A part such as a plug for sewer pipes is used to block certain sections of the drainage network. They are installed by the owners themselves to temporarily or permanently disable a separate branch of the network. In addition, plugs are actively used by utility companies, since the installation of this part is one of the most effective measures to combat debtors.

A plug is installed on a sewer pipe for different purposes. This could be a temporary shutdown of a backup branch or a permanent blocking of a part of the system that has become unnecessary.

Installing an inspection with a plug is necessary to be able to clean the sewer. Such a fitting with a diameter of 110 is placed on the central riser. Recently, management companies have begun to actively use stubs in an attempt to get debtors to pay utility bills.

Calculation of sewer pipe diameter

The diameters of the pipes used depend on the number of plumbing fixtures connected to the system, as well as on the slope.

There are formulas that can be used to calculate the appropriate diameter depending on the following factors. Namely:

- number of turns and joints;

- slope;

- number of plumbing fixtures.

In practice, formulas, for example, for installing a sewer system in a private house or inside an apartment, are used extremely rarely, since this is simply not necessary.

Pipes of 100-150 mm in diameter are installed on the section connecting the riser to the sewer well, as well as on the riser itself. If the previous pipe had a diameter of 200 millimeters, then the diameter of the new one should be the same.

Internal horizontal wiring, as a rule, involves the installation of pipes of 100 mm diameter when connecting to the toilet riser. In other cases, pipes of 50mm diameter are used.

Installing the valve on the riser

Residents of apartments located on the lower floors have the worst situation when the sewer is clogged. All the sewage entering the riser from the apartments located above begins to pour out of their toilet.

To prevent flooding of your apartment with fecal waste, it makes sense to install a check valve on the riser. This device ensures fluid flow in only one direction; reverse flow is excluded.

Installing such a valve on the first floor will lead to the fact that if the sewer is clogged, fecal waste will begin to flow into the apartment located on the second floor. And if a valve is installed there, the problem will “move” even higher. So installing valves on each floor will help avoid such troubles as flooding of the apartment with someone else's fecal waste.

Advice! The cost of a check valve is approximately 200 rubles, that is, the price of safety is quite low.

Sewer inspection: installation features

- What is a sewer inspection and why is it needed?

- Dimensions and material

- Advantages and disadvantages of polyvinyl chloride revision

- Advantages and disadvantages of polypropylene revision

- Installation rules and installation

- Features of operation

- How to clean pipes?

- How to find in an apartment building?

When designing and laying a sewer system, in addition to pipes, auxiliary parts are needed

Among them, sewer inspection is important for the normal functioning and maintenance of the system

A sewer inspection greatly simplifies drain cleaning.

What is a sewer inspection and why is it needed?

A sewer inspection is a special shaped part that is installed to check the operation of the system and remove blockages from the riser without dismantling or damaging the pipeline.

It is a connecting part and is a tee in which the side pipe is not a through pipe, but has the appearance of a window hermetically sealed with a lid.

Having opened it, use a special tool to remove the stuck debris.

The inspection is designed so that it is convenient to carry out inspection and cleaning. It can be located inside or outside the building.

If for some reason it was not installed, cleaning the pipe will be more difficult. And if its integrity is damaged, it will leak and an unpleasant odor will appear. The fitting can be installed on vertical and horizontal sections of communications.

Options for plumbing inspections, what to choose?

Now in almost every bathroom, all pipes and communications are located behind false partitions and access to these communications must always remain. Most often, access is achieved using various plumbing hatches and doors. In this article we will talk about all the main types of such revisions and analyze their pros and cons.

A correctly chosen plumbing hatch should highlight all the beauty of high-quality renovations in the bathroom and toilet! It must fit harmoniously into the overall interior and at the same time fully fulfill the function assigned to it - provide convenient access to hidden communications. An incorrectly chosen revision can easily ruin the entire appearance of the room or make access to communications difficult (some “masters” manage to do both!)

MAIN TYPES OF PLUMBING INSPECTIONS

• A simple plastic or metal white painted hatch is the most budget-friendly revision option! It is better to install it only if the repair is of the same budget, for example, when the walls are lined with plastic PVC panels, or when such a hatch is located somewhere in an invisible place.

When choosing such a revision, it is worth considering that white plastic hatches may turn yellow over time, and large metal hatches are easily deformed.

• An invisible hatch under tiles is the most common revision option, however, it is also the most difficult to implement. Experience shows that not all craftsmen can install such hatches correctly.

The advantage of invisible hatches is undoubtedly their concealability (if installed correctly), they do not distract unnecessary attention and do not conflict with the decor of the tiles.

