The construction and repair of buildings is unthinkable without the use of concrete mixtures, cement and lime mortars, leveling screeds, adhesives, putties and grouts made by thoroughly mixing various binders and fillers with water until completely homogeneous. A significant part of them has to be prepared on construction sites in small quantities. Some compositions require mixing during their production to maintain their homogeneity, mobility and plasticity. Carrying out this work the old fashioned way, with a shovel in a trough, is long, difficult, ineffective, and in the presence of complex special compositions that require especially thorough mixing, it is simply unrealistic. Here you cannot do without such a useful means of small-scale mechanization as a construction mixer. The editors of the YaNashla website bring to your attention a review of “The Best Construction Mixers for 2021,” based on customer reviews and expert opinions.

A few words about the recent past

Until recently, on domestic construction sites, they only knew different grades of concrete and two types of mortars: cement, for laying brick walls, and lime, for leveling and plastering these walls. They were prepared at RBU - mortar-concrete units, and delivered to the construction site by dump trucks. In the body of the dump truck, the compounds “stratified,” the heavy fraction sank to the bottom of the body, and a liquid mass called “cement laitance” formed on top.

At the site, materials were unloaded by dump truck into a bucket and transported to the work site. Before use, the delivered material was mixed with shovels in small containers. No one mixed the concrete mixture. It was loaded into prepared formwork and processed with an in-depth vibrator. The quality of the work was very relative.

Everything changed at the end of the last century. Mortars and concrete began to be delivered to sites in concrete trucks. The concrete or masonry mixture was mixed on the way to the object, the composition did not separate. The quality of concrete work has improved significantly.

In addition, ready-made dry construction mixtures have become available for sale. They were delivered to sites in bags of 25–50 kg. All that remained was to add the required amount of water and carefully move the contents.

This is where the problems started. To mix ready-made dry mixtures, you need a tool. It is difficult to mix the mixture in a bucket manually and obtain the composition of the required homogeneity. The owners of country houses and construction teams involved in European-quality renovations used electric drills and hammer drills for mixing, inserting first homemade and then factory-made devices into the chucks - whisks (or mixers).

To some extent, this was a way out of the situation. If you needed to mix paint or prepare wallpaper glue or mix a small amount of cement mortar, a drill and hammer drill could do it without any problems. But during large volumes of work, preparing viscous mixtures or concrete, drills and hammer drills were “killed” in batches: cartridges were broken, shafts and bearings were ruined, electric motors failed. This continued until hand-held construction mixers from Europe, Asia and the USA appeared on sale.

After some time, domestic manufacturers followed suit.

Material for making nozzles

The service life of the whisk depends on its quality and operating conditions. Professional screws for working with thick mixtures and abrasive substances are made of stainless steel. They can last for several seasons. Budget models made of anodized aluminum or galvanized steel are more affordable, but are designed mainly for domestic use. Screw-shaped nozzles are made mainly of plastic, since they are not subject to significant loads.

Taking these criteria into account will help you choose the construction mixer attachments that are optimal for mixing various mixtures.

05.10.2018

Construction mixer device

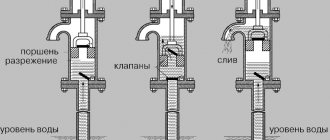

The device is an electric drive that rotates a special attachment (also known as a whisk or stirrer) to mix the solution. For comfortable use, the drive is equipped with a comfortable handle on which the starting equipment is located (start button and button for fixing the operating mode of the tool).

The power consumption and speed allow it to easily cope with the preparation of compositions of any viscosity, including concrete mixtures. The design features of the body and handles make it possible to reduce vibration loads on the operator’s body, and the tool itself can withstand heavy loads without breaking.

Main Features of a Stand Mixer

The main feature is that the stand mixer does not require constant holding in your hands. At the same time, the labor intensity of work on preparing concrete solutions and various building mixtures is significantly reduced.

Advantages of stand mixers

Another important advantage is that mixers of this type can keep a large amount of building material in a non-hardening state for a long time. By constantly stirring the solution, the mixer prevents it from hardening during the time required to use it up.

