A water pump is a device that is almost impossible to do without when living in a private house or cultivating a summer cottage. In cases where it is not possible to purchase a serial model of such a device, you can make a water pump yourself, spending a minimum of financial resources. A homemade water pump is made from materials and parts, most of which can be found in any home workshop or garage, according to one of the design schemes proposed below. Using such a low-cost device, you can solve many household and economic problems.

Manual water pump

Pump classification

Hand pumps take on different and even unexpected appearances

Today you can often find water intake standpipes in courtyards or in the private sector. Such speakers have nothing in common with manual mechanical pumps. Why? In conventional water pumps, water pressure is created by pressure in the city water supply. In a mechanical pump, pressure is created through pressure, which must be constantly pumped up using physical effort.

All mechanical pumps are classified into 4 main groups:

- Piston.

- Rod

- Membrane.

- Winged.

Piston devices are used for sources up to 10 m deep. If the well depth is 30 m, then rod devices are ideal. Membrane ones are mainly used for pumping water in water supply systems. As for vane hand pumps, this is the most expensive device. It is a rotary mechanism in a housing with a suction pipe.

Also, hand pumps differ in operating mode and materials of manufacture. For example, some models can only be used in the summer. The housings of such pumps can be made of plastic. There are also metal models of devices that should be insulated for use in the winter.

Now we invite you to familiarize yourself in more detail with all types of similar devices used to lift water from a well.

Manufacturing of Scroll Hydraulic Pump

For a dacha or a private house, in the immediate vicinity of which a river flows, you can make your own water pump, which looks very similar to a carousel (you can see the principle of its operation in a video on the Internet). The basis of the design of such a pump is a wheel with blades, driven into rotation by a moving river flow. The pumping unit in this device is a spiral made of a plastic pipe with a diameter of 50–75 mm and fixed to a wheel with blades using clamps.

Spiral hydraulic pump

The pipe spiral branch pipe, located on the outer contour of this design, is equipped with an intake bucket, which is made from a pipe of a larger diameter - 150 mm. The internal pipe of the spiral design is connected to a pipe reducer, which is located at the level of the axis of the wheel with blades and is securely fixed to a fixed base.

Pipe reducer is a key component of a volute pump

The maximum height to which such a homemade water pump can lift the pumped liquid medium will depend on the distance covered by the intake bucket of this device under water. The principle of operation of the water pump in question is based on the fact that at the moment the intake bucket is immersed in water, a closed system is formed in the spiral pipeline, consisting of sections of the liquid medium and air cavities, as a result of which the pumped liquid medium moves to the center of the spiral and enters the pipe reducer.

The cost of such a pumping installation, the manufacture of which will require certain knowledge and skills, will depend on how much the consumables and technical devices used in its design will cost you.

With the help of such original pumping equipment, you can organize complete watering of a summer cottage or personal plot in the summer, without using an electric pump for these purposes. This will save energy.

Design and principle of operation

Screw rotors rotating inside the stator displace liquid, increasing its pressure. The liquid is pumped by moving it between the screw grooves located along the axis of the screw and the housing. To improve the quality of the design and reduce the number of leaks, conical and cylindrical elastic casings are used. The spring presses the conical screw quite reliably, and the fluid, due to the pressurized pressure, helps reduce the number of leaks. If it is necessary to withstand heavy loads, metal cases are used instead of elastic ones.

Recommendations

To make a concrete pump with your own hands, it is recommended to adhere to the following recommendations:

- For the cylinder and piston of the unit, pipes and sheets of durable alloy metal are used

- The cord and plug are selected taking into account the engine power and the presence of a ground loop in the network supplying the unit

- Before installing a homemade piston, the inner surface of the cylinder of a homemade unit is ground to a mirror finish

- After completion of concrete work, the cylinder, suction and concrete supply lines are thoroughly washed using a mini-wash

- To reduce the friction force of the piston on the cylinder walls, they are lubricated with machine oil before starting work.