In addition to the complexity of installation, invisible hatches are also quite difficult to operate; they should be used with extreme caution, because they can be easily damaged

Large hatches sag over time due to the heavy weight of the tiles glued to them, so the design of the hatch you choose should allow for adjustment. The cost of invisible hatches is also not their advantage; good hatches are quite expensive.

• Hidden revision on a magnetic mount - used when installing small hidden revisions in visible places. This is something between a simple hatch and an invisible hatch.

The design is a plastic cover with magnetic or mechanical fastening to special mortgages, which are mounted in the location of the inspection device. The tile is glued to the lid and the hatch (if installed correctly) becomes completely invisible.

Such a hatch is ideal, for example, when installing an inspection in a tiled screen under a bathtub to access the drain, but it is absolutely not suitable as the main hatch for all communications.

Exploitation

Access to the inspection must always be free.

Blockages are formed from rags dropped into the toilet, dumped contents of cat litter boxes, sand and household waste.

To remove the plug, an inspection located upstream of the water flow is used. It is opened and cleaning begins using the rotational movement of the cable. During the event, you should ensure that it takes place without the formation of loops. The rags are wrapped around the device and pulled out. In case of operational blockage, it is recommended to flush several buckets of hot water down the drain after cleaning to check. Water is supplied directly into the hatch of the device, since it has time to cool on the way from the installed plumbing.

To carry out cleaning activities in an apartment building in the absence of residents from the lower floors, audits are installed in the basements.

If during operation problem areas are identified where debris collects, a new hatch is installed: the sewer pipeline is cut off above the socket, the cut is cleaned of irregularities, the chamfer is removed and an inspection is installed in the extension. For subsequent connection, use a pipe.

In old houses, the bolts on cast iron hatch doors rust, so they are cut off with a grinder and, after cleaning, replaced with brass ones. If the bolts are not at hand, the cover is tightened with wire. The rubber gasket can be made from a car inner tube.

Material of manufacture and technical characteristics

Before purchasing plastic pipes for sewerage or water supply installations, you need to pay attention to the technical characteristics of the material and weigh the pros and cons

Polypropylene pipes

Socketed polypropylene pipes

Polypropylene is produced in the form of granules, from which pipes of different diameters are cast during heat treatment. PP does not chemically interact with acids and alkalis, does not emit harmful substances, therefore it can be used in cold and hot water supply systems. The material becomes soft at 145 degrees, so it can withstand hot drains up to 95 degrees without deformation.

Physical and mechanical parameters:

- resistant to mechanical shocks;

- low temperatures have no effect if ethylene is added to the molecules;

- wear resistant;

- Aluminum-reinforced polypropylene deforms less when heated;

- sensitive to oxygen and ultraviolet radiation - to reduce the performance, stabilizers are added to the composition.

Depending on the filling, you can create a material with new properties:

- Glass filled. Fiberglass increases bending elasticity and increases the strength of finished products.

- Mineral-filled. The introduction of calcium carbonate increases the thermal insulation properties of PP.

- Elasticated. By adding elastomers, the frost resistance of pipes and their elasticity when bending increases.

- Low-flammability. Produced by mixing granules with antiprene. If a fire occurs, the material extinguishes on its own.

Plastic pipes made of polypropylene are much cheaper and more practical than metal ones. They have a smooth inner surface, which prevents dirt from sticking and clogging the drain. Mineral sediments - calcium, iron - are not able to clog the lumen and change the diameter of the pipes, because the material is not electrified and does not attract salt molecules. It is recommended to install filters for drinking water if it contains dissolved minerals, as they can damage household appliances - dishwashers and washing machines, boilers, boilers or radiators.

PVC pipes for sewerage

PVC pipes

Unplasticized polyvinyl chloride is a material that successfully replaces steel structures, which are much more complex and expensive to maintain. It is used in the food and chemical industries, since PVC can withstand aggressive loads from acids - nitric, hydrochloric, sulfuric, and does not release harmful substances into the transported liquid.

Characteristics:

- low expansion coefficient when heated;

- the material begins to soften at 80 degrees;

- melts at 180 degrees;

- In warm weather, it is shock resistant.

The disadvantage of PVC is that fragility increases with decreasing temperature.

Polyethylene pipes

Polyethylene sewer pipes

High-density polyethylene is used to make pipes. The service life of the material is about 50 years. This is much longer than pipes made of concrete, metal or cast iron last.

Advantages of polyethylene pipes for sewerage:

- do not deteriorate upon contact with water or aggressive liquids;

- environmentally friendly;

- welding does not require additional consumables, as for steel;

- the installation process takes less time due to the relatively light weight of the products;

- elastic – withstands pressure and temperature without cracking or deforming;

- the ice that forms inside the pipe does not damage it;

- Suitable for installation in areas where there is a high load on the ground and where earthquakes occur frequently.

