Many different manufacturers, foreign, domestic and joint ventures, present their products on the Russian market. But in order to choose a truly high-quality engineering board, you need to know what advantages and disadvantages it may have, imagine its structure, and basic characteristics. It’s a good idea to always have information about the manufacturers of these products.

This is what we will dedicate this publication to - engineering board rating of manufacturers and rules for choosing quality materials. Let's start with the rating of manufacturers and a brief description of their products - this is for those visitors who came to us specifically in search of quality material. And in the second part of the article, those readers who do not yet fully understand what an engineered board is will find the necessary information about this floor covering.

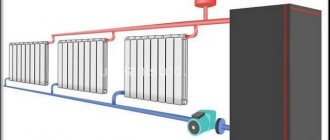

Installation options

The first popular option is mounting on plywood.

It is important to understand that the material used must be up to 15 mm thick. Masonry is allowed only on a base made of concrete

For tight fixation, plywood is attached using special glue or self-tapping screws. At the end of the work, it is necessary to sand the top layer, but it is recommended to do this after 2 days.

- The engineered board is placed on a plywood surface. To ensure a tight fit and no air pockets forming inside, polyurethane-based adhesive is used. For even application, use a spatula. Once the laying is complete, you should avoid putting any weight on the floor for three days.

- In addition to this option, some builders carry out masonry on a concrete base, without the use of auxiliary materials. The process is no different from the previous one, the only requirement is that the surface must be leveled. This will increase the performance and durability of the structure.

As soon as the glue has dried, you should remove all the gaps that form near the walls; skirting boards are used for this.

Advantages and disadvantages

Engineered boards have a number of advantages compared to standard models that are sold at a low price:

- High geometric accuracy;

- Easy installation thanks to special locks;

- Beautiful coating that is resistant to scratches and detergents;

- 3 surface treatment methods;

- High environmental friendliness;

- Safety, since there will be no toxic fumes;

- There is no need to use glue or screws during installation;

- Does not emit allergic substances;

- If the surface deteriorates, restoration work can be easily carried out;

- Dozens of different sizes;

- Long service life. If the material begins to lose color, the product can be restored using varnishes or oils;

- No cracks form;

- Can be installed in any room.

But such a solution also has disadvantages. The first is the high cost of a quality product. The second is a high chance of purchasing low-quality engineered coating. To avoid the second case, you must purchase goods only in specialized stores that provide a guarantee.

In some cases, a person can buy a quality product at a big discount. In this case, the strength characteristics will not be lost. To do this, you should choose last year's collection, with special attention paid to the brand.

Features of parquet flooring

Parquet boards are a type of flooring familiar to many, consisting of three-layer wood planks. Moreover, in 90% of cases, the layers are positioned relative to each other so that the direction of their fibers is perpendicular. This allows you to achieve high strength of the product and resistance to external factors. The planks are connected to each other by locking joints.

Parquet board

The main feature of parquet is its structure. Let's take a closer look at all three layers.

- The outer or front layer is represented by some valuable wood species and has a thickness of about 1-4 mm. The surface of the layer can be tinted, impregnated with oils, or varnished - the latter is needed in order to maximally protect the panel from the outside from moisture and increase wear resistance.

- The middle of the parquet board is small slats laid perpendicularly, about 8-9 mm thick, made from inexpensive coniferous wood. It is the central part of the plank that is equipped with the same locking connection that will fasten the planks to each other.

- The bottom layer is made of wood, most often coniferous, which is also not very expensive. Layer thickness is about 1.5 mm.

Parquet board for flooring

The floor covered with parquet is reliable and beautiful. The locking connections between the individual planks are quite strong and do not allow the wood to twist, which is why deformation of the coating rarely occurs.

Parquet board Befag Oak Royal

Advantages and disadvantages

Like any other floor covering, parquet boards have their advantages and disadvantages.

Parquet boards have many advantages

The advantages of this finishing material.

- Gluing to the subfloor is not required, since all layers inside each plank are mutually perpendicular, due to which it is possible to extinguish internal stress and avoid bending and deformation of the material.

