A small corridor separating the entrance to the steam room and the relaxation room with a washing compartment is always perceived by customers as a secondary room. Its arrangement is often approached only after numerous problems with the steam room and sink have been resolved, and this is wrong. You need to properly make the floor in the dressing room, insulate it and equip it with air vents right away, without putting the problem off for a long time. Otherwise, there is a risk of getting a stinking swamp under the floor.

In a simple country bathhouse, the dressing room is created by installing a wall

How to insulate a dressing room?

Before you carry out any work, you should initially put together a plan.

It must be created before construction begins. This is necessary in order to navigate when choosing insulation, since the installation of each of them requires adherence to a certain technology. There are many different options for insulating such a room. But when using any type of thermal insulator, you will have to remove about 15 centimeters of the base. If you plan to make the floor higher than the foundation, then you can fill the space with bulk materials, such as:

- Earth.

- Expanded clay.

- Slag.

These mixtures will need to be compacted after backfilling.

The ideal insulation for the floor will be a material that is durable and fire resistant. It must be inorganic, so it could be:

- Minvata.

- Perlite.

- Glass wool.

Such elements are not subject to rotting and microbes and/or fungi cannot spread there.

For rooms

When choosing a laminate for flooring in rooms, you can pay attention to class 34 laminate. It has excellent strength characteristics, a long service life of 5 0 years

Its only drawback is its high price.

In the photo - laminate for the room:

When using this laminate, modern technologies were used to obtain an ultra-durable floor covering. But it is advisable to use it for those rooms where there is intense load, and this is the hallway and living room. And if you need to choose a laminate for your bedroom, then class 31 laminate would be a suitable option. In these rooms the load is insignificant, so class 31 can cope with them perfectly and will last up to 5 years.

Laminate is one of the most popular materials when arranging floors. It is actively used in houses, apartments, hospitals and even airports. It is classified according to resistance class into 4 types. Each of them is used under specific conditions, taking into account the applied load.

Causes of wood rotting

Without special treatment, logs and floor boards begin to rot

A tree is an organic environment in which pathogenic microorganisms can develop very successfully. Most of them require two components:

- moisture;

- heat.

In a bathhouse, as a rule, wood is used to finish the floors, walls, ceiling, benches and shelves. That is why, without special treatment, logs and floor boards begin to rot. What are the main causes of rot in a room?

- poor waterproofing;

- lack of normal ventilation;

- high temperature and humidity;

- poor quality wood processing.

Some woods are more resistant to pathogens than others

We recommend reading the Zen channel “”, where you will find a lot of useful information for summer residents and gardeners.

This provides them with “immunity” against mold and mildew. For this reason, in order to prevent floor rotting, it is better to use the following types of wood:

- larch and fir;

- spruce and ash;

- cedar and pine.

The tree species most susceptible to moisture and, accordingly, pathogens are:

- maple and alder;

- aspen and linden;

- birch and elm.

Is it possible to protect wooden materials from rotting? To prevent the appearance of rot in the bathhouse, you can treat the wood with special impregnations and varnishes, which will be discussed further.

Laminate color

When choosing laminate flooring for an apartment, most people first of all pay attention to its design. This is one of the important criteria for creating an aesthetically attractive interior.

In order for the rooms to look harmonious, all furniture and decoration must be combined with each other.

Before buying flooring, you should select and install entrance and interior doors, since the range of doors is much smaller than the types of laminate. Skirting boards are increasingly chosen not to match the color of the floor, but to contrast - this makes the interior look much more impressive. If the floor is light, then the baseboard should match the door and its trim.

The photo shows a living room in warm colors, where the color of the floor echoes the color of the walls and harmonizes with white baseboards and trim.

The main task of laminate is a high-quality imitation of parquet boards, solid wood or parquet boards. The “array” looks noblest and most expensive.

If the walls are decorated in neutral colors, then the floor can be rich, and vice versa: with a bright finish, it is better to choose a muted color of the laminate. Universal options are coatings imitating pine, oak and birch, but this approach requires additional bright accents in the form of furniture or decor.

The photo shows a discreet living room interior in black and gray tones. Laminate with an unobtrusive pattern was used as flooring.

Light wood species fit perfectly into a laconic interior, giving it lightness and air. This is especially true in a small area. But dark wenge-colored laminate makes the decor heavier, so it’s only suitable for spacious rooms.

The most practical solution is a floor covering in gray shades: the dust on it is practically invisible.

Modern technologies make it possible to imitate not only a wooden surface, but also ceramic tiles and stone. The appearance of such products is not much different from the original. The dimensions and shape of the dies are maintained in accordance with the natural material: the panels are square or have an aspect ratio of 1:3 or 1:4.

