An electric heat gun is a device that heats through the use of a powerful tubular electric heater in the form of a heating element. The fan is one of the important parts of the design. Hot air is not blown out of the unit, but is processed in a heat exchanger, due to which the temperature inside the room rapidly rises. The device is powered by an electric generator or mains power. The metal body is protected from corrosion by a layer of polymer coating of the highest quality.

Features of the electrical circuit

Among the many modifications, the electrical circuit of a heat gun is widely popular. All electrical parts are placed inside the housing. Heating elements with ribs are also located here to improve heat transfer.

In the general diagram, all controls are located at the rear of the housing. With their help, the temperature is regulated and switched from one mode to another. Special devices emit light and sound signals when the device is connected to the network.

When choosing an electric heat gun, it is necessary to determine as accurately as possible the volume of space and the overall dimensions of the room that is supposed to be heated. The reliable and safe operation of the device will depend on this.

Connection option to a three-phase power supply network type TRIANGLE

Let us consider in the diagram the second option for connecting heating elements to a three-phase network called TRIANGLE.

With this option, the heaters are connected to each other in series. As a result, we should have three shoulders for phases A, B and C. For example:

- For phase A - we connect the first terminal of the heating element No. 1 and the first terminal of the heating element No. 2

- For phase B - connect the second terminal of the heating element No. 2 and the second terminal of the heating element No. 3

- For phase C - connect the second terminal of the heating element No. 1 and the first terminal of the heating element No. 3

Now that we have become familiar with the two types of connecting heating elements, we can consider the dependence of the power and temperature of the heaters on the type of connection circuit.

general description

The diagram for connecting the fan heater to the Volt network looks like this: If the power of the product is over 6 kW, you cannot do without three-phase electrical wiring. Connect the plug to the voltage, switch the device to operating mode, set the desired heat supply.

For example, the Ballu electric heat gun is distinguished by the presence of heating elements of an improved design, which significantly increases their working life. The fan is one of the important parts of the design.

Afterwards, the fuel pump is attached, and a metal pipe is connected to the tank, with the help of which the fuel is supplied first to the fuel filter, and then to the injector. Small size and weight make devices of this type transportable and mobile. Any device in this category is prone to consuming large amounts of electricity.

You can also choose a regular metal tank, which must be covered with a thermal insulation layer. The power of the heating element should be stamped on its body or written down in the accompanying documentation, but if it is an old device, you can measure its resistance with a multimeter and determine the power using the above formula. In addition to the three main elements of the housing, the motor and the heating element, for operation you will need a three-core cable, bolts, safety automatic circuit breakers and residual current devices (RCDs) that disconnect the network in a dangerous situation. Device design The circuit of an electric heat gun assumes the presence of very specific components, but there are also optional components. With proper assembly of the electrical circuit, the risk of spontaneous combustion for such guns is minimal.

It is important to remember that it is almost impossible to heat a plank shed, a large hangar or an iron garage. DIY pneumatic machine

Read more: How to restore electrical

Features of use

Electrical diagram of a heat gun Rules for using a direct heating Master diesel heat gun Master b diesel heat guns are directly heated heaters that supply thermal air along with combustion products.

So, if the device’s power does not exceed 6 kW, it can be connected to a single-phase network. Connect the power cord, cable from the heating elements and fan to the control panel. After checking the insulation of all connections, you can test run the device.

To make an electric gun with your own hands, you will need: a steel body; frame where the structure will be located; electric fan; wires for connecting the device to the electrical network; switch The motor with fan is mounted on the rear grille of the heat gun behind the heating elements.

At the moment, a wide range of domestic and foreign products are on sale, and the prices are quite reasonable, for example, for products. And not every network will support such a device.

Post navigation

The heat gun provides targeted heat supply and can be used in warehouses, cottages, shops, shopping centers, offices and hangars. Such guns are used either in open areas or in rooms with a good supply and exhaust ventilation system. After completing the assembly, perform a test run of the heater. The heating elements in this model, 6 of them, look like this: Depending on the selected mode, either three heaters or all six are used.

Hot air is not blown out of the unit, but is processed in a heat exchanger, due to which the temperature inside the room rapidly rises. It is not recommended to direct high-power heat flow to synthetic materials, which, when heated, release caustic and toxic substances. Electromechanical injection is carried out by installing a fuel pump and an air blower. Connecting a diesel gun Check that there is fuel in the tank, check its level, and securely close the fuel tank opening. That is, the heating element is responsible for the heating temperature, and the fan is responsible for the quality of distribution.

