Recently we had a little trouble - the ball valve installed on the inlet to the heating tank jammed. We called a plumber, who repaired everything, and then gave valuable advice on how to resuscitate this part if the same thing happens to it again. To be honest, his recommendation already once helped us avoid calling a specialist and unnecessary waste of money.

The tap on the mixer is turning, what should I do?

Unfortunately, plumbing fixtures have the unfortunate tendency to sometimes break down. This applies primarily to mixers and water taps. The most common malfunctions may be various leaks and leaks, noise when opening, low water pressure even when the valve is fully open, the valve turning or the inability to close it completely, as well as difficulty in rotating the faucet spout or the same valve head. If the faucet is leaking in the bathroom or kitchen, then, first of all, you need to find out the cause of the malfunction, and then try to repair it.

Structure of a cartridge disc mixer

This model of faucet with a cartridge is good because they are easy to repair or replace if repair is impossible.

The structure of single-lever disk cartridges with ceramic plates is not complicated. Top down:

- Switch with fixing screw.

- Locking (clamping) nut.

- Cartridge. The water flows are mixed in it, and the same device shuts off the water.

- The mixer body, which has a “seat” for the cartridge.

- Fasteners, studs and gaskets to ensure tightness.

- Spout (gander). It can be a separate part - in rotary models for the kitchen or part of the body - for sinks in the bathroom.

- If the spout is separate, gaskets are also installed below and there is also part of the body.

The disadvantage of a disc cartridge for a single-lever mixer is its high demands on water quality. If even a small foreign fragment gets between the plates, the faucet will leak or stop functioning altogether. In addition, setting the required temperature can sometimes be very difficult.

How to unscrew a broken screw

If your attempts to unscrew the screw are unsuccessful, and the edges of the screw head have already been torn off, you should saw off two edges of the bolt with a hacksaw in order to make a smaller turnkey head. Then follow the previous procedure: fill the old bolt with kerosene or turpentine and leave everything for a while. After waiting a little, try to unscrew the screw.

A hammer and chisel will become faithful assistants in the fight against an unruly screw if all previous methods have proven ineffective. In order to remove an old screw, you need to place the chisel directly against the head of the screw and hit the chisel firmly with a hammer several times. In most cases, this method helps solve the problem of an unyielding screw.

After such operations, the bolt can be easily unscrewed using a wrench.

The main rule for easy handling of screws is their timely treatment with graphite lubricant.

The ball valve does not turn - what to do in such a situation

So, you try to turn off the water, but the handle does not rotate, or turns at a small angle. This does not stop the flow of fluid.

What not to do

You should not use pliers or other improvised means to apply more force when gripping the handle. This almost always leads to the handle breaking off and the problem remaining unsolved.

What to do

In this situation, proceed as follows:

- Use a wrench to unscrew the nut securing the ball valve handle;

- remove the handle;

- Use a wrench to slightly loosen the oil seal clamping nut (for products where such a device is provided). At the same time, the fluoroplastic seal will weaken, and it will be possible to rotate the ball;

- Use an open-end or spanner wrench to grasp the spline of the valve stem. Start rotating it left and right several times at a small angle. At the same time, the ball, weakened by the seal, will begin to rotate little by little. With each movement of the key (without applying much force), the angle of rotation will become larger. As a result, the ball will rotate at an angle of 90°, which will ensure complete closure;

- After replacing the handle, make sure that it points to the “closed” position of the ball. If this is not the case, repeat the steps above until the result is achieved. The situation when the ball valve does not turn should disappear.

Ceramics take over

All hot and cold water mixers fail after a while. Their design provides for quickly wearing elements - the axle box tap for the mixer. In faucets made in old Soviet times, these are rubber gaskets. Time does not stand still and faucets have begun to improve, replacing rubber or bronze wear parts with ceramic ones.

Ceramics is not the clay from which dishes are made. These are powdery mixtures of various metals sintered at high temperatures. They have qualities superior to modern steel. Due to their increased hardness, ceramic parts are tens of times more durable than rubber parts.

Ceramic products have such useful properties as:

- mechanical strength,

- hardness,

- chemical and thermal resistance,

- do not rust.

- high cost compared to rubber ones.

Practical advice

As you have already seen, the service life of cartridges is greatly influenced by the quality of water, its hardness and the presence of hard impurities - debris, sand, rust, etc.

Sediment, plaque and the presence of foreign particles wear out the plates and seals, which complicates the operation of the lever, leads to leaks or “squeezing”, when the hot flow with excess pressure displaces the cold flow through the cracks formed in the tap.

Experts strongly recommend finding out the composition of the water and the impurities in it and, if necessary, including a cleaning filter at the inlet in the water supply wiring diagram.

Wear and tear also depends on the quality of the products purchased. You shouldn’t save a lot, as this can ultimately result in much larger expenses not only for repairing the faucet cartridge, but also for your and your neighbors’ bathroom or kitchen.

What to do if the faucet tap is difficult to turn

First of all, you need to remove the mixer and disassemble it to eliminate the cause of the breakdown. After this, clean all parts - first of all, the cartridge. Next, you need to assemble the mixer and check it for functionality.

Please note an important nuance - all these manipulations should be done only if you understand plumbing and have the skills to do such work. Otherwise, a repair attempt may result in another breakdown, and worst of all, complete inoperability of the plumbing fixture.

If the problem arose due to dirty water, then thorough rinsing and cleaning of all elements of the device will help correct the situation. After cleansing, all mechanisms begin to work correctly. There are 2 main methods that are best suited for washing:

- Using detergent. Mix hot water and mild detergent in a small bowl. Place all the elements in it and rinse. If you find old stains, you can wipe them with paste using a toothbrush. After this, rinse all elements under warm running water.

- Using chemicals. Wear gloves and use a special limescale remover. It will cope with any contamination. If it is not there, then ordinary table vinegar will help, but it cannot be used on iron parts. Dampen a cloth and lightly apply it to the faucet elements. After this, leave all the parts for 30 minutes, and after this time, rinse everything thoroughly under running water.

