To heat country cottages and private houses, combined heating boilers are increasingly being used - devices that provide optimal temperatures regardless of the presence of a centralized gas supply.

Compared to traditional equipment, combined-type units have many advantages, among which the main one is significant savings in money.

However, in order to purchase suitable equipment, you need to carefully familiarize yourself with the selection criteria and assortment.

Electric boiler and heating features

An electric heating device is a consumer of fairly high power. Therefore, it is often necessary to build an individual power supply system for it. This is expensive in terms of purchasing the electric boiler itself, as well as reworking the network and increasing its power.

There are boiler models up to 12 kW and higher. The first ones are produced in single-phase version. Equipment that has increased power is already made three-phase. The basis of such a device are electric heaters, heating elements, which transfer their energy through a heat exchanger. Electric boilers do not require constant maintenance, nor do they require special cleaning.

Mounted electric boiler for heating a bathhouse in a residential building Source 1-teplodom.ru

Electric boilers are less popular than gas boilers, as they require access to 15 to 40 kW of electricity. This is quite a lot, therefore, not every region has such an opportunity. In fairly remote villages and towns there is no such voltage at all, so you will have to abandon the electric boiler. If such a connection is possible, it is important to study several important points:

- Installation is simple. For this type of equipment, there is no need to choose a special place where the boiler can be installed, since it does not emit waste during the combustion process, and therefore there is no need to construct a chimney.

- It is highly safe provided that it is mounted to a grounding system. Even if the device fails, it can give an electric shock, but will not lead to death.

- Basic maintenance. Repairing a boiler and replacing its heating elements is much easier and cheaper than completely rebuilding the combustion chamber structure. It is also very easy to change the heat exchange medium.

- Efficiency (coefficient of efficiency). This parameter reaches almost 95%; this is not found in all heating units. This return is due to the fact that in the design the built-in heating element is placed in a container with water, to which it gives off its energy when heated.

Rating of the TOP 10 best combined boilers for heating

| Place | Model | Price |

| Models of small and medium thermal power up to 30 kW | ||

| #1 | Teplodar Kupper OVK 18 18 kW | |

| #2 | Teplodar Kupper PRO 28 28 kW | |

| #3 | ACV Delta Pro S 25 26 kW | |

| #4 | Protherm Bizon 30 NL 27.1 kW | |

| #5 | Buderus Logano G125 WS-25 25 kW | |

| High power models from 30 kW | ||

| #1 | Teplodar Kupper PRO 42 42 kW | |

| #2 | Sime 1R6 FREEST 64.8 kW | |

| #3 | Ferroli Atlas Evo 47 | |

| #4 | Sime 1R7 FREEST 74 kW | |

| #5 | Lamborghini Calor EL DB DN EVO 32 | |

Page navigation:

Gas boiler and features of its use

Gas boilers are strictly dependent on blue fuel. Therefore, if emergency situations occur on the main line, the owner risks being left without heat. But such situations happen extremely rarely and gas services often find a quick solution to this problem.

If there is a gas main near a country house or in the entrance of a high-rise building, then you should not think about which unit to choose. You definitely need a gas boiler. Such equipment will be cheaper, and utility costs will be lower than with electric heating.

Installation of a gas boiler for heating a residential private house Source domkotlov.by

Gas fuel boilers are now available in a wide range on the market. There are wall and floor models. Each of them is convenient in its own way. The peculiarity of this equipment is that it is necessary to construct a chimney duct for them, if there was none previously. It is also possible to use a pipe to which another type of boiler was previously connected. If the boiler is wall-mounted, then making a chimney for it will not be difficult. It is enough to simply build a hole in the wall of the required diameter.

Important! If you previously installed a chimney boiler, and now you plan to replace it with a parapet boiler, be sure to contact the gas service to obtain permission and redo the project.

Below are a few things that are important to know about gas boilers:

- the efficiency often reaches 80-95%. However, only high-quality condensing equipment can provide such an indicator;

- As for safety, if there is a malfunction, there may be a leak of toxic fuel, and there is also a danger of explosion if a spark occurs;

- installation is carried out with a mandatory outlet under the chimney. It will have to be brought outside through the wall or through the roof.

