When laying ceramics, there is almost always a need to cut holes of different sizes in it. In this case, you have to solve the problem of how to make a hole in the tile for a pipe, socket, lamp, ventilation shaft. The task is complicated by the fact that the industry produces a wide range of different devices and devices for cutting holes in ceramics, and choosing a suitable device should not only take into account the size of the socket, but also taking into account the types of ceramic tiles.

Also, during repair or tiling work, the choice of method depends on whether the tiles laid on the walls are processed or whether holes are cut during the laying process. In some cases, if there are installed pipelines, it is necessary to use combined cutting methods using a tile cutter and power tools with various types of attachments.

Fig. 1 Holes in tiles for pipes

How to make a hole in a tile for a pipe

To cut through holes in ceramics, a wide range of household and construction components are used, which are used in conjunction with a drill, hammer drill, screwdriver, jigsaw and angle grinder.

Drilling with a ceramic drill

Typically, the walls in the kitchen or bathroom are laid with glazed ceramics, which have a soft base and a top layer of durable and smooth glaze (tiles). For drilling it, special feather drills have been developed with a flat, spade-shaped tip with pointed edges, which are practically useless when using any of them when working with harder tile materials (porcelain stoneware).

Fig. 2 Method of drilling a hole in a tile with a flap drill

The main problem when using drills is removing the top layer of glaze on which the tip slides. To do this, apply masking tape to the glazed surface (several layers can be glued) and mark the point for the future hole. Using a tile drill, you can make a large-radius cutout by making a series of holes around its perimeter, although the tip will quickly fail.

Drilling holes using a carbide drill bit for concrete

Drills with a Pobedit tip for concrete are widely used to create small holes in laid tiles; the household drill used should have adjustable speed. When working on tiles, several rules should be followed:

- It is better to drill at low speeds.

- To avoid splitting the surface of the tile, holes are drilled very carefully without perforation.

- It is also necessary to apply minimal pressure to the electric drill or hammer drill, which increases as it passes through the tile layer.

Rice. 3 Drilling tiles using power tools and pobedit drills

Article on the topic:

Calibrator for metal-plastic pipes - purpose and operating instructions. Perhaps while reading about how to make a hole in a tile for a pipe, it will also be interesting to learn about the existing types of calibrators used in the installation of metal-plastic pipes, technology and instructions for working with them.

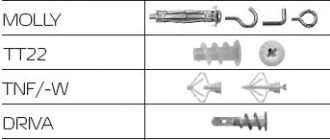

Drilling holes using diamond core bits

Diamond-coated crowns are one of the convenient ways to create cutouts for sockets and pipes, while a circle of the required diameter is obtained by selecting the appropriate cylinder.

To cut a hole with a crown, proceed as follows:

- Place masking tape on the glazed side of the tile to mark the center point of the hole.

- Using a drill, they go deep into the center of the hole, and you can use a drill not only from the kit, but also any drill for drilling, and then replace it with a product from the kit.

- At low speeds, use a crown to cut through the tiled surface until the contour of the circle is deepened to a sufficient distance. In this case, it is not necessary to cut through it completely; it is easily knocked out if the deepening is incomplete.

Basic principles of drilling ceramics

Ceramic tiles are considered the most durable material. After all, it can last on the walls for up to 10 years. And this is with high humidity in the bathroom and kitchen. However, these positive qualities make drilling difficult. There are basic principles that you need to know about in order to drill through ceramics correctly:

- This material is very hard and dense. After all, it is made by pressing. Because of this, making holes requires a tool that is harder than the tile. For example, a drill.

- The top surface of ceramic tiles is almost always covered with a special glaze. This is done so that the material shines and does not absorb excess water. As a result of drilling, the drill may jump off such a surface, and the tile itself may crack.

- Despite the fact that tile is considered a hard material, it is easy to create a crack in it. The thing is that if the tiles are not laid correctly, and there is empty space between the wall and the tiles, the tiles become fragile. As a result, if the drill gets into this place, it can split the tile itself.

If you are not aware of these features, you can easily make a mistake. The price is the replacement of one or even several tiles. And this means extra nerves, additional money spent and precious time.

To make holes you need a tool that is harder than tiles.

Cutting holes in ceramic tiles with improvised tools

As mentioned above, in the manufacture of tiles, rather soft materials are used that can be processed with most household tools. The process is greatly simplified if you keep the ceramic product in water for some time; you can work on wall ceramics with the following consumables and household tools.

Metal drills. They drill holes in soft tiles using ordinary drills for metal processing, the main thing is to use a drill or hammer drill at very low speeds and cool the drill. During the process, its edge must be regularly sharpened - the dulling of the cutting edge of the blade, unlike Pobedit or diamond drills, will occur much faster.

Rice. 7 How to make a hole in a tile with strings

Pliers. A situation often arises when a hole needs to be made at the edge. For these purposes, it is sufficient to use only pliers or special wire cutters, with the help of which small pieces are broken off from the edge until the desired cut is obtained.

Diamond strings. When using strings for cutting, you will need a household hacksaw for metal, into which the string is fixed; the cut occurs along the contour of the cut fragment through a drilled hole of small radius.

Glass cutter. A glass cutter can successfully make straight cuts when using tiles to seal walls with water pipes located in them in cases where the cut area is located within the contour of the tile. To create a hole, cut the tile in the center of the cut-out area, then use pliers to bite out the desired hole. If desired, you can make the cut from the glass cutter almost invisible - to do this, the tiles are glued on the inside with ceramic glue, and after drying, they are glued to the wall using tile adhesive.