In the second case, the main thing is not to use a large amount of chemicals or vinegar, as they can damage the parts and elements of the faucet.

If the mixer's performance problem is related to mechanical faults, then it is important to understand which element needs repair. To do this, you will also have to disassemble the tap and study in detail all the components and components, and then replace the faulty one with a new one.

During operation of the mixer, the lubricant may dry out, which helps make the tap turn smoother. If for this reason it becomes difficult to turn, then the problem can be solved in just a couple of minutes by re-lubricating all the necessary elements.

Use only high-quality lubricant. Products of unknown origin can only harm the elements or dry out quickly, blocking all the holes, and thereby completely render the plumbing fixture unusable.

If the shower mixer in the bathroom is broken.

Broken shower switch.

Another common occurrence is the breakdown of the switch that regulates the shower spout. If this switch is plugged, the repair will be simple and take very little time. Quite often, the problem is that when using a shower, water also leaks from a regular tap. That is, the switch is not securely closed. This task can be easily solved - you just need to carefully check the condition of the O-rings and gaskets.

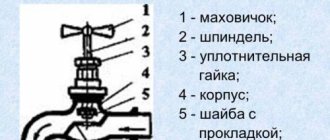

Design of ceramic crane axle box

The part consists of a body, which in plumbing is called a bolt, a connecting part of the components of the faucet axle - a fitting and a hollow hexagon - a rod. The faucet housing has a thread with a gasket for easy connection with the mixer. The front part of the bolt has the shape of a hexagon for a wrench. The fitting is attached to the body using a washer, which also acts as a bearing and protects it from falling out of the mixer.

In ceramic faucet axle boxes, the body has the shape of a cylinder with holes on the sides. The fitting has two protrusions that connect to one of the polished disks - a movable one.

Both discs have holes for water supply. When the flywheel is turned, the discs either overlap each other (then water does not flow) or simultaneously open (then water flows).

The tightness of the ceramic faucet axlebox is achieved due to the fact that a rubber gasket is located between the discs. If the gasket becomes unusable, a characteristic noise appears.

Note! How to change a faucet in the kitchen with your own hands

Replacing the faucet gasket or its core

Share

Link

Share to other sites

- If the water tap is constantly dripping, then in most cases this is due to a leaky gasket. If the faucet valve begins to turn (scroll) and the water does not shut off, then the thread on the core has broken. Let's look at both of these problems and try to solve them. To do this, we will replace not only the rubber gasket, but also the entire core. We will carry out the operation on a standard water tap, where hot and cold water is released using two valves. Such faucets were popular in Soviet times, and are now still used by many unassuming owners.

First you need to turn off the water. In our case, the core responsible for starting hot water needs to be replaced, so we only turned it off. Then you can start disassembling the valve. To do this, you need to get to the screw with which the valve is screwed to the core. To do this we needed to unscrew the small cap (required large pliers). In your case, everything may be even simpler; the red or blue cap is pryed off with a stationery knife and removed. It all depends on the type of valve.

Reasons for turning the tap on the mixer

Conventional faucet axle boxes installed on most modern two-valve mixers break quite often. A plumbing expert will be able to name several possible reasons why such a faucet begins to turn and stops recording the water supply. Among them:

- wear of the threads of the axlebox core (the most common and common cause);

- factory defective core (most often reveals itself when installing a new mixer);

- mechanical damage to the thread (may occur due to overtightening or poor-quality repair of the mixer).

Regardless of the nature and cause of the breakdown, only replacing the core with a new one will help to radically solve the problem . Next, we will consider a detailed algorithm for replacing it.

Attention! If you do not have at least a basic set of tools for carrying out minor plumbing repairs and have never dealt with repairing a faucet yourself, then it is better to leave the solution to the problem in the hands of professionals. It may cost more, but you will certainly avoid more serious damage and save a lot of time.

Repair methods

Removing and replacing the axle box

Before you repair the mixer tap, you need to determine its design. As a rule, two-valve products are equipped with locking axle boxes, and single-lever mixers are equipped with either cartridges or special ball valves. More detailed information about the locking mechanism is contained in the instructions, which should have been included with the product upon purchase.

Note! If there are no instructions, you should not select an axle box, cartridge or gasket by eye. It is better to remove the element that has come out of service from the tap and find a completely identical one in a store or market, otherwise problems may arise in the operation of the part.

We remove the axle box from the socket

Repairing a mixer if the faucet axle rotates

First, turn off the water supply. Typically, valves (taps) intended for these purposes are located just below the flexible supply hoses, however, if there are none, you will have to shut off the entire riser. By the way, you can limit yourself to shutting off only the flow whose valve core needs to be replaced.

Reference. If the hot and cold water pipes are not marked in any way, you can briefly open the tap and feel the supply hoses: the hot water hose will be much warmer.

After the supply is shut off, you need to stock up on the necessary tools. To replace the crank faucet core you will need:

- flat screwdriver;

- stationery knife;

- pliers;

- a set of wrenches or an adjustable wrench;

- new core.

Advice. In order not to make a mistake with your choice and not waste time searching for a new core of the required size, you can go to a plumbing store with the old one as a sample. By the way, if the seller offers you a choice of Chinese and original parts, feel free to choose the second: as you know, a stingy person pays twice, and in our case he also disassembles the mixer twice.

First, you need to carefully use a utility blade or a thin flat screwdriver to pry off the plastic or iron decorative cap that covers the axle box mounting bolt on the front side. Sometimes such a cap can only be removed with the help of pliers, so do not overdo it with the blade.

As soon as the cover is removed, you will see the screw that secures the axle box to the mixer. It may not be easy to unscrew it (such connections often rust, which greatly complicates the process of disassembling them), so you may need a screwdriver or a screwdriver with a comfortable wide handle.