There are also collections with drawings, patterns and inscriptions on the surface, but such eccentric solutions require a thoughtful design project so that the decor does not look tasteless.

The photo shows a bright dining room with multi-colored laminate flooring, giving the atmosphere a playful mood.

Installation of the floor in the waiting room

The simplest option is an earthen floor, but due to constant exposure to water, it will become dirty. Water will drain through such a floor and the composition of the soil will not affect this in any way. But the clay floor does not allow water to pass through at all, or it does pass through, but only in a small amount.

When making the floor in the dressing room, you need to pay attention to the following points:

Boards laid on the ground most often end up below the level of water that accumulates during washing, and from a hygiene point of view this should not be the case. After a few days, the quality of standing water will begin to deteriorate and an unpleasant odor will appear.

You can improve the quality of earthen floors if you arrange them as follows: move 50 cm away from the foundation, remove the soil to a depth of 0.5 m, and pour sand or gravel into the resulting hole. Boards are laid on such a base. With this arrangement of floors, water will fall into this hole and then enter the ground, which means that water will not remain in the room and the appearance of an unpleasant odor will be avoided.

The floors can be made of concrete and tiles can be laid on them as finishing. Wooden grates are placed on top of it, which can be taken outside to dry after taking bath procedures. To install such a floor, it is necessary to organize water drainage away from the bathhouse.

Laying boards directly on gravel or sand is not the best option. It would be preferable to make floors on joists in the waiting room. The distance between them and the gravel will be about 10 cm. Supports must be made under the logs, that is, columns made of concrete or brick. Floorboards are laid with the convex side up and fixed with nails. The boards cannot be laid end to end, as under the influence of water they can swell and bulge.

Therefore, there should be a gap of 1 cm between them.

To protect gutters and joists from rotting, they must be impregnated with compounds specially developed for this purpose.

It is important that the rough coating in the dressing room is moisture resistant.

When choosing from the list of floor coverings what to cover the floor in the bathhouse dressing room with, you need to cross out linoleum from it. This material has a specific odor and is not suitable for use in rooms with high temperatures.

Before covering and painting the floor in the bathhouse and dressing room, it is necessary to select a material for finishing the floors. Such a parameter as heat capacity is no longer so important for finishing flooring. Since near the floor the temperature will almost never rise above 30°C.

When making flooring in the dressing room, it is also necessary to insulate it. Next we will talk about how to make a warm dressing room.

Frame construction: ease of work

Do not forget that first all wooden elements are treated with an antiseptic and fire retardant. The work is carried out as follows:

- the lower frame is attached to the foundation with pins, and there is a beam on it, the cross-section of which is 10x10 cm;

- first, corner support bars are installed, their verticality is checked with a level, then intermediate ones are fixed, their pitch is 80 cm;

- the top trim is attached;

- external corners are additionally fixed with braces;

- floor logs are made from unedged boards;

- elements for door and window openings are installed;

- the frame is upholstered with waterproofing and windproof membrane material;

- The frame work ends with the outer cladding.

After building the frame, they move on to building the roof.

Applying varnish

The final stage of finishing any room is varnishing. However, the materials necessary for treating surfaces in a bathhouse are subject to special, increased requirements (for more details: “Which varnish to choose for baths and saunas - the differences and advantages of different compositions”).

The varnish must provide:

- absence of rotting due to increased effects of antiseptic impregnation;

- protect floors from any damage, including mechanical;

- safety for the health of humans and their pets;

- resistance to high humidity;

- no toxic fumes due to overheating.

After this, you can apply the varnish using a brush or roller - whichever is more convenient for you. The varnish should dry thoroughly, after which another layer can be applied if necessary. Please note that in the steam room you can only use varnishes that do not contain toxic substances released into the air when heated. Another important point is that the varnish must protect the coating from accidental fire as a result of a spark from the oven.

Laminate 32 classes

Laminated panels of category 32 are suitable for residential and commercial premises, the load of which is of an average level with low traffic.

32 value refers to the quality average level: the most convenient option for residential premises, it can also be effectively used on the floor of small offices and uncrowded public places.

Advantages and disadvantages

A special feature of the material is its versatility, the ability to withstand loads that can withstand ordinary apartments, as well as in public places.

In addition, the material has other positive characteristics:

- antistatic properties;

- convenience and ease of installation;

- environmental friendliness;

- resistance to chemicals;

- abrasion resistance;

- fairly long service life;

- resistance to sunlight (the coating does not fade);

- heat-resistant indicators;

- is an impact-resistant coating;

- ability to absorb sound.

