Here you will learn:

- Why do pumps get stuck in pipes?

- Tips for lifting the pump

- How to get the unit if the cable breaks

- The pump is stuck in the well - how to remove it

- Do's and don'ts when removing a stuck pump in a well

- Prevention measures

The pump is stuck in the well: how to remove it depends on the cause of the jam. In all cases, it is forbidden to make sudden movements, forcefully pull or push the pump deep into the well. In severe cases, you will have to drill the well again.

Casing pipe deformation

The process of deformation of the casing quite often occurs due to soil displacement or activation of underground sources, the transformation of a simple underground stream into a seething stream or even a river. Such changes in the structure of the soil in the area are not immediately noticeable from the surface, but in relation to the well, a large number of problems arise here.

For wells with a metal casing, deformation is most often expressed in a change in the internal cavity of the pipe - crushing, bending or fracture. For wells with asbestos-cement casing pipes, the material is destroyed, the couplings crumble, and soil gets into the well.

For wells with casing made of PVC pipes, bending or compression is most common, as a result of which it becomes difficult to lift the pump.

The optimal solution in such circumstances is to turn to professional builders to remove the equipment. Only if you have all the necessary arsenal of search equipment, from a remote video camera to a multi-section rod with hooks, in such a situation it becomes possible to get the pump.

However, when the well is relatively shallow, only 8-10 meters, you can construct a sectional rod with hooks at the end to remove equipment from a profile pipe and try to independently conduct exploration and remove the pump.

Usually, the distance to the point of deformation of the barrel is first determined, then an approximate calculation of the internal cross-sectional area is made and the possibility of extraction through the narrowest point of the pump bend is analyzed, and only after that it is lifted.

What to do if the pump gets stuck in the well

Getting a pump stuck during lifting, as already mentioned, is not such a critical situation, and if lifting is not carried out by professional well service specialists, then the first thing to do is be patient and pull yourself together; panic in this situation can only aggravate the problem.

A simple analysis of the situation will help you quickly determine the causes of equipment failure and choose the optimal way to solve the problem. To do this you need:

- find out the total installation depth of the pump;

- approximately determine the depth of the jam;

- analyze how tight the cable is, determine whether the pipeline and pump are disconnected and the integrity of the power cable.

- inspect the head of the casing pipe;

- prepare the necessary tools for work;

- clear the area of foreign objects.

This algorithm of operation makes it possible to significantly reduce the time required to prepare for lifting equipment and prevent larger mistakes in the future.

Broken cable

The situation when the cable breaks and the entire structure slides down happens quite often. Typically, a metal cable does not break, just the fixing elements loosen over time due to corrosion of the metal, the threads are not able to fix the fastening and the cable is released. For the metal of a steel rope or cable, alloys that are not subject to corrosion or structures that have an additional protective sheath of plastic are usually selected. But an ordinary steel cable, being constantly in a state of tension, can develop abrasions and active corrosion at the point of fixation, because the pump experiences vibration during operation, which is transmitted to the cable.

In this case, it is recommended to continue lifting if the well is shallow and the pump is light in weight, using a hose or pipe as the main lifting device. The upward feed should be smooth, without sudden interceptions or jerks. The use of a cable as a lifting element is unacceptable! With this method, it is necessary to prevent the pump from rotating around its axis, since if the pump jams, a pipe or hose may become disconnected, which will further aggravate the situation.

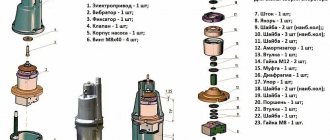

A broken pump at the bottom of the well is also not the best option for the job, but if the power cable is intact and still attached to the pump body, then the chances of lifting the equipment increase significantly. For centrifugal pumps, screw pumps and vibration models, the cable usually has an entry into the housing slightly below the outlet and almost at the level of the cable mounting holes.

For lifting, a device made from a piece of metal pipe and welded wire, on the one hand, and a lifting cable on the other, can be used here. The cable is threaded into the pipe to the bottom, with a wire welded and bent into a hook. The hook is lowered along the cable and, having reached the lowest point on the pump body, is inserted into the eyelet for the cable. This operation is somewhat similar to winter fishing, when the bait is slightly twitched to attract fish, and the lifting hook, with small up and down movements, should enter the eye and engage the pump.

Several ways to remove the device

Salt and limestone deposits

Pull the cable several times without using maximum force, gradually moving the cable up and down, like a fishing rod. If this does not help, there is another way - to break up the deposits with a pneumatic blow. Quite an expensive method, but with positive characteristics. You will need a powerful compressor and a long tube with a diameter of 15 mm. It is lowered to the level of the unit and connected to the compressor. Then they shoot a stream of air into the equipment body or along the pipe wall. The shot should break the coating and release the device.

Cable slack

Cables are different. They are selected depending on the power of the unit. Stronger devices require a rigid, reinforced cable. If it sags, it will not wrap around the body, but will simply warp the device, which will make it impossible to lift it to the surface. It will be enough to pull out the cable along with the cable and hose. If the cable does wind up around the pump body, it thickens it. In this case, you need to bring it down and also move it by the cable, like a fishing rod. The cable will gradually unwind and allow the pump to continue moving.

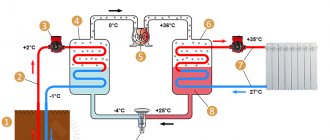

Silting of the bottom

When silt and dirt form at the bottom of the well, the apparatus is pulled out by gradually swinging from side to side by the rope and hose. However, if the depth is large enough, the length of the cable will not allow the device to be swung to the required extent. To remove a stuck unit, you need to dilute the sludge with plenty of water. Preferably under good pressure. An additional source of water and equipment to supply it to the mine shaft will be required. It is advisable to lower the tube to the very bottom and use a pump to pump water into the well under pressure. Simultaneously with the supply of liquid, the cable must be pulled up, creating tension in the ground lock. After a few minutes the equipment should be free. But don’t rush to pull it up right away. To rinse the sludge a little, the pump must be dipped into water several times without stopping its supply.