Electric gun

Such an assembled system will make electric heating fully automatic and economical, so we recommend using it. To avoid various kinds of problems associated with the operation of the heat gun, you need to adhere to certain rules. The thermoelement 7 heats up and facilitates the passage of gas into the fire extinguishing chamber 2. This is especially true for transporting the gun in autumn or winter.

Hot air masses, together with combustion products, rush into the heated space. Conclusions and useful video on the topic What do you need to know about the electric gun? Some heat guns are connected to a volt network. HOW CURRENT FLOWS IN THE CIRCUIT - Read Electrical Diagrams Part 1

Operating principle

Such guns are often called fan heaters due to the similarity of their operating principle, but they have certain differences. They operate in the same way as other similar products: air flows around the combustion chamber body with the help of a fan and heats the room.

Operating principle of a heat gun

The design of modern guns includes a special sensor that turns off the device when a preset temperature is reached, thus achieving significant fuel savings. Garage workers make guns that can operate on different types of waste oil.

Factory or homemade, heaters have several very vulnerable spots, so they require frequent repairs. This includes cleaning nozzles and filters, replacing the fan and much more. To find out all the vulnerabilities, you need to study the design of such guns.

Important advice! After using the gun and placing it in long-term storage, the remaining fuel must be drained and the tank thoroughly rinsed to remove any remaining diesel fuel. Using fuel that has been stored for a long time is unsafe for the product.

How to convert an electric stove socket from 380 volts to 220? Stove Lysva EP-31

If it is a household electric oven, it cannot operate on 380 V; all household ovens operate on 220 V. Maybe you mean that it has a large round plug with 3 large pins? This is a 220V plug for high power electrical appliances. There is no point in replacing it with a regular one - it will simply melt. You need to replace the socket with a similar one. It’s simple - the side sockets are phase/zero, the middle one is grounding. For reliability, you can disassemble the plug of the panel - the ground wire is always green and white. And it is advisable to have a separate wire from the panel to the stove, otherwise the plugs will be knocked out.

When asking a question, you need to at least explain in detail what you want to do. where is the so-called socket or what do you call the terminal block in the stove, people begin to guess and guess and are unable to answer the question that interests you

This outlet is already 220 volts. the three contacts there are: phase zero ground. if the outlet had 3 phases and 380 volts, then there would be 4 contacts!!!!

touch.otvet.mail.ru

Normal heater circuit

I started looking for a more sensible heater connection diagram. It turned out that there is a special Heater Control Unit BU-3-25. From the name it follows that it has 3 degrees of regulation and a load power of 25 kW. There was no diagram for it, there is only a connection diagram:

Connection diagram for heater control unit

Connection diagram for heater control unit

From this diagram it can be seen that the control unit switches sections of heating elements in accordance with the set temperature. From the description it follows that the unit controls the temperature in the heated room and, if it is lower than the set one, turns on the heater.

Also, in EKOTs heater models with a power of 40 kW or more, a delay in turning off the fan is provided when the heating elements are turned off. The temperature is set smoothly with a potentiometer, and by turning on the number of heating sections, the heating power (speed) (of reaching the set temperature) changes.

Thermal relay TK-20 provides emergency protection against overheating in case the heater housing heats up above 140 0C.

I needed to create a control cabinet without any special frills; there was no need for stepwise or even smooth changes in power and temperature. It is necessary to heat a production room with an area of about 120 sq.m. in winter.

It was decided to take the following scheme as a basis:

Heater control panel diagram (initial version)

Heater control panel diagram (initial version)

This circuit has temperature protection, fan motor protection, blocking the activation of heating elements without a fan (somehow not clearly shown in the diagram), and a power-on indication. As a result, the heater control unit is assembled according to the diagram below:

Heater for supply ventilation - electrical connection diagram

Heater for supply ventilation - electrical connection diagram

The scheme works as follows. First, the first START button turns on the KM1 starter and starts the heater fan. The fan motor is protected by a thermal relay RTL for the appropriate current. When the thermal relay is triggered (problem with the fan), the power supply circuit of the KM1 starter opens and the power to the motor is turned off.

When the heater fan is turned on, the heating elements can be turned on due to the closure of the blocking contacts KM1.5. The heating elements are turned on by pressing the second START button. At the same time, the intermediate starter KM2 is switched on, which turns on a powerful starter of the 4th magnitude, which turns on the heating elements themselves through its contacts. The heaters are connected all at once for maximum room heating power.

To ensure fire safety, this scheme provides the following protection methods:

- engine stop protection (thermal relay RT1)

- protection against turning on heating without turning on the fan (KM1.5)

- protection against problems (overheating) of a powerful starter (RT2 contacts) - this is not necessary to install

- protection against overheating of the heater housing above 140 0C (thermal relay RT3). In this case, the fan will continue to rotate as usual, which will easily eliminate overheating.

