pump power, increase the volume of the expansion tank, increase the number of battery sections and even the cross-section of the heating circuit.

- Automatic valves for bleeding gas plugs may not work properly. Therefore, it is better to immediately install manual analogues, such as the Mayevsky crane.

- Before filling in new artificial coolant, the system must be washed with a special agent.

- To dilute the concentrate to the desired concentration, only distilled water can be used.

- After filling in compliance with all recommended standards, the system can only be started gradually. This is necessary to check the compatibility of all components with the new type of coolant.

TOP 10 best antifreezes

In order to choose the best antifreeze for your heating system today, you need to consider the TOP 10 products from modern manufacturers:

- DIXIS-65.

Universal for gas and electric boilers. Works down to -65 degrees. Service life 5 years.

- Warm House Eco.

Based on propylene glycol - harmless. Compatible with sealants and tow. Does not destroy pipes when frozen.

- THERMAGENT-65.

Retains properties for up to 20 seasons. Suitable for low temperature climate areas. Contains ethylene glycol.

What is the service life, how do you know: when to replace?

The question is quite common.

Andreic

Experts, clarify the situation: today contractors said that antifreeze has a validity period of 5-7 years. Then it loses its properties, begins to precipitate, and generally does not flow through the heating system as it should. True or not?

For coolants that contain organic (carboxylate) additives, the service life is 10 seasons (10 years), for coolants with “ordinary” silicate additives, this period is about 5 years (heating seasons). In order to control quality, every year, after the end of the heating season, you can carry out a simple procedure - pour a small amount of coolant into a transparent glass container. The resulting sample is visually inspected for the presence of mechanical and other impurities, color, and transparency. If the coolant contains mechanical impurities (crumbs, grains of scale), it can be drained, filtered, flushed the system and refilled. If there are traces of chemical changes (flakes, clots), you need to contact a specialist.

Video description

Video about what you need to consider when pouring antifreeze into the heating system:

- RODA.

Glycerin coolant, works down to -30 degrees. Does not require rinsing before filling. Completely safe.

- AMT-300.

Designed for closed systems, applicable down to -15 degrees. Does not cause corrosion. Requires powerful pumping equipment.

- Hot Stream.

Based on ethylene glycol with additives. Serves for 10 years, works at temperatures down to -30 degrees. Available in diluted form.

- Teplokom.

Based on food grade glycerin. Completely safe. Suitable for use in systems with steel and aluminum radiators. Valid down to -50 degrees.

- WARME BASIC-65.

Contains ethylene glycol. Applicable down to -65 °C. Suitable for northern regions. Service life 2 years.

- Thermagent Eco 30.

Based on propylene glycol. Maintains performance characteristics at temperatures down to -30 degrees. Safe, lasts up to 10 years.

- FTX-30.

Coolant with additives based on propylene glycol. Freezes below -30 degrees. Does not corrode seals.

When choosing a coolant, price is not the last thing. However, more important characteristics are equipment efficiency and safety.

Features of pouring coolant into the heating system

For successful and trouble-free operation of autonomous heating of a private home, it is important not only to know which coolant is best to use in the heating system, but also how to fill it correctly. There are two main ways to do this:

- By gravity.

- By pump.

In the first case, the liquid is poured through an open socket at the highest point of the heating piping system. The method is quite simple, but requires a lot of effort and time. More suitable for small-volume open systems operating in a one-story house.

The second is more preferable when large volumes of coolant need to be filled. In this case, the use of both submersible and pressure testing pumping equipment is allowed. The main nuance of pumping coolant in this way is to eliminate or minimize the entry of air into the system.

The procedure for pumping coolant into the heating system must be carried out by experienced specialists strictly in accordance with the technology and control of technical parameters of pressure and volume, as well as the removal of air pockets.

When to start repairing heating pipes

If you find a leak in your heating pipes, you need to start solving the problem immediately before it becomes more widespread, regardless of the season. It is much better if the breakdown is detected in the summer - then you can immediately make a full repair of the leak by replacing a section of the pipe or the entire system. It would be nice if morally and physically obsolete heating pipes are replaced with new ones made of reinforced polypropylene. Although, of course, everything depends on the available budget.

Rehau pipes can be a good choice for laying a heating system. These products are optimally suited for use in domestic apartments and, with skillful installation and use, practically do not cause problems.

It is worth noting that although it is more convenient to repair the heating system in the summer, if a leak is detected during the heating season, you need to urgently begin to fix it, without waiting for warmer weather. Any repair work, even temporary, must be carried out in a short time.

Please note that in order to avoid troubles with pipe leaks in winter and not be left without heat, as well as to protect your property and family budget, it is necessary to regularly diagnose all heating communications in order to eliminate any problems in a timely manner.

Briefly about the main thing

The coolant for heating a private house allows you to efficiently and safely transfer thermal energy from the heating circuit of the boiler to the radiators, which in turn release heat to the surrounding space. The coolant must meet the following series of requirements:

- Complete heat transfer.

- Chemical inertness.

- Optimal operating temperature range.

- Absence of harmful components.

- Stability and constancy of operating parameters.

- Safety for people and the environment.

Water can be used as a coolant. It tolerates heat best, is free and accessible. However, it freezes already at zero degrees, causes corrosion and can form insoluble salts. Non-freezing liquids do not have such disadvantages.

Antifreezes are divided according to their chemical composition into ethylene glycol, propylene glycol, and glycerin. There are also special ones for electrode boilers and mineral ones. Antifreeze cannot be used as a cheap alternative. You can add antifreeze manually or with a pump. At the same time, monitoring performance characteristics and strict adherence to technology are extremely important.

Ratings 0