- Laying parquet boards without glue is much cheaper (about 6 times) than gluing installation of engineered boards (in the absence of locking joints).

- The parquet is easy to disassemble and assemble, which allows you to take the flooring with you even if you move (if necessary).

- Laying parquet boards is accessible to everyone - it can be done with your own hands.

Finishing the floor with parquet boards

Disadvantages of parquet boards.

- With sharp fluctuations in humidity, the inner layer of the parquet board may collapse. This is especially true for cheap material, in the manufacture of which low-quality adhesives were used.

- The thickness of the parquet board is quite large - up to 1.4-1.5 cm. Therefore, such a coating can be difficult to combine in height with another.

- Parquet cannot be used if a heated floor system is installed.

- In doorways, at the junctions of two types of coatings, thresholds are necessarily used, since the material does not adhere to the glue.

- There is no way to lay parquet boards other than deck laying.

- If the parquet is laid using a floating method, then it can only be sanded using expensive equipment.

Aged parquet boards in the interior

Parquet board - installation

Proper Maintenance

To improve performance characteristics, you should not only carry out high-quality masonry, but also carry out timely maintenance:

- Polish is applied to the outer part 5-8 times every 12 months;

- Use carpets to prevent mechanical stress: it is best to choose felt products, they are of higher quality and will help maintain an aesthetic appearance;

- When washing floors, you should use only appropriate detergents, for example, Osmo Wisch-Fix is widely popular;

- Walking in heels on ID is prohibited, especially if you do it often. Because of this, cracks and dents form, which spoils the appearance and worsens the technical characteristics.

By following these rules, a person will be able to increase their service life by 1.5-2 times. And the surface will always remain clean and tidy.

Terradeck (Russia)

Advantages: due to the high density of the structure and evenly spaced stiffening ribs, the decking is resistant to static loads. In the case of solid ipe, the natural properties of exotic wood are responsible for the performance indicators. Longitudinal corrugation on the top surface (Velvet), imitation of a natural surface (ECO) in artificial material and textured weaving of fibers on the longitudinal section of the board form an anti-slip surface. The main advantage of WPC is its reasonable price; array - exclusivity.

Disadvantages: the array must be covered with protective compounds. WPC - branded fittings and frequently spaced (250-400 mm) logs are required.

Conclusion: the clear relief of WPC decking and the natural texture of the boards from Terradeck create a non-slip floor.

Options for composite materials are suitable for a terrace and gazebo on a private plot, a summer banquet hall of a restaurant and cafe. Brazilian board - for a bathhouse, swimming pool, patio on the territory of an elite mansion. Terradeck Specifications

| Terradeck Velvet(WPC) | Terradeck Eco(WPC) | Ipe Classic(Array) | |

| Application area | Symmetrical profile - neat seams of a private terrace, garden path | The seamless joint profile makes it easy to clean commercial floors. | Natural material - for exclusive terraces, private patios, private baths, saunas. |

| Dimensions, (L-W-T), mm | 3000,4000x152x28 | 3000,4000,6000x155x28 | 1800-6000x145x22 |

| Weight, kg/rm | 2.1 | 2.4 | 6.5 |

| Density, kg/m³ | 1200 | 1200 | 960 |

| Operating temperature range, °C | -40… +70 | -40… +70 | -30… +60 |

| Quantity per package, pcs. (m²) | Depends on the specific combination of dimensions, can be completed in accordance with customer requirements | ||

| Price, rub/m² | 1 260 | 1 980 | 6 700 |

"Terradayek" in "Fazenda":

Laying method

Consider the advantages of each method.

Laying in the lock:

- efficiency of work;

- the ability to lay the coating yourself;

- dismantling and installation in a new location;

- if a board is damaged, it is possible to disassemble a piece of flooring and lay it again, replacing the board with a new one;

- installation costs are significantly lower.

Glue method:

- allows you to lay the board in a single field throughout the apartment without breaks; sound insulation increases;

- no squeaking of the slats, quiet walking;

- maintainability - scraping, grinding. Sufficient thickness of the top layer allows the board to be restored after several years. Based on the results of restoration, it is possible not only to update the structure, but also to change the tone and select the optimal type of coating in accordance with the interior design.