Reverse siltation

In this case, the apparatus is completely blocked in the ground, and often a soil cap is formed above it; even more water will have to be poured into the well. Simply swinging and pulling out the device will no longer work. Otherwise, the cable will break and it will be more difficult to get it out. To dilute the sludge, you need to lower a tube with a diameter of 15-25 mm into it, and then use another pump to pump water down from the surface, and the more water, the better. Now the stuck unit can be safely pulled out.

The most common reasons for pumps getting stuck in wells

Based on the experience of the repair and restoration work carried out, we can identify the most common causes of pumping equipment getting stuck in wells.

The cable that supplies the pump with electricity can have different degrees of tension with the cable that secures the device in the pipe. Slack cables can form a loop that gets into the gap between the pump and the cable wall and jams it.

Secondly, the reason may be the unsatisfactory condition of the internal volume of the well.

During operation, a layer of silt or lime deposits may form in it, which, like a cork in a bottle, clogs the pumping equipment in the mine.

Thirdly, this is the entry of foreign objects into the well shaft.

If the well head is not adequately protected, stones or branches may fall into it, which will not only jam the pump housing itself in the pipe, but also become entangled in the cable or power supply cable.

Construction of a well with a deep pump

How to get a pump out of a well

Removing pumping equipment that is stuck or has fallen to the bottom of a well is carried out in exactly the same way as for a well. They use a homemade anchor.

If the depth of the mine is more than 10 m, then it is recommended to contact companies involved in cleaning wells. Their workers have special equipment at their disposal, thanks to which they can quickly fix the problem.

If pumping equipment gets stuck in a well or ends up at the bottom of a well, you need to know what to do correctly in such a situation. It is important to quickly take all necessary measures to reduce the negative consequences and eliminate the problem.

Emergency

Getting a pumping device stuck in a well is, to put it mildly, not a pleasant situation. It usually occurs when trying to lift the device to the surface for routine maintenance or repairs. As a result, a stalemate arises: the pumping equipment does not work and it cannot be repaired either, because there is no access to it.

In some cases, you will be able to independently remove the pumping equipment from the well without damaging it, but sometimes you have to say goodbye to the pump. In the most extreme situation, the water well is completely out of order.

Getting a pump stuck in a well is an emergency

Causes of the problem and solutions

There is one common reason why the pump becomes difficult or even impossible to remove from the well. This is non-compliance with the technological requirements for the construction of the well itself and the mounting of equipment in it, as well as improper operation of the water source. If the instructions were strictly followed during this work, dismantling the device will be easy and simple.

What leads to such consequences?

Siltation of a sand well

But it is even more important to equip it correctly, starting with the manufacture of the casing, which must be perfectly straight, with smooth inner walls

- Install sediment in the well of such a diameter that the gap between its body and the pipe walls is sufficient. It will cost more than larger analogues, but its price cannot be compared with the cost of equipping a new well.

- To install submersible equipment, use only a strong, high-quality stainless steel cable, securely attaching it to the device.

- Neither the hanger nor the pressure hose must be spliced from separate sections. They may separate when lifting the pump; pieces will fall down and jam it, preventing free movement.

- To prevent the electrical cable from sagging, secure it with clamps to the hose before starting to lower the device into the well.

Types of waterproofing

Moisture is the enemy for builders. If water penetrates into structures, they will quickly become unusable. The same goes for the pool. There is water inside it, but it should not penetrate the walls. Therefore, the entire structure must be reliably protected. For this, two types of waterproofing are used:

- external;

- internal.

The outer layer is required to protect the pool bowl from moisture penetrating from the surrounding soil. For this purpose, special additives are used that are mixed with cement. Therefore, external waterproofing is carried out at the construction stage. Internal moisture protection covers the bowl itself and protects against penetration of water poured into the bowl into the supporting structures. It is performed before finishing.

Work production technology

Before you remove the failed pump with your own hands, you need to prepare the necessary materials and tools. Their list will be given below. After this you can start working.

If the unit has fallen to the bottom along with the hose, then the procedure for performing rescue measures is as follows:

- A rod called a “cat” is used. This is a steel hook, the end of which must be sharpened.

- Then the end of a steel wire is electrically welded to the cat.

- The second end of the wire rope is tied to the crane boom.

- The hook is lowered into the hole, making rotational (like screwing in a screw) movements. This is necessary to hook the hose. Usually such work has to be done blindly.

- If you manage to hook the hose, you can try to remove the pump unit with a lift. Lifting must be done slowly, otherwise the engagement may break.

It is recommended to take insurance when performing work. There is no need to skimp on a metal cable, since if the quality of the material is poor, it will simply break. Therefore, you need to buy a high-quality stainless steel cable.

When removing the pump, do not use a cable made of several parts. During lifting, the joints may burst and the unit will get stuck in the well.

For prevention, buy a pump with the smallest diameter possible, then the possibility of the unit jamming during lifting will sharply decrease. Such models are more expensive than conventional units, but if you skimp, you will have to drill a new well in the event of an accident. It is recommended to install protective equipment over the well; this will prevent foreign objects and debris from getting into the well.

