People are spoiled by civilization and cannot imagine existing without its benefits. These undoubtedly include heating of buildings. Heating systems are constantly being improved and are becoming more efficient and convenient to use.

But this is not enough. Agree, it’s not bad at all if heating equipment is also economical. And this desire is quite feasible - you can make an induction heating boiler with your own hands. It is capable of not only providing the required level of heating of the room, but also very economically using energy resources.

Moreover, even a novice master can assemble such equipment if desired. How to do this correctly and what materials will be needed for manufacturing - we will examine these issues in detail in our article. Let us first consider the design and operating principle of the equipment, as well as the advantages of its use.

Design and principle of operation of the equipment

Before you start assembling an induction boiler yourself, you need to understand its structure and operating principle. And only after understanding these points can you start making homemade products.

How does an induction boiler work?

To understand how induction equipment works, you need to become familiar with the principle of its operation. So let’s remember the school physics course.

When electrical current passes through a conductive material, it generates heat. In this case, the amount of heat received will be directly proportional to the voltage and current. This pattern was discovered by Joule and Lenz, after whom the physical law is named.

Image gallery

Photo from

Operating principle of induction heaters and boilers

Advantages of no direct heating

Standard components of an induction boiler

Homemade induction heater option

But electric current can appear in a conductor not only when it is directly connected to a power source. There is another method, discovered in the century before last by M. Faraday. This is a non-contact method that does not involve interaction between the power source and the conductor.

Its essence lies in the fact that when the parameters of the magnetic field that crosses the conductor change, an emf or electromotive force appears in it.

This phenomenon was called electromagnetic induction. This is what is used in the operation of the induction boiler. It turns out that if there is an EMF, then there will be an electric current, and accordingly, there will be heating of the conductor.

In this case, it will be produced in a contactless manner, using induced currents or, as they are also called, Foucault currents.

Electromagnetic induction can be obtained in two ways. In the first case, to obtain induction, a conductor is rotated or moved within a constant magnetic field. This method is used in electric generators.

Another way to obtain induction is that the conductor remains stationary, while the parameters of the magnetic field in which it is located, namely the direction of the field lines and intensity, are constantly changing.

The operation of any induction boiler is based on the phenomenon of electromagnetic induction

This would have been quite difficult to do if not for Oersted’s discovery. He found out that if a wire is wound around a coil, then when a power source is connected, it turns into an electromagnet. When the direction and strength of the current changes, the magnetic field that this device generates will also change.

If a conductor is placed inside the field, an electric current will arise in it, which is accompanied by heating.

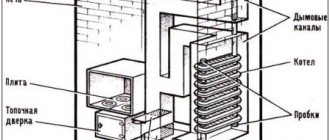

It is on this principle that an induction boiler is designed. Its design is very simple. It includes a housing, which must be thermally insulated and shielded. A pipe is placed inside it. It is best if it is an alloy, but steel can also be used.

However, in the latter case, the performance characteristics of the device will suffer slightly. The pipe is installed in a sleeve made of dielectric material.

The coolant in induction-type boilers is heated from a steel core located inside, which is heated by eddy currents arising in the electromagnetic field

A copper busbar is wound on top of the sleeve using the coil principle. It is connected to a power source. To tie into the heating system, two pipes are used through which the coolant will move.

When power is applied, current flows through the coil and activates an alternating magnetic field, which in turn induces eddy currents inside the pipe. They heat the walls of the part, and partially the coolant that is located in it.

There are variations of the induction boiler with several small diameter tubes installed in parallel. They are used instead of one large pipe. This gives a gain in the speed of heating the device.

In this form, the equipment can already work, but the heating will be weak. To amplify it, you need to pass a high-frequency electric current through the coil. Therefore, the equipment must be supplemented with an inverter and rectifier.

The alternating current from the network has a frequency of 50 Hz, which is not enough for the induction boiler to operate efficiently. Therefore, it is supplied to the rectifier, where it is converted into a constant one.

After which it is sent to the inverter, which is an electronic module with a control circuit and two key transistors. The device converts direct current into high frequency.

It must be admitted that the use of a rectifier and inverter increases the cost of an induction boiler. Therefore, there are models that work without them. They connect to a regular network. But such equipment has impressive dimensions, which makes it possible to increase its efficiency. Devices with an inverter are more compact.