Among the disadvantages of the adhesive method, the difficulty of installation should be noted. Not every master can cope with this task, so you need to entrust the work to a professional, especially if the installation takes place on a screed without plywood. Also, the cost of such work is an order of magnitude higher than floating installation (about 2-3 times), and it is necessary to purchase parquet chemicals: glue and primer. But such parquet will last a longer time, and it does not need to be replaced entirely, for example, after 10 years. It will be enough to sand and re-coat with varnish or oil.

What to consider when choosing?

Engineered board can consist of two or three layers. Each of them performs its own function. The widespread use of this finishing material has led to a diversified market. The assortment offers products of domestic and foreign production. Given the wide choice, you need to be able to navigate it.

The first thing you need to pay attention to is the thickness of the board. The floor finish for an apartment will be different from that used for office or other high-traffic areas

This indicator can vary from 10 to 22 mm. Experts recommend choosing the “golden mean” – from 13 to 15 mm.

You also need to take into account the characteristics of the type of wood that was used in production. Some varieties are not afraid of moisture, while others tolerate mechanical loads well.

Appearance plays an important role. The color of the flooring and the pattern on it should be in harmony with the interior of the room, complementing it. A wide variety of products allows you to choose the perfect option for every style.

The next important criterion is length. To withstand intense foot traffic, it is recommended to choose boards whose length varies from 2 to 2.5 m. Shorter panels may create squeaking noise.

Before going to the store, it is recommended to study the market, compare prices and reviews from real customers. You need to make a purchase in a trusted store that provides a guarantee on all products.

Features of flooring

The first thing a buyer notices when choosing an engineered board is the presence of three layers, which guarantee reliability and practicality. There are also budget versions consisting of two rows, where the first part is plywood and the second is wood. In the first version, all layers are made only of wood.

The advantage of engineered wood is its high strength properties and absence of deformation, even with prolonged use. In appearance, the product resembles standard parquet. Builders recommend using the material if the flooring is constantly exposed to mechanical stress.

The best solid board with a tongue-and-groove connection

The tongue-and-groove connection is most common for solid wood slats. It has a simpler design than a lock, and allows even strong wood to spring back, ensuring the durability of the coating. However, such a connection requires additional fixation: installation with glue, screws or staples, since natural wood can “play” and separate the boards. This type of coating is not suitable for floating installation either.

Preverco “Oak Red”

5.0

★★★★★ editorial assessment

98% of buyers recommend this product

Canadian flooring manufacturer Preverco names its solid plank collections after the type of wood used. One of the most popular materials is red oak. It is distinguished by its strength, reliability and durability.

The “Red Oak” collection includes 15 color options, both natural and tinted slats. There are also options with different board widths from 108, 127 and 131 mm.

Solid boards from Preverco are treated with a patented varnish with microparticles that protect the coating from bacteria, dust accumulation and fading. The presence of a microbevel around the perimeter makes the finished floor covering especially beautiful, and the thickness of the planks of 19 mm allows it to withstand significant loads.

Advantages:

- Variety of colors;

- High strength;

- Protection against the accumulation of bacteria;

- Antistatic coating;

- Micro chamfer.

Flaws:

Expensive.

The collection of solid red oak boards from Preverco consists of warm shades of Select brand wood, giving the room a special coziness and comfort.

Amber Wood “Jade Collection”

4.9

★★★★★ editorial assessment

92% of buyers recommend this product

Russian manufacturer Amber Wood has released a collection of solid boards, which includes 8 design options. The covering consists of narrow single-strip lamellas of rustic selection. Their main highlight is the brushing effect, as a result of which the wood acquires a pronounced structure of fibers and rings. At the same time, the surface of the board remains smooth with a semi-matte shine.

The array has an antistatic coating, does not attract dust and is easy to clean. Factory varnish was used as a finishing coat.

Advantages:

- Brushed board;

- Smooth surface;

- Varnish coating;

- Antistatic effect;

- Deep semi-matte shine.