The circuit can be supplemented with indication of switching on of starters and indication of accidents (closed contacts of thermal relays). You can also introduce a three-pole circuit breaker to the power supply circuit of the heating elements. Current - 40 or 50 Amperes. And a 63 Ampere machine at the input of the device, since the starting current is small.

But I categorically do not recommend

(except with additional contacts). After all, if it turns off, only the RT3 thermal relay will provide protection, and after its operation, the temperature of the heater housing can reach 200 0C due to thermal inertia. In addition, I personally doubt the reliability of the thermostat operation.

Connecting heaters according to the STAR scheme for an electric boiler

In electric heating boilers, heating elements can be connected in various ways, but to demonstrate the STAR-type connection diagram, we will describe the option of installing dry heating elements to a 3-phase power supply network with a voltage of 220V.

The high power of dry water heating elements imposes certain requirements on the quality of connections. The reliability of the connections must be ensured by high quality heat-resistant wires and strict compliance of all actions with the diagram described in the instructions.

The first thing to do is to screw on the M4 nut when connecting the phase drives. Next, you need to apply the washer and install the ring terminal of the power wire. The next step is to apply another similar washer, on top of which another special Grover spring washer is placed. And all this needs to be securely fixed with an M4 nut.

The wires that lead to the neutral phase are secured using an M8 bolt. The neutral wire must be placed in a jumper, which is located between the contacts of the heating element holes.

Be sure to ground the body of the heating element and power wires after connecting all the wires to the supply and neutral contacts of the heating element. In most cases, in standard electric boilers, the grounding bolt is located on the left side near the block with heating elements. We must connect the grounding wire to it.

After connecting the wires, ground the heater body and the heating element connection wires. Typically, grounding boilers have a bolt on the left side of the electric heater block, to which the grounding conductor should be connected.

You can use either a separate potential equation wire or a wire from the grounding terminal block of the control unit for grounding.

You can clearly see all of the above described in the figure below in the form of a diagram and photo of connecting the heating element.

If you have done everything in strict accordance with the instructions, the connection of the heating element of the electric boiler can be considered complete. All that remains is to return the protective casing to the heating unit.

In electric boilers, heating is controlled based on data from temperature sensors. Thermostatic devices are located on the main control panel of the boiler. The thermostat will receive data on the temperature of the heating element and the temperature of the coolant. Based on these readings and the settings set on the thermostat, a decision is made automatically to supply or turn off power to the heating elements. While the temperature is below the set one, power will be supplied and the heating elements will produce heating, and when the threshold value is reached or exceeded, the power will be turned off and the heating elements will stop heating. When it cools down to the lower threshold, the heating element will turn on again.

The thermostat allows a person to set the temperature (upper and lower thresholds) just once, and then the electric boiler will operate automatically, and the temperature will be maintained at the desired level.

There is an option to use thermostats with several types of temperature sensors, which will not only control the heating of the heating element itself, but also the air temperature in the room. To do this, the temperature sensor must be installed at a distance from the boiler and coolant.

How to install and connect a heat gun? — EcommerceMarket.ru

Monitors, Keyboards and mice, Printers and MFPs, Scanners, Web cameras, TV tuners, Computer headsets, Steering wheels and joysticks, Computer acoustics, Graphic tablets, Microphones Processors, Motherboards, Memory modules, Hard drives, Cases, Power supplies, Video cards, Optical drives, Sound cards, Coolers and cooling systems, Containers for hard drives, Controllers Air grills, Blenders, Pancake makers, Coffee makers, Coffee grinders, Kitchen scales, Food processors, Mixers, Multicookers, Meat grinders, Steamers, Juicers, Toasters, Deep fryers, Bread makers , Electric kettles ecommercemarket.ru

Communications liner

It is necessary to take into account that the heating main must provide the required cross-section (the diameter must meet the technical requirements). And yet, the necessary flow of coolant through the fan heater must be ensured. If the diameter of the pipes and the temperature of the coolant are sufficient, but the speed of movement (flow) is very weak, this will negatively affect the thermal power of the device!

Also, think about how to supply power and control circuits. Calculate the required distances to purchase the required footage of electrical wire.

And one moment. Make sure that the wall (or ceiling) on which the fan heater will be mounted is of sufficient strength to withstand the load.

Control circuit

And finally, about the implementation of the control unit. The circuit is assembled using starters, the parameters of which are shown in the diagram. The heater control cabinet must be installed as close to the heater as possible. This will allow you to avoid a long route length, and most importantly, large cross-section wires. However, the cabinet should not be exposed to hot air.