Working with a ballerina

The sequence of actions is similar to the previous point, but to reduce vibration, it is better to reduce the speed to 400 per minute.

IMPORTANT: the drill must be held strictly at an angle of 90˚ . You can determine whether you are maintaining the correct angle at the moment the cutter touches the surface of the tile. If the cutter strikes only along one edge of the circle, then there is an inclination. And an incorrect angle increases vibration.

Please note that the larger the diameter of the hole drilled by the ballerina, the stronger the vibration will be!

How to drill a hole in large diameter tiles - step by step guide

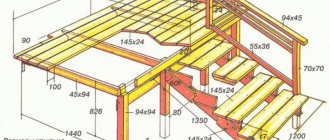

When carrying out repair work, there is often a need to obtain holes with a large diameter of 100 mm. for installing sewer outlets or drains in floors. Crowns and ballerinas of this size for household purposes are difficult to find on sale; drills take a long time to complete the job, so the optimal method is to use an angle grinder. Ceramic cutting is carried out as follows:

- First of all, to reduce dust and make cutting easier, the tiles are immersed in water for a while. It should be borne in mind that all adhesive compositions are designed for gluing dry tiles, so after cutting the hole it will take some time for it to dry. To speed up the work, many tilers do not wet the ceramic, gluing it immediately after cutting the fragment.

- On the inside, use a marker or pencil to mark the outline of the cut area. Many tilers do this on the glazed side, which later results in the glaze clumping and producing poor quality edges.

- A round fragment is cut out from the inside. The large diameter of the hole allows you to do this immediately along the contour without preliminary cross-cuts in the center and cutting out squares. At the same time, the grinder is held at an angle with an inclination towards the center of the circle; first, a small depression is made, which is increased with each pass. The radius of the cut circle is made several millimeters smaller than the required size.

- After several passes of the grinder around the circumference, it is necessary to determine the moment when the circle can be easily knocked out; for reliability, you can leave solid slits in some places.

- Since the circle was cut from the inside, its edges inside will be greatly thinned - this will make it easy to give it the correct geometric shape with wire cutters or pliers.

Fig.9 Cutting the middle hole with a grinder

General rules

Under the general name tiles lies a wide range of finishing materials with very different properties. First of all, you should pay attention to the presence of glaze and firing temperature. If the finishing material was fired at a high temperature, 1200˚C or higher, then it has increased strength and will be more difficult to verify. This applies to porcelain stoneware and Metlakh tiles.

In any case, adhere to the following settings:

- The rotation speed of the drill should not exceed 800 rpm. Exceeding this speed has an almost linear effect on the probability of tile breakage;

- Use only special drills;

- Don't try too hard. The pressure on the tool should be even, without jerking or impact;

- “Wet drilling” is preferable to dry drilling, as it avoids local overheating.

- When drilling, be sure to place the tiles on a flat, horizontal surface. The best option is to lay a piece of drywall or plywood.

- Always drill from the front side of the tile. It is easier to center the drill on the reverse side, but when exiting there will almost always be chips in the glaze.

Compliance with the requirements of only these six points guarantees an excellent result by 90%.

Straight Tile Cutting Tool

When carrying out tiling work, ceramics are cut in a straight line using the following special tool.

Glass cutter

The glass cutter is suitable for cutting wall tiles; it is quite difficult to cut hard porcelain floor tiles with it; work with a roller glass cutter is performed in the following sequence:

- Place the product on a flat, hard surface and draw a line along the ruler with slight pressure towards you.

- Break the tile against a sharp hard corner along the drawn line.

Manual tile cutter

A standard tile cutter is a bed with a rubberized surface, above which there are two guides - the cutting element mounted on the handle moves along them. The slab is placed inside the device towards the base, the cut is made by smoothly moving the cutting wheel along the surface with slight pressure. Upon completion of the pass, the handle lowers and a special lever presses on the slab, breaking it along the cutting line.

For convenience, each tile cutter is equipped with an angular ruler, which allows you to cut pieces of the same size; high-quality expensive tile cutters have a floating bed and one durable guide, which allows you to cut with high quality edges.

Rice. 10 Tool for cutting ceramics straight

Electric tile cutter

The main elements of the device are an electric motor, on the shaft of which a diamond-coated disk is installed, and a water pump, immersed in a cuvette with water and supplying liquid to the working surface of the disk during cutting.

An electric tile cutter is a rather expensive device; it is used for high-quality cutting of tiles at right and sharp angles without dust; it can be used to cut narrow strips less than 10 mm wide, which is difficult with a conventional mechanical tile cutter.

When cutting holes for a pipe, an experienced tiler needs only one grinder with a diamond disc for concrete. To drill deep through holes in walls, it is better to use special crowns or Pobedit drills for concrete. In domestic conditions, in the absence of an angle grinder, holes in soft tiles can be made using special drill attachments in the form of feather drills, ballerina drills and crowns, while the price of the latter is too high for one-time household use.

Measures to protect the material from chips and cracks

When dealing with questions of how to drill tiles, we must not forget about precautions during work, thanks to which it will be possible to avoid deformation and complete destruction of the finishing material. First of all, to prevent the tile from cracking, it must first be soaked in plain water for 1 hour. If there is not enough time for such a solution, you can moisten the area where the holes are being drilled with a spray bottle.

To make it easier to start drilling large holes, you can cut out a stencil from fiberboard or plywood, then press it tightly against the tile to start drilling.

It is quite possible to reduce the likelihood of cracks if you step back at least 15 mm from the edge of the ceramic tile to the cutout. It’s better to calculate the installation point of the socket/shelf so that the hole for the fastening element is located on the connecting seam.