The material is presented in a wide range of colors. The most common options are panels that imitate cut wood.

The only drawback of 32 marking board panels is their water resistance. They should not be confused with moisture resistance, in which they can be used with high air humidity. Water resistance is characterized by the absence of damage when moisture gets inside the seams.

The outer coating has water-repellent properties, but if water remains on the surface for a long time, as well as inside the seam, the board or its joints may swell, which will lead to damage to the product.

Specifications

The size and thickness of laminated boards can be different: in width they can be from 9 to 20 centimeters, in length - up to 140 cm. The thickness of the product varies from 0.7 cm to 1 cm. The most common panel thickness is 8-9 mm. The most durable and relatively durable product is 1.0 cm thick.

With careful use, a laminate with a value of 32 will last in a public space for 5 years, and in a residential building for 10 years.

Panel design and composition

The multilayer structure of category 32 boards is presented by manufacturers as follows (from the inside to the front):

- the bottom layer consists of paper impregnated with resin to ensure moisture resistance;

- HDF board - main layer with a locking part;

- decorative layer with a textured pattern;

- acrylic protection on the outside.

In cases where the laminate has a high moisture resistance, the main board is covered with a protective moisture-resistant film, and the locking elements are treated with resin impregnations for a water-repellent effect.

Coating concrete floors

Unlike wooden floorboards, a concrete base remains insensitive to moisture in any form, as well as temperature changes. Concrete floors in bathhouses are made relatively rarely, and only if the problem cannot be solved by protecting and waterproofing the base. Before covering the screed with a protective varnish layer or applying paint, the concrete floor must be carefully leveled horizontally, otherwise water will collect in puddles in several places.

On concrete floors, leveling the surface is more hassle than painting.

Next, you should cover the floor with a primer. If you compare concrete with wooden floorboards, the situation is the opposite. The cement-sand base turns out to be little sensitive to temperature, while the varnish or paint on its surface under the influence of water and hot steam can peel off. Therefore, it is always necessary to prime.

Next, we lay out the main layer of paint, you can take latex or butyl-styrene compositions or the popular Tikkurila Betolux Aakva Base, designed specifically for rooms with high levels of humidity and temperature, like in a bathhouse.

Characteristics

When purchasing laminated flooring for an apartment, you should pay attention to the properties that allow you to directly evaluate its quality. From the descriptions that manufacturers most often give on their official websites, one can easily draw conclusions for which room this or that type or class is best suited. There are several features that most manufacturers indicate in the description of their products.

There are several features that most manufacturers indicate in the description of their products.

The main ones:

Wear resistance and thickness

This parameter directly determines what loads a laminated floor can withstand (which is especially important for rooms with heavy and bulky furniture), its strength and degree of abrasion, as well as sound insulation properties. The last two properties are very important for the living room, which, as a rule, has a variety of furniture, and for the bedroom

- Light fastness. The higher this characteristic, the less the coating will be susceptible to fading under the influence of direct sunlight.

- Resistance to chemical dyes and agents. Cleaning chemicals or paint can damage your floor, so it's best to make sure that the chemicals in your cleaning products won't damage the surface. In addition, this characteristic is very important if in the future the residents decide to repaint the floor in a different color or re-coat it with reinforcing paint.

- Moisture resistance. Wooden products have the unpleasant property of absorbing moisture, and laminate is no exception. If you decide to purchase this particular type for a house with high humidity, then you need to look for a special material made from solid wood fibers and treated with resin or wax.

Construction stages

The wooden floor is built using classical technology using logs and floorboards. The wooden floor in the steam room is somewhat different, where it is built in the form of a leaking grate, which must be especially carefully protected from water. The construction of a wooden floor begins with the installation of joists.

Before making a wooden floor in a bathhouse, you need to purchase lumber.

You need to purchase it in such a way that there is a minimum amount of waste.

The length of the lumber should not differ from the finished workpiece, or be such that cutting can be carried out without much loss.

The maximum length for lumber is 6 m. Long transport is not required for their transportation. The selected type of board depends on how to paint the floor in the steam room and the rest of the bathhouse. If it is a covering paint, then you can take second grade boards. If it is a transparent varnish, then only the first one with a minimum number of defects.