This is convenient if slow material consumption is required. Especially if there should be a lot of material and strictly the same consistency. For example, decorative plaster, which is applied over a large area by one specialist using coloring components. Frequent mixing will lead to uneven coloring of the material, which can be unacceptable. Using a stand mixer will free you from this kind of disadvantage.

The presence of a special container frees you from the need to use additional construction utensils, the shape of which is not always convenient for stirring mixtures. The special internal shape of the containers of stand mixers is ideal for mixing the entire volume of the material used.

What types of mixers are there?

Drill - mixer

An electric mixer runs on mains power or batteries. There are two types of devices: drill mixer and mixer. The first option is a low-speed hammerless drill equipped with a key or keyless chuck for fixing the drill and whisk (mixer). The shafts of some models are equipped with a thread onto which a cartridge or stirrer can be screwed. The weight of this type of device does not exceed 4 kg. Too much for a drill. Strictly speaking, as a drill, it is unlikely to please anyone. You can drill a couple or three holes with it if you don’t have a normal drill or hammer drill at hand.

The main purpose of the tool is a mixer. It is better not to use it for mixing concrete or not to use it too often and for small-volume batches. It does an excellent job of mixing cement and lime mortars, screeds or adhesives for tiling walls and floors with ceramic tiles. Models from some manufacturers of drill mixers include a case, which is very convenient for storing the tool. Perhaps the main advantage of devices of this type is that they are inexpensive. If you are choosing a tool for your home, this is the most suitable option.

Construction mixer

A tool intended only for mixing construction mixtures. Depending on the power consumption, the number of revolutions per minute, torque, and the number of spindles (one or two), mixers are distinguished for the preparation of moving or viscous compositions. Some models successfully replace a small concrete mixer, since they are almost as good as it in performance and are free from some of the inconveniences associated with its use:

- The concrete mixer has solid dimensions and weight. It requires two people to move it.

- Upon completion of work, the tool must be stored somewhere and preferably under lock and key. Finding a place to store even the smallest concrete mixer is not easy.

- At the end of the working day, the mixer drum must be cleaned of any remaining mortar or concrete, otherwise the device will very soon fail. To clean the drum you will need a lot of water and a place to drain this water.

The mixer is free from all of the listed disadvantages. It doesn't need much storage space. One worker can move it anywhere on a construction site, including multi-story buildings, without much effort. There is no need to pour buckets of water to clean the whisk. It is enough to “spin” it in a bucket of water in a timely manner and wipe it with a rag.

Which mixer to choose

Depending on the power consumption, there are three types of mixers:

- For the preparation of low-viscosity mobile solutions, plaster compositions, and paints and varnishes, devices with a power consumption of 600–1000 W, a rotation speed of 500 to 900 rpm, with a single-speed electric motor and one spindle are sufficient. An example of such a tool is the Fiolent MD1 - 11E model.

- For heavier mixtures - devices with a capacity from 1000 to 1800. As a rule, these are devices with a two-speed gearbox. Switching modes (speeds) is carried out by a translator located on the product body. At first speed – from 130 to 450 rpm, they work with low-moving, viscous mixtures and concrete. The second speed – from 450 to 1050 rpm, ensures high-quality mixing of painting, plaster, putty and adhesive compositions. Two spindles rotating the nozzles in opposite directions ensure high productivity and uniformity of the composition. The Elitech 1600/2ED model is endowed with these parameters.

- Mixers with a power of 1800 W or more, with a two or three speed gearbox, are considered professional equipment. They are used to prepare mixtures of any viscosity with various fillers, including for mixing concrete. Professional mixers can withstand intense loads for a long time without failures or breakdowns. They are quite expensive and it is not practical to purchase them for household use. An example of one of the professional models is the Bosch GRW 18 – 2E Professional.

Criteria for choosing a construction mixer

- Work intensity. For professional use, it is better to choose powerful two- or three-speed devices, preferably from well-known brands known for the high quality of their products. They are more expensive, but more productive and reliable. The costs will be repaid by long-term intensive use.

