Almost every owner of a private home has to face the need to install a new front door. This problem may arise during the construction of a building, major repairs, or in the event of failure of an old structure. The range of models offered by manufacturers is wide, but you should navigate this issue in order to choose the best option for yourself.

Which entrance door is better to install in a private house?

What functions do entrance doors to a private house perform?

The front door to a private house is a multifunctional attribute of the building, designed to serve for many years. When choosing it, the owner decides several important issues:

- Thermal insulation. The higher the latitude, the longer the winter and the more severe the frosts, the more important this characteristic becomes. The design should not only insulate the room from the cold outside, but also prevent heat leakage from the inside, preventing the formation of cold bridges (fragments of fabric with poor insulation). The problem is solved with seals and insulation, which at the same time improves sound insulation.

- Wear resistance. The fundamental factor determining practicality and resistance to weather vagaries, as well as accidental (from furniture brought in) and intentional damage.

- Safety. A metal entrance door to a private house meets modern safety standards (including fire safety) better than analogues made from other materials.

- Design. Entrance doors in a country house should not fall out of the overall design concept. Thanks to modern technologies, the design fulfills its main tasks without disturbing the harmony of the architectural style. The choice is striking in the wealth of decorative solutions - manufacturers offer models with mirror elements and inlay, with forging, glass inserts and a variety of fittings.

A door that adds lighting and visually expands the interior space of the house Source erp-mta.ru

Best metal door with MDF finish

Profdoor-MD10 design is heavy and large in size, suitable for decorating entrance and front doors of an apartment. Thanks to the built-in stiffening ribs, the elastic metal sheet becomes reliable and durable.

The door is equipped with a reliable security system, there are lower and upper locks and a peephole. The noise and heat insulation of the model is at the highest level; this design will bring comfort and coziness to the house. MDF finish is used to create a natural effect.

Characteristics:

- dimensions – 200 by 80 cm;

- weight – 70 kg;

- 2 pyramidal stiffeners;

- MDF finishing;

- reinforcement with profile pipe;

- noise and thermal insulation of the door vestibule;

- accessories (two locks, peephole).

Pros:

- the structure is protected from outside penetration;

- high-quality insulation of the model;

- high sound insulation;

- Stiffening ribs ensure wear resistance and reliability of the structure;

- MDF finishing brings the model closer to a natural design.

Minuses:

- weighty design.

What materials can you choose from?

The main entrance to the house attracts the most attention from the street. When it comes to choosing a material, you need to consider cost, functionality and visual appeal.

Plastic

The material of such structures is sheet plastic and PVC profile, with or without double glazing. The thermal insulation properties of double-glazed windows reduce heat loss. Street doors for a private home made of PVC have their advantages:

- relatively low cost and ease of installation;

- durability;

- sound insulation;

- no corrosion.

Cons: the structure can become deformed under prolonged exposure to the sun; When melted, toxic substances are released.

Aluminum

A popular option with many benefits:

- Resistance to environmental influences (higher than plastic and wood).

- Strong, durable, environmentally friendly, fit well into any interior.

- Soundproofing.

- Thermal insulation. This is achieved thanks to thermal break technology (a polyamide insert that separates the profile metal and eliminates the cold bridge).

The wooden model goes well with stained glass inserts Source hullcoexteriors.com

Tree

No matter what material appears in the home construction industry, there will always be consumers who choose classic natural wood models. The wooden entrance door to a private house is made either entirely from solid wood of different species (does not contain any additional elements), or from a combination of wooden boards and metal elements. Their advantages are:

- Attractive appearance and variety of models.

- Low thermal conductivity.

Some serious disadvantages prevent you from enjoying the classics:

- High price.

- Expensive maintenance - wood inevitably cracks and deforms, so it needs periodic treatment.

- Low security level (easy to hack).

- Low fire safety.

Using fiberglass Source pezcame.com

Fiberglass

Such designs, due to their high insulating properties, are among the most energy efficient doors on the market. The benefits don't stop there:

- Safety: they have the strength of steel structures, but without their tendency to corrosion.

- A variety of styles, the ability to imitate natural wood.

- Easy to care for and resistant to dents.

Metal (steel)

The most popular models, thanks to the many options, optimal price ratio and level of security provided. Besides this they:

- have excellent thermal insulation;

- fireproof;

- does not require maintenance (periodic lubrication of hinges and locks is carried out).

There are few disadvantages:

- possible corrosion in budget options;

- The canvas is susceptible to scratches and dents.

Finishing option for steel entrance doors Source erp-mta.ru

See also: Catalog of companies that specialize in installing windows and doors

Features of the door leaf include:

- Thickness. Entrance doors for a private house are assembled from metal sheets 1.5-2 mm thick. If the value is larger, the door hinges need to be strengthened.