Induced eddy currents very quickly heat the heat exchanger and the liquid inside it

Basic elements of heating equipment

Any induction type boiler consists of several structural elements:

- Inductor. The main part of the device. It is a kind of transformer with two windings. The primary is wound on the core. When current passes, this is where an electromagnetic field arises, forming eddy currents. The boiler body acts as a secondary winding. It takes on eddy currents, heats up and transfers thermal energy to the coolant.

- A heating element. This is the coil core. For the boiler, it is made in the form of a pipe of sufficiently large diameter or several parallel-connected pipes of smaller cross-section.

- Pipes. Designed for inserting the device into the heating network. One at a time, coolant flows into the device; through the second, the liquid leaves the boiler and is supplied to the heating circuit.

- Inverter. This device - an inverter - converts direct electric current into high-frequency current, which is then supplied to the inductor.

Before you begin self-assembly, you should carefully consider what and how the main elements of the device will be made of. Some of them you will have to make yourself, and some you can buy.

For example, you can use an inverter from a welding machine. It would be good if it had the ability to adjust the power.

The inverter converts direct current into high-frequency current. To make homemade devices, you can use a standard inverter for welding

We have listed the main elements of an induction boiler.

A little theory

Anyone can make this device

Many people know that induction cookers exist, but not many know about the principle of their operation. And this is very simple - a special coil of the plate generates magnetic fields of a certain frequency, which, when exposed to metal, excite electric vortices in it.

The latter, in turn, heat it up due to the resistance of the metal. This is how kitchen utensils: pots and pans are heated. The main condition in this process is a metal with magnetic properties, for example, stainless steel, cast iron and iron, but aluminum and other non-ferrous metals will not heat up.

Induction boiler assembly instructions

Induction heating devices can be purchased at the store, but their cost is quite high. Therefore, many home craftsmen try to make it with their own hands. To make a homemade induction boiler, you need to prepare materials and tools.

First you need to purchase a welding inverter. It can be inexpensive, but it is advisable that the device be equipped with a current regulator.

In addition, you should pay attention to the current strength with which the device operates. The standard value for welding inverters is 15A. This won't be enough. You need to look for a more powerful unit.

In addition, you need to prepare a rod or stainless steel wire with a diameter of 7 mm or so. It should be cut into fragments 40-50 mm long. They will be placed in an electromagnetic field, where they will heat up.

The heating element of a homemade induction device is made of copper wire, for winding which you can use any cylindrical object of suitable diameter.

To make the boiler body, a thick-walled plastic pipe is taken. The diameter of the part may vary, but, as practice shows, the optimal option is 50 mm in internal diameter.

Adapters are used to connect equipment to the heating system. Through one of them, cold coolant will flow into the boiler, and through the other, hot liquid will be supplied to the system.

The wire fragments must be placed in the housing. To prevent them from falling out, the bottom of the part is covered with a fine-mesh metal or nylon mesh, which is securely attached to the body. After this, you can lay the wire inside the housing.

Now the upper part of the part is covered with the same mesh as the bottom, and it is secured to the walls of the part. Adapters are put on the ends. The result is a blank from which the induction coil will be made.

To do this, you need to wind an enameled copper wire around it. On average, you need to apply 90 turns. They should be located closer to the center of the part. They need to be done very carefully and evenly, so that you get a high-quality induction coil.

The resulting device can be installed in a heating system. This is done as follows. First, the coolant is drained from the system.

After this, the location where the boiler will be installed is selected. The pipe in this area is marked, after which a fragment is cut out of it, equal in length to the heating device.

Then a homemade induction boiler is installed in the prepared place. The coil is connected to the inverter, and the installation can be considered complete. After this, the system is refilled with coolant.

A copper wire is carefully wound onto a plastic pipe with pieces of metal wire inside.

Only after this can you test the new device. There must be liquid in it.

If you turn on the induction boiler “dry”, the plastic casing will melt from the high temperature. This will lead to partial destruction of the heating system, which is unacceptable.

Another important point is the proper arrangement of grounding of the heating device, without which its safe operation is impossible.

When is it better to make your own?