Gas boilers will be more economical than electric ones in terms of utility costs.

Mounted gas boiler with chimney outlet through the wall Source 999.md

conclusions

When planning to purchase a combined heating boiler for heating a private home, you must remember that:

- the main criteria for choosing equipment are the maximum thermal power, the type of fuel used and the heat exchanger material;

- Increased attention also to the coolant temperature, control system and design dimensions ;

- For organizing one heating system, a single-circuit device would be a good solution, but if the device is also selected for hot water supply, you should give preference to a dual-circuit model.

Electric gas boilers as an alternative

There are cases when residents in their own homes install two types of heating equipment: both gas and electric. This is in case there is a power outage in one of the power sources. Such a solution will be very expensive, so you should use an alternative - install an electric gas boiler that can operate on two sources.

Electric gas boiler for home heating Source perm.santechbomba.ru

Typically such devices will switch between modes automatically. There are very few models of combined boilers in the range, so they will be quite expensive. Inside such devices there is a gas burner and water heating elements.

Important! Such a device requires a separate room in the house. Due to such operating conditions, they try to use such structures exclusively in regions with harsh climatic conditions in winter.

Advantages of an electric gas boiler:

- the device has compact dimensions;

- has a high efficiency, which can reach 97%;

- the unit is economical, as the cost of producing thermal energy is reduced;

- not only heats the home, but also supplies hot water for kitchen faucets and showers;

- has a reduced level of environmental load due to minimal emissions.

As a rule, such installations make all the necessary switching automatically, but the user can always start it manually.

Design of an electric gas boiler for heating residential premises Source m.onlinetrade.ru

Operating principle of combined equipment

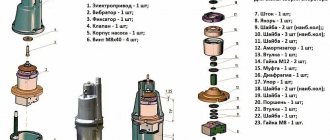

Electric gas boilers have a separate internal structure, which is not similar to simple non-combined heating devices. In the body of such a device there is a separate chamber in which the gas mixture is burned and a separate one with an internal heating element.

Both chambers are installed in a structure one above the other, which ensures that the boiler independently switches to the required type of fuel. In the event that both fuel resources are missing, the equipment goes into standby mode. And when fuel arrives, it can automatically turn on.

Minimum required power

For an average house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m2. We also recommend setting aside a power reserve of 20-30%.

For example, for the average house described above with an area of 100 m2, the minimum required power of heating equipment is 100/10 * 1.3 (30% reserve) = 13 kW. Boilers of this power are not found on the market, so we round up to the nearest higher value - 14 or 15 kW.

When choosing a double-circuit boiler, it is recommended to add another 10-15% to the result, since when heating hot water, the heating circuit is not heated.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

What is more profitable from an economic point of view in the end?

Despite the fact that the installation of gas boilers requires the creation of additional structures, compliance with standards for the area of the room in which it is installed, and this, not counting the cost of purchasing the boiler itself and its components, such heating will be more economical than electric.

Profitable heating of your own home with a boiler Source saucyintruder.org

Due to the current economic situation, gas heating is much more profitable than an electric appliance. But an electric boiler can also find its application and justify the costs in premises with a total area not exceeding 40-60 m2.

On a note! An electric boiler will be economically beneficial for houses in which residence is temporary, for example, a weekend getaway. In a few days, the equipment will generate less kilowatts than a gas unit of cubic meters.

Operating the device

For long and safe operation of a boiler that consumes electricity and gas, several rules must be followed:

- Sufficient traction must be ensured during use. To do this, you need to accurately select the cross-section of the chimney.

- The chimney should be insulated with non-combustible materials. This way you can avoid fire from touching flammable parts.

- During periods of intensive use of the unit, it is necessary to clean the ash pan as it becomes dirty.

- To protect the floors from sparks, a sheet of metal must be laid in front of the firebox.

Following these simple steps will allow you to enjoy the warmth during the most severe frosts and allow the whole family to enjoy hot water all year round.