Flaws:

High price.

Despite the rustic selection, the solid board from Amber Wood has an expensive appearance. Thanks to brushing, the presence of rings and small knots in the design only improves its appearance.

Sherwood Parquet "Classic 800"

4.8

★★★★★ editorial assessment

90% of buyers recommend this product

The Classic 800 collection from Sherwood Parquet is unique in that it includes not just different designs, but also solid planks made from various types of wood, as well as types of selection. Thus, the line includes 17 types of flooring made from oak, acacia, birch, maple, merbau and other species of natural and select class.

The solid board has a smooth semi-matte surface with anti-slip protection. The boards have a sufficient thickness of 18 mm, therefore they are characterized by durability and practicality. The presence of a 4-sided bevel gives the design a certain ethnicity and makes it suitable for interior styles such as country, loft or chalet.

Advantages:

- Variety of colors;

- Wide selection of breeds;

- Smooth surface;

- Anti-slip protection;

- Thickness 18 mm.

Flaws:

The coating is incompatible with heated floors.

In the Classic 800 solid wood collection from Sherwood Parquet, absolutely everyone will find the best option for themselves - regardless of their different preferences and tastes.

Missouri "North America Wide Plank"

4.7

★★★★★ editorial assessment

85% of buyers recommend this product

The North America Wide Plank collection from the Missouri manufacturer is presented in 16 options of solid boards made of American walnut. The material is sorted by nature and selected. The coating consists of wide boards with a thickness of 19 mm, which provides the coating with high wear resistance.

The solid board has universal use: it is suitable for applying oil and varnish - at the discretion of the buyer. The surface of the material is smooth, matte. There is antistatic treatment. Alas, despite its large thickness, the coating is not compatible with the “warm floor” system.

Advantages:

- Thickness 19 mm;

- Possibility of applying varnish and oil;

- Smooth surface;

- Antistatic effect;

- High wear resistance.

Flaws:

- High price;

- Poor compatibility with heated floors.

Solid board from North America is suitable for both home and high-use areas.

Solid board

Solid board is an old-timer in the luxury parquet market. It consists of wide and long planks, compared to ordinary piece parquet, made entirely of valuable wood and is suitable for those who want the parquet to last for centuries. The top layer can be treated with wax or decorative varnish, which provides additional decorative solutions.

Brown lacquered solid board Hajnowka Oak Carmelo

Entirely natural wood “sounds” great on the floor and has a very special natural energy. At your disposal are both classic non-tinted wood options and any design whim: tinting, various varnish options, artificial aging, inlay, staining and much more. The thickness of the solid board allows you to create decors that are not possible with layered structures.

Pros of solid boards:

- maximum comfort;

- durability, will withstand many scrapings and will serve your grandchildren;

Disadvantages of solid boards:

- high price;

- long and expensive installation;

- can only be mounted on a thick layer of plywood or on a special substrate, and with a large amount of glue;

- it is difficult to maintain one floor level when combined with other materials;

- sensitive to the choice of household chemicals;

- a thick layer of natural wood with changes in temperature and humidity in winter can create large gaps.

If you want to more clearly understand the difference between different types of parquet, pay attention to reliable manufacturers whose line includes all three main varieties. These requirements are met, for example, by the Polish brand “Hajnowka”, whose products will allow you to compare how light oak parquet will look and feel in the version of parquet, engineered and solid boards

Solid board with natural oil Hajnowka Oak Classic

All parquet options are a beautiful, environmentally friendly and natural material, differing only in the ratio of valuable and cheap wood species, installation and maintenance options. For example, in a parquet board the ratio of coniferous species to valuable wood will be approximately 20% to 80%, while we are still talking about real wood, and you get the opportunity to decorate the interior with natural parquet without the extra costs and hassle of installation.