What to do if the pump cannot be removed

If the electric pump cannot be removed to the surface after all operations (it has become detached from the pressure pipeline, hose with cable), proceed in the following ways:

They continue to use the well source. The bodies of most centrifugal electric pumps are made of stainless steel, and the internal parts are made of polymers or corrosion-resistant metals. The materials are designed to supply drinking water, so the presence of fallen electric pumps at the bottom of a well for many years is unlikely to affect its quality.

The greatest danger to humans is oil, which is present in the mechanism of almost all pumping units; over time, it can leak through a damaged housing. Also, stainless steel in budget models, usually of low quality, can become rusty over time, affecting the quality of drinking water.

The body of the vibration pump is made of aluminum, which is not susceptible to corrosion, the internal parts consist of rubber and steel, and the mounting bolts are also steel - they are susceptible to corrosion over time.

The well is being mothballed and a new one is being drilled. If the owner cares about his health, the service life of the old well source is coming to an end, you can drill a new well relatively inexpensively - in these cases, the old one is mothballed or liquidated.

Breaking an electric pump with a drill. The operation is permissible if the pump is stuck in deep artesian wells with internal steel casing and the pressure pipe is torn off, if the unit prevents the source from filling with water. It will not be possible to push the electric pump deeper - a standard artesian has a tapering channel at the bottom.

After the electric pump is destroyed by a drill, its small parts fall into the artesian water basin through a filter pipe that does not have a lower cap. Over time, the oil will wash out and small parts will sink to the limestone bottom.

Rice. 14 Example of removing a pump along with a casing pipe

Why is the pump stuck in the well and how to get it out ↑

When the pump is installed, only a small distance remains between the device body and the walls of the service pipe. Therefore, jamming is a fairly common occurrence. Due to the design features, it is impossible to visually determine the cause of the problem. Only companies that professionally service hydraulic structures have special equipment. Most often, the well owner has to rely only on “indirect signs.”

There are several reasons why a pump can get stuck. The most common:

- clogging of the service pipe;

- cable sagging;

- foreign objects;

- damage to the column walls.

When installing a submersible pump, the electrical cable should not sag, but it should not be pulled too tightly either. If the cable sag, a loop may form, which, getting between the device body and the wall of the service pipe, jams the pump. To prevent this from happening, when installing the pump, the cable is secured to the hose. The procedure must be repeated every time the pump is raised or lowered, but it is better not to neglect safety measures. If this is not done, the device will jam. The main thing is not to pull it with a winch or jack.

When purchasing water-lifting equipment, it is advisable to immediately choose a model whose diameter is noticeably smaller than the diameter of the pipe. This will ensure the proper amount of clearance between the body and the walls. The narrower the well, the greater the likelihood of the device getting stuck. If you have to pull the device by the cable, and not by the cable (for example, the cable breaks), then all elements of the column must rise simultaneously, without slack. If the pump jams, you need to push it down a little into the well, then carefully remove the slack in the electric cable, and then slowly, without jerking, lift the column.

The well silts up during long periods of inactivity, and then the pump may get stuck. If something similar happens and it is obvious that the pump is not jammed “tightly”, but it cannot be lifted without effort, there is no need to rush and pull with force. By slightly pulling and releasing the cable, you can gradually “swing” the device. When the pump “comes off” from the sludge, it will become easier, because... the water will wash away the blockages and the silt will flow down. It will take a little patience. Methodical “swinging” will give results, and the pump can be pulled out.

In some cases, it is necessary to resort to well cleaning in order to wash away dense silt deposits. To do this, use a second pump, which works to pump water into the pipe. Some well owners manage to come to an agreement with firefighters. They lower the fire hose into the production pipe and erode the plug under pressure. But this is a rather exotic method. It is easier to lower the hose of the surface pump and clear the blockages in the traditional way.

Obstacles can be dents or burrs on the pipe, foreign objects that have fallen into the well (tools, loose fasteners, etc.). Sometimes such problems arise if mistakes are made during well construction. It is not difficult to determine the cause of jamming in such cases: the device does not go up, resting against the barrier with a dull thud, but it easily goes down. You can try to pull it out by rotating it around its axis to go around the obstacle. If this does not help, you will have to contact specialists. Self-indulgence in such cases leads to even more serious problems.

Tips to prevent the problem

- When installing pumping equipment, you need to choose a very strong cable. It is better if it is stainless metal covered with silicone braid. Locking rings with bolts are attached to the ends of the cable.

- The well must be flushed and cleaned every two or three years of use.

- If water is not used, the equipment must be pulled out of the mine shaft.

- The pumping device is selected according to technical characteristics that are suitable for different types of wells individually.

- The diameter of the flask is chosen to be 40-50 mm smaller.

- To prevent the supply cable from sagging in the column, it is tied with special clamps to the cable and pipe.

- Do not pull on the hose.

Advice : when a pump is stuck in a well and it is impossible to push it, the principle of pressure on the lever will come to the rescue. The mash depth is shallow and you can see where the flask is. We take a pipe or fittings with a diameter of 32-40 mm and immerse it in the shaft. We weld or screw a strong eyelet onto the edge of the casing, into which we thread another tube 2-3 meters long. Now we simply press the lever on the axial pin. Gradual pressure on the flask will ensure a smooth push down.

Why is the well pump stuck?

As a rule, for artesian wells, casing pipes of small diameter are used. In addition, plastic pipes with a diameter of 100 - 110 mm are inserted into them. To lift water from a well, deep submersible pumps are used, which operate in the limited space of the casing pipe. The distance between the pump and the inner edge of the well usually does not exceed a few centimeters. For this reason, any violation of this small gap leads to the pump getting stuck in the casing.

The reasons why it is not possible to freely pull the pump out of the well may be different. The most common among them:

- Cable slack.