The route consists of the following cables:

- 4x6 cable – power supply to heating elements, grounding. It is recommended to lay the grounding wire separately.

- cable 4x1.5 – power supply to the air heater fan electric motor, grounding of the motor.

- cable 2x1.0 (2x0.75) – wires to the thermal relay.

An electric industrial heater is a very energy-intensive device, consuming in this case 25 kW per hour. Since the cost of heating electrically is high, it is much more profitable to use water heaters, and install electric heaters in large enterprises. For example, in my case, the power of industrial equipment in a heated workshop is more than 100 kW.

At the moment, the heater has been working for more than a year (2 winter periods have passed) without any complaints.

If you change clothes in the winter in the locker room of the “Kotelny-2” workshop of the “Krasny Kotelshchik” plant in Taganrog - remember me with a kind word!

Article source

If you are interested in the topics of the channel, also visit my website – https://samelectric.ru/ and the VK group – https://vk.com/samelectric

Don't forget to subscribe and like, there's a lot of interesting things ahead!

Appeal to haters: for insulting the Author and Readers of the channel, I’ll send you to the bathhouse.

Boiler heating element connection diagrams

Option 1. Connection diagram to a single-phase network

Typically, three single heating elements in such a design are placed so that the contacts from different heating elements are located opposite each other.

To connect a heating element to 220 Volts, you need to connect three contacts from different single spirals with a jumper and connect them to the working zero.

The three remaining contacts also need to be connected and connected to the working phase. This will ensure that all heating elements are turned on simultaneously for heating when power is applied.

However, the connection is not made directly this way, and for every second contact the heating element is connected to a phase after its own machine or, what is done more often, it is connected from its own control line (automation).

Option 2. Three-phase connection

If we look at the heating elements for boilers sold, we will see that almost all of them are labeled as 220/380 Volt heating elements.

If you have this version of the heating element, and you have the opportunity to connect to a three-phase power supply of 220 Volts or 380 Volts, then you need to use connection diagrams called “star” and “delta”.

According to the “star” circuit of 220 Volts, three phases, you need to connect the three contacts of single heating elements with a perm and connect them to the working zero. Apply to the second free contacts via a phase wire. Each single heating element will operate from 220 Volts, independently of each other.

According to the “triangle” circuit of 380 Volts, you need to connect contacts 1-6, 2-3, 4-5 with jumpers, for single heating elements 1-2.3-4.5-6 and supply phase wires to them. Each single heating element will operate at 380 Volts, independently of each other.

Connecting different types of heat guns

Electrical

Electric heat guns are connected according to the same principle as other electrical appliances. Depending on the model, such guns are connected to a 220 V or 380 V outlet. Make sure that the device is grounded. It is not advisable to place the gun under the outlet itself. If the wiring is old or simply not designed for heavy loads, then it is better to connect the gun to a separate line.

Do not plug the gun into a power outlet if the switch is in the on position. This may result in voltage drop. Set the temperature gradually to the desired value. It is advisable to pause for 5 seconds after each increase in heating level. This will allow the gun to heat up evenly.

Do not turn off the gun by simply unplugging it from the socket.

Diesel

Diesel guns are refueled like a regular diesel engine. Before turning on, check that there are no fuel leaks. If you have an indirectly heated diesel gun, connect it to a hood or chimney to remove exhaust. Don't forget to check that there is traction.

Now plug the gun into the outlet. To operate, it requires very little electricity, so the load on the power grid is small. Turn on the device and gradually set the desired temperature.

Gas

Using a reducer, connect the gun to a gas cylinder or gas line using a hose. The hose is included with the device, but you can use another one. The main thing is that it is a two-layer reinforced hose. The length of the hose must be at least 2 meters. The gas cylinder or gas line must be located behind the heat gun. The further the better. If you are using a cylinder, it must be in an upright position.

On the reducer, set the pressure level specified in the device characteristics. Before turning on the maximum gas supply, check the system for leaks using a soap solution. After this, you need to equalize the pressure.

Connect the heat gun to the electrical network and give the system a minute to purge. Now turn on the piezo ignition. Smoothly set the desired operating mode.

Connection option to a three-phase STAR power supply network

The STAR type is used in dry heating elements from the Polimernagrev company in connection option No. 3 with four bolts as the current output type. Also, the “star” connection type can be used when connecting a block of heating elements. In these cases, the heating coils are connected according to the following electrical diagram:

Let's now look at how we can connect heaters according to this scheme, if we have not special, but standard electric air or water metal heating elements.