Tips for choosing parquet boards

Any parquet board consists of three layers, where the bottom one is responsible for strength, the middle one is needed for volume and rigidity, and the top one is used as decoration. The cost and durability of the floor covering depend on the materials and manufacturing technologies used. Here are some criteria for choosing a parquet board that you should remember when starting to search for a manufacturer and product:

Top layer material and protective coating. Valuable wood species such as oak, ash, beech, maple, and walnut are used as a decorative layer. The thickness of the layer varies from 0.5 to 6 mm, where 4 mm is considered optimal. The top of the wood is varnished or impregnated with oils. In the latter case, this gives the board a dark tone

What is important here is the number of layers of varnish, varying from 4 to 12.

Board thickness. The board cross-section ranges from 10 to 30 mm

The thicker the parquet, the warmer the floor. An even larger layer allows the surface to be restored (sanded, removing 1 mm, and re-varnished), which increases the service life of the board. We recommend buying parquet with a thickness of 14 mm or more.

The structure of the top layer. The outer decorative surface can consist of a single-strip structure or contain 2 to 3 planks tightly placed next to each other. This makes the look of the parquet more interesting, but complicates the manufacturing process, and therefore increases the cost.

Processing technology. Depending on the technologies used, the quality of the board can be significantly improved. For example, brushing removes soft wood fibers from the structure, increasing the strength of the material and making the surface rough. Heat treatment stabilizes the wood, protecting it from swelling or drying out.

Assembly method. The parquet is laid by connecting the dies together using a locking system. It can be of the “groove-tenon” type (insert from above and press down) or with a rotary principle (the edge is turned at an angle of 45º and lowered). The second option is more reliable and therefore preferable. Each manufacturer calls these systems differently and may differ slightly in nuances, which is important to clarify on site.

Board size. The dimensions of the typesetting elements from which the parquet is assembled can range from 45x5 cm to 20x250 cm. The speed of installation, the possibility of installing the board diagonally, and the appearance of the floor depend on this. Experts also say that the length of the board affects the suppression of step load. In this regard, the longer the board, the better. In the case of short slats, the risk of squeaking is higher.

With or without chamfer. The presence of a chamfer on two long sides (2V) creates expressive stripes on the floor. The 4V bevel defines the rectangle of each board, emphasizing the segments. Panels without chamfer visually make the wooden floor monolithic. Experts say that parquet with chamfers looks more beautiful, but debris collects in these cracks.

The middle and bottom layers of parquet are made of spruce, pine, poplar, and sometimes plywood (engineered parquet). Since they only serve to fill the height and are not visible to the user, they do not play a big role when choosing a board.

Tarkett

Tarkett is rightfully recognized as the next giant. Parquet board Tarkett (Tarkett) is the embodiment of impeccable quality and the widest range of wood.

Dimensional stability and strength are achieved through the use of selected high-quality raw materials. Like Kahrs, Tarkett also distinguished itself in the invention of locking fasteners and began to produce planks with a T-lock locking system, ensuring ease of installation and increasing the speed of installation in general.

It is worth noting that the material is produced on behalf of 2 brands:

- Directly Tarkett. The products are presented in 14 fantastically beautiful selections. Of these, the most widely represented is Salsa, with almost 60 unique color options.

- Sinteros. The collection consists of 3 species.

The Tarkett plant is perhaps the only one of its kind that fully cares about the environmental component of its activities and the materials it produces.

In accordance with the organization's mission in the field of environmental protection, a new concept for the manufacture of parquet flooring was developed, which promotes the effective use of the most valuable wood, which is directly used in the manufacture of the top layer.

In 2014, Tarkett parquet boards underwent some changes in the geometry of the three-strip planks. Now, instead of the classic size (227.2x19.2 cm), products with parameters of 228.3x19.4 cm are produced.

Similar changes have occurred with short dies, the size of which has been changed from 111.7 x 19.2 cm to 112.3 x 19.4 cm. Such changes will help to use wood more efficiently and significantly reduce waste.

Another know-how of the brand is an ultra-modern technology for processing the end part, which reduces the ability of the coating to absorb moisture in particularly vulnerable places - at the ends.

Aqua Guard, as this miracle impregnation is called, is effective against frequent wet cleaning and water spills on the surface. Before the invention of this impregnation, the only drawback of Tarkett products was insufficient moisture resistance, but now this disadvantage has been successfully eliminated.