- How to clean the inside of a bathroom faucet

How to install eccentrics for a bathroom faucet

- How to connect a hygienic shower to a regular mixer

Advice. If the mount is stuck “tightly”, you can try treating it with a product called WD-40, familiar to every car enthusiast.

After the valve has been successfully removed, you will see the core, which needs to be replaced. The core is unscrewed counterclockwise using an adjustable wrench or spanner (at worst, with pliers). If the mixer has served faithfully for several years and has never been repaired, it may not be easy to unscrew the core, but just make a few turns with the key and things will go easier.

The new core is screwed into place of the old one clockwise using the same key. Try to tighten it as tightly as possible, but at the same time not damage the threads. If you feel that the part is not following the thread or is screwed in too tightly from the very beginning, it is better to immediately unscrew it and clean both threaded connections with a soft rag or brush.

When the valve returns to its place and the screw securing it is tightly tightened, you can insert the decorative cap into place. Next, you need to turn on the water supply and check the functionality and tightness of the mixer.

If you did everything correctly, the axle box will completely block the feed without much effort after just a couple of revolutions. If a sudden leak appears or the quality of work does not satisfy you for any other reason, it’s time to contact a professional plumber.

Repair of single-lever mixer and prevention of breakdowns

The single-lever or joystick faucet has virtually replaced two-handle or wall-mounted faucets in bathrooms and kitchens. Single lever taps are easy to use and repair, and have a long service life. The main advantage of their design is that there are no metal parts rubbing against each other.

Types of lever faucets

The joystick mixer is a compact body with a lever handle. According to their internal structure, single-lever mixers come in ball and cartridge types.

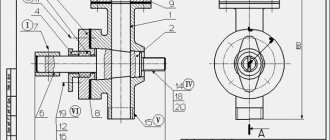

Sectional view of the ball-type mixer mechanism

The design of a mixer with a ball mechanism means that water is mixed in a small ball located in the body and resting on sealing gaskets (seats). Three holes in the ball are designed for hot, cold and already mixed water. The space inside the ball is called the mixing chamber. When you turn the adjusting rod (mixer switch), the pressure of the incoming water, both cold and hot, changes, and its temperature and pressure at the outlet also change. It all depends on how much the hole in the ball and the corresponding incoming hole overlap each other.

To mix water, a cartridge-type faucet uses a cartridge made of a pair of ceramic plates (disks) with holes. In this design, discs replace a ball: the pressure and temperature of the water flowing from the tap depends on the degree to which the holes in the upper and lower discs overlap each other. If you have cartridge-type taps, then repairing a faucet in the kitchen or bathroom usually comes down to replacing the cartridge.

Problems that arise when operating a single-lever mixer

Although single-lever faucets are considered very reliable, they can also cause problems. Most often, repairs are required for leaks, cracks, decreased pressure, unsatisfactory adjustment (sharp transition from cold to hot water).

Problems under the sink

You notice constant dampness and notice water accumulating under the sink. What to do? The first thing suspicion falls on is the siphon or corrugated stainless steel hoses. If everything is fine with them and the sink is well sealed, then check the faucet itself.

Incorrect fit of the faucet body to the sink and displacement of the gasket to the side can cause quite severe leaks and urgent repairs.

Problems from above - troubleshooting faucets

- A typical problem with ball mixers is the rapid wear of the rubber or Teflon seats on which the ball rests. This causes water to leak. To prevent this malfunction of the mixer, you can change the seals every two to three years.

- Disc faucets break due to hard, clogged water. Chips and scratches occur on ceramic surfaces that fit tightly together. All this leads to leaks and reduced mixing accuracy. In this case, the cartridge needs to be changed.

- Another common problem with disc mixers is poor adjustment. This is a common problem with inexpensive models that have too low a setting angle. Choose cartridges and mixers from trusted brands and manufacturers, with a long service life, with an adjustment angle of up to 15°.

Recommended reading: Choosing a bathtub faucetRemoving the valve and checking the faucet seats for wear

General problems - water leaking through the faucet

- An incorrectly installed lever can cause constant leaks in the kitchen. If this is the reason for unsatisfactory operation, then the tap must be rebuilt and the lever must be tightly adjusted during installation.

- Some faults require the installation of a new faucet. These are cracks in the mixing ball or in the housing. If there are cracks, then there is always a puddle of water near the faucet. The same can happen if the sealing rings in the spout block wear out.

- Also, the problem may not be related to the mixing chamber. A decrease in pressure usually occurs due to clogging of the aerator at the outlet of the tap.

Repair of a single-lever mixer with a cartridge

Repair of a faucet with a cartridge must begin with dismantling. Before disassembling the single-lever mixer, turn off the water and drain the remaining water from the taps. It is recommended to cover the sink or at least the drain hole with something.

Cross-section of single lever cartridge mixer

- Unscrew the nut with the aerator from the faucet spout. This can usually be done by hand.

- Remove the decorative plugs and unscrew the screws that secure the lever. To do this, you need a hex wrench or a screwdriver with a suitable blade. As a last resort, you can use a drill with a thin drill bit. To find out which head the screw has, shine a flashlight into the hole. You need to act carefully: if you tear off the slot, dismantling the mixer will become a much more difficult task. If the screw does not budge, treat it with WD-40, wait a little and try again.

- Remove the lever: pull it up. This must be done carefully: for a number of models, removing the lever requires some effort.

- After removing the lever you will see a decorative cap. Take it out: it is made of plastic or weak metal and can be unscrewed by hand. If it doesn't work, try gently turning it with pliers or a gas wrench.

- After removing the cap, you need to remove the fixing nut under which the cartridge is located. To do this, you will need a Swedish adjustable wrench or open-end wrench.