Cross-linked polyethylene

Cross-linked polyethylene

Not inferior in strength to solid substances. It is obtained by adding peroxides, silane, and nitrogen.

Advantages of cross-linked polyethylene over regular polyethylene:

- thermal insulation properties are 30% higher;

- resistant to ultraviolet radiation and atmospheric conditions, therefore can be used for arranging open water pipes;

- high mechanical tensile strength, as well as flexibility of the material;

- shockproof in frosts below 50 degrees.

Advantages of polypropylene revisions

A modern pipeline for drainage water is assembled from lightweight material. Revisions have also changed, so today it is most practical to use polypropylene elements. They have a number of advantages that have proven irreplaceable. What subtleties are we talking about?

- Maximum wastewater temperature 95 degrees;

- Smooth surface reduces the risk of blockages;

- Does not require painting;

- Service life up to 50 years;

- Frost resistance;

- Mechanical strength;

- Resistance to corrosion and chemical environments.

A separate element of the sewer system design is in no way inferior to a pipeline. After its installation, you don’t have to worry about violating technical specifications. Because of this, after adding to the project, it is not necessary to make categorical changes to ensure the reliability of wastewater movement.

Audit is a mandatory element approved by current standards. Professional design requires resorting to various fittings that are often considered unnecessary. By clarifying the reasons for installation, you can make sure it is necessary, so that you don’t have to worry about cleaning and regularly checking for blockages.

How to choose the right drain pipe diameter

Even at the stage of the initial design documentation, the dimensions of the sewer pipes in the future building must be agreed upon. In 90% of cases, parts with a diameter starting from 100 mm are used to install a wastewater system in a bathroom. To install the system in the bathroom or kitchen, it will be enough to use a 50 mm pipeline. The difference in the given values was chosen for a reason. It is determined by several factors:

- A toilet is a plumbing fixture, the peculiarity of which is the passage of a significant volume of water in a short period of time (when the flush button is pressed). At the same time, the water may contain solid particles, which will be problematic for elements of the waste structure with smaller circumferences than those given above to cope with. There is a high probability of blockages.

- Even without looking at the fact that when draining water from a bathtub, its volume is no less than the volume of water from the toilet, the diameter of the sewer pipe will be smaller due to a simple rule of hydraulics - the permeability of the system should be equal to the value provided in the place with the narrowest circumference parameter. This release value in the bathroom is significantly less than in the toilet. Therefore, it is impractical to mount parts with a large diameter.

Required pipe slopes (Example - 1:30. Where 1 linear meter per 30mm slope)

Chemical method

The basic principle is to use alkaline components.

You can pour the drug “Mole” into the sewer yourself; it is often used to remove blockages. After reacting with water, the mixture will begin to boil and the sewer plug will gradually dissolve. It must be said that this method can only work if the plug is metal, since the rubber ball does not corrode. In addition, it will take at least a week for “Mole” to dissolve the metal.

What is a revision?

This is a fitting similar to a tee, in which, instead of a through side pipe, there is exactly the same one, only hermetically sealed with a lid. In those days when cast iron pipes and similar fittings were used in sewer systems, the revision was a unique design. It was a rectangular hole that was closed with a cast iron lid. The latter was fastened to the revision using four bolts, which were inserted into the slots in the corners of the flange on the tee and cover.

The tightness was ensured by a rubber gasket that completely covered the hole. As a result of tightening the bolts with nuts, the cover was pressed against the inspection flange. By the way, the bolts must be tightened crosswise. This created uniform pressure along the entire perimeter of the hole. Those who did not know this spent a long time trying to achieve hermeticity.

Currently, cast iron pipes and fittings are gradually going out of use. They have been replaced by plastic products, which in some technical and operational indicators are superior to their outdated counterparts. The same thing happened with the sewer audit:

- Firstly, raw materials became different.

- Secondly, the form has changed. This is still the same tee, only the hole has become round, which simplifies the process of its manufacture. Accordingly, the lid has also changed. The bolts have disappeared, because the fastening is carried out by screwing the cover onto the pipe, that is, using a threaded connection.

Features of use

The operation of the audit is sporadic. There are many elements that have never been used during their entire service life, so home craftsmen have no experience working with such devices. There are no fundamental requirements for the use of revisions, the only condition is accuracy and attention - it is easy to damage the edges of the outlet with a cable, which will break the tightness of the connection between the cover and the pipe. This can cause a bad odor and leaks, which will require labor-intensive replacement of the entire element. During cleaning, you should take into account the danger and act as carefully as possible, then the result of the work will be fully expected and favorable.