- The petal valves at the inlet and outlet of the cylinder are changed once a season - when working with aggressive concrete, they often fail and stop opening

With careful selection of materials and a responsible approach to the manufacturing process of the main components, a do-it-yourself installation will be little inferior to store-bought small-sized analogues. At the same time, the cost of such a pump will be several times lower than that of the factory model.

Making a homemade pump of the simplest design

How to make a pump more convenient? You can make such a device from ordinary plastic pipes. To do this you will need the following consumables:

- 1 meter of plastic sewer pipe with a diameter of 50 mm;

- two ½” check valves;

- plastic sewer pipe with a diameter of 24 mm;

- a piece of rubber;

- “bolt-nut” pairs with washers (Ø 6–8 mm);

- bends, plugs and sealing collars;

- bends, clamps, fitting clamps and other plumbing parts.

The proposed design (on the right in the figure) is based on the design of a classic hand pump (on the left)

The homemade pump of the proposed design can be manufactured according to two design schemes: with water draining through the handle and with a side drain.

Handle drain device

A water pump with a discharge handle is the simplest option of the two proposed above. Water will rise up the piston rod, made of plastic pipe, and then flow out of the top of the device.

To make a water pump sleeve, you need to do the following.

- First you need to prepare the base of the sleeve by cutting a piece 650 mm long from a pipe with a diameter of 50 mm.

- A petal valve is installed at the lower end of the sleeve, which is made in the following sequence: several holes (8–10) with a diameter of 3–4 mm are drilled in the plastic plug; A circle with a diameter of 50 mm is cut out of rubber 3–4 mm thick, which is secured in the center of the plug using a rivet or bolt.

- The plug with the finished petal valve is installed on the lower end of the sleeve and fixed using self-tapping screws screwed into the walls of the sleeve pipe. The junction of the sleeve and the plug must be sealed with sealant.

A homemade water pump piston can be made using the following brief instructions.

- A check valve is installed on a piece of pipe 70–80 cm long and Ø 24 mm, which will serve as a piston rod. The latter should allow water to pass in the direction of the pipe-rod. To install the valve, the end of the pipe is heated, then the valve fitting is inserted into it. The resulting connection is further strengthened with a worm clamp.

- To make the piston itself, you can use the nose part of a used 350 ml sealant tube. In order for the future piston to take the shape and dimensions of the internal section of the sleeve pipe, it is heated and placed inside such a pipe, allowing it to cool completely in it. After the piston is ready, it is trimmed and fixed to the check valve using a male threaded coupling and a union nut.

- The final stages of manufacturing such a pumping device are its installation in the sleeve, fixing the upper plug with a pre-made hole for the rod on the sleeve, and installation of the 90° drive rod on the upper end of the drive rod.

Thus, making a mini water pump with your own hands is quite easy. It is reliable, but not entirely convenient to use, since the water outlet point is constantly moving.

Side drain device

When wondering how to make the pump ergonomic, you can consider a model with a side drain. To manufacture such a water pump, it is enough to modify the above-described design.

- A 35° tee is installed on the top of the sleeve pipe.

- Holes are made in the hollow piston rod so that it does not interfere with its rigidity.

After such modifications, water from the rod will enter the inside of the liner, rise by the piston to the level of the drain hole and pour out through it.

Metal pipe pump

What tools and materials are needed for the job?

To make a homemade concrete pump, you will need to prepare everything you need:

- A sheet of whatman paper, pencils, a ruler, a compass to create a diagram.

- Iron sheet 5 mm thick.

- Screwdriver, wrenches, bolts.

- Electrical engine.

- Reduction gear.

- Lathe.

- Pipes for moving the solution.

- Steel for piston and valves. It will be more convenient if the pieces are round in shape.

- The welded frame is the basis of the structure.

Having prepared the necessary materials, you can make a mortar pump with your own hands.