Making a boiler with your own hands is advisable for houses with seasonal residence. As a rule, low-power equipment is installed in such buildings, and there is no need to spend huge amounts of money on purchasing a ready-made model. The costs of making the device yourself are minimal.

Even for a home-made unit, it is easy to select additional automation units that allow you to set the required temperature parameters. Such a device will not only allow you to set the desired parameters for a long period of time, but will also provide remote control of the entire heating system.

Features of Vortex Induction Boiler

We are already familiar with the operating principle of an induction heating device. There is a variation of it: a vortex induction boiler or VIN, which operates somewhat differently.

Distinctive features of VIN

Like its induction counterpart, it operates on high-frequency voltage, so it must be equipped with an inverter. The peculiarity of the VIN device is that it does not have a secondary winding.

Its role is performed by all metal parts of the device. They are necessarily made from materials that exhibit ferromagnetic properties. Thus, when current is applied to the primary winding of the device, the electromagnetic field strength increases sharply.

It, in turn, generates a current, the strength of which rapidly increases. Eddy currents provoke magnetization reversal, as a result of which all ferromagnetic surfaces heat up very quickly, almost instantly.

Vortex devices are quite compact, but due to the use of metal, their weight is high. This has the added advantage that all massive elements of the housing take part in the heat exchange. Thus, the efficiency of the unit approaches 100%.

This feature of the device must be taken into account if you decide to make a VIN boiler yourself. It can only be made of metal, plastic should not be used.

The main difference between a vortex induction boiler is that its body acts as a secondary winding. That's why it is always made of metal

How to assemble a vortex induction device?

As we already know, such a boiler differs from its induction counterpart, however, making it yourself is just as easy. True, now you will need welding skills, because the device must be assembled only from metal parts.

To work you will need:

- Two pieces of thick-walled metal pipe of equal length. Their diameters must be different, so that one part can be placed inside another.

- Winding (enameled) copper wire.

- Three-phase inverter, maybe from a welding machine, but as powerful as possible.

- Casing for thermal insulation of the boiler.

Now you can get to work. We start by making the body of the future boiler. We take a larger diameter pipe and insert the second part inside. They need to be welded one into the other so that there is some distance between the walls of the elements.

The resulting part in cross-section will resemble a steering wheel. A steel sheet with a thickness of at least 5 mm is used as the base and cover of the housing.

The result is a hollow cylindrical tank. Now you need to cut into its walls the pipes for supplying cold and discharging hot liquid. The configuration of the pipe and its diameter depend on the pipes of the heating system; additional adapters may be needed.

After this, you can start winding the wire. It is carefully wound onto the boiler body under sufficient tension.

Schematic diagram of a homemade vortex-type induction boiler

Actually, the wound wire will serve as the heating element, so it is advisable to cover the body of the device with a heat-insulating casing. This way it will be possible to retain maximum heat and, accordingly, increase the efficiency of the device and make it safe.

Now you need to connect the boiler to the heating system. To do this, the coolant is drained, the required length of the pipe is cut off and the device is welded in its place.

All that remains is to power the heating device and do not forget to connect the inverter to it. The device is ready for use. But before testing, you need to fill the line with coolant.

You don't know which coolant to choose to fill the circuit? We recommend that you familiarize yourself with the characteristics of various coolants and recommendations for choosing the optimal type of fluid for the heating circuit.

Only after pumping coolant into the system carry out a test run.

First you need to run the device at minimum power and carefully monitor the quality of the welds. If everything is in order, we increase the power to maximum.

On our website there is another instruction for making an induction device that can be used to heat the coolant in the heating system. To familiarize yourself with the assembly process of an induction heater, follow this link.

Simple option

The simplest boiler can be assembled at home if you have the skills to work with a welding machine, as well as an angle grinder. Before making a boiler, you need to prepare a square metal pipe measuring 50x50 mm with a wall thickness of 2 mm. You can see the manufacturing process in the Video section.

The dimensions of the pipe and the shape of the pipe may differ, but the wall thickness should not be small.

- Using a grinder, you need to cut the profile pipe into pieces 50 cm long. You will need 5-6 pieces (everything will depend on the width of the induction cooker used).

- Additionally, you need to prepare two elements 25 or 30 cm long (it all depends on how many sections were selected).