Sewer audit and reconnaissance

Any sewer system, even if it was properly installed and properly maintained, can present problems in the form of a blockage. At the same time, removing a blockage can sometimes be very difficult, because the sewer pipe in some houses is a rather branched and long network. In such a situation, it is sometimes simply impossible to get to the site of the blockage. The sewerage developers have already taken care of this, having come up with a special shaped element that makes it easier to carry out work on clearing blockages. This product is called a sewer inspection. This element is installed during the installation of the sewer network.

Make it yourself or buy it

Independent production of locking devices requires professional skills and a set of special equipment. The sewer system is subject to increased requirements in terms of reliability and tightness.

In the retail chain you can purchase ready-made plugs or parts for their manufacture. It is advisable to take on such work yourself only in cases where the necessary products are not available for sale or their cost is excessively high.

Standards for maintenance and repair work

Sewage is a developed engineering system that periodically requires repairs. The loads on pipelines or equipment are quite large, and problems that arise become noticeable at a later stage. Prevention does not always eliminate the failure of individual elements. Therefore, regulatory documents have been created for the repair of sewerage networks, which clearly define the order and priority of all activities.

Problems in the operation of drainage lines negatively affect the quality of wastewater treatment. Therefore, control and timely restoration of pipelines are strictly regulated by both technical and sanitary requirements. Any detected malfunction must be immediately corrected in accordance with instructions, technical regulations

Particular attention is paid to wastewater networks of industrial enterprises. If the technology involves aggressive compounds, toxic or active substances, the condition of the pipes is constantly monitored by special monitoring devices

The condition of pipelines requires special attention. the appearance or growth of deposits on the pipe walls poses a threat to the operation of the entire line. Bandwidth decreases, network operation mode changes. With increasing layers, there is a possibility of blockages and complete blockage of the pipe lumen. Regulatory documents for flushing external sewers determine the criteria and frequency of measures for cleaning the network cavity from deposits. A specific cleaning method and the number of activities per unit of time are indicated

Particular attention is paid to pressure pipelines, the condition of which requires constant monitoring and control. An accident on a line under pressure will stop the sewer system for a long time and will require lengthy, expensive repairs.

Such incidents cannot be allowed to occur, therefore special standards for flushing pipelines have been developed.

Sewer audit and reconnaissance

Any sewer system, even if it was properly installed and properly maintained, can present problems in the form of a blockage. At the same time, removing a blockage can sometimes be very difficult, because the sewer pipe in some houses is a rather branched and long network. In such a situation, it is sometimes simply impossible to get to the site of the blockage. The sewerage developers have already taken care of this, having come up with a special shaped element that makes it easier to carry out work on clearing blockages. This product is called a sewer inspection. This element is installed during the installation of the sewer network.

Advantages and disadvantages

Installing locking devices gives property owners the following benefits:

- the ability to localize sewage in the event of an emergency;

- access to individual sections of the wastewater system for servicing its individual sections;

- advance reservation of non-working pipes.

Utility service employees use plugs as an effective means of dealing with debtors. The product is inserted into the riser and blocks the pipe coming from the toilet.

Disadvantages include additional costs for the purchase and installation of plugs. In addition, each joint reduces the strength and reliability of the highway.

Features of polypropylene products

The sewer inspection is a kind of tee. One of the outlets of this fitting is hermetically sealed with a lid. This prevents leakage.

When purchasing a sewer inspection, you should inspect it for integrity

You won’t have to look for a blockage for a long time after installation, since there is a short distance between inspection points in accordance with the standards. Before choosing the size of the clearings, decide on the diameter. Steel and cast iron revisions are no longer in demand these days. Polypropylene and plastic revisions are available in three standard sizes with a diameter of 50 mm, 75 mm and 110 mm. At high pressure, polymer elements can operate in pressure and gravity drainage systems. Polymer cleaners are installed on those pipelines that are made of polyvinyl chloride. Their installation can be done in horizontal and vertical planes.

The main advantages of polymer revisions:

- Weight – shaped elements are much lighter than steel or cast iron fittings;

- Frost resistance – at low temperatures, fittings retain their properties;

- Durability – polypropylene revisions are plastic and are not afraid of impacts.

Such fittings are used to drain risers of various origins, even those that contain aggressive chemical substances.

Tips for choosing

Professionals recommend taking a responsible approach to choosing methods and means for blocking sewer pipes.

You should pay attention to the following aspects:

- strength;

- durability;

- tightness;

- material compatibility;

- maintainability.

Calculations must be made for extreme operating conditions.

Thus, clearing blockages can be carried out using household chemicals, a cable with a sharp tip and a jet of water under high pressure.

Clearing the blockage

To understand how to clean the sewer system through an inspection hatch, you need to find the cause of the blockage.