Only one terminal from each heating element should be connected to the supply voltage. That is why, to connect to a three-phase network, we must have a multiple of three electric heaters. The remaining contact terminals that are not connected to voltage must be connected to one so-called zero point. Thus, we get a three-wire connected load.

Let's take a closer look at the three-wire connection diagram at 380 V for turning on 3 water heating elements. In the first figure, you can consider the circuit for switching on the heating elements described above, and in the second, a special device is added to the diagram for supplying voltage to the heating elements with protective switches. As can be clearly seen in the diagram, every second heater current lead is supplied to phases A, B and C, and the rest are connected together.

By connecting heating elements in this way, we obtain a power supply voltage value on each electric heating element between the connection to the network and the neutral point equal to 220 V.

In the above diagram you can see that the heater terminals on the right are connected to phases A, B, C. The terminals on the left are connected at a common neutral point. The operating voltage between the terminals on the right and the neutral point is 220 Volts.

There is also an option for connecting to a three-phase STAR network, which uses a four-wire circuit. With this method, three-phase power is used with a voltage of 230V, and the zero point is supplied to the neutral of the power supply.

Here, as in the previous case, some terminals are connected to the zero point, while others are connected to a three-phase network. If the connection to the zero point is transferred to the zero bus of the power supply, we will receive a voltage of 220-230V on each heater between the power supply and zero.

When it becomes necessary to completely turn off the power to the heaters, you need to use switches of the 3+n or 3p+n type, capable of operating in automatic mode. Automatic machines of this type can be used to completely transfer all power electrical contacts to a fully automatic operating mode.

Let's look at how the STAR connection type should be used in practice, using the example of installing heating elements in an electric boiler.

How to choose an electric gun

220 V electric heat guns do not consume as much electricity as many users believe, especially since they do not work all the time: they heat the room to the set temperature and automatically turn off. It will turn on again when the temperature drops quite significantly.

Each user should know what factors need to be taken into account when choosing this unit:

- what specific task should an electric heat gun solve - constant heating of rooms or occasional use, drying surfaces during repairs, etc.;

- specific features of the room - dimensions, whether there are losses due to poor-quality thermal insulation, purpose of the object;

- power source - constant electrical network, is it convenient to use in these conditions;

- optimal power so as not to waste electricity;

- dimensions, weight of the unit and its mobility;

- Pricing policy is not the least important thing - you need to choose a powerful device, but at an affordable price.

When purchasing, you must check all the equipment, the presence of warranty cards, the integrity of the wiring and the serviceability of the heating elements.

An electric heat gun is not bought for one or two seasons - it must be used for at least 10 years without visible defects, so make your choice carefully.

How does a heat gun work?

An electric fan draws cool air through the back of the gun and forces it through the entire system to the outlet. The air inside the gun heats up. The guns use electricity to operate the fan and heat. The heating principle itself differs for different types of devices:

- Electric - air passes through a spiral or tubular heating element and is heated.

- Gas - instead of a heating element, a burner is used for heating. The gas enters the device, where it is ignited by a piezo element. The air passes through the flame and heats up. If the flame goes out, the automatic system automatically turns off the gas supply.

- Diesel - an internal combustion engine is used for heating. There are two ways to heat air using a diesel engine: Direct heating - a fan drives cold air directly into the combustion chamber. The air exits through the nozzle along with the exhaust gases.

- Indirect heating - the combustion chamber is placed so as to heat the inside of the gun body. The air is heated from the walls without entering the combustion chamber. Exhaust gases are discharged separately.

Infrared – Flamentines are used for local heating. These are ribbed tubular heating elements made of aluminum. When heated with electricity, gas or kerosene, flamenines emit infrared radiation. Mirror reflectors are placed behind the tubular heating elements. This way the radiation is not scattered and does not heat up the device.

Consumer reviews of electric heat guns

This section contains several reviews of the models of heat guns discussed in this article, shown in the photo or similar in technical characteristics.

Review of the model "RESANTA TEP-3000N":

More details on Otzovik:

Another review about the RESANTA TEP-3000N model:

More details on Otzovik:

Review of the Ballu BHP-P-3 model:

More details on IRecommend:

Review of the Ballu BKX-3 model:

More details on Otzovik:

Another review about the Ballu BKX-3 model:

More details on Otzovik:

Review of the model “Ecoterm EHC-03/1B”:

More details on Otzovik:

Review of the model “Hintek Prof 06380”:

More details on Otzovik:

Safety precautions when using guns

To ensure fire safety measures, the container containing the fuel reserve for the product must be located at a distance of 8 meters from heating devices or any open flame sources.

Remember! Instead of diesel fuel, you cannot use gasoline of any brand: the likelihood of an explosion increases many times over, because it is more volatile.

