A thermocouple is a control and measuring module installed in gas boilers that acts as a protective element for emergency shutting off of the gas supply valve when the fire goes out. Its operation does not depend on the supply of electricity, that is, this module is completely autonomous. It is also actively used in industry for accurate temperature measurement in aggressive environments. And thermocouples are now installed everywhere in smartphones and computers. It is with their help that the device monitors the heating of components located on motherboards.

The design and principle of operation of a thermocouple

Indeed, not every material can be constantly in the open flame zone.

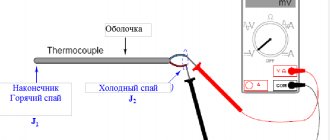

The thermoelement is made of metal, or rather, of several metals, so it is not afraid of high temperatures. When operating a gas boiler installation, there is no way to do without it; failure of the thermocouple means a complete shutdown of the unit and immediate repairs. The thing is that the thermoelement works in conjunction with an electromagnetic shut-off valve that closes the entrance to the fuel path. As soon as this part fails, the valve will close, the fuel supply will stop and the burner device will go out. To better understand the principle of operation of a gas boiler thermocouple, it is worth considering the diagram presented in the figure.

Thermocouple circuit

This principle is based on the following physical phenomenon: if you reliably connect 2 dissimilar metals together, and then heat the junction, then a potential difference, that is, voltage, will appear at the cold ends of this junction. And when a measuring device is connected to them, the circuit will close and a direct electric current will arise. The voltage will be very small, but this is quite enough for induction to occur in the sensitive coil of the solenoid valve and it to open, allowing fuel to pass to the igniter.

For reference. Some modern solenoid valves are so sensitive that they remain open until the input voltage drops below 20 mV. The thermocouple in normal operating mode produces a voltage of about 40-50 mV.

Accordingly, the device of a gas boiler thermocouple is based on the described phenomenon, called the Seebeck effect. Two parts made of different metals are firmly connected to each other at one or more points, and the quality of the connection plays a big role. It affects the operating parameters of the element and the durability of its operation. The connection point will be the very working part placed in the open fire zone.

Since many different pairs of metals are used for the manufacture of thermoelements, without going into details, we note that the thermocouple for a gas boiler uses a chromel - aluminum pair. Conductors enclosed in a protective sheath are welded to the cold ends of these metals. The second end of the conductors is inserted into the corresponding socket of the unit automation and secured with a clamping nut.

In the process of igniting the igniter and burner of a gas boiler to supply fuel, we open the solenoid valve manually by pressing its rod. The gas enters the igniter and is ignited, and the thermocouple is located nearby and is heated by its flame. After 10-30 seconds, the button can be released, since the thermoelement has already begun to generate voltage that keeps the valve stem open.

Specifications

According to GOST P 8.585-2001, a thermocouple is a temperature-monitoring device consisting of 2 conductors made of different alloys. Each alloy has a different resistance and electrical potential. Contact between conductors occurs at one or several points, and in some models it is possible due to the presence of a compensation wire. Base metals are used to make thermocouples.

The thermocouple looks very simple and consists of a cast head housing, equipped with a cover and phosphor pads, thanks to which the linear expansion of the electrodes is compensated. The tip of the product serves to reliably isolate the working junction, and the protective tube consists of a working and non-working section. All connecting wires are routed through a fitting with an asbestos seal. If the electrodes are made of noble metals, products made of phosphorus or quartz can be used as protective tubes.

The error in instrument readings is one degree , which is considered a fairly significant indicator in the operation of gas heating equipment, and does not allow the devices to be considered high-precision instruments. The inaccuracy of temperature measurements is explained by the design features of the thermocouple. The fact is that the connection of conductor plates to each other occurs in different ways. In some models, the connection is made using spot welding, in others - by soldering or crimping.

If the junction of two conductors is made poorly, the error will be one or more degrees. This is a critical error value, an increase in which can negatively affect the operation and safety of the boiler. Therefore, when choosing a thermocouple, it is necessary to focus on products from well-known and trusted manufacturers, since for AOGV an error of one degree is an unaffordable luxury.

How does a flame sensor work in a gas boiler?