- Characteristics of mixed compositions. Two or three-speed devices with a high rotation speed of the mixer and a power of 1800 W are more advisable to use if the team often works with heavy mortars and concrete. Devices with a power of up to 1000 W and a nozzle rotation speed of up to 600 rpm are more profitable to use for the preparation of finishing compositions: plaster mortars and putties, adhesives and paints. If an organization carries out general construction and finishing work, it is better to have tools of different types and power on hand.

- For domestic use, everyone chooses the equipment themselves, taking into account the upcoming nature and volume of work. Considering that the intensity of work of a household tool is an order of magnitude lower than that of a professional one, it is better to choose semi-professional devices. They are affordable and the possibilities are quite wide.

What else should you pay attention to?

It will not be possible to prepare high-quality solutions for various purposes with one type of whisk. The fillers for each composition are different. Some, heavy ones, tend to sink to the bottom of the container. Others, light ones, rise up. There are mixtures in which the presence of air bubbles can reduce the quality of finishing work. For each type of composition, certain types of nozzles with different blades have been developed.

Straight blades.

Such whisks are used for preparing adhesive compositions. The presence of air bubbles and foreign objects, even the smallest in size, is unacceptable. A nozzle with straight blades does an excellent job of removing air bubbles from the batch.

Spiral blades.

The most common attachments. Several spirals are wound from the lower edge of the rod, bounded at the top by a ring. There are spirals of left and right rotation. A nozzle rotating clockwise is used to prepare starting and finishing putty, since during rotation it presses the composition down. Mixers with a left-handed spiral are used for preparing cement-sand mortars and concrete. They lift heavy ingredients up, preventing them from settling to the bottom of the container. Double-spindle mixers use right- and left-hand rotation beaters.

Oppositely directed blades are used for mixing paint and varnish mixtures. The material is liquid and splashes at high stirrer speeds. The lower spiral is busy mixing the composition, and the upper one “presses the liquid mixture down, preventing splashes from scattering.

Nozzles for heavy compounds

To mix sand with crushed stone or gravel, you need a particularly durable mixer with blades of a certain configuration. A whisk for paint or putty will not last long in such conditions.

The homogeneity of the material and the performance of the device depend on the correct choice of nozzle. You should not choose stainless steel whisks with anti-corrosion coatings. This is money thrown away. Any coating will come off after a few kneads, and stainless steel is no stronger than regular steel. Choose a durable whisk, taking into account the nature of the mixtures being mixed. It is better to always have different types of attachments.

DIY mixer attachment

If your income does not allow you to splurge on the purchase of a mixer, or the volume of proposed work is so small that such costs are irrational, you can build a nozzle for mixing light solutions with your own hands. If you have a small welding machine and manual arc welding skills, this will not be difficult. It is enough to select a steel rod with a diameter of 5 - 8 mm, roll up a ring no more than 12 mm in diameter, weld three rods of the same diameter to it on three sides so that you get a cone about 100 mm high. A rod 40–60 cm long and 8 mm in cross section is welded to the top of the cone. The free end of the rod is ground to give it the shape of a triangle in cross-section, to securely fix the homemade mixer in the jaw chuck of a household drill or hammer drill. The nozzle is ready.

You can do without electric welding. You will need an M 8 mm pin and three metal plates. The length of the plates is selected depending on the diameter of the container for mixing the solution. A hole with a diameter of 8 mm is drilled in the center of each plate. Then, with the same diameter, another pair of holes is drilled to the right and left of the central ones. A pin is threaded through the central holes of the plates. Each plate is fixed to the rod with M8 nuts at the top and bottom. The shank of the improvised attachment is ground to fit the cam chuck of the drill (the cross-section should be a triangle). The nozzle is ready.

Which brand of mixer is better to buy?

The number of manufacturers of construction mixers is difficult to count. To the numerous European, Asian and American brands, no less numerous manufacturers from the countries of the former USSR have been added. Let's look at the best manufacturers who have managed to establish themselves by producing high-quality instruments from different parts of the world.

Bosch

The oldest and one of the most famous German companies producing high-quality household appliances. Engineer and inventor Robert Bosch founded it in 1886. Currently, the Bosch group of companies is one of the world's ten largest manufacturers of household and professional electrical equipment and tools.