- Made from high quality steel. The design has stiffening ribs and protection of external hinges (anti-shear).

- Locks. Certified options are desirable. The locking area is reinforced with a metal plate or box.

- Noise and heat insulation. The space between the stiffeners is filled with non-flammable sealant - mineral wool or polyurethane foam.

The best metal door with a thermal break

NORTH is used in harsh winter conditions, withstands temperatures down to -39 degrees, vulnerable areas are reliably sealed with contours. The thickness of the canvas is 80 mm. The design is reliable as it is equipped with 10 locking points.

The average weight of the model is 100 kg. The stylish design and beautiful appearance are ensured by the polymer powder coating of the model. The door is simple to install, easy to maintain, wear-resistant and durable if used correctly.

Characteristics:

- weight – 100 kg;

- dimensions – 860 by 2050 (960 by 2050) mm;

- 2 sealing circuits;

- 10 locking points;

- canvas thickness – 80 mm;

- polymer powder coating.

Pros:

- the structure does not freeze, there is no ice;

- reliable protection system against penetration;

- multilayer insulation system;

- functionality;

- thermal resistance;

- wear resistance and durability;

- average weight, transportability;

- high-quality fittings, reliable fastenings;

- convenient installation and maintenance of the door.

Minuses:

- high price.

What should you pay attention to when buying, besides appearance?

Quality of materials. The quality of products must be confirmed by manufacturer certificates (product warranty).

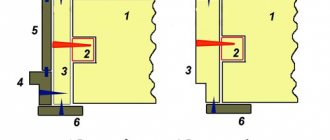

Thermal insulation is effective if:

- thermal insulation thickness is not less than 5 cm;

- the total thickness of the frame and canvas is not less than 8 cm;

- the design contains thermal bridges and a perimeter seal.

Security and external control elements. The burglary resistance of the structure is determined by 13 classes. The street entrance door for a country house, like all analogues for residential premises, belongs to the first 4 (preferably 3 or 4). It is equipped with a drill-resistant lock and a pull-resistant handle.

If you choose a model with glass , use a multilayer (shock-resistant) option. The peephole is selected according to the thickness of the structure, the optimal viewing angle is 180°.

Hinges for outdoor doors. The most reliable (and expensive) are cut-resistant, adjustable, hidden hinges. They are made of steel and can be adjusted (if skewed). If the weight of the product is relatively small, bearings are used for hinges. For massive structures, the option with hardened balls is suitable.

Adjustable hidden hinges Source wareneinkaufen.me

Locks. The place where the locks are attached is ideally reinforced with an armor plate (protection against knocking out and drilling). It is more useful to install two mechanisms - lever and cylinder; they should be comfortable for all family members.

Narthexes and platbands:

- Platband. The purpose of this element is to mask the gap between the door frame and the wall opening, plus, to protect the door from breaking in with a crowbar.

- The narthex The protruding part of the outer sheet that protects the gap between the closed structure and the frame.

Fastening the door frame to the wall. The door frame is the frame on which the door hinges and the structure itself are mounted. It experiences a large load, so the steel in its profile must be thicker than in the door leaf.

The planes of the box and the opening must coincide. During installation, this parameter is regulated by the building level.

Correct thermal insulation

A high-quality entrance door has good thermal insulation. If the structure consists of several canvases with voids between them, then they are filled with a special material that provides reliable thermal insulation.

The best material is mineral wool, because it does not burn and does not emit dangerous toxic substances. Popular materials for filling voids are polystyrene foam and polyurethane foam. They also provide good thermal insulation, but are a fire hazard.

Selection of swing iron structures for a private country house

Sometimes external doors for a private house are designed in the form of hinged double-leaf models, which have their own advantages:

- the doors open easier due to the distribution of the load on the hinges;

- the design takes up less space when opening;

- the façade makes a solid impression.

Models are available with sashes of different widths or with symmetrical sashes, as well as with fixed side transoms, allowing you to narrow a large opening.

Double-leaf entrance doors for a country mansion Source genduk.hk.access.ly

Briefly about the main thing

The front door to an apartment or private residential building has long ceased to be just an element of the enclosing structure. The modern products presented in this TOP are combined solutions that allow you to order a door leaf that is ideal for the interior design of the space being used, and also contributes to high-quality thermal insulation of the room. When purchasing a door, you should pay attention to its dimensions, thickness, weight, as well as the number of locks, the presence of anti-removal bolts and other elements that affect comfort and safety during operation.

Entrance door manufacturers and costs

Experts say that up to 90% of models sold are of domestic origin, which is understandable. The quality of products from local manufacturers meets foreign standards, as they are produced using imported equipment, but the price and delivery time are often significantly less. Buyers are provided with warranty service; Companies are willing to produce non-standard designs to order.