Despite the availability of combined units, users still ask the question “electric boiler or gas boiler, which is better?”

How to significantly save fuel to reduce costs

Each owner has a real opportunity to reduce the cost of electricity or blue fuel, even if the device does not provide automatic mode switching. To achieve significant savings, you will have to separately purchase a thermostat and install it on the equipment.

A room thermostat is usually programmable and during its operation it is guided by the air temperature in the room. For normal operation and performance of the function specified by the thermostat, it is necessary to program the settings not only for the next day, but also for the entire week in advance.

Saving fuel resources when heating your home Source chiamamicitta.it

If it is a working day and the owners are absent, then the temperature limit is set to 15 degrees. During sleep, it is rational to set priority to 18-19 degrees. By specifying these parameters, the level of comfort will not decrease, and fuel consumption will noticeably decrease. This can be determined by the amount of utility bills.

Device prices: summary table

In order for the buyer to quickly choose an option that suits his needs and income level, the offer of trading enterprises is as follows:

| Model | Number of circuits | price, rub. |

| Teplodar Kupper OK 15 | single-circuit | 19 900-21 200 |

| Karakan 20 TEGV | double-circuit | 22 500-25 000 |

| STS V25 FG | double-circuit | 330 000-500 000 |

Video description

Heating with gas and electricity: which is cheaper, comparison.

In the case of the second, the owner must find out about the condition of the power line near the house and what parameters the nearby transformer station has. It must provide enough voltage to the equipment to keep it running smoothly. Also, the electrical network must be able to create a three-phase connection with a voltage of 380 Volts.

Options for gas and electric boilers for home heating Source chiamamicitta.it

Choosing a heating scheme for a country house

According to our expert Vladimir Sukhorukov, the rating of closed-loop systems is as follows:

- Dead-end two-pipe.

- Collector.

- Two-pipe associated.

- Single-pipe.

A single-pipe version of the heating network is perfect for a small house with a square footage of each floor of up to 70 m². The Tichelman loop is appropriate for long branches that do not cross the door, for example, heating the upper floors of a building. How to choose the right system for houses of various shapes and number of storeys, watch the video:

Regarding the selection of pipe diameters and installation, we will give several recommendations:

- If the area of the home does not exceed 200 m², it is not necessary to carry out calculations - use the advice of the expert in the video or take the cross-section of the pipelines according to the diagrams given above.

- When you need to “hang” more than six radiators on a branch of a dead-end wiring, increase the diameter of the pipe by 1 standard size - instead of DN15 (20 x 2 mm), take DN20 (25 x 2.5 mm) and lay it to the fifth battery. Next, run lines with a smaller cross-section specified initially (DN15).

- In a building under construction, it is better to do radial wiring and select radiators with bottom connections. Be sure to insulate underground lines and protect them with plastic corrugation at the intersections of walls.

- If you don’t know how to properly solder polypropylene, then it’s better not to mess with PPR pipes. Install heating made of cross-linked polyethylene or metal-plastic on compression or press fittings.

- Do not embed pipeline joints in walls or screed, so as not to have problems with leaks in the future.

The procedure for installing a gas heating system in a private house

The procedure can be described as follows:

- Drawing up a project and its approval (when connecting to the main line), concluding a contract with the installation team.

- Purchase of gas equipment (project requirements do not limit the choice of model).

- Installation of a gas holder or insertion and connection to a common line.

- Installation and connection of the boiler.

- Trial run, technological checks.

About the installation of a boiler room with a double-circuit boiler in the following video:

Single pipe system

And the most common of those myths is about the single-pipe heating scheme. The coolant is directed to the radiators and back through one pipe, and many people believe that this is an ideal option for a small house, as it is cheaper to maintain than other variations. But that's not true.

Due to the fact that all the batteries are connected to one pipe, the efficiency drops noticeably, and the radiator at the end of the chain differs significantly in temperature from those at the beginning. This leads to a forced increase in boiler power and, as a consequence, to an increase in fuel consumption.

However, this scheme remains popular due to the low cost of the installation itself. A small number of structural elements allows you to save on materials, and in small rooms, temperature losses at the extreme points of the circuit are not so important; they are leveled out by natural air circulation.