- Silting of the well.

- Mechanical damage to the pipe walls.

- Foreign objects getting into the pipe.

Due to the small gap between the pump and the casing, it is simply impossible to see what happened there without special equipment. Therefore, you will have to find out the causes of the problem based on the symptoms.

Where to begin?

Removing the device begins with assessing the current situation. Having carried out high-quality diagnostics using video technologies, we, having found out the reasons, develop a plan to eliminate them. The cost of the service depends on the depth at which the pump is located.

The procedure for resolving the issue - a pump is stuck in a Moscow well - may be different. The course of action depends on the condition of the device and what type of fasteners were used during its installation. Our company actively uses several methods in its activities, each of which is effective in its own way. To solve the problem that has arisen due to salt deposits or silting of the pump, we actively use special equipment that, using vibration waves, gradually destroys the resulting accumulations, thereby facilitating the process of removing the stuck device.

The situation that arose for a reason - the pump got stuck in the well - is not uncommon among owners of private houses. Some are trying to solve this problem on their own, while others are turning to commercial organizations asking for help. Our company provides services in this area. A team of specialists will quickly help you resolve the problem associated with a stuck pump in a well in Moscow and the Moscow region. We take a responsible approach to resolving each client’s issues and guarantee high-quality removal of the device and work performed by experienced specialists!

This problem often happens when you have a pump stuck in a well in Moscow and the Moscow region and you cannot get it out. This is one of the disadvantages of deep-well pumps, since the device operates at depth, and each time for its prevention or maintenance, repair work, the unit must constantly be raised. How to get a pump from a well in Moscow and the Moscow region? In this case, you won’t be able to use the pump for maintenance, and you won’t be able to use the water. Obviously, in any case, you need to get the equipment, but at the same time, you shouldn’t panic. The depth of the well, as a rule, is not so huge, and it is quite simple to find out exactly why the deep-well pump is stuck in the well in Moscow and the Moscow region, how to remove it, and also understand whether drilling is necessary.

It is necessary to find out what caused the jam in order to get the pump out of the well. Moscow and Moscow region. After this it will be much easier to eliminate this problem. Due to the effect of reverse siltation, for example, it is impossible to remove the pump from the well. It appears in the place where the well was built in limestone soil. In this case, as the well is used, a sedimentary layer begins to appear above the pump installation site. After a certain period of time, there will definitely be a traffic jam there. If you clean the well periodically, every few years, this process can be stopped.

Limestone deposits are quite thick; it is unlikely that you will be able to remove them on your own; you need to call in professionals. Specialists operate using two methods: mechanical and chemical. Chemical is when a plug of sediment is influenced with special reagents in order to dissolve it.

However, this raises the question of whether the chemicals will spoil the quality of the water in the well. In the second method, the plug is exposed to a fairly powerful stream of compressed air under high pressure, which contributes to its destruction. The cost of removing a pump from a well in Moscow and the Moscow region with the help of specialists is different, but this will help save your nerves, effort and time.

It often happens that your pump breaks in a well in Moscow and the Moscow region, then the pump falling into the well can occur for various reasons. Often, a damaged apparatus falls to a depth when attempting to rise. Quite often the pump gets stuck in the well, and absolutely any attempt to remove the unit can lead to a break in the cable, cable or water pipe. In such cases, the owner of the equipment will incur additional costs not only for raising the pumping unit, but also efforts will be required to restore the break.

How to get a pump out of a well in Moscow and the Moscow region if it breaks? If the casing string is deformed, then most often it is necessary to fully repair the existing well or lay a new one. Moreover, this will have to be done regardless of whether the owner pulled his pump out of the well or not. If not only the apparatus falls, but along with it the cable, hoses, and cables fall to the bottom, then the owner may lose not only the specified equipment, but also the entire well. In other cases, it is possible to remove equipment from the bottom and then continue operating the well.

All of the above methods will help you get a deep pump from a well in Moscow and the Moscow region and will alleviate your problem.

Photos of our work

What not to do and what to do

When removing pumping equipment that is stuck in a well, its users often make erroneous actions that can only lead to aggravation of the problem rather than to its resolution. Let's consider such actions in more detail.

Excessive effort

The result of this is often a break in the cable or hose holding the pump, and the device may fall into the well

It should be borne in mind that removing a stuck deep-well pump must be done with the utmost care. When placing a pump in a well, you should initially use a cable that can withstand increased loads.

Reliable cable made of 4 mm stainless steel with a tensile strength of 1000 kgf

Using various devices (hooks, assault cats, etc.)

In most cases, the use of such devices to remove a pump stuck in a well results in both the pump and the device for removing it remaining in the well. This situation will greatly complicate the task of removing the pump, which is stuck in the well shaft.

The use of such devices can both solve the problem and aggravate it.

Using a crowbar tied to a rope or cable

In the event that such scrap falls into a well, there is no hope for the prospects for its further use.

If we talk about the most effective and safe methods for removing a pump stuck in a well, then among them we can highlight the following:

- removing the cable holding the pump in the well, fixing it in a taut state and tapping it (this procedure should be performed several times until the pump begins to rise up the well pipe);

- pushing a stuck pump into the lower part of the well, for which a load tied to the end of a cable or rope is used (a piece of steel pipe of the appropriate diameter can be used as a load in this case).

A homemade hook trap, similar to the devices used by professionals, will help you pull out a stuck pump.

If a pump stuck in a well cannot be moved by any means, to solve the problem it is better to use the services of specialized companies that have special equipment and all the necessary tools.