For strip concrete, rubble foundations, as well as concrete foundation blocks, logs are used along the entire length of the bathhouse and a regular floorboard for the floor in the bathhouse (tongue and groove boards of the same thickness). The logs in the bathhouse are placed strictly horizontally. This is the main installation requirement. Here are some other general rules:

- Logs can only be made from solid timber, joints are not allowed;

- For all lags, timber or board of the same section is used;

- The logs are made from coniferous species: pine, larch;

- Treatment with an antiseptic is mandatory;

- Waterproofing the ends from the foundation is also required.

Do-it-yourself logs in the bathhouse are installed in pre-prepared places on the foundation. In this case, a standard set of carpentry tools is used, which are now almost all made electric.

The use of power tools greatly increases work productivity. The timber for the logs is cut to the required length and immediately installed in place. Places for logs are prepared in the foundation in advance.

Typically, logs are simply placed on concrete through a layer of waterproofing. Their ends are simply wrapped in roofing felt and placed in sockets in concrete.

Screw pile foundations are now becoming widespread. On them, the cross-section of the lag can be much smaller. The span length there usually does not exceed 1 meter. The logs are installed directly on the metal frame of the pile foundation.

Metal is not a conductor of moisture from the soil, so waterproofing is not required. The logs are placed directly on the frame protected by an anti-corrosion coating. In some cases, corrosion due to damp wood may occur. Then it is possible to provide in advance a simple waterproofing in the form of a bitumen coating.

Information. There are two sources of moisture in the bath. This is water seepage from the floor surface and moisture seepage from the foundation. Waterproofing must take both of these points into account.

Interior style options

There are several most popular ways to decorate a relaxation room inside a bathhouse or sauna.

Russian

To create this part of the bathhouse in the Russian style, all surfaces must be decorated with wood without additional finishing, for example, clapboard or boards. This solution is especially popular among owners of bathhouses made of timber or rounded logs. The furniture is also chosen from the same material - laconic and simple tables, benches, buffet. The main accent of the room is usually a brick Russian stove with a stone chimney, decorated with special plaster or patterned tiles. As decoration you can use wooden dishes and figurines, dried birch brooms and carved elements of various bath accessories.

Scandinavian

The Scandinavian style, which is popular today, will look natural in a relaxation bath room. The walls will need to be covered with plaster or painted with moisture-resistant paint. The dominant colors in this case are white, gray and blue. It is better to choose simple furniture, painted with white and brown paints, and made of wood. The brick stove should also be painted with white paint and decorated with ceramic tiles with a blue pattern.

Multi-colored pillows, patterned curtains and bright panels are suitable as decor for a Scandinavian interior. When decorating a relaxation room, you need to focus on a calm background and bright accents.

Japanese

A Japanese-style bathhouse looks very unusual. Wall coverings should be chosen in natural shades, for example, dark brown or marsh. You should definitely install a bamboo screen, thereby highlighting the locker room area, and also hang fans on the walls. The tea table should be small in size and on small legs, and it is better to use pillows instead of chairs. In such a relaxation room, the lighting should be soft and diffused, so instead of a bright chandelier, preference should be given to floor lamps and wall sconces.

Country

Country style is similar to Russian style, but is more neat and tidy. The walls can be left untreated, and it makes sense to mount several beams under the ceiling. Either wooden boards or ceramic tiles are placed on the floor. Furniture should be selected from light wood, after which it must be artificially aged or polished. A variety of textiles are suitable for decoration - pillows, curtains, tablecloths and towels made of linen and cotton.

To get closer to American country, you should choose white colors with a red checkered pattern, and to create a European look, you will need to look for pastoral sketches. A fireplace will be a good addition to a country style interior.

Provence

Provence style is quite similar to country style, but still has its own unique characteristics. For example, the recreation room should have antique furniture painted white, and the windows should be decorated with checkered or floral linen curtains. An important rule should be the use of light shades, an abundance of living plants and floral patterns. The use of decorative elements with lace, embroidery and forged parts is encouraged.

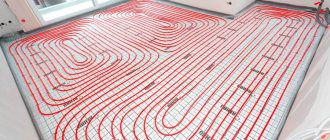

What type of heating is optimal for a bath?