Purpose of manual models

The main purpose of using pump-type equipment is to pump water from a source to certain points: to a residential building, bathhouse, garage, garden. In suburban areas, the source most often is wells and wells, less often - ponds and other bodies of water.

All residential or country houses can be divided into three categories: permanent, seasonal and periodic residence. Not all of them have electricity, and some are supplied irregularly.

If we summarize all these factors, we can draw the following conclusions:

- in permanent residences, electricity is used by default, so the main equipment for pumping water is an electric pump, and the manual model is a spare backup unit;

- if the cottage is used only in the summer and power lines are connected, then the energy-dependent option is also ideal, and the manual device plays a secondary role;

- a summer cottage without electricity most of all needs manual equipment.

To irrigate 2-3 flower beds, you can still draw water with buckets, but to ensure complete and daily watering of beds, greenhouses and lawns, a pump is needed. This is where a model that requires a pair of hands to operate comes in handy.

You can make a simple speaker yourself by using the skills of welding and assembling metal or plastic parts.

An example for making your own model can be a factory product assembled from durable cast iron or steel parts, with a comfortable handle for use

Some craftsmen build reliable equipment for wells and wells that serves well for years. We present an overview of homemade products, for the manufacture of which scrap materials were used.

Advantages of automatic concrete pumps

- For correct and uninterrupted operation of the device, a special electronic control unit . It allows you to select a specific operating mode and also provides continuous monitoring.

- An autonomous flushing system is provided for the concrete pump and its concrete pipeline , which can significantly reduce the time for servicing the equipment.

- To make it easier to operate the concrete pump at night, there is special lighting for the machine itself and the working area.

- The equipment also has a warning system in the form of an audible alarm .

- The device provides the ability to adjust the gaps of the concrete distribution unit.

- Any set of concrete pumps includes the following elements: a flushing system, software and a concrete pipeline (can reach 80 m).

- In addition, the kit can include a concrete distribution boom , which greatly facilitates the delivery of concrete to the construction site.

- It is noted that the concrete pump engines meet all necessary standards, including EURO-4 .

- In the process of designing a screw concrete pump of this complex equipment, spare parts from world manufacturers , which allows to increase the service life of the equipment and reduce repair costs.

What types of concrete pumps are there?

There are several types of concrete pumps:

- on mobility (stationary and mobile);

- by type of mixture supply (piston and vacuum).

As mentioned above, the most popular are piston pumps . Vacuum ones are used less frequently; the concrete mixture is fed into them by creating a vacuum in the receiving tray.

Stationary concrete pumps cannot move independently; they are transported on a trailer. They also do not have arrows for feeding the mixture, which is not always convenient. Mobile installations are the most common; they most often use truck-mounted concrete pumps and units on vehicle chassis.

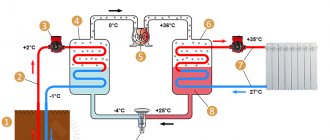

Creation of an airlift

Pumping water from reservoirs and underground sources can be organized without the help of standard pumping equipment. To do this you will need an original device called an airlift. To make such a simple but quite effective water pump with your own hands, you will need two pipes of different diameters, one of which will supply compressed air, and the second will pump out water, and a regular air compressor.

Operating principle of an airlift pump

The operating principle of the airlift, which was invented 200 years ago, is as follows. If you place two tubes in the water column, one of which will supply compressed air, this will lead to the formation of a mixture of liquid and bubbles. Such a mixture, having a lower density than water, will begin to rise up the second tube.

To see how such a water pump works, you can conduct a simple experiment by placing two tubes in a bottle of water, one of which is connected to an aquarium compressor powered by a low-power motor. When the compressor is turned on, water will begin to pour out of the second tube. The efficiency of such a water pump, usually not exceeding 70%, directly depends on several parameters - air flow, immersion depth and the total height to which the pumped water must be raised.