A flame ionization sensor is a device that is designed to ensure the safe operation of gas boiler equipment. The device monitors the presence of fire, and if it detects a lack of flame, it automatically turns off the boiler. The operating principle of the gas boiler flame sensor provides the following:

- the functionality is based on the formation of ions and electrons when the flame is ignited. The formation of an ionic current causes the process of attracting ions to the ionization electrode. The device is connected to a combustion control sensor;

- If, when checking with a combustion control sensor, the formation of a sufficient level of ions is detected, this means that the boiler is operating normally. If the ion level decreases, the sensor blocks the operation of the boiler equipment.

The key reasons for the operation of the ionization sensor include contamination of the valve and incorrect gas-air level ratio. This also happens when a large amount of dust settles on the ignition device.

Prices: summary table

| Model | Type of fuel | power, kWt | Fuel consumption, l/h | Operating time, h | Cost, rub. |

| Denzel GT-950i | petrol | 0,9 | 0,5 | 4,5 | 19 800 |

| Daewoo Power Products GDA 1500I | petrol | 1,4 | 1,25 | 4 | 17 000 |

| Huter DY5000L | petrol/gas | 4,5 | 2,3 | 9 | 34 000 |

| CHAMPION IGG980 | petrol | 1,1 | 0,6 | 4 | 9 800 |

Temperature sensors. Classification

There are several main types of thermocouples. They are distinguished by the material they are made of. The main materials used for temperature sensors are metals - noble and base. It was their combination that became the basis of the classification. Here are the most common types of thermoelectric elements

:

- Type K: Chromel and alumel. Temperature range (long term): from 0°C to +1100°C;

- Type J: Iron and constantan. Temperature range (long term): from 0°C to +700°C;

- Type N: Nicrosil and nisil. Temperature range (long term): from 0°C to +1100°C;

- Type R: Platinum-rhodium (13% Rh) and platinum. Temperature range (long term): from 0°C to +1600°C;

- Type S: Platinum rhodium (10% Rh) and platinum. Temperature range (long term): from 0°C to +1600°C;

- Type B: Platinorhodium (30% Rh) and platinumrhodium (6% Rh). Temperature range (long term): from +200°С to +1700°С;

- Type T: Copper and constantan. Temperature range (long term): from -185°C to +300°C;

- Type E: Chromel and constantan. Temperature range (long term): from -50°С to +800°С;

Types of thermoelectric elements

Of course, each type of thermoelectric element is used for different purposes. Expensive thermocouples are used in science and industry, while simpler and cheaper ones are ideal for domestic use - in gas boilers or stoves.

Purpose

The thermocouple serves to shut off the gas and prevent possible leaks. The device is based on the conversion of thermal energy into current and serves as a key component of emergency control systems.

The device is made of heat-resistant metals, because it must withstand high temperatures. The thermocouple controls the actuator - an automatically activated shut-off valve that shuts off the flow of fuel into the gas boiler. The process is fully automated.

In addition, the heaters are equipped with protective circuits that close the valve if the thermocouple breaks down.

Advantages and disadvantages

Due to the fact that making a thermocouple is quite simple and inexpensive, it has become an indispensable element of automation and control in gas-using equipment. In addition, there are other advantages of these products:

- Acting as a flame control sensor, the thermoelectric element can also work as a temperature sensor.

- The absence of moving parts, complex components and expensive materials makes the product inexpensive and durable.

- Wide range of measured temperatures.

- Sufficient measurement accuracy to allow the use of this device in heating equipment.

- The simplicity with which the thermocouple is installed or replaced in a gas boiler.

Among the disadvantages of thermoelectric sensors, it can be noted that the increase in the potential difference does not occur in proportion to the increase in temperature, that is, the dependence is nonlinear. In addition, the voltage increase has a limit and it is small; in the thermocouple of gas boilers its value reaches 50 mV. Such properties of the product do not create problems when interacting with a cut-off device, but when measuring temperature, such a weak and nonlinear signal requires amplification and calibration.

The simplicity and reliability of the thermoelectric sensor design also have a negative side. When this element fails, which sometimes happens due to poor quality of the junction, repairing the thermocouple is impossible. The product may simply burn out and there is nothing to repair; all that remains is to replace it, as quickly as possible, since a gas boiler will not work without a thermocouple. But there should not be any special problems here, the device can be easily removed and disconnected, and its price is not at all high.