To understand how to clean the sewer system through an inspection hatch, you need to find the cause of the blockage. Common causes of its occurrence:

- rags that fell into the sewer through the toilet after washing windows or floors;

- construction waste, sand, cat litter;

- fat.

To perform cleaning, it is necessary to open the inspection hatch located above the blockage. If you open the bottom revision, then after clearing the blockage, accumulated wastewater may flow down through the hole.

For cleaning, use sewer wire or cable. The device moves through the pipe to the place of blockage while simultaneously rotating the handle. In this case, loops of the cable should not form. Once the plug is removed, the tool will be able to easily move further into the pipe. Your next steps are as follows:

- to pull out the rag, pull the cable towards you, continuing to rotate in the same direction;

- when clogged with sand or construction debris, pour several buckets of water into the toilet;

- To get rid of fatty deposits, use hot water.

How to clean a hatch

If you are faced with a sewer blockage in your plumbing, you must remember that the obstruction is always located above the place where the blockage formed. Therefore, it is necessary to study the diagram of your system and check the hatches - only then can you accurately and quickly determine where the problem occurred.

It is best to start cleaning the pipes closer to the place where the blockage has formed (near the closest hatch).

You can use an electric drill or plumbing wire as a tool. To be effective, clean the hatch that has the most direct path to the blocked area. A large amount of drainage can accumulate above the area where the blockage has formed. Before cleaning the underlying hatch, wait a few hours (after the last time you used the sewer). During this time, some of the water will pass through the place where the plug forms. Otherwise, you will end up with stagnant water after the blockage is cleared.

Sewer inspection may vary in color

How to properly clean a drain in a manhole:

- Place rags and newspapers around the work area. When you unscrew the screws on the manhole cover in preparation to open it, waste water may pour out on you. A bucket, mop, rags and newspapers will help you quickly remove them (they will absorb waste).

- Remove the cap and use the tool to move in the direction of the clog. When you reach the blockage, try to push it to the inspection hatch located nearby. Pull it out or try to destroy its integrity.

- Next, you need to clean the pipes from any remaining dirt and plugs. For this, a strong stream of water supplied from a rubber hose is best suited. Since sewer pipes are laid on a slope, flush from the hatch located above the place where the blockage is located.

Cleaning a sewer using a hatch is an effective and inexpensive solution for clogged sewer lines.

Installation standards

Installation of the revision is provided for by SNiP 2.04.01-85. In panel houses, hatches are installed across 3 bays; in a five-story building, their location in a vertical riser is limited to the first, third and fifth floors.

On horizontal sections, elements are placed at a distance of 8 or 10 m, as well as at turns and branches. Inspections with a diameter of 50 mm are installed on clean industrial wastewater every 15 m, on domestic pipelines - every 12 m, on contaminated industrial waters - with sections of 10 m. For elements with a diameter of 110 mm, under the same conditions, the following distances are accepted: 15, 20 and 12 m.

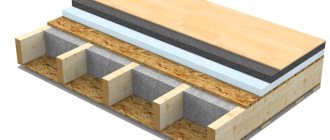

Passing the riser through the ceilings

To pass through the floors, a hole is made at the place where the sewer riser is installed, allowing the riser to be wrapped with rolled waterproofing and the passage to be sealed to the full thickness of the floor with cement mortar.

The section of the riser above the ceiling by 8-10 cm is also sealed with cement mortar. The thickness of the protective layer of cement mortar should be 2-3 cm.

The passage of the sewer riser through the reinforced concrete ceiling is shown in the figure:

***As you can see, laying internal sewerage does not present any particular difficulties and can be done independently if you follow the recommendations given in the article.

In the following publications we will talk about sewer repair, clearing blockages and replacing pipe sections if necessary. We will also learn how to select and install a septic tank and how to carry out all the work on installing an external network.

Bookmark the site so you don't miss new useful publications.

Share this page with your friends on social networks:

When constructing a log house, it is almost impossible to avoid gaps between the logs or beams from which the crowns are assembled. Even when building a log house from rounded logs processed on a machine, it is not possible to fit the crowns to each other tightly enough to... Read.

In order for interior wooden finishing to please the eye with its beautiful appearance for many years, the wood must be treated with a special composition that will prevent wood-boring insects from eating the wood, and will also be able to withstand the effects of... Read.

Many bathhouse owners believe that strong hot steam can cope with any ailment and in case of any illness they advise going to the steam room to warm up properly. But is this really so and is it possible to visit the bathhouse with purulent inflammation of the maxillary sinuses... Read.