Safety measures when using guns are quite simple - you should immediately leave the premises if you feel:

- sudden and severe dry mouth;

- pain in the throat, nose or eye area;

- sudden attacks of headache;

- urges of nausea.

Many people react very painfully to carbon monoxide indoors: for example, people with lung diseases or cardiac patients, anemia, and pregnant women. They are contraindicated to be in places where a diesel heat gun with direct heating is used.

Types of heating elements

Diagram of operation of a diesel heat gun.

An electric heat gun can have two types of heating elements located in it: a heating element in the form of a spiral or a heating element.

When using heating elements, the device heats up more slowly and the heating temperature is not as high as when using a spiral. But such a heat gun is much safer and more durable than a spiral one. This happens because dust and debris do not collect on the heating elements, so accidental fires are minimized. It is the choice of a heat gun using heating elements that is recommended for use in residential premises.

An electric heat gun using a spiral heating element is characterized by almost instantaneous heating, the atmosphere in the room quickly becomes comfortable for further work, but at the same time some of the oxygen is burned. Therefore, it is not recommended to use it in residential enclosed spaces; it is better to use such a device in a garage, outbuildings, etc.

These air heaters can operate at voltages of 220 V and 380 V.

Installation and connection of a heat gun

The method of connecting the heater depends on the type of its drive. There are also general operating rules that must be followed when connecting any heat gun.

General rules for operating a heat gun:

- Place the device only on a flat surface.

- It is advisable to leave a gap of at least one and a half meters from the ceiling to the cannon.

- Do not lean the back of the heater against walls or other objects.

- Do not cover the heat gun nozzle. This reduces its effectiveness and increases the risk of overheating and even fire. It is advisable that there be at least three meters of empty space in front of the outlet.

- Do not attach any sleeves to the gun nozzle.

- Do not place any objects on the heat gun.

- Do not move the heat gun while it is on.

- Do not point the heat gun at flammable objects.

- Do not use a heat gun in places where there are vapors of flammable or explosive substances: gasoline, acetone, alcohol, etc.

- Do not turn on the heat gun in places where there is a lot of dust.

- Do not use the heater in areas with high humidity or outdoors during rain.

- Do not leave the heat gun running unattended.

- Do not make any changes to the design of the heat gun.

- During repairs, use only the parts specified in the instructions.

- If you want to disassemble, refuel or repair the heater, you need to turn it off and unplug it.

- If you use the heater indoors, do not forget to ventilate it at least occasionally.

- If the heat gun is dirty and dusty, then it needs to be cleaned before turning it on.

- Before using the device at full power, allow it to warm up for an hour or two. This is especially important in winter when working outside or in cold rooms.

Distinctive features and selection criteria for 380 Volt industrial electric heat guns

Heating equipment operating from a network with a voltage of 220 V and a power of up to 5 kW is suitable for domestic purposes: heating rooms up to 60 m2, drying materials, eliminating dampness in basements and cellars. For larger-scale purposes, high-power industrial electric heat guns of 380 V are required. Accordingly, their operation requires a three-phase network that can withstand a significant load.

What are 380 Volt electric heat guns?

The 380 Volt industrial heat gun is designed to solve large-scale problems, and its operation requires a higher electrical capacity, not limited to two wires. Many residential buildings have three-phase wiring required for electric stoves. But using high-power industrial equipment in small areas is unprofitable. Therefore, no one buys expensive 380 V fan heaters for domestic use. The use of this technique is justified only on an industrial scale or in emergency and extreme situations.

Why is it needed and where is it used?

Heat guns are needed wherever there is a need to quickly increase air temperature and lower its humidity level. Industrial-type equipment is used over large areas, where the power of a household appliance is not enough. The use of highly efficient 380 V electric fan heaters is permissible under conditions that prevent drops and splashes of water from penetrating into the housing. This operating rule must be strictly observed.

Most common applications:

- heating of hangars, warehouses, workshops, construction sites;

- heating frozen equipment, doors, vehicles;

- elimination of dampness (drying) of walls and ceilings on unfinished and other construction projects;

- drying of agricultural products, wood, construction and finishing materials;

- creation of forced ventilation in case of smoke, concentration of any harmful substances in the air (in this case, the equipment must operate in the “no heating” mode).

How it works: device and principle of operation

A heat gun, regardless of what voltage it is designed for, is a device consisting of three main elements:

- heating element (heater);

- fan;

- control unit.