So, what type of floor heating should you prefer - water, cable or infrared? Let's compare their characteristics in the following table:

| Factor | Water heating | Cable heating | Film heating |

| Utility room | Need a boiler room | Not required | Not required |

| Floor thickness with screed | 110-120 mm | 50-100 mm | 5-10 mm |

| Installation time | 4-5 days | 1 day | 1 day |

| When can you start using it? | After 28 days | Straightaway | After 28 days |

| Reliability | If one of the parts is damaged it immediately fails. | If one of the parts is damaged it immediately fails. | Even if a significant part of the system is damaged, the remaining elements continue to work |

| Service | Required | Not required | Not required |

| Freezing in winter | Maybe | Absent | Absent |

| Heat distribution | Depends on installation method | Uneven | Uniform |

| Zoning | Room zoning is not possible | Possibility of organizing separate spot zones | Possibility of organizing separate spot zones |

| Installation costs | High | Relatively low | Relatively low |

| Operating costs | Minimum | Payment for electricity (high consumption) | Payment for electricity (low consumption) |

| Repair costs | High | High | Minimum |

The most economical option for premises of this type is a water-heated floor, but its installation is a rather labor-intensive process that requires considerable effort and time. To install a water heated floor, it is necessary to design a rather complex circuit; in addition, it will noticeably reduce the space in the bathhouse due to its thickness. If you are attracted by ease of installation, it is better to choose an infrared film floor, the advantage of which is that it is ready for use immediately after installation.

Specifications

Laminate flooring has a number of indicators due to which it is in great demand among users:

- This floor covering has a collapsible locking design.

- An excellent indicator of the moisture resistance of the material, which allows it to be used in rooms with high humidity.

- Additional noise and thermal insulation for the floor.

- Laminate flooring is made from environmentally friendly materials. Thanks to this, products of this class are used in children's rooms, schools, and hospitals.

- Resistant to UV rays, high temperatures and the formation of mold and mildew.

- High wear resistance. The floor covering is resistant to mechanical damage (impacts, scratches).

- The flooring has high antistatic properties.

- When installed correctly, the laminate flooring does not dry out and cracks do not form between the planks. There are also no squeaks when walking.

- Class 33 laminate does not require special maintenance costs. At the same time, the aesthetic appearance is maintained for a long time.

- The service life of the coating depends on the thickness of the material. For panels with a thickness of 8-10 mm - 12 years, 11-13 mm - 15-17 years, laminate with a thickness of 14 mm and more - 20 years. The service life of the coating also depends on correct installation.

- The packaging weight of laminate panels is determined by the length, width and thickness of the planks. If the length of the planks is 1.4 m, thickness – 12 mm, width – 16 cm, then the pack weighs about 17 kg.

- High frost resistance.

- When interacting with chemicals and grease-containing substances, stains do not form on the laminate flooring.

- Fire resistance of the product. When in contact with a smoking cigarette, the laminate coating does not change.

- Easy installation, no special tools required. Thanks to the existing locks on the material, the installation procedure becomes quick and easy.

- Fixation when walking, in other words, the surface of the coating does not slip.

Acrylic-based antiseptics

Acrylic products not only protect wood, but also give different shades

Acrylic-based antiseptics help prevent the development of almost all types of pathogens. Before application, they are diluted with water, after which they are applied to walls, joists and floor boards. The distinctive features of such antiseptics include:

- Resistance to temperature fluctuations, which allows surface treatment not only in the rest room, but also in the washing room or steam room;

- Resistance to moisture, which helps prevent wood swelling, which subsequently leads to warping;

- High vapor permeability, thanks to which the wood can “breathe”.

If desired, this impregnation can be applied with your own hands. But before breeding and processing wooden surfaces, it is recommended to use protective glasses and gloves that will protect the skin and eyes from contact with the synthetic product.

Drying oil for processing and floors

As a result of polymerization, drying oil forms a very durable protective film

Drying oil is a film-forming composition that is made on a plant basis. Drying oil can be used to treat wooden coverings in the following rooms:

- washing;

- steam room;

- rest room;

- dressing room

As a result of polymerization, the liquid composition forms a very durable protective film that prevents moisture from entering the wood. Drying oil is used to treat coatings not only for disinfection, but also to prevent the appearance of splinters.

Door installation

The door to the steam room should be multi-layered so that the heat is retained inside.

The steam room has an entrance door, and sometimes there is a lockable opening to the washing compartment. The flap in the hatch sits firmly, without gaps, but opening should be easy, without effort.

Step-by-step guide to work:

- assembly of the hatch and sash;

- marking hinges on the box and canvas, installing the corresponding parts of the canopies;

- installation of holes in the opening, spacers before applying foam, foaming;

- hanging the canvas on the awnings after the foam has hardened, trimming;

- installation of seals, cover strips;

- installation of platbands.

Choose solid wood so that canopies and handles are held in it. Doors from the steam room are always opened outwards for safety reasons.

Where to begin?

In fact, the problem of choosing the optimal floor design and materials for its installation is not so significant. It all depends on the type of foundation and ceiling. Having decided on them, the acceptable options for implementing the base of the dressing room will be reduced.