The standard thickness is 1.32 cm or 1.4 cm. The price for Salsa, Salsa Art Vision, Salsa Art and Salsa Premium ranges from 1500 to 5500 rubles, Performance Fashion - within 5000, Tango, Tango Art and Tango Vintage - 2500 -9500, Rumba – 2700-4500 rub., Samba – 2000-3000, Bolero – 1500-3000 rub.

N3. Weitzer Parkett

The company from Austria is the oldest manufacturer of parquet boards, which has been ranked among the best for many years. The company began producing parquet in 1955, annually adding new inventions to its collections. At the moment, the Austrian brand has more than 3,500 options for parquet boards, ranging from single-piece solid wood to multi-layer premium parquet. The main feature is cooperation with Greenpeace, which confirms the environmental safety of products at the highest level.

Weitzer Parkett aims to increase service life and comfort of use. The company was the first among its peers to develop a parquet board equipped with sound insulation. This decision was the main impetus for gaining great popularity among residents of apartment buildings. It’s not for nothing that Weitzer flooring is called “quiet flooring” in other words.

Main advantages:

- Large selection of wide and narrow parquet with a variety of effects.

- Natural wood is used, 75% of which is grown on the company’s premises.

- Along the entire perimeter of the board and its ends are treated with water-repellent hydrostop.

- Installation of products is carried out using the Double Click system.

- The product lasts for about 30 years.

Rating of the best manufacturers

| Photo | Name | Rating | Price |

| #1 | Hajnowka | 98 / 100 | |

| #2 | Boen | 96 / 100 | |

| #3 | Panaget | 94 / 100 | |

| #4 | Goodwin | 95 / 100 |

Hajnowka

A Polish brand whose products are considered one of the best and are known throughout the world. The highest quality, environmental friendliness, and beauty inherent in Hajnowka engineered boards have allowed us to take a leading position in the market. Interestingly, the line of models has unique shapes that cannot be found from other manufacturers - this is the merit of professional designers. Material thickness – 15 mm.

pros

- high quality;

- large palette of colors;

- two types of wood are used (oak and ash);

- average price category.

Minuses

not detected.

engineering board Hajnowka

Boen

A fairly well-known company, whose production is carried out in Lithuania and Germany, as well as in other countries of the world, except Russia. The engineering board of this company belongs to the category of premium products and has a lot of shades.

pros

- environmentally friendly product;

- boards are represented by three classes;

- high wear resistance and complete safety of use.

Minuses

high price.

Boen engineering board

Panaget

Board from France, made on the basis of plywood. There are both methods of connecting planks, depending on the model - both locking and tongue-and-groove. Has an additional stabilizer.

pros

- the material is environmentally friendly;

- Warranty from the manufacturer for more than 20 years.

Minuses

- high price;

- It is better to entrust installation to professionals.

Panaget engineered board

Goodwin

A German-Chinese brand whose products have their own characteristics. For example, the short length of the slats is 120 cm, although in general slats are available in lengths up to 2 m.

pros

- base - birch plywood;

- top layer - solid wood of Russian oak or American walnut, 4 mm thick;

- low cost.

Minuses

In some batches the boards may differ in shade.

Goodwin engineering board

Features of laying engineered boards

It's time to get acquainted with how the engineering board is laid. The instructions will help you figure it out.

Step 1. The sub-concrete floor is thoroughly cleaned of debris.

Preparing the base

Step 2. The floor surface is primed with a two-component epoxy primer - be sure to coat the area near the walls well, as well as the entire surface. You need to start applying the primer from the side opposite to the exit from the room. It is more convenient to cover large surfaces using a roller.

Applying primer with a brush

The primer is applied with a roller

Step 3. The surface is well dried.

Next you need to wait for the surface to dry.

Step 4. A special perforated underlay is laid on the floor.

Laying a perforated underlay

Laying process

Step 5. The adhesive composition is applied along the wall where the laying of the engineered board will begin.

Applying glue along the wall

Bostik KPA, shear-resistant, universal in use

Step 6. The adhesive composition is also applied to the perforation holes.