Advice. Sometimes a thermocouple stops working only because there is a weak contact at the connection point. You need to loosen and unscrew the clamping nut, remove the conductor from the gas valve and very carefully clean its end, and then put everything back together.

Advantages and disadvantages

Like any device, thermocouples have both advantages and disadvantages. Among the advantages of the devices are their low cost, which is due to a fairly simple design, and a long service life. The durability of the devices is explained by the absence of complex components and moving elements subject to friction. An important advantage is the wide range of measured temperatures, as well as easy installation and dismantling of the device. The versatility of thermocouples cannot be ignored, allowing the device to be used both as a flame control sensor and as a thermometer.

Disadvantages include the voltage limit, which is limited to 50 mV. This is one of the reasons for errors in readings that occur when measuring temperatures. The lack of a linear relationship between temperature values and potential difference is also a disadvantage of the device. In addition, the part cannot be repaired, and if it fails, it is replaced with a new one. However, sometimes the thermocouple stops working due to poor contact. To resume boiler operation, you need to remove the thermocouple, clean the conductors and reinstall the device.

How to check the serviceability of a thermocouple in a boiler

Determining a thermocouple malfunction is quite simple. The bypass valve has a clamping rod that regulates the flow of gas. When the boiler is ignited, the solenoid valve opens manually. It is pressed, gas is supplied to the burner, which is ignited using a piezoelectric element or manually. After 10-30 seconds, the mechanical valve is released. At this moment, the rod is blocked by the generated static electricity. Gas continues to flow.

We recommend: How to choose the right heating radiator

Replacement of the thermocouple is required if the mechanical clamping time of the valve exceeds the permissible limit. To trigger the temperature sensor, it takes 10-30 seconds of intense heating of the metals. Exceeding this limit indicates the need to replace the sensor.

Changing a thermocouple in a boiler is not difficult. The boiler design provides a special technological hole for installation. The technical characteristics of the sensor are indicated on the information label affixed to the boiler control unit.

You can correctly install the thermocouple in the boiler yourself. At the same time, it should be noted that according to existing requirements, all repair work must be carried out by licensed specialists, representatives of the Gas Service.

It will not be possible to use a faulty thermocouple. During operation, the electromechanical gas inlet valve will not operate.

Thermocouple check

Sometimes it happens that a gas boiler stops working stably and there can be many reasons for this, but often the most common is a malfunction of the thermocouple. The first sign of a gas boiler malfunction is most often a problem with the button on the magnetic box, or rather, it does not lock while the boiler is operating.

In most cases, owners of gas boilers in such a situation simply fix the button in the pressed position using adhesive tape or insulating tape. But, firstly, this solves the problem only temporarily, and secondly, this method can lead to unpredictable consequences, for example, complete failure of the gas boiler or an accident.

If such a problem with the button begins to appear, you should immediately take measures to eliminate it. First of all, you need to check the thermostat. There is a simple method to check a thermocouple with a multimeter:

- First, you need to disconnect the gas boiler from the electrical network and gas pipeline to ensure safety during repair work.

- At one end of the thermocouple there is a temperature sensor, and at the other end the thermocouple is attached to the solenoid valve using a nut.

- The nut is unscrewed from the valve, and the thermocouple is removed from the gas boiler.

- Next, you need to heat the thermoelectric converter sensor over a source of stable fire (for example, a gas burner on a stove or a candle). The sensor must be kept at a height of approximately 1 cm from the flame.

Attention! When the sensor heats up, the body of the thermoelectric converter can heat up to the middle. When heating the thermocouple, you should use gloves to protect your hands from burns.

- After the thermocouple has heated up, it is necessary to use a voltmeter or tester set to mV. One probe is applied to the thermocouple body, and the second probe is applied to the output contact.

- Within 45-60 seconds after the thermocouple starts heating, the multimeter will begin to record electrical voltage. If the readings fluctuate between 18-25 mV, this will mean that the thermostat is working properly and the problem is most likely poor contact between the solenoid valve and the thermocouple.

Also, in cases where the voltage of the thermoelectric converter does not exceed 18 mV, it may still be operational. It is necessary to move the thermostat in the flame and measure it with multimeter probes again.