Advice from craftsmen

- A stuck pump in a well with a cable broken as a result of the applied efforts can be pulled out with a metal device with pins, popularly called a “cat”. Hooking the pump directly is considered a great success. Most likely, you can grab the end of a cable or hose while trying to pull the equipment up.

- To push down a stuck pump, some inventors manage to use a crowbar tied to a cable. The main thing is to tie the crowbar tightly so that when you throw it into the well, you don’t leave it there. Of course, this can be done if the old pump is no longer intended to be used, because the probability of its damage is very high. It may work at a shallow depth of the pump.

- Weld an “ear” to a meter-long section of pipe. After passing the cable, hose and cable through the pipe, lower the pipe on a separate cable into the well. Under the pressure of its weight, the pump can slide down and hang freely on the cable. Next, the pipe and pump are simultaneously pulled out of the well. Since the weight of the structure can reach 50 kg, the work must be carried out with an assistant.

- If the pump suspension has not yet been torn off when trying to forcefully remove the equipment from the well, you can fix it taut and periodically tap it. If any slack occurs in the cable, re-tension it and tap again. These actions can be carried out over several days. This is a method for those who are especially patient, but in some cases it is crowned with success.

What pushes people to invent different ways to solve the problem with a stuck pump? The answer is simple: the high cost of services from companies specializing in this area. In some cases, their cost reaches the cost of installing a new well. Therefore, in order to save your budget, you need to do everything possible in advance to prevent the pump from jamming.

From simple to complex

For deep-well pumps that have a large diameter and short length, the connection of which is carried out via a flexible polyethylene hose, and these are most often vibration pumps, during lifting a situation may arise when the electric cable of the pump gets caught between the pump housing and the wall of the casing pipe.

Such pumps are most often lifted by a cable and a hose, but the cable, the entrance to the pump body, which is located below the level of the hose connection and the cable fastening, is simply tightened periodically. At the moment when the cable is most weakened and has excessive length, it fixes the rise of the entire structure. The small distance between the housing and the wall into which the cable enters becomes a big obstacle to removing the equipment to the surface.

In fact, this is the simplest of all possible cases of jamming during lifting. The problem here can be solved quite simply - just lower the pump a little into the well and at the same time tighten the cable. After tensioning the cable, continue lifting, ensuring the tension of all elements - hose, cable and cable.

Siltation of the well

A well in clay soils or a sandy layer is most often susceptible to silting. The situation when soil gets through the drainage holes into the casing pipe and settles, preventing the equipment from being lifted, is most often typical for wells that have been maintained for a long time without maintenance.

For circulation or screw pumps, this is quite painful, since they have quite impressive dimensions, and the sludge does not just settle, but is tightly compacted between the pump body and the walls of the casing pipe. In this case, when it was not possible to pull out the pump the first time, it is necessary to apply the tactics of gradual release from the bottom sludge.

The pump is alternately raised and lowered, first by 5-10 mm, and then. When the dirt plug begins to become saturated with water and erode, gradually releasing the pump housing.

Prevention

To avoid debris from entering the source, it is necessary to use a factory-made well head that fits tightly to the edge. Soil particles can get between poorly connected parts of the pipe, especially concrete ones, which are simply installed on top of each other, so the choice of material must be taken seriously.

When purchasing a pump, it is advisable to select it in such a way that there is more space at the edges - between the walls of the pipe and the housing. In this case, even if the shaft is deformed, the device can be obtained using traditional methods.

Cleaning a well is much cheaper than drilling a new one, so if there is a large amount of sand in the ground, it is necessary to call a team for a professional inspection of the source. You can do the cleaning yourself. In order to carry out preventive measures less frequently, when constructing a well, a filter is installed that prevents sand and soil from entering the pump area. In this case, the diameter of the mechanical filter cells matters.

If the well is not in operation, at least once every 3 months it is necessary to pump out about 100 liters of liquid from it so that organic matter and soil do not clog the pump.

https://youtube.com/watch?v=fT7su3AKSBQ

What should I do if the pump gets stuck while lifting?

If you pull the unit out too quickly with your own hands, it is likely that it will get stuck. The same situation will occur if the electrical cable sags during lifting. This often creates a loop that can wrap around the body of the apparatus and then jam it between the walls of the well. In this situation, there is no point in using a jack or winch, since it will be almost impossible to pull the pump out with a cable. Often in such a situation the cable simply breaks.

Then you need to try to lift the device not with a cable, but by hooking it onto a hose, pipes or electrical cable. However, it is recommended to ensure that all of these parts are lifted together. There should be no slack on these parts. If it appears, you need to push the pump unit down in any way, for example, by holding a pipe or hose.

After this, they continue to lift the product. This must be done slowly. If the device is so stuck that it cannot be pushed down, then it is better to part with this unit than to spoil the well. There is no guarantee that a pump that has fallen from a great height can be repaired. Therefore, you need to decide what is more important, a well or a pumping unit.

Sometimes a situation arises when the equipment is easily lifted, there is no slack in the cable or cable, but the unit is stuck, buried in some obstacle. It goes down well, but when going up it gets stuck at some level.

In such a situation there is no need to rush. The unit may rest against the casing, for example a dent, weld residue, or flattened edge. You can try to remove the pump by rotating the device around its axis. To do this, take it by the pipe or hose. This often helps, the unit slides off the obstacle and then rises.

When a foreign object enters the well, it can block any attempts to remove the equipment. Many people have screwdrivers and other small objects fall into wells. This leads to this. That the pump goes down well, but it is impossible to lift it up. Then it is better to call a specialist, and before his arrival it is advisable to select the slack of the cable and tension it to the maximum height. This will securely fix the device in one position.