How to buy a replacement ceramic cartridge

Cartridges have different hole diameters. Therefore, it is important to have a defective cartridge in hand when you go to buy a new one. In addition to different diameters, there are various types of clamps on the side of the bottom plate. Give preference to discs with silicone gaskets from well-known European companies. Then you won't have to repair your faucet for the next few years.

Single-grip ceramic cartridge disassembled

Installing a new cartridge and assembling the mixer

Reassembling the faucet after replacing the cartridge is performed in the reverse order:

- Use a soft cloth to clean the cylindrical cavity of the housing. Make sure the case is intact inside. Remove limescale.

- Insert the cartridge. It has centering lugs for proper installation. All that remains is to combine them with the recesses in the body.

- Tighten the locking nut, but do not over-tighten. Otherwise, the cartridge itself or the seals located below may be deformed. And this will cause new leaks. So tighten it halfway and turn on the water. If it protrudes from the sides of the housing holes, then turn off the water and tighten it a little more. Continue tightening the nut a little at a time until the housing remains dry after turning on the water.

- Next, proceed in the reverse order of disassembly: install the cap, install the lever and secure it with a screw, install plugs with cold and hot water indicators.

The new cartridge is inserted into the grooves in the faucet and aligned along the holes, as shown in the picture

Repair of a single lever mixer with a ball block

Single lever ball valve problems are usually caused by a broken valve mechanism. The lever, fixed with a screw, is removed in the same way as in the case of a mixer with a cartridge. The dome-shaped metal cap, which is located below, secures the entire valve mechanism in the body. Under the cap is a plastic cam that limits the movement of the control lever. At the bottom of the cam there is a dome-shaped washer for a tight fit to the mixer ball. We have already described the structure of the ball and the principle of mixing above.

The ball lies on rubber saddles, which are pressed by springs. Below, in the part of the spout block, the faucet with a ball mechanism is designed in the same way as a faucet with a ceramic cartridge.

Disassembly procedure

- Remove the plastic red and blue covers and unscrew the lever according to the diagram described above. The difference will be that the pin from which you need to twist the lever is not polymer and rectangular, but metal, with a thread for the screw securing the lever.

- Unscrew the dome cap. It can be equipped with slots for easy grip. But if there is no slot, use a screwdriver: press it into the groove and gently push it up and clockwise, tearing the part out of place. You can also use pliers, inserting them into the grooves from the inside of the cap.

- After removing the cap, remove the cam with the shaped washer. Clean them from dirt with a rag.

- Remove the mixing ball and examine its valve part.

- Remove the valve seats. They are easily removed using a thin screwdriver. You can use tweezers or a screwdriver to remove the pressure springs under the seats.

Scheme of assembly and repair of a single-lever ball-type mixer

Typical problems with the valve mechanism of a ball mixer

Leaks or excessive noise can be caused by the following problems:

- The inside of the dome washer or the socket in the housing where the lower part of the ball rests is worn or heavily soiled. These spherical cavities must be thoroughly cleaned.

- Ball wear. It may show cracks and grooves. All this is caused by dirty and hard water mixed with solid particles. The only way to fix this is by replacing the ball.

- Worn valve seats. If they begin to fit poorly to the ball, they let water through. They also need to be replaced.

- Poor seat fit can be caused not only by wear, but also by weakening springs. The issue is resolved by replacing the springs with new ones.

Recommended reading: DIY acrylic bathtub repair

Assembly of a single lever mixer with a ball mechanism

It is performed in the reverse order, with cleaning and lubricating the old parts and replacing new ones:

- Clean the faucet cavity.

- Insert new springs into the saddles, place the assembly in its designated slots.

- The cleaned ball is lubricated with silicone grease. The ball is inserted into the mixer body.

- The washer with the cam is installed. For proper assembly, there is a groove in the housing that should be aligned with the protrusion on the cam.

- Place a clean metal top cap and screw it on. It is important to avoid distortions.

- Place it on the metal rod and screw the lever to adjust the water.

Problems with the swivel spout block

If water from a single lever faucet flows above and below the swivel spout block, this is caused by worn seals. Rubber rings and, less commonly, cuffs are used as seals. To replace the rings, you need to disassemble the mixer as follows:

- After removing the cartridge, you need to remove the rotating side of the spout from the body. How to do this will become clear during disassembly. In some models this unit can be removed upwards. It is locked on the body with a special coupling. But more often the spout block is removed downwards, where a corrugated flexible hose is attached. To remove the unit, you need to disassemble it, including removing the faucet from the sink or sink.

- On the bottom side of the dismantled mixer, you need to unscrew the ring-shaped nut and remove the fluoroplastic ring located under it.

- Now you can remove the spout block from the body by pulling it down. Worn rubber seals will be found at the joints with the body. You should purchase the same new ones, and at the same time replace the fluoroplastic rings on top and bottom before installing the mixer.

Crack in the body

This malfunction is immediately noticeable and requires replacing the entire mixer. Some DIYers resort to silicone sealant to “repair” the case. But this is a temporary measure. Soon you will still have to go to the store for a new faucet.

The aerator is clogged

If, with the taps fully open, you observe insufficient pressure, then there may be several reasons. This is a blockage in pipes and inlet hoses, and simply poor pressure in the water supply network. But it could also be a clogged aerator on the spout pipe. To repair, unscrew the aerator. If your hands are not strong enough, use an adjustable wrench. The aerator has slots for unscrewing. On the mesh inside you will find a lot of solid particles and deposits that prevent water from flowing and reduce pressure. The mesh can be cleaned under running water.

If dirt remains, disassemble the aerator and clean the holes manually with a toothpick or needle.