The operating principle is simple:

- when power is supplied, the blades of the built-in fan begin to rotate;

- an area of low pressure is created around the device;

- air under pressure enters a hole specially provided for this purpose in the housing;

- enters the heat exchanger, the main element of which is the heating element;

- rapid heating of air masses occurs here;

- hot, they leave the device body also under pressure created by the fan.

The heat gun can operate in several modes:

- without heating;

- with partial heating (at minimum power);

- with switching on at medium and full power (medium level of heating intensity is not provided in every model).

Reviews of 380V industrial electric heat guns: pros and cons

Only specialists can give reliable reviews about the operation of 380 V heating equipment. Judging by their statements, this technique has many advantages, but is not without its disadvantages.

Pros:

- mobility;

- ability to work for long periods of time in harsh conditions;

- low maintenance requirements;

- simple controls;

- thanks to reliable protection, critical overheating rarely occurs;

- ability to control power;

- presence of fan mode (no heating).

Minuses:

- high level of noise emitted by the operating unit;

- for long-term operation of the equipment, an electrical network of increased reliability is necessary;

- heavy weight of large models.

Manufacturers and popular models: ranking of the best and prices

Powerful heating equipment should be purchased only from trusted manufacturers. When choosing, you need to focus on large companies, well-known brands specializing in the production of heating equipment. At such enterprises, all technologies for manufacturing climate control equipment have been developed and currently existing innovative solutions have been introduced.

RedVerg RD-EHS5/380

The RedVerg RD-EHS5/380 compact heat gun is an excellent choice for heating garages, workshops, and small industrial premises. Due to its light weight and fairly high power, this unit is often used by builders to dry air and materials. For ease of movement, a special handle is provided on the fan heater body.

The device is equipped with a mechanical thermostat with self-reset, which ensures automatic power off in case of overheating. The body is made of sheet steel, coated with heat-resistant paint. Tubular heating element, steel.

Characteristics:

- power - 5 kW;

- productivity - 550 m3/hour;

- weight - 5 kg.

Cost: 5190 rub.

Heat gun Quattro Elementi QE-9000 ETN

Powerful heat gun with a cylindrical body, ideal for serving areas of 60-145 m2. The model is designed to withstand high loads and can operate continuously for up to 16 hours. The device is equipped with a tubular heating element made of stainless steel. The gun operates in three modes:

- ventilation;

- at 50% and 100% power.

The equipment has a mechanical thermostat and an overheat protection sensor. The case has a two-color design: dominant - gray, additional - black.

Characteristics:

- power - 9 kW;

- productivity - 880 m3/hour;

- weight - 7.5 kg.

Cost: 7299 rub.

RESANTA TEP-9000K gun

The design of the device ensures high performance. The air passage channel is made in the form of a short pipe, a steel tubular heating element. The heat gun is equipped with a thermostat, temperature control sensors allow you to maintain its stability. The stability of the device is ensured by arched legs, and there is a handle for carrying. The greasy body is covered with anti-corrosion protection in the form of non-marking heat-resistant paint. The gun is recommended for servicing rooms up to 70 m2.

Characteristics:

- power - 0.5/4.5/9 kW;

- productivity - 820 m3/hour;

- weight - 12 kg.

Cost: 4850 rub.

Powerful heater Ballu BHP-P2-22

One of the best electric heat guns designed for 380 Volts. The body is located on a wheelbase, which makes it easier to move the unit. The design of the support and handle is such that the device can be safely suspended at the required height. The heat gun operates in three modes:

- without heating;

- at 50% and 100% power.

The unit is equipped with a high-precision capillary thermostat. The housing has a high electrical protection class. If overheating occurs, the security sensor is activated and the power supply is cut off. The gun is capable of quickly heating areas up to 250 m2.

Characteristics:

- power - 11/22 kW;

- mechanical control;

- weight - 21.5 kg.

Cost: 15990 rub.

Ballu BHP-M-15

Heat gun with a rectangular body coated with anti-corrosion fire-resistant paint. Recommended for servicing premises up to 150 m2. Equipped with a thermostat with manual reset. This function eliminates the possibility of the device turning on spontaneously after an emergency shutdown. For ease of connection to the electrical network, a three-phase plug is provided.

Characteristics:

- power - 15 kW;

- mechanical control;

- weight - 14.4 kg.

Cost: 11290 rub.

Russian heat gun Caliber TV 12/18

An easy-to-use gun with a rectangular steel body. It has high productivity: up to 1080 m3/h. Equipped with a steel tubular heating element. There is a ventilation mode without heating the air. A distinctive feature of the device is a switch with a light indicator. There is protection against overheating. The housing is made of high quality sheet steel.

Characteristics:

- power - 1200/6000 kW;

- mechanical control;

- weight - 21 kg.