For clarity, we present in the table the main types of foundations and possible types of floors (the table is a recommendation):

| Bathhouse foundation | Optimal overlap | Possible overlap |

| Tape | Wooden beams, metal beams | Beamless (floor slab) |

| Columnar with reaming | Beam wooden | Beam metal, beamless (floor slab) |

| Slab | Insulation screed | Beam wooden |

| Pile | Beam wooden | Beam metal |

Let's look at the most common types of floors in more detail and continue choosing the optimal floor design for the dressing room.

What materials should be preferred for wall insulation?

Traditionally, the walls in the bathhouse are made of wood. This is an environmentally friendly material that gives the structure a solid appearance and good quality. It is easy to breathe in a wooden room, and the steam becomes richer. But some still prefer to build a bathhouse from brick or foam and cinder blocks, the latter themselves being a heat-insulating material, having a porous structure. However, in severe winters they freeze, making the room cold and causing stains on the walls. Therefore, the walls in the dressing room can be insulated:

- mineral stone wool;

- fiberglass;

- polystyrene foam. The process of insulating a bathhouse with foam plastic

It is best to cover the top of the insulation with polystyrene foam; it is very durable, cannot be compressed, is frost-resistant, durable and does not rot.

Choice of varnish and paint

Wooden floors in a bathhouse can be varnished, but not all varieties are suitable for finishing. You can only use non-toxic, safe compounds that do not emit substances harmful and hazardous to human health when heated. The application of varnish is carried out only after careful preparation of the wooden surface: cleaning it, sanding, filling, removing and treating mold-damaged areas with an antiseptic.

When choosing paint, you should take into account the characteristics of the composition. Some of them cannot be used in a steam room, but can be used in other rooms.

Table. Types of paints

| Paint type | Description | What rooms is it suitable for? |

| Water-based | Natural base. Short service life (no more than 3 years). | All premises |

| Acrylic dispersion | Dries quickly. Large selection of shades. | All premises |

| Alkyd | Dims when heated. | Not recommended for painting the floor in a steam room. |

| Silicate | Has excellent water resistance | All premises. |

| Oily | Not resistant to high temperatures. Dims when heated. | Not recommended for washing and steam rooms. Suitable for painting the floor in the dressing room, rest room. |

Requirements

Before building a dressing room, you need to study the requirements that the room must meet:

- There should be enough space in the room. One person needs 1.5 meters of free space.

- If the bathhouse will be used in winter, the rest room should be heated to make it comfortable to be inside.

- A high-quality ventilation system must be installed inside - natural or forced.

- The room should have furniture installed for a comfortable stay.

- The light in the recreation area should not be too dim or bright.

Often the furnace channel with the firebox is discharged into the dressing room. In this case, the area around the firebox door must be fenced off. This space should not be subtracted from the free space.

Interior decoration

Upon completion of insulation, work begins on finishing the dressing room. Usually it is covered with wooden clapboard, taking into account the unique design and style of the bathhouse. When covering the floor, the first step is to lay the beams on the waterproofing layer. And again, the entire tree needs to be treated with a water-repellent solution.

You need to fix the floorboard to the beams using self-tapping screws using the tongue-and-groove system. It would be a good idea to install a rubber coating on top of the boards. After the floor is covered, we proceed to finishing the ceiling and then the walls. You can sheathe walls in different ways. So, you can make clapboard cladding horizontally, vertically or diagonally. This is where your imagination comes into play.

Foundation for frame construction

As a foundation for a frame dressing room, a lightweight foundation should be used: pile or shallow foundation.

Creating a shallow foundation is done as follows:

- The area is being planned and marked.

- In places where the walls of the building should be located, half-meter trenches with a width of 30 centimeters are dug.

- Sand is poured into the trench in layers and also compacted layer by layer with water wetting.

- Formwork is created along the perimeter of the trench.

- The base of the formwork is reinforced.

- The concrete solution is poured according to the level of the formwork.

- After the concrete hardens, waterproofing roofing felt is laid.

If a bathhouse with a large dressing room is being built, then you need to additionally insert reinforcement into the poured solution, which will increase the strength and reliability of the structure. In the same way, a bathhouse with a utility block can be built, which is quite practical.

Why paint the floor

Many bathhouse owners believe that painting the floors in such buildings is unwise from the point of view of durability, practicality and safety. After all, natural flooring material looks much more impressive, and does not harm human health.

According to experts, painting floors in bathhouses is advisable and has many advantages:

- The service life of wooden floors is doubled, and the susceptibility of the boards to rot and mold as a result of exposure to increased moisture is reduced.