Prevention of breakdowns of a mixer with a cartridge or ball

If your plumbing requires constant repairs, it means that the quality of water in the water supply pipes in your region is unsatisfactory. It is worth thinking about installing filters. Conventional mechanical filters connected to corrugated hoses will significantly extend the life of any plumbing fixtures in the house. Suspension and sediment from the water will not wear away silicone and rubber parts as quickly, as well as the ball and ceramic valve mechanism of the faucet.

abvmaster.ru

The handles of the crane axlebox are dangling

Hello. I bought a Rossinka Silvermix G02-72 sink mixer 1.5 years ago

The cross handles on the crane axle rods are loose and one of the handles has started to turn idle. The water jet is poorly regulated. The splines (20 ribs) of the rods and the splines of the handles are poorly matched, there is a large gap. How to remove this gap so that the structure is free of backlash and detachable? Is there any special adhesive-sealant or solder to put in there?

For scrap metal, complete rubbish. Buy a new ball mixer.

- Which is better, bath or shower reviews?

- Which brand of bathtub mixer is better?

Installation of a bathroom faucet on polypropylene pipes

Buy a set of cheap Dexter keys.

There is a 2mm wrench there, just for tightening the handwheel screws. Wrap it tighter. It should help. If it weakens, repeat the procedure again.

The gap can be reduced using epoxylin. Insert a ball from it into the flywheel, and then press the splined end of the rod, lubricated with some kind of grease, into the socket until it stops. Excess epoxylin will be squeezed out. It is important to wrap the lower part of the splined rod with electrical tape to prevent the epoxy from catching the narrower part of the rod. Otherwise, the connection will be inseparable. The tip of the screw that is screwed in must also be lubricated with oil or grease so that it does not stick. Wrap it tighter. It should help. If we are talking about improvised materials, then use what you have on hand: electrical tape, adhesive tape, a plastic bag, etc. Some are filled with epoxy and the handle is no longer removable.

If, according to science, you don’t want to change the entire mixer, then:

- Change the handles to ones that match the already installed axle boxes.

- Change axle boxes that match your handles.

- Exchange your axlebox with handle for a set of axlebox with handle.

Removing decorative caps and valves - sequence of actions

To unscrew the faucet, decorative caps and nut with screw, you will need a flat-head screwdriver and a sharp knife. Before carrying out work, turn off the water. On the side of the valve, remove the decorative cap by prying it off with a screwdriver or knife. We do this carefully so as not to damage the coating. If the handle is solid, without a plug, just unscrew it. Remove the plastic rings. Next, use a flat screwdriver to unscrew the bolt mount and remove the valve.

If the handle is solid, without a plug, you should simply unscrew it

If the faucet valve cannot be turned off, lubricate the inside of the valve with a WD-40 solution, which is sold at any auto parts store, or pour in vinegar. Leave for a couple of hours so that the solution penetrates the threaded joint and softens hard deposits. After this, the tap should be easy to remove. In the next step, we’ll figure out how to unscrew a stuck faucet axle box.

When planning to restore the functionality of a ball valve, you should ensure not only the availability of the necessary tools, but also good lighting.

When restoring the operation of the faucet, you should first unscrew the self-locking nut (in some cases you should simply unscrew the screw that holds the rotary handle). All this can be easily done using a size 8 or 10 spanner wrench, and an open-end wrench also helps in this matter (everything initially depends on the crane model).

Next, you need to carefully remove the faucet handle. This, as a rule, is not easy, only after its gradual rocking, accomplished by alternating pressure on one or the other side of the structure. In this case, it is important not to knock on it - this will lead to the integrity of the flags and their breakage.

Now you should select the most suitable key, and then try to turn it, alternately changing the direction: first you can try to do it clockwise, and then counterclockwise. When carrying out the described actions, it is important to monitor their amplitude - it should be low, because with great effort there is always a risk of breaking the rod or tearing off the edges.

As soon as movement is noticed, the amplitude of the movements and their scope can be increased. When performing this work, it is very important to ensure that one of your hands holds the head on the rod, and the other turns it.

As soon as the rod moves as freely as possible, at this point you can put on the handle, and then secure it with a screw (or nut). Now you should continue the rocking process until the water supply is completely blocked.

Insure against breakdowns: how to choose a quality gander

When purchasing such a simple part, it is enough to pay attention to the main characteristics so that the issue of repair will not be relevant for a long time. The future acquisition will be assessed according to the following parameters:

- Rotating or non-rotating. If the mixer is to serve a bathtub and a washbasin installed next to it, there is no choice left, and you will have to buy a rotating model. In other cases, it is better to buy a fixed mixer, insuring yourself against leaks in the connection area.

- Mounting location. For installation on a bathtub, a model in which the gander is attached to the bottom of the body is preferable - this reduces the height of the water fall and the accompanying noise. Only faucets with top mounting are installed on the washbasin or sink. For the kitchen, take a closer look at kitchen faucets with a flexible gooseneck - they are convenient to adjust in length and height, adjusting them to the dimensions of the dishes or sink.

- Availability of an aerator. This is a very desirable option that reduces water consumption by increasing the volume of the stream due to air, which is especially important for houses with meters. Even if you have your own well and water consumption is irrelevant, think about the amount of wastewater, because calling sewerage equipment is also not a cheap pleasure.

- Diameter of the fixing nut. When replacing the spout, do not forget to make sure that the purchase will fit the faucet body. If you are not sure about the parameters of the old gander, take it with you to choose the right one on the spot.

- Aerator shape. Cleaning the aeration mesh will sooner or later become necessary, so it is better to choose cut models. To unscrew the round aerator you will have to work hard.

- Material. It is impossible to see what the part is made of under the chrome coating, so ask the seller for documents confirming that the gib is made of brass. Instead, under the chrome there may be silumin - a fragile, easily deformed material. You can simply test the weight of the selected spout: a brass one will be three times heavier.

- Length. This does not affect the functionality of the mixer in any way, but it is advisable to choose a model with a spout length such that the water stream falls directly on the drain hole. This little detail will significantly reduce the amount of splashes that, when dry, form streaks on the mirror, walls and furniture around.

Mixer installation

Mixer installation diagram.