Differences between plastic sewer inspection

Inspections for plastic sewer pipes are very different from cast iron ones. At first, buyers noted only a change in material, but manufacturers also made several design changes. These are the ones that should be studied, giving a detailed description:

- The bend on the plastic revision is installed at a right angle, and on the cast iron revision it is mounted at an angle of 45 degrees.

- The lid screws tightly without bolts, as on cast iron structures.

Both features suggest that it is easy to install an additional element on a 110 pipe. To do this, simply insert the fitting into the cuff without wasting time. Professionals definitely use such projects, and not only because of the current SNiPs.

Kinds

Any plug, regardless of the scope of its application, performs the same function - blocks movement. When using this part in a sewer system, it blocks the flow of liquid.

Plugs for installation in the sewer system are made of the same materials as the pipes, that is, plastic or cast iron. In addition, there is a special type of plugs - pneumatic.

Advice! It is very important that the sewer pipe plugs are made of the same material as the pipe itself. You cannot place a cast iron part on a plastic pipe and vice versa. But there are also universal options that utility companies use.

According to the installation method, there are two types:

- Permanent. They are installed for a long period.

- Temporary. They are installed for a short period, for example, during repairs.

Based on the type of fastening, the following types are distinguished:

- with flange connection;

- covers with a sealing ring made of elastic material;

- parts with threaded connections (usually used on metal pipes);

- Welded parts are parts that are permanently fixed.

The following types of plugs can be installed by utility services:

- Mesh. This type allows liquid waste to pass through, but retains solid waste.

- Pneumatic. A pneumatic plug is installed to shut off a separate riser in the general sewer system.

What is a sewer inspection

Inspection of the sewer riser

It's no secret that the sewerage system is a tangle of problems that can sometimes present unpleasant surprises. Of course, they arise if the sewer system was installed incorrectly or was improperly operated. The most unpleasant moment is the blockage, which has to be removed by any means. But how to get there? After all, some sewer systems have a very long and extensive network. Scientists and developers have taken care of this a long time ago. They proposed a special shaped element for the convenience of cleaning work in this engineering system. It's called a sewer inspection.

Problems and solutions

What to do if the cast-iron inspection on the sewer pipe does not open due to rusted bolts?

The bolts are cut off with a grinder or a hacksaw and, after clearing the blockage, they are replaced with new ones. Preferably, brass ones: they won’t rust again.

Opening a cast-iron inspection on an old riser is a non-trivial task.

How to fix a cast iron cover if you don’t have bolts of the appropriate size at hand?

It can be tightened with a pair of improvised clamps made of annealed steel or thick copper wire.

How to ensure the seal of the lid?

- The gasket for the plastic revision can be cut from an old car inner tube;

- It is better to place microporous rubber under the cast iron lid. The edges of the saddle are rarely even; They may simply not press the thin hard rubber gasket around the entire circumference of the hatch.

What to do if there is no inspection near the blockage?

Open the pipe below the blockage as close to it as possible. It is lower - so that the drains standing in the pipe do not flood the house. For cleaning, a hole with a diameter of 3 - 4 centimeters is sufficient: a hook of wire or cable should pass through it. The method in which the hatch can be made is determined by the material of the pipe.

- In plastic, the easiest way is to drill several holes in a circle, and then cut the pipe with a jigsaw or a sharp knife;

Opened plastic sewer.

- The cast iron is chipped around the perimeter of the hole with a sharp chisel or cut with a grinder, and then punched with several blows of a hammer.

When cleaning from the bottom up, be prepared to dodge the waste water rushing into the hole.

How to reseal an improvised hatch after cleaning? As a temporary measure, you can apply a rubber bandage to the drain.

For this we need:

- A rubber bandage or a bicycle tube cut lengthwise;

- Knitting wire.

Temporary sealing of a pipe.

A complete repair is carried out by installing an inspection pipe into the rupture, which will clear the blockage if it reoccurs. The method of installing the revision near the bell is described above. If the hatch needs to be cut into a section of pipe that does not have socket joints, in addition to the inspection and compensator, a sewer coupling will be needed.

The procedure will be as follows:

- The pipe is cut in two places;

The revision can be inserted into any section of the pipe.

- The ends are cleaned of burrs;

- The outer chamfer is removed at both ends;

- The compensating pipe is put on the upper pipe until it stops;

- A coupling is pulled onto the lower one, into the free socket of which a revision is inserted;

- The compensator settles into the revision socket;

- The neck of the compensator is fixed with a clamp to prevent accidental disconnection of the connection.

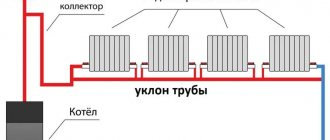

Sewer slopes

Sewer pipes must meet two necessary conditions - to freely pass the probable flow of waste liquid and not to become silted due to sediments accumulating on the internal walls.