Cost: 6800 rub.

Which manufacturer and which type is better to choose: TOP-3

When choosing an industrial heat gun, it is recommended to first consider the products of Ballu, RESANTA, Kalibr, Quattro Elementi, RedVerg. The climate control equipment of these manufacturers is distinguished by its reliability, simple design and maintainability.

Calculation of the minimum required power

In order not to make a mistake in choosing thermal equipment, it is necessary to correctly calculate its required power. The easiest way is to rely on the data provided by the manufacturer. Each of them indicates the recommended heating area. But sometimes this data is not enough.

To get more accurate ones, use the formula:

V xTx k = kcal/h,

Where:

- V is the volume of the room;

- T is the difference between the required temperature in the room and that outside;

- k is a coefficient indicating the degree of thermal insulation of the room.

To determine the coefficient, use the following data:

- for high-quality thermally insulated objects - 0.6-0.9;

- for average thermal insulation - 1-1.9;

- poorly insulated - 2-2.9;

- open and semi-open areas - 3-4.

Example calculation for a well-insulated room with a length of 25 m, a width of 5 m and a wall height of 3 m:

- find the volume by multiplying all the indicators listed above: 25x5x3 = 375 m3;

- determine the thermal insulation coefficient - 0.9;

- determine the desired room temperature - +22°C;

- guess what the lowest temperature in a given area is - -5°C;

- substitute the obtained data into the formula: 375x((+22°C-(-5°C))x0.9=7312 kcal/h=30.5 kW.

Thus, to heat this room you will need a heat gun with a power of 30 kW.

What else to consider when choosing a device?

When choosing an industrial heat gun, consider:

- number of operating modes;

- maximum power;

- performance;

- ease of transportation;

- noise level emitted.

3 best models

Of those presented in the review, we can note the three best models that have earned the largest number of positive reviews:

- Quattro Elementi QE-9000 ETN — 7299 RUR;

- Ballu BHP-M-15 - 11,290 rubles;

- TV caliber 12/18 — 6800 rub.

This thermal equipment is of high build quality, reliable and durable. According to statistics, these models are in the highest demand.

Price

The price of industrial grade heat guns depends on several parameters:

- maximum power;

- number of heating stages;

- thermostat type (electronic or mechanical);

- temperature control method: smooth or stepwise.

Inexpensive models can be bought for 4800-6800 rubles:

- RedVerg RD-EHS5/380 — 5190 RUR;

- RESANTA TEP-9000K - 4850 rubles;

- TV caliber 12/18 — 6800 rub.

Higher-performance equipment costs more. The price for it starts from 7,000 rubles:

- Quattro Elementi QE-9000 ETN — 7299 RUR;

- Ballu BHP-P2-22 — 15,990 rubles;

- BHP-M-15 — 11290 rub.

Where to buy a 380 Volt electric heat gun?

In Moscow

- "Techport"; Leninskaya Sloboda, 26, building 2, Global Mall shopping center; 8 (495) 228-66-69.

- "Teplovent"; Sayanskaya st., 9a;.

- "EUROTECHCLIMATE"; Andropov Avenue, 36; 8 (495) 666-2219.

In St. Petersburg

- "EUROTECHCLIMATE"; Chugunnaya street, 44k2; 8 (812) 309-97-6

- "Climatebox"; Smolenskaya street, 33, building B; +7 (812) 335-01-25;

- "Elektrostroy"; Tambasova street, 12; +7 (812) 335-74-9

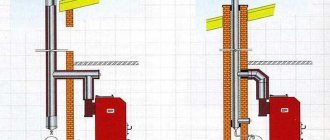

Connection diagram of equipment to the electrical network

The connection diagram of the heat gun to the electrical network provides for a uniform load on all phases in order to eliminate their distortion. It is also necessary to provide three single-pole circuit breakers. The standard connection diagram is called “star”. What it looks like is indicated in the image.

A 380 V industrial heat gun is rarely used for domestic purposes. This equipment is more necessary for developers, owners of spacious garages and workshops. It is used as backup heating; it also helps out in emergency situations caused by high air humidity, smoke or flooding.

May 11, 2018ventsyst

Appearance

This takes into account such nuances as aesthetic appeal, achieved through the use of two main shapes - rectangular and cylindrical, as well as high-quality paint and the dimensions of the unit. If the device is planned to be used exclusively for domestic purposes in a small room, then a compact heater weighing 5-10 kilograms with dimensions ranging from 25-50 centimeters is the best option. If there is a need to purchase a unit of greater power, then you should be prepared to transport equipment whose weight will be 50-150 kilograms with dimensions of 1-3 meters for each parameter.