The beginning of such work is associated with the installation of decorative overlays on the flanges. The gaskets are then placed on the flanges, with the black soft rubber piece being the first. Then you should fix the solid base of paronite in color. This installation procedure protects the rubber gasket during the process of screwing on the eccentric fitting.

The final stage of installation work involves tightening the union nuts manually and tightening them with a wrench or adjustable wrench. It is important to ensure that the rubber gasket does not bend due to excessive force. Otherwise, water will leak and the gaskets in the taps will have to be replaced.

The installation of a kitchen faucet must ensure that the spacer ring remains in its original form during operation and is not allowed to be crushed. The shower in the bathroom is fixed in a similar way. Two gaskets are used here: rubber and parotin. In some types of shower such parts are not installed.

If changing the gasket does not bring the expected results, you can resort to replacing the tap itself. Before installing a new plumbing fixture, the water should be turned off and the broken tap should be unscrewed.

When the cross-section of water pipes is such that the outlet pipes of the tap do not correspond to the established dimensions, the problem is solved by using adapter bushings; they have threads on both sides. Here the axis of symmetry shifts, and this makes it possible to connect pipes of a different size and diameter. As soon as the new tap is installed and the union nuts are screwed in, its condition can be checked.

Diagnostic databases

Before you start repairing, you need to study the structure of the mixer tap and find out the nature of the breakdown. This can be done quite simply, especially if you use the table below:

- Siphon malfunction.

- Damage to the hose for the flexible faucet spout.

- Leaky connection of pipes with warm or cold water.

- Repair or replace the siphon.

- Replace the hose.

- Tighten the nuts where the pipes are attached, using plumbing sealant if necessary.

As can be seen from the analysis of the third column, to perform most of the work we do not need any special skills. All you need is some simple skill and study of the recommendations, which we will give below.

Main Factors

The main reason that caused a plumbing fixture to leak would be:

- gasket wear;

- abrasion of the rod thread, as a result of which the gasket is not tightly connected to the saddle;

- loss of the initial qualities of the cushioning base, complete decay and other reasons.

Tools for changing the gasket in the faucet.

The faulty faucet must be disassembled, after which the indications for leakage should be determined. Whatever the consequences of a malfunctioning plumbing product, the water should first be shut off, and after that you can begin repair work.

If a completely new faucet leaks, we can talk about the presence of a manufacturing defect.

To solve this problem, you can consult a specialist and, if the diagnosis is confirmed, return the mixer to the store.

If similar troubles occur with a ball valve, then a number of problems arise here. Their main reason is associated with the entry of debris into the product body.

Main faults

Before repairing a water faucet, it is worth taking time to analyze the situation. This way we can understand exactly what actions should be taken, thereby saving quite a lot of time.

The list of breakdowns includes the following items:

| Breaking | Description |

| When the valve is closed, drops of water flow out of the tap | The locking mechanism becomes unusable. To fix the problem, you need to either replace the element responsible for blocking the pipe clearance, or install new sealing gaskets. |

| Water drips at the connection point of the spout, hose or valve | The tightness of the connection is broken. It is possible to return it either by replacing the gasket, or by installing a plumbing winder on the thread. |

| The flywheel turns | The flywheel housing has come off the rod or the rod has stopped working. In the first case, it is enough to put the part in place, in the second, you will need to replace the locking element. |

| The faucet makes a humming sound when operating | The gasket has worn out and its edges begin to vibrate under water pressure. In most cases, replacing the gasket is enough to eliminate extraneous sounds. |

| Leak on the body or on the spout | The integrity of the product has been compromised. It is temporarily possible to seal by “cold welding”, but it is worth replacing the valve as soon as possible. |

| Splashes fly from the aerator, water flow is obstructed. | The aerator grille is clogged and requires cleaning. |

In principle, this table outlines the main faults. Other situations that may arise during the operation of the crane are derivatives of those already analyzed, and therefore they must be repaired using a similar method.

In addition, before starting work, be sure to carefully familiarize yourself with the design features of the model you have installed. In most cases, the assembly drawing of the water tap comes with the product itself, so when installing a new faucet, this document should be kept.

Note! If you can’t find the diagram, then you should enter the query “assembly drawing for indicating a water tap” in a search engine and select your model. Most manufacturers post technical documentation online, so the chance of finding what you need is high.

Now let's figure out what to do in each specific case. And let's start with the most common situation, in particular with eliminating the circumstances of the leakage of the shut-off element.

The Bugati ball valve is leaking, I urgently need advice, I can’t find a plumber

Please tell me the Bugatti 3/4 ball valve (original according to the characteristics) has been standing on the riser for 4 years; when the butterfly is turned, it does not reach the stop by 2-3 mm. The tap does not completely shut off the riser. Is it possible to do something in this situation without removing the faucet and/or without turning off the riser? There are also taps from other Chinese manufacturers on the wiring, they have become sour and do not turn, everything was bought at Maxidom. Please let this mini-house burn down.

Does the handle just not reach the stop, or does it reach but not block?

In the first case, the problem is probably deposits on the ball. Secondly, the mounting hole in the handle was simply broken. Remove it and carefully close the valve by the stem with the key.

By the way, what does it look like? Are the nuts rusty? If so, this rust may be preventing the handle from turning.

By the way, for some comrades: YES, BLADJAD, there was such a situation, and I’m not just making it up!

Pixel – to “extend the life” of the ball. tap - it cannot be used as an adjustment valve. There are only two acceptable positions - completely open, or completely closed, and you most likely had the valve handle in the middle position for a long time, or the ball valve was not fully open and the part of the ball protruding into the pipeline caught flying grains of sand from the flow , various abrasive particles, so under the seal the ball. tap, Teflon, or fluoroplastic got this abrasive and now it is difficult, and maybe even impossible, to revive it, you will only have to change it and, based on the experience gained, not repeat such mistakes in the future.

If you think competence is expensive, you always have the chance to try incompetence.