Interesting! Robert Bosch was the first to switch his workers to an 8-hour workday and a two-shift schedule, believing that only a well-rested worker could produce high-quality products. His motto: “It is better to lose money than the trust of customers.”

Hitachi

One of the world's largest electrical goods companies. Its product range includes over 200,000 units. Hitachi is one of the world leaders in the production of information technology equipment, household electrical appliances and electronics. Founded at the beginning of the 20th century in Tokyo.

Interesting! Hitachi, translated from Japanese - dawn. Thus, according to the founder of the company, its activities are aimed at improving the quality of life of customers with the help of high-quality Hitachi equipment.

Makita

Another Japanese company leading in the production of household and professional power tools. Founded at the beginning of the last century. The company produces popular models of high-quality professional and household tools with electric and gasoline-powered drives.

Stanley

The company, founded in the USA in 1843, originally produced bolts and bolts. Over the 150 years of its existence, the company has grown into one of the most powerful manufacturers of household and professional power tools, famous for its reliability and wear resistance. The popularity of Stanley models is due to their performance and excellent wear resistance.

DeWalt

The owner of the brand is the American concern Stanley Black & Decker. The company was founded in 1924. Since 1994, it has been producing cordless power tools and producing the most powerful cordless drill at that time - a 14 V impact wrench. Currently, it is a leader in the market of power tools powered by batteries and brushless motors. An example of this is the DeWALT DCD 240N model, powered by a battery (rechargeable battery), with a voltage of 54 V.

Interskol

A Russian company that is a leader in the production of power tools not only in Russia, but also abroad. The company's products are supplied to the markets of Western Europe and Israel. It is in demand among professionals due to its high quality and reliability.

Hummer

A relatively young German company. Year of foundation: 1987. In a short period of time, it has achieved significant success in the production of garden equipment and power tools. Hammer products are distinguished by high quality, durability and affordable prices. Very popular among professionals.

The list of companies producing quality tools can be continued for a very long time. When planning to purchase a mixer, you should ask the advice of professional builders and finishers, listen to the advice and recommendations of experienced users who buy power tools for household use. Sellers of specialized stores can tell you a lot of interesting things. Before purchasing, be sure to study the description, ask how much your model costs and where the service centers for its maintenance are located.

Mixing concrete with an electric mixer: features and operating techniques

Everyone who builds a house on their own, without hired workers, wants to simplify the task for themselves. For example, use a concrete mixer to mix concrete. A high-quality concrete mixer is not a cheap pleasure. Many will say that its price will be recouped during the construction season. But I want to save money and not break my back mixing concrete with a shovel. This is where the idea comes - to use an electric mixer to mix the solution of sand, cement and crushed stone.

OtherNickFORUMHOUSE Member

I saw a video on YouTube - a man, alone, using a two-spindle mixer, mixed concrete and poured a strip foundation in two days. I thought maybe this was an advertisement for a tool? The builder claims that it is more convenient to knead with a mixer than with a concrete mixer. The question is relevant for me. I mixed concrete in a concrete mixer. It's hard for one. We have to lift buckets. Load the pear. I rented a concrete mixer. There is nowhere to store yours. And with a mixer you can knead the concrete right at the pouring site. It weighs a little. Tell me, is this realistic if you knead small volumes? Maybe someone has already used a mixer? Will the tool break?

beutiflet FORUMHOUSE Member

I think tools should be used strictly for their intended purpose. A mixer is needed to mix plaster and adhesive mixtures, and a concrete mixer is needed for concrete. The weak point of the mixer is the attachments. On heavy concrete with crushed stone, the rim's blades may come off or it will bend.

Just Grandfather FORUMHOUSE Member

Compare the price of a normal mixer and a concrete mixer. The difference is small. It seems to me that health is more important! Using a concrete mixer, you can work together. One carries sand and crushed stone, the second monitors the batch. You work alone as a mixer. Oh, what strength is needed for this. You'll get tired quickly. My concrete mixer is already 10 years old, and it has long since paid for itself.

Now let’s listen to the opinion of those FORUMHOUSE participants who actually kneaded concrete with a mixer.