- Parts of 50 cm are welded together. All of them must be positioned vertically. First, you can fix them with tacks, and then thoroughly weld all the joints.

- Two additional blanks need to be cut off on one side to form a U-shaped profile.

- To the finished module of 5 elements, two sections with one wall removed are welded onto the lower and upper parts. Their goal is to combine all the individual sections into a circuit.

- Next, you need to hermetically seal the resulting holes on the sides.

- The inlet and outlet pipes are inserted. They should be located diagonally, one at the bottom, the other at the top. You can use a ¾" pipe. Two threaded outlets are welded to them to make it easier to install into a finished heating system.

- All seams after welding are cleaned using a grinder. The finished structure is degreased and coated with paint.

- The device is mounted in the installed circuit. The return flow of the coolant is supplied from below, and the outgoing pipe is supplied from above.

- The heating element is a conventional induction cooker. It is necessary to purchase a stove with the ability to adjust the current and temperature.

- It is located behind the boiler close to its back wall.

- Water passing through this structure has time to warm up. The system must have an expansion tank, as well as a forced circulation pump.

The same option can be made horizontally. To do this, we need a 20x25 cm profile pipe. Its two ends are welded using metal plugs to form a closed vessel. Two holes are cut in the upper wall, an air release valve is installed in one, and a pipe through which water will flow into the system is installed in the other. The return pipe cuts into the side.

What is it

The concept of electromagnetic induction, which was discovered back in 1831 by Michael Faraday, is when a conductor located in a magnetic field creates an electric current.

Every modern transformer works on this principle.

When two insulated windings are wound onto a ferromagnetic core and, for example, 220 V is supplied to one, the second begins to have a voltage that relates to these 220 V to the same extent as the size of the turns of the secondary winding concerns the size of the primary turns.

Transformer windings allow you to remove the required amount of voltage and use it in the operation of electronics or an electric motor. What if a ferromagnet, not connected to anything, is placed in a winding that generates eddy currents?

It is clear that the resulting EMF will be completely converted into the kinetic energy of movement of its molecules, or into heating.

Well, what if you place a ferromagnetic core in a water flow that is distributed along a closed circuit? It is clear that it will begin to be cooled by water, which will then itself heat up.

With this information, you can make an induction heating boiler with your own hands.

But first you need to deal with technical issues:

- find a suitable core made of a material that does not corrode;

- isolate it from the coil, while the impermeability of the structure must be ensured;

- protect the coil from overheating when interacting with high currents.

Main structural elements

In general, an electric boiler consists of the following components:

- Heat exchanger: This is a reservoir connected to the heating system in which the working medium flowing through it receives thermal energy.

- Heater: An element in a heat exchanger in which electrical energy is converted into thermal energy through resistance.

- Electrical circuit: a set of parts due to which electric current appears in the heater.

- Automation unit: monitors the temperature of the coolant using sensors and, if necessary, turns on or off the electric boiler.

All of the above is placed in a steel box with thermal insulation - the housing.

Results

So, the efficiency of induction boilers is approximately 99%, they operate silently, using any liquid heat carrier, they do not require maintenance, and it is also safe and practical. Although such a boiler is quite expensive, such costs are recouped. And if you create it yourself, it will be even more profitable.

Of course, the choice is yours, but it’s better to contact specialists who will tell you whether such heating is suitable for you. But, in general, induction boilers are an excellent alternative to traditional heating systems.

Reviews

Reviews about these heating devices help to paint some picture. It is worth remembering that the durability of the boiler depends not so much on the design principle as on the quality of workmanship.

- “I’ve been heating my house with an induction boiler for the fourth winter. During this time I encountered both pros and cons. Whether I installed it in vain or not, I haven’t decided yet.”

- “I like my boiler. It consumes the same amount as other electric boilers. It has been in service for 8 years without interruption.”

- “The factory boiler is bulky. It costs a lot. A friend of mine took out a loan to buy it. But I’m happy with the purchase – I’ve been using it for several years.”

- “I’m not happy - the advertisement promised more. The power is 5 kW (small), but the machines constantly knock out. It’s a problem for him to heat up to 60°! I called the service center and they told me to bring it to Moscow myself. In general, nothing good, it would be better for this money to buy a heating element with a lot of electronics!”