You can’t close the stem completely with pliers either, you can’t tighten it just a little and the water flows in a thin stream, there’s no rust, the faucet looks like new, I removed the handle and the nut under it, unscrewed the nut a little but nothing changed, why is this nut there anyway, it doesn’t hold anything ? If you tighten it with pliers, it crunches a little inside. scary under pressure

the valve has never been in the middle position, I know about this feature of ball valves

the system was assembled not 4, but 9 years ago, but the crane is 9 years old

Pixel wrote: . the system was assembled not 4, but 9 years ago, but the crane is 9 years old

Protection against souring of the ball is periodic (at least twice a month) manipulations completely “open-close”, but 9 years is a good period for a Bugatti, so it’s time to change it.

If you think competence is expensive, you always have the chance to try incompetence.

Most likely, the ball initially had some misalignment (this happens), and due to the fact that the ball was not opened “at 0,” there are now deposits on the edges of the ball. Unfortunately, nothing can be done “at home.” If only you try to move it back and forth, just until it “crunches”, to try to destroy the growths. Nothing should fall off if no effort is made, and the faucet itself does not look rotten.

manipulations were carried out very rarely.. is it possible to remove the handle and turn the tap one turn in the opposite direction? maybe this will help? after applying forceful pressure with pliers, the stream of water became noticeably smaller

There are also taps from other Chinese manufacturers on the wiring; they have become sour and do not turn

You still need to do something with your water supply, so it’s easier to turn off the riser. You will still have to take decisive measures sooner or later.

Now, as I understand it, you wanted to make some minor repairs?

The tap, as I understand it, is located at the inlet. Since it doesn’t close, contact the management company, let them repair it, change it, etc. This wound is under their jurisdiction. Something could have gotten in.

yes, the kitchen is being renovated, the faucet needs to be changed, the taps on the manifold have turned sour, so I wanted to turn off the input. In general, I understand, thank you very much, repairs in one place, as always, drag on everything else))

Is it possible to remove the handle and turn the tap one turn in the opposite direction?

I wanted to suggest the same thing. Try it, it won't get any worse.

ma-masha wrote: I wanted to suggest the same thing. Try it, it won't get any worse.

Masya, in this way you can break the seals of the ball, and the tap will already be pouring.

The author of the topic, there is a lot of advice in the topic above. Mine: Change EVERYTHING before you get into money. Then, as a rule, everything is too late.

I agree with the idea of going the other way. I won’t deify Bugatti, but local Fittingville supplies some strange Bugatti cranes to LM. There have been examples when the edge of the ball bites the fluoroplastic sealing ring and cannot move further. That's why turning it around can help.

IMHO, it sucks. There are FIV, Giacomini, Cimberio. Yes, there are a lot of good Italians.

The corner Giacominis were leaking a lot

Any corners are ugly. But, of course, they shouldn’t leak. Unfortunately, it happens to everyone.

I vaguely remember that Bugatti has a seal tightening function. I don’t remember how to pull it up, but I think one of the confectioners should remember

))

The rod seal can be tightened. This will not affect the curve ball.

Similar problem. Two Bugatti Nevada 3/4 taps on the hot water riser. Only 10 months. Original. Immediately after the purchase, the balls on both taps were alarming: they did not open/close completely. I decided that since I bought two at once and bought them from the officials, I don’t have to worry. Today I dismantled one of the taps. Air hissed from the drained riser through the tap, i.e. he doesn't hold it anymore. The butterfly rests against the limiter. It shouldn’t turn sour in 10 months; besides, I covered them a couple of times during this period. Does it make sense to manipulate the butterfly: remove it and tighten it with pliers, or turn the butterfly the other way around? From the pictures with the design of ball valves, I concluded that without a butterfly and a limiter, the ball can rotate around its axis 360 degrees. Those. the butterfly does not allow it to open/close completely. Or the crooked ball that was written about here in the thread?

DIY valve repair

Valve taps are also called classics in water supply. And, despite the fact that such cranes are gradually replacing newer designs, there are still enough of them. Over several decades, their structure has not changed, only the design, which has become many times better, more diverse, and more refined.

At the moment, you can find both the simplest models and quite unusual ones. Taps for water taps of this type are also used, as they are reliable and simple, and can last not just a few years, but several decades. If all the “insides” of the structure are made in accordance with all the requirements and GOSTs, then the only thing that can fail during all this time is the gaskets. Replacing rubber seals is the main way to repair a valve tap.

Replacing the rubber seal (gasket on the valve)

If the valve is completely closed, but water continues to drip in the bathroom or kitchen, then the whole problem is in the gasket on the valve, which has lost its elasticity. The fact is that over time it ceases to press tightly against the saddle, which is why water continues to flow, and because of this the faucet can not only drip, but even leak. In this case, fixing the faucet means changing the gasket. This will require a wrench, but it will be more convenient to use an adjustable wrench and a set of rubber gaskets.

Before you begin to repair a dripping faucet, you should turn off the water supply (if possible, turn off the water only in this branch). After this, check that the water is turned off, and if nothing is leaking, you can begin repairs. You will need an adjustable wrench or wrench to unscrew the head housing, i.e. upper part of the body.

Ideally, when repairing, you need to work with an adjustable wrench, and in order not to spoil the surface during the process, you should wrap it with a soft cloth, and then apply the wrench. When the head is unscrewed, remove the valve, and now you can change the gasket or install a new valve. The old valve should be pryed off with any sharp object - a screwdriver with a spatula, for example, or an awl.

When selecting a gasket, it is important to ensure that the edges are beveled at approximately 45 degrees, otherwise the water supply will begin to make noise. If you don’t have this in your arsenal, you can trim the edge with something sharp - scissors or a knife. So, to fix a dripping faucet in the absence of a suitable gasket, you can cut this element out of dense rubber (porous material is not suitable). The thickness of the rubber sheet should be 3.5 mm, and the internal diameter is slightly smaller than the diameter of the rod, please note that the outer edge should not protrude. Remember to bevel the edges at 45 degrees.