Bath1

I poured the strip foundation for the fence using a mixer. Tape length 25 m. Section – 200x300 mm. I also concreted a 5 m lintel under the gate and wicket. From my own experience, I will say that you get more tired not from working with a mixer, but from throwing sand, cement and crushed stone, and pulling out concrete. But you also need to throw ingredients into the concrete mixer. It still needs to be washed later, but the mixer spun in the water and went home. Of course, I wouldn’t dare to pour a foundation for a house with a mixer, but for small volumes, it’s quite a suitable option.

The Bath1 mixture was prepared as follows:

- First he mixed dry sand and cement.

- Then he added water. The consistency of the mixture is like sour cream.

- Then he threw in 3 buckets of crushed stone. Stirred the mixture. Then I added another 1.5 buckets of crushed stone.

CartmanSr

I mixed concrete in a cast iron bath with a two-spindle mixer. Two spindles are better than one. The torque is damped and, in the case of a wedge, will not wrap around the tool. I threw cement, sand, crushed stone of fraction 5-20. I stirred for ten minutes and 200 liters of the mixture was ready. I won’t say it’s easy, but it’s not hard either. The crushed stone between the augers did not jam. The tool didn't break.

OtherNick

Briefly speaking. I listened to everyone and also decided to knead concrete with a mixer. I'm reporting. I mixed about 1.5 cubic meters of concrete for the columnar foundation. The mixture is hard. Proportions: 1 part cement, 3 parts sand, 4 parts crushed stone and 0.75 liters of water. Mixed in a 100 liter trough. I made 5-7 batches per day. I couldn't do it anymore. Your arms, especially your hands, get very tired. I’m not saying that I’m weak, but the twisting load on my joints is decent. Crushed stone of fraction 5-20 did not get stuck between the rims. The instrument also held up. Verdict: the method is suitable for small volumes for one-time work.

I wonder if it is possible to fill larger volumes using a mixer? The construction experience of FORUMHOUSE users says: “Yes.”

Veter753

My assistants and I poured 4 cubes of concrete with a mixer. There were 4 people working - two men and two women. The women put cement and enriched sand and gravel mixture into buckets. One man is kneading. The second one carries the buckets, and then the two of us dump the mixture into the formwork. Mix proportions: 1 bucket of cement, 1 bucket of sand, 3 buckets of OPGS, 0.7 buckets of water. In total, we made 115 batches with smoke breaks. It was still raining. The old tub was also leaking. They repaired it. As a result: started at 10 am, finished at eleven o'clock in the evening. Then they added a little more in the morning. The back gets tired, but if you get used to holding the mixer without bending over, with your legs spread wide apart, there is no fatigue. If they started to interfere at 7 am, there were 3 men, not women, it didn’t rain, and the tub didn’t leak, then I think they would have finished it before 6 pm. The mixer kneads the mixture quickly. The main fatigue comes from dragging buckets with OPGS through the formwork and lifting the bucket to the level of the formwork to dump the concrete.

Veter753 tips for using a mixer when mixing concrete:

- First load water, cement and sand.

- Knead the mixture until it becomes sour cream.

- Add 2 buckets of OPGS.

- Stir the mixture until it is a uniform gray color.

- Add another bucket of OPGS.

- Stir evenly again.

The concrete is ready.

If you keep the mixer in one place, it will not mix the mixture, because it will mix in one place. To mix the concrete well, you need to move the mixer in a circle, and zigzag, left and right.

Valeron 1983

The two of us, in 4 days, poured 17 cubic meters of concrete with a mixer. Monolithic slab. Concrete was mixed in a bathtub. They placed it on the reinforcement inside the formwork and turned it over after each batch. We were tired, of course, but we would have been tired with a concrete mixer too. I liked working as a mixer. It gets in the way quickly. He doesn’t twist his arms, his back doesn’t hurt, even though they kneaded with a single-spindle tool. You get more tired of carrying sand, cement and crushed stone.