The optimal electrical voltage value for stable operation of the solenoid valve is 20-25 mV. But even at 18 mV the valve can continue to operate without knocking out. The button will constantly turn off when the voltage value is less than 16-17 mV.

The most common type of thermocouple failure is burnout of the temperature sensor.

If, upon visual inspection, a deep black dent or hole (burnout) is visible on the surface of the sensor, then the thermoelectric converter must be replaced. Burnout of thermoelectric converters occurs in gas boilers of any manufacturer, which is normal practice in their operation.

Also, to increase the voltage in the thermocouple, and, consequently, increase the sensitivity of the solenoid valve, the igniter hole was specially further enlarged. This leads to an increase in voltage to 30 mV, but the service life of thermostats in such conditions is reduced.

The best known manufacturers and models: characteristics and prices

Denzel GT-950i

One of the best inverter gasoline generators for a gas boiler with a power of 0.9 kW and economical fuel consumption of 0.5 l/hour. Designed for continuous operation for 4.5 hours, it has compact dimensions, a more stable and quiet 4-stroke internal combustion engine, a body in the form of a soundproof casing, which makes its operation quite quiet.

According to reviews from the owners, the mobility of the generator allows it to be used not only to power the boiler, but also other equipment in the house, and to take the generator to the garage or fishing at any time.

Daewoo Power Products GDA 1500I

An excellent, more powerful 1.4 kW inverter synchronous gas generator, which is enough to provide electricity to the most complex heating systems. The four-stroke engine is housed in a soundproof casing, making its operation virtually silent. However, the model has higher fuel consumption - 1.25 l/h, which is still compensated by the presence of an inverter and the ability to adjust the speed. With a sufficiently high power, it has only one outlet.

Through practice, the generator has proven itself to be optimal in performance, reliable and durable.

Cost : 17,000 rub.

Huter DY5000L

Powerful 4.5 kW dual-fuel (gas/petrol) synchronous generator. Designed to power not only the boiler, but also the full-fledged electrical network of an average country house. Designed for continuous operation for 9-9.5 hours, the generator automatically turns off when overheated, overloaded or low oil level. No obvious shortcomings were observed due to the practice of use.

CHAMPION IGG980

An excellent inverter gasoline generator with a power of 1.1 kW and economical fuel consumption of 0.6 l/h. It is distinguished by an extremely affordable price, small size, greater power than stated by the manufacturer, and the ability to adjust it. But, like other inexpensive models, it has characteristic disadvantages in the form of a low-quality sinusoid at the output, noisy operation, poor assembly, which causes oil and gasoline leaks.

Possible malfunctions and methods for eliminating them

If, when you press the gas supply button, the burner turns on and immediately goes out, this indicates a malfunction of the thermocouple. It may also be the result of poor contact between the converter and the solenoid valve.

Repairing a gas boiler thermocouple malfunction is as follows:

- remove the end of the thermocouple by unscrewing the clamping nut with a wrench, with which the transducer is attached to the valve;

- if upon inspection the presence of contaminants or oxides is detected, clean the contact area with fine sandpaper;

- Next, use a multimeter to check the functionality of the device.

If, when checking, the sensor shows a voltage of 50 mV, you can try to start the boiler. If the problem persists and the burner goes out, this may indicate a faulty solenoid valve.

If the valve is in working condition, it is necessary to ensure the correct connection of the converter to the valve: find the appropriate position of the clamping nut for optimal contact.

You should know that if the gas boiler converter fails, the device cannot be restored. Here it is necessary to replace the thermocouple by installing a new sample in its place. Products in this category are offered by many domestic and foreign manufacturers, including Arbat, Zhukovsky AOGV plant, Honeywell concern and other industrial companies. The price range for this device varies between 600-2000 rubles.

The main areas of application of thermocouples are automation of gas equipment, foundry industry installations and many other areas of production. Based on this device, a whole range of thermostats and thermometers for household and industrial use has been developed. In the hands of folk craftsmen, a thermoelectric converter can become the basis for a mini power station; it is used to create chargers with which you can charge low-power devices from an open fire, including from a fire.