As an example, here’s what a domestic manufacturer of entrance doors offers customers:

Doors to a private house from

presents a series of entrance doors for private houses and country cottages with different levels of burglary resistance.

All door models produced have hinges on support bearings, plus reinforced stiffeners and frame, which makes them resistant to burglary. Thanks to the use of a double sealing circuit and the placement of insulation around the entire perimeter of the door, modern models are distinguished by high sound insulation and heat-saving characteristics.

For the manufacture of door leaves, steel sheets with a thickness of 2 mm to 6 mm with additional reinforcement in the lock area are used. Door frames are made from a profile pipe, angle, channel, plus they have a double rebate, which further increases heat and sound insulation.

When ordering a metal entrance door, you can choose any design and finishing option: forged elements, powder coating, patina, cladding with SIBU panels, veneer, plastic or PVC film, solid oak.

Depending on the budget planned for the purchase, Bastion-S experts will select the best option for fittings, locks and burglary protection.

Entrance doors for a country house from Source bastion-s.ru

Metal doors

A metal front door inspires confidence in many people just by its name. It is widely believed that such blocks are the most durable and reliable. What are the disadvantages of using them and is it all that simple?

Characteristics of entrance door designs

How strong the front door will be is influenced by the following points:

- Production process

- Design qualities

It is clear that the greater the thickness of the steel, the higher the strength of the door. Surfaces with a thickness of 1.2 mm or more will have good properties. length 2mm. Steel ribs will increase rigidity and strengthen the structure.

Stiffener systems:

- Longitudinal (vertical reinforcement elements)

- Transverse (horizontal reinforcement elements)

- Combined (combination of several types)

A longitudinal system of ribs will protect the door from bending corners. Transverse - will make it difficult to push through the door surface. Combining both stiffener systems will achieve optimal results.

Video description

In this video, advice from Bastion-S specialists on choosing doors:

Prices depending on door class

The price of street doors to a private home can vary quite widely, depending on the door material and the design solutions used.

Economy class:

- The price for standard economy class metal doors with vinyl leatherette trim starts from 4.5 thousand rubles.

- For models with laminate or spraying they will ask from 6.5 thousand rubles, and if the shape of the opening is non-standard (arched and similar), then from 9.5 thousand rubles.

- Doors with reinforced leaf, although without any special frills, will already cost 11-15 thousand rubles.

Middle price segment:

- Doors with glass and forging - from 16.5 thousand rubles,

- A variety of models with MDF finishing, the cost of which will range from 23 to 38 thousand rubles.

Premium class. Divided into two main categories:

- Just doors made of natural materials - with solid wood finishing, or models of wooden entrance doors for a private house made entirely of wood. Price ranges from 39.9 to 70 thousand rubles.

- Elite class products, the cost of which depends entirely on your wishes. A price tag of 100-120 thousand rubles and above is not uncommon here - this is the price for an individual approach to the client and an original design, which is developed taking into account the entire space surrounding the door.

Among foreign models, doors from China are widely represented, but their budget prices often mean lower quality than their average domestic counterparts. The remaining foreign manufacturers share a small part of the Russian market among themselves. Italian (MASTER, Panto, Dierre), Finnish (ALAVUS, Fenestra), Israeli (Super Lock) and Polish (Gerda) brands offer premium products using advanced technologies and natural materials.

You don't have to open the doors to see who's outside Source kenneyandcompany.com

The best metal door made in Belarus

Veldoors Chocolate design is available in two sizes. The door opens from both sides. Beautiful design and high-quality finishing using PVC. The simplicity of geometric shapes and dark chocolate color give the design elegance and special charm.

Characteristics:

- dimensions – 860 by 2060 (960 by 2050) mm;

- 2 sealing circuits;

- filler – ISOVER mineral wool;

- covering – structured MDF panel;

- accessories (2 hinges with bearings, 2 locks, night bolt, anti-removal pins).

Pros:

- Possibility of opening from the right and left sides;

- environmentally friendly insulation;

- external and internal finishing of MDF;

- compaction of vulnerable areas of the metal sheet;

- the main lock is protected by an armor plate;

- stylish design;

- quality headset.

Minuses:

- difficulty in care;

- accumulation of dust.

How is installation done?

Whatever the street doors for a private house, the work proceeds according to the same plan:

- Dismantling the old structure (optional) and preparing (leveling) the opening.

- Checking the completeness and operation of the lock.

- Installation of the box (frame). The correct position (coincidence of the planes of the box and the opening) is checked with a building level.

The level checks vertical and horizontal planes Source bulgara-ny.com

Door locks

Access to a private home must be protected by at least 2-3 locking systems. Almost half of the protective measures are related to the installation of reliable locks. For greater protection, it is recommended to use different types of locks (level and cylindrical, cross-shaped, disk, as well as electronic types of locks).