- Concrete bases coated with paints are resistant to moisture, sudden temperature changes and intense mechanical loads.

- A wide color palette of modern paints and varnishes allows you to create a unique interior style of premises.

- Paints and impregnations allow you to save on expensive floor finishing.

Why is this necessary?

Painting concrete solves several problems at once:

- First of all, the concrete floor is painted to prevent dust. The surface of concrete gradually collapses even in literally greenhouse conditions - at stable temperature and humidity; the rate of surface destruction increases many times with fluctuations in these parameters.

So, in a bathhouse with its periodic heating there will be much more dust than in a constantly heated workshop;

- Painting or impregnation will significantly delay the time of the next repair. The notorious mechanical and temperature effects, uneven moisture (for example, melted snow from the roof of a car), fuel and electrolyte from the battery inevitably spilling onto the floor will sooner or later decorate the floor with chips;

- Finally, don't forget about aesthetics. In fact, who would like the dull gray color prevailing in the room?

Painted concrete floor in a gym.

How to paint depending on the room

Well, we have already partially begun to cover this question above, but now it’s time to more clearly distinguish what kind of room we are talking about.

In the dressing room and rest room

We see no reason to distinguish these two rooms. The fact is that most owners of country baths have a dressing room size (if they have one at all) that is quite modest. And purchasing separate materials so that you have something to paint the floor in the bathhouse waiting room is somehow redundant, or what?

Unless there is some kind of different covering than in the rest room.

Wooden floor in the dressing room

We strongly doubt that anyone would want to leave a concrete floor in the rest room and dressing room. And there are not many options. The only alternative is wooden. So let's talk about it.

Here is a complete list of “candidates” for painting a wooden floor in a bathhouse vestibule:

- varnish;

- acrylic paint;

- alkyd;

- oil;

- enamel.

IMPORTANT! Pay attention to the labels - façade paints cannot be used indoors. Some of them are very toxic, and dyeing is only possible in the open air

Is it necessary to paint the floor in the steam room and washing room?

We do not consider this point particularly controversial - it all depends on the quality of the coating. There is no point in taking special care of a spilled floor in a summer shed. But the more money you have invested in the arrangement, the more powerful the desire to take care of what you have achieved becomes.

We did not write above, but now it is appropriate to mention that the Finns (Tikkurila, in particular) offer a special type of oil designed specifically for impregnating the floor in the steam room and washing room. First reaction: but he will slide! The Finns think differently and actively promote their sauna product.

It is assumed that this impregnation will be done on freshly planed or freshly cleaned boards - then it will be well absorbed and the wood will stop absorbing moisture and dirt. The layer itself will be invisible and will not cause slipping.

But still, let's return to the two types of floors that are made in the steam room and washing room: dry and wet.

Dry floor paint

The top layer is often made of tongue-and-groove boards that fit well together. This is an almost monolithic coating that practically does not absorb water and does not allow it to pass down at all. What happens next depends on the wood - there are species that do not rot from moisture, for example, larch or oak. Conifers resist well - due to the presence of resins in them, which serve as a natural antiseptic.

In addition to protection from rotting, there is a second argument: the wood darkens, looks untidy, and those who don’t like it look for ways to preserve its beauty. As an option, varnish coating is practiced, for example, “Unika Super” from the same “Tikkurila” or a similar composition from other manufacturers.

By the way, poor-quality floor installation or poor-quality painting can lead to such a problem as in the video below.

In general, use either specialized products for sauna floors or varnish at your own risk.

Paint for pouring floors

A flood floor is a board with gaps through which water flows either into the subfloor or is collected and discharged into the sewer. Usually, good ventilation is needed here, which goes well with a summer bath. Although... plugs are placed on the ventilation holes in the foundation, so the process is regulated. This means that ventilation dries the floor and prevents it from rotting. She should be enough. But you can also protect it further.

But here it’s up to the owner to decide whether his poured floors are worth buying for them, not so much as cheap sauna oil or varnish. For some, even without this, 15 years pass before repairs.

BY THE WAY! If we are going to cover it with some kind of compound, then it should be so that both the gaps themselves and the bottom are coated, otherwise what is the point of covering only the top if the floor is torrential?

We have other materials that talk about: all interior paints, all facade paints, as well as coatings for walls and stoves.

Design features

The dressing room is a special bath room where a person gets ready to receive the procedure and relaxes after washing. The entire design should create comfort and a good mood. The interior of the dressing room is selected taking into account the following main factors.