General recommendations for safe lifting

It is easier to prevent a stuck submersible pump than to correct the problem later.

To do this, you need to follow a few simple recommendations:

- Use a reliable, strong and rigid cable. The cable that comes with the submersible pump often does not meet these requirements. Don’t skimp, buy a high-quality cable and fasteners (clamps) made of stainless steel.

- Do not use multiple pieces of hose. If the hose included with the pump is not long enough, you should not extend it; it is better to buy a new one in one piece. This will reduce the risk of breakage and serve as additional insurance if the cable breaks.

- Select the correct pump size. It should be 2/3 smaller than the diameter of the casing pipe. Thus, the risk of the unit jamming will be significantly reduced even if the pipe is deformed or foreign objects fall into the well.

- Be sure to install a header. It will protect the well from falling debris and various objects.

And remember: when using the methods described above, under no circumstances use brute force when trying to pull the unit to the surface. This will lead to aggravation of the problem: the pump will get stuck even more tightly inside the barrel, the cable may break, and the wall and casing may become deformed.

Lifting the submersible pump, as well as all actions aimed at removing the stuck unit, must be carried out together with an assistant; it is impossible to remove the stuck pump alone

How to prevent pump lifting problem

Pulling a deep well pump out of a well with your own hands if it comes off is not at all difficult if you follow all the recommendations of specialists.

The catchphrase is: “Forewarned is forearmed.” To prevent unpleasant situations from occurring, you need to follow a number of simple rules that can save equipment, time and money.

- Work only with strong cables. You can't skimp on this item. Choose quality products and fasteners.

- The hose must be intact. Buy one of sufficient length, even if the one included in the kit does not meet the required parameters. This will reduce the risk of breakage significantly.

- Choose the right size. The unit should be one third of the diameter of the pipe. Otherwise, congestion during lifting cannot be avoided.

- Set the header. This will ensure “protection” of the well from unwanted “guests”: garbage, bottles, stones, boxes.

What can cause a pump to fall?

The reasons for a possible device fall are:

Broken cable, power cable or pipe rupture. When installing a trunk, builders try to connect a hose, a cable and a power cable in order to maximize the strength of the supporting structure

But many simply do not pay attention to this, and as a result they lose the pump. Only specialists using the necessary equipment can obtain it. Mine deformation

Rarely occurs. The main reason is a violation of drilling technology and the use of poor quality concrete. Ingress of foreign objects. When lifting pumping equipment, mechanical loads arise. Therefore, when the device gets stuck, the load increases sharply. As a result, the hose, cable and power cable break. The device is lost forever, you need to buy a new one and install it above the bottom level. But modern technologies make it possible to retrieve a lost device, which is quite expensive.

Remedies

Having determined the reason for the pump stopping when lifting inside the well, you can try to fix the problem yourself.

When the cable sag

This situation is not among the most difficult, but still requires careful and fairly clear actions:

- the pump should be carefully lowered to the bottom of the well;

- the cable, which becomes loose during such actions, must be carefully pulled up;

- When the electrical wire reaches almost the same tension as the lifting cord, you can begin to remove the pump from the water source.

When considering a pump, it is necessary to use not only a cable, but also a cable with a hose. All elements should be pulled together, tightening them every one and a half meters with special connecting parts - clamps or clips. The device must be taken out without sudden movements, smoothly and gradually.

silted pump

When a well becomes silted

If sediment has formed during regular use of a water source, then the problem can be eliminated quite simply. The pump must be carefully swung while simultaneously tightening and loosening the lifting cable. From such movements, water will gradually penetrate into the gap formed under the device, helping to erode sand accumulations.

In such a situation, 20 minutes is enough to raise the pump. But it should be borne in mind that the entire process of freeing the pump from the sludge must take place without sudden movements that could damage the equipment.

Sometimes deposits in wells harden. This process usually occurs if the source has not been used for a long time. Solid sediments are quite difficult to wash away, but quite possible. For these purposes use:

- Water under pressure. This method is used when there is a small layer of silty hardened deposits. Washing should be carried out with water under sufficiently high pressure. To eliminate strong formations at the bottom of the well, a long flexible hose is used, which easily reaches the bottom of the source.

- Chemicals intended for descaling. For these purposes, suitable means that are used in everyday life to decompose deposits. But it is necessary to take into account that in order to wash away solid accumulations at the bottom of the well, a large amount of such substances will be needed, and this will lead to quite considerable costs.

- Citric or acetic acid. The products are diluted with water and poured into the pipe. This method is used in rare cases, since acids can damage pump parts. But if you plan to replace the device, then this option is perfect for removing formed deposits.

If you have a metal cable, you can use a hammer to try to create vibration. To do this, pull the lifting cord and tap on it. Such actions can quickly destroy the hardened small layers inside the water source.

Large volumes of hardened sediments in the well require repeated procedures. The erosion process may take more than one day. You can speed it up by periodically turning on the equipment for pumping water, as well as making attempts to pump the pump.

To clean wells, household chemicals designed to remove scale are used.

In case of damage to the settling pipe

In such a situation, you can remove the pump by moving the pump using a cable:

- rotate around its axis;

- slightly change the vertical position of the device.

Small tilts must be done carefully, without excessive force, otherwise the lifting cord may break.

If the sediment pipe is damaged, do not use sudden movements to pull the device through the problematic structural element. These actions will lead to even greater fixation of the device inside the well.

The option of removal through an opening in the pipe is possible if its internal cross-section is much larger than the diameter of the pump. But only if there are no serious dents on the walls of the sedimentary structure, which significantly narrow the passage. If the pump jams at a short distance from the surface, you can try to remove the pipe to the point of damage.