Deadbolt lock

The main element of the front door is the deadbolt (also called the deadbolt). Oddly enough, the last and most reliable means of preventing thieves from entering is a regular deadbolt. When the key locks the lock, the bolt fits into a special hole in the box. The closed door is secured with a spring-loaded latch. The bolt is moved by a steel rotating cam. The command to move the cam comes from a key inserted into the mechanism.

Level lock system

A design feature of the lever lock is a set of plates with cut teeth. The key bits engage with these teeth. The secrecy of the lock is given by the special arrangement of the teeth and their size. At the customer's request, for example, if a key is lost, the lock can be recoded without disassembling the case.

Lever lock systems are recognized as the most reliable due to their increased resistance to burglary and mechanical stress: the lock cannot be damaged if small objects get into the hole.

Cylinder lock or “English” system

The side face of the cylinder lock has grooves. When the key enters the cylindrical part of the cylinder, thin plates from the 2 halves are pushed out. The joints of the plate parts are located at the boundary of the housing with the cylinder and the rotary cylinder. This makes it possible to turn the key and activate the cam. As a result, the protective bolt moves.

Cylinder locks are most often installed in metal doors that are locked with flat keys with ridges and recesses. A distinctive feature of such locks is increased secrecy, however, such devices are little protected from vandals. Even a match stuck into the cylinder can cause such a key to become inoperable.

Cross locking system

Cross-shaped locks work in conjunction with keys that are shaped like a cross. The larva consists of 4 rows of plates. These locks are easy to open, so they are not particularly reliable. Another drawback is the low vandal resistance. Such a system can only act as an additional means of protection and is not suitable for the main lock.

Disc locking system

The locks of this system contain special discs that do not allow the cylinder to turn without inserting a key. The shape of the key has grooves that are placed at angles. The inclination of each slot corresponds to the inclination of the disk. The well resembles a truncated circle, so foreign objects are easily removed from it.

Disk systems are characterized by high secrecy of the mechanism, which does not allow opening the door with master keys.

How to choose a lock for the front door - security and privacy class

Video description

About the choice of doors from various materials in the video:

And a few examples in the photo:

Few people use door knockers, but they look very nice Source timgori.pw

Although half of the door area is occupied by glass inserts, it is quite difficult to break into. Source stroy-masterden.ru

Forged elements will never go out of fashion Source formywife.info

The door design is ideal for a home with a second light Source deavita.fr

The door design looks very “powerful”, despite the transparent wall Source masterlad.prom.ua

Type of external finishing of the canvas

The outer side of the door structure is the calling card of the living space, which obliges the owners to think about decorating this surface. Among the most popular methods of finishing the front side of the front door are the following types of materials:

- Hammer paint. The simplest and cheapest finishing option is that the paint and varnish composition is applied directly to the degreased metal surface, reliably protecting it from corrosion.

Hammer painting

- Natural wood. This type of finishing is usually used in business-class apartments or in private residential buildings. The materials used are carefully prepared panels made of valuable wood, which are fixed to the metal with hidden fasteners.

Refers to goods of a higher price category. To protect the wood from rotting and loss of its original appearance under the influence of an aggressive environment, the material is coated with several layers of varnish, and, if necessary, a pigment composition is applied to the front surface.

Natural wood finishing

- MDF panel. Unlike the inside, on the front surface of the door, this material can only be used when installing the product in an apartment. The structure of the panel absorbs moisture, which leads to its destruction when installed outdoors. As a rule, the panel has a machined surface, imitates panels, and is also covered with a high-strength colored laminated film.

MDF panel from the front side

- Lamination. Polymer flexible films with a matte or glossy tint are widely used when finishing doors in economy class apartments. The material can be equipped with a self-adhesive surface and can be installed with your own hands. However. in most cases, lamination is fixed under the influence of elevated temperature, in factory conditions.

Lamination on the door surface

- Powder polymer coating. It is applied to a prepared metal surface using a spray gun, since the molecules of the dry substance have magnetic properties.

After application, the product is placed on hangers in a thermal chamber, where the powder melts and sinteres at a temperature ranging from 180 to 200 oC for 20 to 40 minutes. The coating is characterized by a uniform layer, an attractive semi-gloss shine, as well as increased wear resistance and mechanical strength.

Powder coating

- Leatherette upholstery. This finishing option has been known to many consumers since Soviet times - batting is glued to a metal sheet, which is covered with leatherette. After fixing the material, its surface is tightened using nails and wire.

Leatherette screed

- Carriage tie. This finish is a premium type of upholstery. For the screed, natural leatherette or high-quality leatherette is used. The stitching of the canvas is carried out in the factory, the product looks more voluminous and noble compared to the classic leatherette finish.

Carriage tie

Products such as carriage screed or upholstery contain internal filler, which helps to increase thermal insulation properties and absorb vibrations.