To pass the flow rate, the appropriate diameters are selected, but to comply with the second condition, the minimum slopes are calculated to ensure the movement of the waste liquid at the so-called non-silting speed. In other words, at such a flow speed, smoothness of the pipe walls and slope, all contaminants slip into the pipe without being deposited on the walls.

The slope values are given in the table above.

In cases where it is not possible to maintain a normal slope, it is allowed to lay pipes with a minimum slope.

You can approximately determine the minimum slope for any diameter offhand as follows - divide the unit by the pipe diameter in millimeters. That is, for a pipe with a diameter of 100 mm, the minimum slope that ensures that the pipe does not silt at the design flow rate with sufficient filling of the working section of the pipeline will be:

For a pipe with a diameter of 200 mm, the minimum slope will be 1.200 = 0.005.

This method of determining the slope is convenient to use for a quick approximate calculation of the design elevations along which the pipeline will pass when installing an external network. After all, the depth of the wells and the ability to maintain the distance to the standard freezing depth in the area where the sewage system is laid will depend on this.

But do not forget that this way you can determine the smallest possible slope. Normal slopes should be taken according to standard values, which are the following values for different diameters: D100 – 0.02 D150 – 0.01 D200 – 0.008

We also recommend watching a video about the slopes of internal sewers:

We put a plug on the sewer - what to do?

Consumers who find themselves in a situation with a blocked sewer outlet have several ways to solve the problem; they can be roughly divided into legal and illegal. The measures taken by the consumer debtor consist of the following actions:

- Full payment of the rent debt, in this case the contractor must remove the plug within 2 days.

- Usually, a person who finds himself in a difficult life situation can always come to an agreement with the management organization in the form of a written agreement with the executor on debt restructuring. In this case, an agreement is concluded between the parties with phased monthly payment of the resulting debt, although for the last month the rent will have to be paid in full.

- Since, in the opinion of many human rights activists, this method of dealing with defaulters is a humiliation of human dignity and even equates to torture, if the consumer-debtor has valid reasons for not paying rent on time, you can file a claim with the European Court of Human Rights ECHR after going through all legal proceedings authorities of the Russian Federation.

It is clear that citizens with such capabilities are unlikely to find themselves in the situation of rent debtors, because filing a claim will require the services of expensive lawyers. In addition, the cost of the issue is not too high and the application is likely to be rejected for consideration.

- The reason for appealing to the Russian courts may be a violation of user rights when installing a blind sewer plug. Since, according to the law, the contractor does not have the right to turn off cold water to debtors, and the use of a plug actually leads to its shutoff due to the impossibility of draining, there is some probability of obtaining a decision in the courts to cancel the installation. It is clear that suing the state housing maintenance service from the same branch with the court is problematic, however, if the management company is a private structure, the chances of winning the case increase.

- Another legal clue for appealing to the courts is blocking the sewer system for a defaulter in a communal apartment with several owners who do not have rent arrears. A similar situation is if tenants live in the same apartment with separate settlement accounts for rent and one of the parties has no utility debts.

- You can turn to “black” plumbers who have equipment for installing and removing plugs, but this will require free access to the roof through a closed technical floor, and the cost of the service can be quite significant.

- If a consumer-debtor has been given a plug, he has already received money in the amount of about 10,000 rubles, which will be forcibly deducted from him for installing and dismantling the device. There is no doubt that this amount also includes the price of the plug itself, the cost of which is not too high and it cannot always be reused.

Therefore, the debtor consumer can independently try to remove the plug with virtually no consequences, while at the same time providing a good service to the company - its specialists will not have to go to the site and waste time dismantling it.

Rice. 7 Sewer plug for debtors. installed on the toilet

Methods for inserting outlets from household appliances

It is this problem that often causes sewer connections. Moreover, it occurs not only in houses with old layouts, but also in new apartments designed taking into account modern operating conditions. It is in such houses that the pipe in the bathroom, where the washing machine is installed, is concreted into the wall. So it turns out that it is easier to make an insert than to install a new siphon with seven ensuing consequences.

To work you will need the following tools:

- Metal strip, drill and large diameter drill bit.

- A clamp intended for fastening the outlet.

- FUM tape.

The work is carried out in the following sequence:

A clamp is placed on the outlet, intended for fastening metal strips. To fix the clamp on the wall, you need to drill holes in it. Since a connection is made into a pressure sewer, it is necessary to let water through. This action will avoid the appearance of a foul odor. A hole is drilled in the pipe. If you cannot find a drill of a suitable diameter, then for further work you will need a sharp knife or file. They can be used to widen the hole.