Rating of quality construction mixers

Fiolent MD1 – 11E

The tenth place in the ranking is occupied by a product of the Russian brand “Fiolent”, model MD1 - 11E. A simple and reliable mixer with a drill function. With a power consumption of 1.1 kW and a maximum torque of 85 N•m, the device has impressive performance compared to a drill or hammer drill. In addition, these parameters allow you to use the product as a hole drill if you purchase the appropriate attachment and stand, which is also useful when mixing solutions, since Fiolent weighs 4.7 kg. Electronic speed control facilitates high-quality mixing of compositions of any consistency, from preparing wallpaper glue to cement screed. An excellent tool for household and professional use, with an average price of 3,745 rubles.

Fiolent MD1 – 11E

Advantages:

- power 1100 W;

- advanced functionality;

- high performance;

- the presence of a convenient removable frame;

- affordable price.

Flaws:

- Not effective enough as a drill.

Hammer UDD 1050A

In ninth place is the model UDD 1050A, of the Czech-German brand Hammer. The company's corded power tools are famous for their quality, reliability and durability. Power 1050 W, sufficient for professional use. It copes well with mixtures of any viscosity, does not leave lumps, and can be used as a drill. The maximum dimensions of holes for metal do not exceed 13 mm, for wood - no more than 32 mm. Package Included:

- corolla, length 120 mm, diameter 14 mm;

- whisk extension;

- side and rear handles;

- the jaw chuck clamps drills with a diameter from 3 to 16 mm;

- keys for 17,19 and 22 mm.

Electronic rotation speed control and reverse facilitate high-quality preparation of solutions of any viscosity. The model is equipped with a handle - a stop on the back side and a removable side handle, which is very convenient when using the tool as a drill and mixer. A comfortable pistol grip, a cam chuck and a relatively low weight (4 kg) allow you to successfully use the Hammer UDD 1050A as a drill. The delivery set includes a whisk for mixing, with an adapter and an extension. The main whisk is convenient for mixing small volumes of building mixtures in small containers. The whisk extension allows you to make batches in large containers. Buyers appreciate the Hammer UDD 1050A for its performance, reliability and reasonable price of 4,770 rubles.

Hammer UDD 1050A

Advantages:

- power 1050 W;

- rpm (idle) – 550;

- high performance;

- excellent build quality;

- modest price.

Flaws:

- not found.

Metabo RW 18 LTX 120

In eighth place is a German drill - the Metabo RW 18 LTX 120 mixer. The tool is powered by a removable 18 V battery. The rotation speed of the mixer in idle mode is 750 rpm. Designed for household and professional use when mixing light and mobile solutions. The manufacturer does not recommend making batches whose volume exceeds 40 liters. Users appreciate this device for its lightness (4.2 kg) and portability. Typical battery charging time ranges from several hours to a day, depending on the level of charge remaining. Metabo's concept is a complete elimination of network cables on construction sites. The average cost of the device is 16,965 rubles.

Metabo RW 18 LTX 120

Advantages:

- powered by removable battery;

- comfortable handle;

- high performance.

Flaws:

- lack of charger included;

- high price.

Caliber ERMD -1600/2E

Russian products are known as “good tools from China.” This fully applies to the Caliber ERMD -1600/2E model. Power 1600 W, 750 rpm. at idle speed, two speeds, two spindles with right and left rotation beaters - all these characteristics suggest professional use of this model. The start button is conveniently located on the ring-shaped handle, and the speed switch is located on the body. The rotation speed is adjusted by pressing the start button. Right- and left-hand rotation whisks allow you to very quickly prepare a solution of any viscosity in significant volumes. The purchase will cost 5329 rubles. This is the average cost. According to buyers, this is a good budget tool for professionals. The model takes seventh place in the ranking.

Caliber ERMD -1600/2E

Advantages:

- high power;

- high performance;

- working with two whisks;

- affordable price.

Flaws:

- short power cord;

- The sharp edges of the whisks can damage the mixing containers.

Interskol KM - 60/1000E

In sixth place in the ranking is the model of the leader in sales of quality tools in Russia – Interskol KM-60/1000E. In terms of its parameters, the device is more consistent with a household tool:

- Power consumption 1050 W.

- Idle speed – 850 rpm.

- Number of spindles (and rims) - 1.