Strong displacement of the sedimentary device requires the involvement of professionals with special equipment. In rare cases, it is necessary to crush the stuck structure and remove it in small parts. But such a process takes a lot of time and requires considerable expenses. Therefore, in such a situation, problematic wells are often mothballed and new ones created.

If the sedimentary pipe is damaged, the problematic well is mothballed and a new one is drilled

If the pump is misaligned

To remove a pump that has become stuck due to incorrect positioning, you must:

- loosen the cable;

- lower the device down so that it is in its original position;

- lift the pump up.

Such manipulations should be carried out with the same tension on all outgoing cables - electrical wire, cord and hose. The incorrect position of at least one element will cause subsequent distortion of the device.

If the pump does not move and it is not possible to lower it at all, then it is better to contact specialists who will be able to use special tools to remove the equipment without damaging it.

If foreign objects enter

Often the pump gets stuck in the well due to various parts falling into it. There are several ways to solve this problem:

- Gently move the equipment inside the source. An object that prevents the pump from lifting may fall.

- Push the part. This can be done using a crowbar or a long stick. Care must be taken when doing this, as you may accidentally damage the device itself.

- Lower the pump down. If you can’t lift the equipment to the top, you can try to lower it a little. When this is successful, you need to pull out the element preventing the rise. To remove debris, use hooks, ropes, nets or sticks.

If all methods fail, it is better to contact a specialist. Incorrect independent actions may damage the design of the equipment.

If the lifting cord breaks

It is much more difficult to pull out the pump if the lifting cable breaks. In this case, all methods depend on the complexity of the situation:

- Lift the device using an electrical wire and hose. If, when the cable breaks, the remaining cables remain intact, then sometimes it is possible to carefully pull them together to remove the pump from the well. But it should be borne in mind that these elements are not strong enough and can break at any time.

- Hook it with a hook. This method is used if the pump has a rather heavy structure and removal by pulling the cable and hose is impossible. A hook is firmly tied to the end of a strong cable or rope. It is lowered into the well to hook and then pull out the pump. For safety reasons, the remaining intact cables are used.

If all the elements holding the pump break and the device falls into the well, it is recommended to use this option. A corkscrew-shaped device is attached to a metal rod, which is lowered into the well and screwed directly into the body of the stuck device. It is quite difficult to get the pump in this way and after removing it, its structure will be damaged.

You can try to pull out the pump using an electric wire and hose.

Reasons for pump jamming in the well body

Basically, all the reasons leading to the occurrence of this unpleasant problem are due to the human factor. When, during pump installation, the technological requirements for fastening elements of pumping equipment are violated, and due attention is not paid to their workmanship, it is difficult to expect a favorable outcome during pump dismantling.

Sagging electrical cable

For this reason, the largest number of cases of equipment jamming occurs. This happens by biting a slack electrical cable in a loop that is tightened around the pump body.

In this situation, you should not pull the device with all your might, as this will not lead to success. But what you pull on may break. Then it will be difficult to do anything on your own.

Experts who have lifted pumps from wells more than once advise in this case to try pushing the device back. Repeating the attempts, try to feel the slack and at this moment continue to slowly rise.

In general, “it is better to prevent a disease than to treat it.” In order to avoid encountering sagging electric cables in your practice, it is necessary to fasten it with special clamps to a pipe or hose at the installation stage of the system. Moreover, it is not recommended to attach an electric cable to the cable, since when it is tensioned, the clamps may fly off.

When lifting the pump, you must also ensure that the cable and hose exit simultaneously to the surface. There should be no slack in either the cable, the cable, or the hose.

Silting of the well as a result of long-term downtime

There are often cases in practice when a long-term shutdown of a well leads to severe siltation. The resulting layer of sludge becomes an insurmountable obstacle to the pump. When a pump is stuck in a well for this reason, experts recommend starting to rock it, during which the device is either raised or lowered.

What does this lead to? Water may gradually begin to erode silt deposits. In the end, it is possible that the path up will become clear, allowing the pump to be removed outside. The main thing is not to rush things and do not be overly active in order to prevent the pump from jamming.

There is also a non-standard way to deal with a silted well. It is necessary to involve firefighters in solving the problem, who, with the help of a hose lowered into the well, will be able to wash away the silt deposits. The released pump will move smoothly upward.

To prevent the process of silting of a well, it is necessary to carry out preventive cleaning, the frequency of which should be once every three years.

Solid obstacle - complex barrier

There may be a solid obstacle in the path of the pump movement, which will act as a wedge. Such a barrier could be:

- a dent in the pipe caused by soil movement;

- flattened edge of the pipe;

- burrs from a sloppy weld;

- a defect in the assembly of a sedimentary column, in which instead of a threaded connection of pipes, they are welded, allowing axial displacement.

Meeting such an obstacle is accompanied by a characteristic hard knock, while the downward movement of the pump occurs freely.

Is it possible and how to pull the pump out of the well in this situation? There are known cases when rotation of the pump with the help of a pipe around its axis helps to go around an obstacle that stands in the way. However, a 100% probability of freeing the movement of the device is not guaranteed. This could be a one-time success. But it’s worth a try, maybe in a specific situation the problem will be solved this way.

A tool, fastener part, or other foreign object that accidentally falls into the well can also become a solid obstacle. In this case, the pump stops abruptly and unexpectedly during ascent. This happens when a solid object gets into the gap between the well wall and the pump, which leads to jamming. In this case, the downward movement is free, and the upward jamming intervals vary depending on the selection of the cable. The object will not be able to slip through, the gap is too narrow. Therefore, experts advise stopping and calling specialists. The special equipment they have is capable of removing the interference from the well.