It is important to understand that the hole must remain round, and its diameter can only be two millimeters less than the identical parameter in the outlet. The outlet is wrapped with FUM tape and inserted into the hole. There is no need to try to save on the tape and, if necessary, it is better to rewind it completely for reliable fixation. Places for attaching metal strips are marked on the wall, holes are drilled in them and dowels are screwed in

The fastener is twisted with maximum density in order to tightly and securely fasten the clamp to the outlet.

The last step is to coat the edges of the joint with sealant. As soon as the lubricant hardens, an additional connecting layer is formed at the joint.

How to use the toilet if you put a stopper for debts

The toilet can be used if the drainage service is partially interrupted, when a coarse mesh is installed instead of a blind plug. Theoretically, feces can be washed away with large amounts of hot water, in which they gradually dissolve by pushing them down the drain with a plunger. Once a blind modification has been installed, and various methods of removing the plugs have not been used or have not brought a positive result, there can be no talk of using the toilet and sewerage system.

The debtor user can negotiate with neighbors, visit bathrooms at work, in the building of housing and communal services or management company, at public catering establishments (McDonald's), in places of cultural recreation (cinemas, theaters, cafes, bars), dry toilets on the streets or construction sites, paid establishments. In emergency situations, green spaces or high snowdrifts in winter, located near the debtor’s place of residence, can help out.

Rice. 12 How to remove and install a sewer plug for debtors using manipulators

Installing a sewer plug for debtors is a rather extreme measure of influence on the debtor, incomparable in the nature of the inconvenience introduced with a shutdown of electricity, hot water, gas, and besides, the consumer-debtor will have to pay a considerable amount for its installation and dismantling. Although in practice, in order to clear the sewer, any plug can be removed or damaged, it is better to avoid rent arrears, and if such a situation arises, agree with the management of the performing company on the gradual monthly payment of part of the debt according to a jointly drawn up schedule.

Providing sound insulation

Additionally, you can take measures to soundproof the sewer riser; they will be useful both in a private house and in an apartment.

Noise in the sewer can occur for a number of reasons, namely:

- When wastewater hits the walls of the pipeline;

- Penetration of foreign air into the system;

- Contact of pipes with walls or ceilings.

Soundproofing work will help eliminate noise-related inconveniences. This can be done in different ways:

- Installation of risers from special pipes. Of course, this measure is mainly used in the process of replacing an existing sewer system or laying a new one. Such products are distinguished by increased wall thickness and high density of the manufacturing material;

- Use of soundproofing materials. Most often, roll insulation or foamed polyethylene is used for this;

- The use of a special insulating “shell”. It is a finished product that is mounted on a laid pipe;

- Installation of the box and lining it from the inside with mineral wool.

Sound insulation work using roll materials includes the following actions:

- It is necessary to check the tightness of the joints, clean and degrease the surface of the riser;

- Apply vibration-damping material and roll it on top with a regular paint roller;

- Wrap the pipe with rolled sound insulation, securing it with flexible clamps (craftsmen often call them ties).

Installation of a soundproofing plasterboard box is carried out as follows:

The pipes are carefully checked for leaks, because if a leak occurs, the entire structure will have to be disassembled; Wrapped with rolled soundproofing material; Markings are being made for the future box

Please note that its walls should be 50-60 mm away from the surface of the pipe; A frame made of a metal profile is installed, with horizontal jumpers attached every 400-500 mm; We begin to install drywall, it is better to give preference to moisture-resistant. After one side is assembled, we lay mineral wool and sew up the remaining part.

What is a sewer plug for debtors?

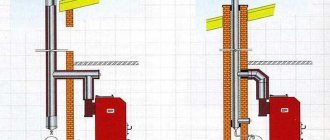

According to the government decree of the Russian Federation dated 05/06/2011 354 (last amended on 05/22/2019) on the provision of utility services to users or owners of premises, the management organization (executor) has the right to take measures to suspend or completely disconnect the apartments of defaulters from certain sources of life support. The legislation does not specify specific utilities from which an apartment can be cut off; the ban only applies to turning off heating and cold water. Accordingly, the management organization has the right to stop the supply of electricity, gas, hot water and shut off water drainage.

With the exception of electricity, the distribution panel of which is installed in the common corridor, access to the apartment is required to turn off gas or hot water - this is not always possible if the tenant simply does not open the door. Therefore, the contractors use methods of blocking communications without access to apartments, and the only one of them after a power outage in a common area is installing a plug on the debtors’ sewer system. The plug is installed through the outlet of the sewer riser on the roof without access to the living space; it is lowered on a long cable and automatically closes the sewer outlet from the apartment after the automatic system is triggered.

Rice. 2 Sewer plug for debtors - operating principle and placement for disconnecting the sewerage service