- Device weight 4.3 kg.

However, the tool is in high demand among professionals. A two-speed operating mode and a maximum torque of 53 N•m are already characteristics of the professional model. Its relatively light weight makes it indispensable in finishing teams for the construction of multi-storey buildings. The model is valued for its ease of use, high performance, durability and reliability, and lack of overheating during intensive use. The delivery set includes a whisk with an extension rod and a set of keys. The start and lock buttons are conveniently located on the ring-shaped handle. There is an electronic adjustment of the spindle speed. Average product price: 5997 rubles.

Interskol KM - 60/1000E

Advantages:

- high performance;

- reliability and endurance during long-term operation;

- no engine overheating;

- whisk with extension included;

- light weight.

Flaws:

- not found.

Elitech 1600/2ED

The fifth place in our rating is occupied by the professional model of the Russian brand Elitech 1600/2ED. A two-spindle device with a power of 1600 W and 790 rpm is capable of working with compositions of any consistency, from plaster mortars to concrete mixtures. The power and lock buttons are located on a convenient ring-shaped handle. Nearby, on the body, there is a switch for selecting one of two speeds. Equipped with two beaters of right and left rotation, for high-quality mixing of compositions, a network cable 3 meters long. Users love that the brushes are easy to access and can be changed quickly. Average cost of the model: 5997 rubles. Quite an affordable price for a professional tool.

Elitech 1600/2ED

Advantages:

- high power and rotation speed;

- two-speed operating mode;

- work with two whisks;

- high productivity, even when working with concrete mixtures.

Flaws:

- the device is heavy, 7.6 kg;

- large dimensions;

- high noise level.

STANLEY SDR1400

In fourth place in our ranking is the model of the American concern STANLEY SDR 1400. The device has impressive technical characteristics:

- Power 1400 W.

- Rotation speed – 800 rpm.

- Torque - 80 N•m.

- Number of speeds – 2.

All this puts it on a par with a professional instrument. At the same time, the device is much lighter than many similar devices. Its weight is 3.5 kg. With high productivity, working with it will not be tiring. A whisk with an extension rod allows you to mix compositions in containers of various capacities equally efficiently and efficiently, without splashing the operator with the solution. The power and lock buttons are located on comfortable handles. The average cost of the product is 7049 rubles.

STANLEY SDR1400

Advantages:

- powerful;

- high performance;

- durable and hardy;

- easy.

Flaws:

- noisy;

- expensive (relatively).

Makita UT1200

The top three in the ranking is opened by a tool of Japanese design and German production – Makita UT1200. Manufacturers position this model as a professional power tool designed to work with mobile (not too thick) mixtures. These include paints, adhesives for covering walls and floors with ceramic tiles, plaster and putty mixtures. Its technical characteristics confirm this:

- The power of the device is 800 W.

- In idle mode it spins up to 400 rpm.

- Operates in single speed mode only.

However, the tool does its job perfectly. Even during continuous operation, the device does not overheat, does not break, and has a well-deserved reputation as an “indestructible” mechanism. Its weight of 3.2 kg is minimal for a tool of this type. The product is equipped with a comfortable ring handle with power and lock buttons on it. There is an electronic speed control. The combination of Japanese technical thought and German quality and accuracy during assembly delights users for many years. The average cost of the device is a little annoying, equal to 8450 rubles. What to do, you have to pay for quality. According to most buyers, the Makita UT1200 justifies the cost of its purchase due to many years of intensive use without breakdowns or malfunctions.

Makita UT1200

Advantages:

- high build quality;

- reliability and durability;

- a light weight;

- Excellent performance when mixing not too thick mixtures.

Flaws:

- high price.

Hitachi UM16VST

Second place in the ranking is occupied by another representative of the land of the rising sun, the Hitachi UM16VST construction mixer. A power consumption of 1500 W, an idle speed of 1050 rpm with a maximum torque of 45 N•m, allow this device to cope with the “tightest” mixtures without breakdowns or stops. Users leave rave reviews about it. From under its rim come high-quality concrete mixtures, especially with the addition of plasticizers - special additives that increase the mobility of the concrete mixture. The average price of a product is 10,609 rubles.