DIY thermocouple repair

To fix the problem yourself you need to:

- Unscrew the clamping nut with a wrench and remove its end;

- Use a zero-string lacing to remove dirt;

- check the thermocouple with a multimeter;

- make sure that all indicators comply with the standards;

- put the thermocouple back together and start the boiler.

If you cannot repair the thermocouple, you can always buy a new one. The Russian market offers a wide range of these devices produced by various manufacturers, for example, ABAT, AOGV, AKGV. Their price ranges from 300 to 2000 rubles. For foreign-made gas boilers (for example, Bosch, Viessmann, Vaillant), the price of the thermocouple will be higher.

Today, thermocouples have found active use in the automation of gas boilers; there is a large selection of them on the market, and everyone has the opportunity to purchase a universal thermocouple. However, when choosing a thermocouple yourself, you may encounter a number of difficulties. You should contact a specialist who will tell you how to choose a device that meets all the characteristics of a gas boiler. You can also use the table of the dependence of the technical characteristics of the device with the characteristics of a gas boiler.

The thermocouple is practically the only device designed to measure extremely high temperatures. The device is widely used in various boiler equipment, monitoring thermal conditions and protecting systems from overheating.

How and in what cases can it be restored?

The thermocouple is designed in such a way that any damage or contamination can reduce the voltage it produces below a critical level. A very common cause of malfunction is carbon deposits or a layer of soot on its working (heated) part. To restore the thermocouple, just clean it with a soft brush or cotton wool and alcohol, while avoiding scratches and other damage. After cleaning, it is worth checking the voltage again following the instructions above.

We recommend: Double-circuit floor-standing gas boiler: specifics of device and choice

Oxidized contacts are also a common cause; they can be carefully treated with sandpaper. If the thermocouple has a deep black dent or hole due to burning, it is guaranteed to need to be replaced.

What metals are thermocouple conductors made of?

All thermocouples are created from certain alloys of noble and base metals that have a constant, repeatable relationship between temperature difference and voltage.

Each group of alloys is used for specific temperature ranges and is used in installed heating appliances.

There are three main types of thermocouples most commonly used in boiler markets:

- Type E. Made from chromel and constant plates. It is highly reliable. Has the factory marking THKn. The operating temperature range is from 0 to +600°C.

- Type J. Similar to the previous thermocouple, but iron is used instead of chromel. The device is practically not inferior in functions to type E, but the price is much lower. Labeling: TFA. The temperature range varies from -100 to +1200°C.

- Type K. The most common and widely used type of thermocouple. Marking: THA. The composition contains plates made of chromel and aluminum. Operating temperatures range from – 200 to +1350°C. Such devices are quite sensitive to the slightest temperature changes, but at the same time they are highly dependent on the environment. For example, carbon dioxide can significantly reduce the life of a device and cause premature repairs.

Measurement speed

The performance is determined by the ability of the primary converter to quickly respond to temperature surges and the subsequent flow of input signals from the measuring device.

Factors that increase performance:

- Correct installation and calculation of the length of the primary converter;

- When using a converter with a protective sleeve, it is necessary to reduce the mass of the assembly by selecting a smaller diameter of the sleeves;

- Minimizing the air gap between the primary converter and the protective sleeve;

- Using a spring-loaded primary converter and filling the voids in the sleeve with a heat-conducting filler;

- A fast moving or denser medium (liquid).

Why does a gas stove need a thermocouple?

The gas in the stove burner is ignited with matches, a manual piezo lighter or a built-in electric ignition. Then the flame should burn on its own without human intervention until the fuel is turned off by the valve.

However, often the fire on a gas hob or oven goes out as a result of a gust of wind or a splash of water from a boiling pan. And then, if there is no one nearby in the kitchen, methane (or propane) begins to flow into the room. As a result, when a certain concentration of gas is reached, a bang occurs with fire and destruction.

The thermocouple monitors the presence of an open flame in the burner, and if there is none, it shuts off the gas supply within half a minute to a minute to prevent a tragedy

The working function of a thermocouple is to control the presence of a flame. While the gas is burning, the temperature at the tip of the control device reaches 800–1000 0C, and often higher. As a result, an EMF arises, which keeps the gas solenoid valve on the nozzle to the burner open. The burner is working.