First launch of TP

Warm floors are very convenient.

All that remains is to figure out how to turn on the heated floor. The first start can be carried out only after the screed has completely dried - this is about a month. First, the system is filled with water. This is done manually using a pressure test pump or through a pre-installed connection to the water supply circuit.

The technique is as follows:

- all air vents and all shut-off valves open;

- the circuit is filled with coolant;

- when water begins to ooze from the air valves, they close;

- the temperature regime is set at the mixing unit;

- then the boiler turns on.

As the coolant heats up, air will come out of it, so it will need to be vented. After several cycles of heating the coolant, the system will stabilize and you will only have to adjust the hydraulic resistance on different TP circuits using flow meters. As you use it, you will make adjustments to the coolant temperature.

Single pipe system

And the most common of those myths is about the single-pipe heating scheme. The coolant is directed to the radiators and back through one pipe, and many people believe that this is an ideal option for a small house, as it is cheaper to maintain than other variations. But that's not true.

Due to the fact that all the batteries are connected to one pipe, the efficiency drops noticeably, and the radiator at the end of the chain differs significantly in temperature from those at the beginning. This leads to a forced increase in boiler power and, as a consequence, to an increase in fuel consumption.

However, this scheme remains popular due to the low cost of the installation itself. A small number of structural elements allows you to save on materials, and in small rooms, temperature losses at the extreme points of the circuit are not so important; they are leveled out by natural air circulation.

Option 2: gas and diesel

Device

A universal boiler is installed in a single heating circuit, designed to use both types of fuel. Switching from solar to gas and back requires only replacing the burner.

The VAILLANT VKO 408 universal boiler is capable of switching from diesel fuel to main gas after simply replacing the burner.

Advantages

Coordination of connecting a built house to the gas main and installation of the input take from several months to 2-3 years. If you have already moved into a built house, in winter you need something to heat.

A universal boiler will be an excellent compromise, requiring minimal investment:

- Before connecting gas, you heat with diesel fuel;

- As soon as the house is connected to the gas mains, you switch to gas without any additional investments.

The wait for gasification at home may be lengthy. A universal boiler will allow you to provide heating from the moment you move in and then quickly switch to a new type of fuel.

Reference: the price of a kilowatt-hour of heat when burning diesel fuel and main gas differs by 5-7 times (0.5-0.7 rubles versus 3.5-4).

Restrictions and standards when installing a warm water floor

Let's start with the fact that water heated floors do not belong to high-temperature heating systems. According to the standards, the coolant temperature cannot be exceeded or heated above 55C.

In practice, heating occurs to a maximum of 35 or 45 degrees.

However, do not confuse the temperature of the coolant and the temperature of the floor surface. It can range from 26 to 31 degrees maximum.

where you are constantly (living room, bedroom, kitchen) - it’s 26C

in rooms with temporary stay (bathroom, separate hallway, loggia) - 31C

Also, don't forget about the circulation pump. A warm floor is still a separate independent circuit. The pump can be either built into the boiler or mounted outside it.

With the help of a pump, it is easier to fulfill another requirement regarding temperature differences. For example, between supply and return, the difference should be no more than 10 degrees.

Knowing all these limitations and recommendations, let's move on directly to the schemes themselves.

Connection diagram for batteries and one TP circuit

The TP can be inserted into the supply line through a tee. A mixing unit must be installed.

Often heated floors are combined with conventional radiators. Let's consider how to connect a water heated floor to a common circuit if we have only one circulation ring. In this case, we do not need to convert the two-pipe heating system to a radial (collector) heating system. The TP can be inserted into the supply line in the same way as radiators, that is, through a tee. The return line is cut in the same way.

To reduce the temperature to the required level, you need to make a mixing unit. In this case, a pump is not required, since it will be either in the boiler or in front of it on the return line of the general system (after the expansion tank). No flow meters, air vents or other control elements are needed. It is enough to install a three-way thermostatic valve and, of course, like on every radiator, shut-off valves.