Reverse siltation effect

This effect is observed in wells drilled in limestone soils. As a result of long-term operation, a sedimentary layer forms above the pump location, turning into a “plug”. To stop this process, clean the well every three years.

Why do pumps get stuck in pipes?

- deposits in the mine;

- sagging power cable;

- siltation of the bottom of the source;

- reverse siltation;

- obstacles, debris;

- deformation of the casing;

- pump misalignment;

- caught on the pipe joints.

Deposits in the well. The reason is the soil in which the casing is installed. Limestone rocks interact with the metal body of the device plus oxygen to produce a durable stone coating. Deposits can form both on the device itself and on the walls of the pipe where the equipment is located. If, when lifting the device by the cable, there is no movement either up or down, and the cable and cable do not move when tensioned, this is a sure sign that there are salt deposits in the shaft.

Slack cable. The pump is held suspended in the pipe using a cable and a reliable bolt connection. In addition, a hose or pipe and a power cable are connected to the device. Often, when pulling the device by the cable, we forget to pull out the cable in parallel, and after a few meters it sags and wraps around the pump body. This can happen if, when the equipment was first submerged, the power cable was not attached to the rope with special clamps. It sagged during the operation of the well and was wound around the device due to vibration. If, when you try to pull the device by the cable, it goes tight and constantly gets stuck, the reason is the sagging cable.

Silting of the well bottom. After drilling and installation, the casing pump is lowered too deep. Equipment almost always gets stuck in sludge. In the pipe there is a natural process of formation of sludge at the bottom. In the first years of water consumption, the problem of siltation will not be identified, because it comes in clean and soil has not yet accumulated at the bottom. After prolonged use, the water from the device may contain an admixture of liquid clay and change its color. This is a sure sign that he drowned in the mud.

Reverse siltation. In addition to the accumulation of sludge at the bottom of the source, there is the problem of complete blocking of the device body inside the casing pipe with sludge. This happens due to displacement of the seams at the joints, or due to improper installation of the casing pipe. It also occurs in a mine on sandy soil, since sand and eroded soil enter the holes above the pump along with water. Gradually, the silt covers it completely and envelops it, preventing it from being pulled to the surface. If the cable, when taut, moves little by little, then up and then down, it means that the pump is stuck in silt, and reverse silting has occurred in the well.

There was garbage. There is little space in the water well; pumping equipment barely fits into it; however, during use, debris or foreign objects may get into the well for some reason. It is not always possible to keep track of the head of the well pipe. Children throw stones and toys; small animals and birds are found in the pipe (although this rarely happens). Foreign objects make it difficult to remove the pump from the well. Debris that gets into the barrel falls to the very bottom and rests against the pump. A clear sign of a foreign object getting into the shaft will be a characteristic shuffling and grinding sound when trying to pull the cable.

Deformation of the casing. Incorrect installation and dishonest attitude towards work lead to problems in the wellbore. Deep water-bearing pipes are assembled using a screw connection or a tongue-and-groove method. There is therefore a risk of detachment at the joints. This happens due to the negligence of workers, or due to the characteristics of the soil. The pipes move away from each other and become askew. A shelf is formed in the trunk, and accordingly, the channel narrows. A characteristic sign of casing deformation is knocking and a sharp stop during lifting.

Pump misalignment. The decision to remove the device from the mine shaft has been made, and it’s time to start pulling it out. But after several movements in the upward direction, it gets stuck and does not move, which means there is a misalignment. The reason is a rope or cable that, during lifting, got caught on the bottom of the equipment or a side connection, as a result of which the equipment became a wedge.

The device got caught on the pipe joints. During the lifting process, it may have hit a butt joint. Determining the cause is quite simple. The average length of a metal pipe is 6-8 meters, polyethylene – 4-6 meters. You need to measure the appropriate length on the cable; when you pull it out, it will become clear what the depth is and which seam the pump rests on.

What not to do

Even if the situation is not hopeless, incorrect actions can worsen it, and then you definitely won’t be able to lift the pump from the well with your own hands - you will have to call a special service that is engaged in pulling out flooded pumps and removing foreign objects from the well.

Brute force should not be used until the cause of the equipment jamming inside the source has been determined. If unsuitable materials were used during installation, the cable may fail and burst.

It is not recommended to pull out a heavy pump using only the electrical cable. It is much weaker and can break at any moment. To secure yourself, you need to use hooks and work at the same time.

Do not lower poorly connected parts from pipes and hoses inside. In the process, they may remain in the well and make the task even more difficult.

Do not attach heavy equipment to low-quality cables. When exposed to water, they corrode and lose strength.

How to get the unit if the cable breaks

This is a problem in which owners abandon equipment right in the trunk and lower new ones there. Of course, this can be done if the unit fell to the bottom and sank. And the depth of the mine allows water intake to be higher than before.

When the break occurs above the water level, the unit will still have to be removed. You need to make a special device yourself. By analogy with a mixer or a kitchen whisk, we twist a spiral from the fittings with a sharp end slightly larger than the pump itself. We lower it into the well and weld the rod, immerse it again and attach another rod. So all the way to the bottom. The armature is needed to twist the spiral and grip the device. If the device fails to hook, after rotational movements the rest of the cable will twist onto the trap and the pump will rise.

Important: to avoid problems with cable breakage, from the very beginning it is selected with a sufficient margin of safety. A safety bolt is installed in the coupling with the unit.

What not to do

- Pull forcefully on the hose or cable. They can come off.

- Continue operating the pumping equipment. This will make the situation worse.

- Start lifting the pump without finding out the reason why it is stuck.

- Work with the power cable connected to the pump connected to the socket.