Hitachi UM16VST

Advantages:

- power;

- high performance;

- ability to work with all mixtures of any consistency;

- soft start and flexible power cord;

- build quality, endurance and durability.

Flaws:

- serious price.

Shank type

Here more attention is required, since according to the type of rim shank there are:

- Cylindrical,

- Hexagonal,

- M14,

- SDL-Plus.

Look at the connector on the hammer drill or drill and select the shank type from here. For Bosch rotary hammers, SDL-Plus shanks are suitable, which have 4 grooves - 2 open and two closed. For drills, cylindrical shanks are suitable, less often hexagonal ones. When choosing a hex shank, keep in mind that the diameter of the mixer will be equal to the diameter of the drill.

When purchasing, it’s easier to tell the seller which hammer or drill you will use for kneading, and he will select an attachment with the right type of shank for you.

Parameter importance ★★★★★.

Types of hand-held devices

If you want to purchase a tool for use at home to solve simple problems, then it is better to opt for mixers with a power of less than a thousand watts. If you are planning to carry out large-scale construction finishing or repair work, then it is advisable to purchase equipment with a power of more than a thousand watts.

Light mixtures, for example, paint or glue mixtures, are made using a less powerful device. In such cases, attention should be paid to the rotation of the nozzles. Manufacturers offer models that can operate in different speed modes. For such tasks, it is recommended to purchase a mixer that allows you to make different batches of the required density.

Return to contents

Criterias of choice

In order not to make a mistake when choosing the appropriate model of a hand-held construction mixer, experts advise taking into account the following criteria.

| Manufacturer | Of the large number of tools, preference should be given to well-known brands that pay special attention to the issue of product quality. Among them: BORT, FIOLENT, Hammer, ELITECH, BOSCH, Interskol, BISON. |

| Type | Tools for mixing construction mixtures are available in the form of a mixer and a hammerless drill. The second option is considered multifunctional. |

| Power, W | The indicator determines the performance of the tool. To work with high-viscosity mixtures, it is recommended to choose models with a power above 1000 W. The product range is represented by mixers with power from 600 to 1800 W. |

| Maximum torque, Nm | Most models have a torque rating in the range from 35 to 60 N•m. The maximum value reaches 70-75 N•m. |

| Is there a reverse | This is a mode due to which the cartridge can rotate in the opposite direction. The option of using a nozzle with spiral blades allows you to lower the solution and lift it up during mixing. In this case, the entire procedure is performed with one nozzle. |

| What type of power does it work on? | Models are available that operate on mains power or batteries. When choosing the second option, check whether the battery is included in the kit, what power it has, and how long it works continuously. |

| Chuck type | The models use quick-release and key chucks. The first option does not involve the use of any devices for installing the nozzle. The second option requires a key. |

| Number of whisks included | Most often, construction hand mixers are equipped with 1-2 whisks. Less often, the number of devices for mixing mixtures exceeds 3 pieces. This parameter determines the functionality of the tool. The more attachments, the wider the range of applications of the device. |

| Weight, kg | On average, the weight of the structure is 3.5-5 kg. The lighter the tool, the easier it is to hold while working. But light weight is not always the same as the power of the mixer. |

| Case included | Often the product comes with a cardboard box. Much more practical is a case in which the mixer is folded along with attachments and other accessories. |

Before purchasing a tool, it is important to determine your goals. For a small amount of work on mixing the solution, it is quite possible to get by with the power tools available on the farm with torque and a mixer attachment.

For professional activities, it is worth considering high-power models. If an electrical connection is not available, battery-powered models are suitable.

Scope of application of hand mixer

The tool is a simple design that is equipped with a nozzle with a whisk. Use a mixer for mixing dry mixtures, concrete, cement-sand mortar. Thanks to interchangeable attachments and torque, the range of applications expands to cover the following operations:

- mixing plasters, including dense compositions;

- dilution of adhesive mixtures;

- stirring paints and varnishes;

- preparing putty from dry ingredients.

For each type of work, a suitable whisk is selected.

TOP—7. The best construction mixers. Rating 2021! (electric, battery)