Once the gasket is installed, the valve can be put back in place and the head screwed back on. Newer models of taps do not require winding onto threads. Even more, winding is contraindicated, since it is precisely this that often causes cracks to form in the body. If you are repairing a USSR tap, you should lay tow on the threads and then tighten it. After this, turn on the water, but not at full pressure, but gradually.

Sometimes with such a gasket on the valve a completely different story can happen - the water barely flows or does not flow at all. In this case, it is obvious that the gasket flew off the rod and simply blocked the flow of water. To begin with, you can try closing and opening the tap several times, and if this does not help, then repeat the operation described above, i.e. change the rubber gasket. The main thing is that you do not forget to remove the old element that is stuck to the saddle.

Water leaking from under the stem

If water drips from under the valve, then the seals are worn out. A leaking faucet can be repaired using two methods. First, try to tighten the head housing harder. This all needs to be done using the same adjustable wrench. It is not advisable to use pliers as they leave marks. Tighten the head as much as possible, but not too much. If the threads are tightened perfectly, but water still oozes out, then you should also change the gaskets on the oil seal. To do this, you need to tighten the tap to the limit, and then remove the tap head again, remove it with a sharp object and remove both rubber rings, replacing them with new ones.

Which cartridge lubricant should I choose?

The problem of the faucet being difficult to operate can be solved by removing the ceramic cartridge and coating the discs inside with lubricant.

Let's look at what types of lubricating compounds are better and what they are:

Tsiatim-221 is a plastic composition made in accordance with GOST. Perfectly suitable for metal parts, rubber, plastic, ceramic, as well as for friction units. This lubricant is often used not only for mixers, but also for bearings in electrical machines and aggregate bearings in aircraft.

The consistency of Ciatim-221 is such that it does not dissolve in water. Resistant chemical composition - provides good lubricating quality, even at a pressure of 600 Pa it is not washed off. Temperature changes from -60 to +150 degrees will also not cause harm to the composition.

Due to its characteristics, Tsiatim-221 is in great demand, so purchasing it is very problematic, and sellers offer a less effective analogue - Tsiatim-201.

Silicone Grease. This composition is used to fill the space between the plates of the ceramic cartridge - the gap is too small, and without lubrication it is impossible to even move the handle from its place. This consumable material softens the rotation of the lever and allows it to be turned freely. If you feel like the lever is sticking when turning, then you need to update the silicone lubricant.

Silicone grease is a white, translucent paste. Do not confuse it with silicone sealant under any circumstances, otherwise the faucet will have to be thrown away. One application of paste should be enough for 50,000 lever revolutions. It is usually sold in auto parts stores and car markets. Price 8-10 dollars.

When applying silicone grease to the top plate, for convenience, the cartridge should be held upside down, but keep in mind that in this position it will be the bottom plate - there is no need to pour it into the holes. Next, you need to distribute it evenly; to do this, rotate the rod in the cartridge. If necessary, you can apply a little more.

If, after applying the composition, sand or rust still gets between the plates, then you need to buy a new cartridge.

RAVAK – Teflon lubricant. It is also insoluble in water, but is washed out over time, so the frequency of the need to lubricate parts increases.

But thanks to the list of advantages, Teflon grease is in demand among consumers:

- wide temperature range - withstands where others fail;

- It is enough to apply one drop on the face - ergonomics;

- its property does not allow it to turn yellow over time, as is usually the case with pastes;

- It can also be used to lubricate door hinges and shower enclosures, shower frames, and door handles.

This information will help you select and apply faucet lubricant correctly to prolong the operation of your plumbing fixtures.

General information

There are two types of shut-off valves with a ball mechanism:

- All-welded.

- Collapsible.

Product repairability

The all-welded body, as you might guess, cannot be repaired and, in the event of a malfunction, is completely replaced.

But a faucet consisting of several parts with a ball mechanism is not difficult to repair.

Enough to know:

- housing design

- design features

- crane disassembly sequence

Before you begin troubleshooting and disassembling the structure, the first thing you need to do is turn off the water. Drain off the remaining liquid.

The ball valve does not turn - what to do in such a situation

So, you try to turn off the water, but the handle does not rotate, or turns at a small angle. This does not stop the flow of fluid.

What not to do

You should not use pliers or other improvised means to apply more force when gripping the handle. This almost always leads to the handle breaking off and the problem remaining unsolved.

What to do

In this situation, proceed as follows:

- Use a wrench to unscrew the nut securing the ball valve handle;

- remove the handle;

- Use a wrench to slightly loosen the oil seal clamping nut (for products where such a device is provided). At the same time, the fluoroplastic seal will weaken, and it will be possible to rotate the ball;

- Use an open-end or spanner wrench to grasp the spline of the valve stem. Start rotating it left and right several times at a small angle. At the same time, the ball, weakened by the seal, will begin to rotate little by little. With each movement of the key (without applying much force), the angle of rotation will become larger. As a result, the ball will rotate at an angle of 90°, which will ensure complete closure;

- After replacing the handle, make sure that it points to the “closed” position of the ball. If this is not the case, repeat the steps above until the result is achieved. The situation when the ball valve does not turn should disappear.

Attention! If a small amount of water appears (a few drops), it’s not a big deal. This means that the released oil seal is not yet performing its function. It will be restored after the work is completed.

- when the valve ball is in the required position (“closed”), rotate it several times by the handle to open and close. Make sure this happens without unnecessary stress;

- remove the handle and tighten the gland clamp nut so that water does not leak (we restore its function);

- Install the handle completely and secure it with the nut. Rotate the handle, make sure that this happens without unnecessary force. Of course, there will be no perfect job. This will be felt, but significant force will not be required to close.

The work is finished, and the crane will still serve. In the future, do not forget to perform preventive opening and closing operations. Do this once every three months to prevent the problem.