Furniture and equipment. In a small room, mandatory items are clothes hangers, shelves for shoes and hats, cabinets for small things and bath accessories, as well as a bench where you can sit for a while. In more “respectable” bathhouses in terms of volume, this room is combined with a relaxation room, and the corresponding pieces of furniture are located there: sofas, a table, a bar, a refrigerator, armchairs. The shape, material and color of the equipment makes it possible to give a certain gloss to the entire interior. You can make furniture yourself or pick it up in a store. Rest will become even more comfortable when there is a TV in the waiting room, where you can all watch a football match together. Don't forget about the opportunity to listen to music.

Style. Any room looks better when it is decorated in a certain style. Most often, traditional baths use the Russian approach to creating an interior. A fairy-tale plot is in demand when decorating a dressing room. Currently, modern design solutions are also highly rated.

Decor. Various fittings can give the dressing room a sophisticated appearance. A special role is given to decorative shelves, figurines, wood carvings, embossing, paintings, etc. All this makes a significant contribution to creating the original appearance of the room.

Lighting. In the waiting room, you should not rely on natural light through the window. Lamps can give the interior a cozy look and emphasize the chosen style. Of course, a chandelier, especially a large one, would be out of place in a bathhouse. Sconces and lamps in the form of candlesticks look good here.

The design decision largely depends on what type of room it is. Although it does not have the extreme conditions of a steam room, its specificity requires a special approach. You can build and decorate a dressing room yourself, but to do this you need to carefully plan all the work and choose the right material.

The dressing room is an important and obligatory room in the bathhouse. It can be very tiny (only for undressing) or larger, where you still need to make optimal use of the space, allocating a place for relaxation.

We can do it ourselves, with our own hands.

If we are not talking about an ambitious project, but about a simple village bathhouse for a summer cottage or a country house, then with today’s possibilities in the construction market, you can build it with your own hands.

Let’s assume that you did just that, erected a free-standing log house according to a traditional design, of which there are so many “walking around” on the Internet.

How to reliably protect this room from the severe winter frosts of the middle zone, if the cold spreads from the bottom up, from the frozen earth along the walls? There is only one answer - insulate the floors. How to insulate the floor in a bathhouse?

To choose the best insulation option, you need to evaluate the type of bath floor:

- clay floors (do not provide insulation);

- earthen floors (do not provide insulation);

- wooden floors (leaking and non-leaking);

- concrete floors;

- warm water;

- and the principle of obtaining and maintaining heat in a Russian bath.

And after reading this article, you will learn how to make a garage roof.

Recommendations

When choosing what to paint bath floors with, you should focus not only on the color of the paint mixture and its service life, but also on the following points:

If the color of the paint has changed, this may be a sign that the coating will crack in the near future. To prevent the wood from getting wet, you need to repaint the floors. Read also: “Which floors are best to make in a bathhouse - choosing a coating.”

Summarize

So, how to paint the floor in the steam room? A steam room is a place where humidity and temperature are always high. Therefore, when painting wooden surfaces, it is necessary to use water-based and acrylic paints, which are non-toxic.

In the recreation room, the floors are painted with alkyd or oil paint.

Source

Recommended coating materials

It is no secret that the floors in the dressing room are the coldest zone of the entire building. The room temperature rarely rises above 25⁰C, so before installing them you need to make waterproofing, vapor protection and carefully insulate the base.

Waterproofing

Depending on how the floor will be made and the type of foundation built, several methods can be used to waterproof the base of the dressing room.

Moreover, they differ significantly from each other not only in the material used for this, but also in the method of its installation.

The most acceptable in this situation are the following types of moisture protection:

- cast;

- pasting;

- backfill;

- impregnating.

Vapor barrier

Vapor barrier will protect the structure from steam penetration

Before insulating the floor of the dressing room, it is necessary to carry out a number of preparatory work, without which the base will not last long.

In addition to protection from moisture, you need to think about installing a vapor barrier material in a timely manner. It will prevent steam from penetrating inside the structure.

This primarily applies when laying floors in a wooden building. In some cases, it is possible to install a second layer of vapor barrier, located above the thermal insulation and directly on the floor. The most common type of vapor barrier today is polyethylene film. In addition to it, other materials can be used:

- Polyethylene with a special aluminum coating.

- Polypropylene material.

- Membrane with limited or variable vapor permeability.

Thermal insulation

When choosing thermal insulation for the floor in the dressing room, you should take into account that there is no material that does not have disadvantages, so it is necessary to analyze all types and, taking into account the design features of the room, select the most acceptable option.

You can stop your gaze on one of the presented materials:

- Expanded polystyrene.

- Extruded polystyrene foam.

- Expanded clay.

- Ecowool.

- Mineral wool.