Glue is applied into the holes of the substrate

Another photo of the process

Step 7. The first panel is placed along the wall on the glue applied in advance and the substrate laid close to the wall.

The first board is laid along the wall

Step 8. The entire first row is laid out close to the wall.

Laying the first row

Step 9. The second row is being installed. The panels are laid very tightly to each other and are connected to each other by a fastening system.

Laying the second row

Engineering boards are laid closely

Step 10: Apply glue to subsequent holes as needed. Laying of the covering is underway.

Glue is applied to subsequent holes in the substrate

Step 11. To connect the planks more tightly together, you may need a hammer, which is used to carefully knock the panels together. The entire floor is finished in the same way.

A hammer is used during installation

Video - Laying engineered boards

Using engineered wood is one of the best ways to create a beautiful flooring that resembles real solid wood in your apartment. More and more people are choosing this material. In any case, engineered wood has quite a lot of advantages, and therefore it can be an excellent alternative to laminate and other types of coating.

Pros and cons of engineered fabric

Most ID samples on the market today have the following average indicators (for an individual element, that is, roughly speaking, for each board):

- Thickness – from 15 to 25 mm;

- Length – from 500 to 3000 mm;

- Width – from 110 to 450 mm.

The positive qualities of engineering boards undoubtedly include the following qualities:

- Engineered fabric is a material glued together from several layers, which means it is less susceptible to mechanical deformation. It also has the highest geometric stability.

- The ID can be laid directly on concrete, and there is no need to additionally lay plywood as a base. The main thing is that the concrete is smooth and has increased waterproofing. The versatility of ID also lies in the fact that it can be laid directly on top of the “warm floor”.

- The engineered fabric is durable and can be varnished and sanded several times. However, for re-processing, the top layer of ID must initially be greater than the minimum by 2 millimeters (i.e., at least 4 mm).

- The material in question is characterized by its resistance to external influences: the percentage of its likelihood of cracking/drying is much less than that of parquet.

- The installation process is extremely easy - a sleeve-groove (tenon-groove) connection is used.

- The design range is very large - the veneer covering can be “aged” for a retro style, brushed (painted) for a classic one, tinted in light gray colors for a “high-tech” style.

- Engineered flooring is also famous for its environmental friendliness and high level of noise and thermal insulation.

The engineering board has few disadvantages, and they are purely repair and technical in nature:

- Individual elements of the covering are difficult to repair; it is difficult to re-cover the entire board;

- The high cost of the canvas itself;

- Each batch is painted individually, so choosing a replacement for repair from a similar one and getting into the color tone can be difficult;

- Markets are overflowing with low-quality counterfeits;

- Floating installation is not possible.

The best domestic manufacturers of solid boards

Amber Wood

The company is mainly engaged in the production of floor coverings, but the production of solid boards is one of its main activities. Over 11 years, the company has significantly improved wood processing technology, which has had a positive effect on the quality of its products.

Amber Wood uses only legally harvested and environmentally friendly raw materials: birch, oak and ash, varnished, oil-impregnated or in their natural form. A variety of designs is provided by tinting or brushing the boards.

Pros:

- High quality materials and strict selection of raw materials by grade;

- Wide range - currently 57 designs in different sizes are presented;

- Modern equipment that allows you to obtain excellent board geometry without chips and cracks;

- Well-developed dealer network - online orders can be picked up at any retail outlet;

- Relatively low prices (compared to European leaders);

- Manufacturer's warranty.

Minuses:

- The varnish on all models is not of impeccable quality;

- The unpopular variety classification system makes the choice a little more difficult.

Material advantages

Engineered boards are a little more expensive than parquet boards. But it is necessary to take into account that this coating is many times more reliable and durable. Companies producing these products have increasingly begun to use valuable wood species, which are known for their excellent performance characteristics.

The best engineered flooring board is no different in appearance from solid wood, but its service life is much longer. This coating can be scraped and then varnished. This can be done many times. Another advantage of this coating is the possibility of laying it on a “warm floor” system.