However, when the open flame disappears, the thermocouple stops producing EMF to the electromagnet. The valve and fuel supply are shut off. As a result, the gas does not enter the kitchen without accumulating in it, which eliminates the possibility of a fire from such an emergency situation.

A thermocouple is a simple temperature sensor without any electronic devices inside. There is nothing to break in it. It can only burn out from prolonged use.

The following article, which is entirely devoted to this interesting issue, will introduce you to a complete set of sensors designed to control and safety the operation of a gas water heater.

Thermocouple burnout usually occurs only in gas boilers and boilers that operate continuously. In gas stoves, the gas control temperature sensors in question last 20–30 years before replacement.

Among the advantages of thermocouples:

- simplicity of the device and the absence of breaking mechanical or burned out electrical elements;

- the device is cheap - about 800–1500 rubles, depending on the model of the gas stove;

- long service life;

- high efficiency of flame temperature control;

- quick gas shut-off;

- ease of replacement, which you can do yourself.

The thermocouple has only one significant drawback - the difficulty of repairing the device. If the thermocouple sensor is faulty, it is easier to replace it with a new one.

To repair such a device, it is necessary to weld or solder two different metals at high temperature (about 1,300 0C). It is extremely difficult to achieve such conditions in everyday life at home. It is much easier to buy a new control unit for a gas stove as a replacement.

Thermal generator for gas water heater

Buy a spare part for the Protherm boiler Bear 0020027521

Multiple thermocouple 820mV. Article - 0020027521. Original. this is not analogue.

Used on Protherm Medved boilers 20, 30, 40, 50 TLO

Serves to generate Thermo EMF. When heated, it generates a small current and keeps the gas valve of the burner open.

Multiple thermocouple, Thermal generator, Multiple thermocouple Proterm boiler

If you suddenly don’t know exactly whether this thermocouple will fit your boiler, then the best thing to do is call us and ask. Our professionals will accurately select you a spare part specifically for your boiler.

This item is not considered a custom item and is always in STOCK. You can pick up your spare part Thermocouple multiple 820mV Protherm (article Protherm-0020027521) from the warehouse (see Contacts)

Delivery of thermocouples in Moscow and the Moscow region is carried out by our couriers throughout the day to your address.

This thermocouple is installed on the Proterm Medved boiler and also on other boilers where the SIT gas valve is used / it is mounted in a wick group and connected to the gas valve with 2 wires. It is especially important to correctly configure the thermogenerator using a multimeter. . If you suddenly don’t know how to do this, it’s better to call our master.

Buy Spare part 0020027521 Multiple thermocouple 820mV For Protherm gas water heaters.

If you suddenly do not know the number of the spare part you need, call us by phone or write a letter in the “Feedback” section. We strongly do not suggest that you choose the number of the spare part you need on your own. Call our specialists.

How to Buy Without any problems - click the Buy or Buy without registration button and place your order through the shopping cart. We will contact you

Payment Cash at the warehouse Payment by account Payment to Sber Bank card

Delivery 0020027521 Multiple thermocouple 820 mV in Moscow and the region to your address. Pickup from our warehouse from 9 to 18.

0020027521 Purchase multiple thermocouple 820mV.

Design and principle of operation

The operation of a thermocouple is based on the thermoelectric Seebeck effect. According to it, at the ends of conductors connected in series from different metals, provided that their contacts are at different temperatures, thermo-emf (TEMF) occurs.

That is, it is necessary to have two conductors of different compositions that can withstand intense heat, and high-temperature heat (in this case from combustible natural gas) at the point of their connection.

In most pairs, the electromotive force that arises between the cold and hot contacts is very small and of little use. But there are metals and alloys, the combination of which gives up to 4–5 mV/100 0C. And this is already quite enough to control the electromagnet that controls this or that shutter.

The thermo-EMF in most types of thermocouples for gas stoves reaches 15–30 mV, and 5–10 mV is usually enough to keep the solenoid valve open

The operating principle of thermocouples built into gas stoves is extremely simple:

- There is a flame - TEMF appears between the contacts, the valve for the gas supply to the burner is open.

- There is no fire - the thermoelectric force disappears, the valve closes under spring pressure and shuts off the gas.

A thermocouple consists of two thermostable conductors up to one and a half meters long, which are connected at one end by soldering or welding.

It is this tip that is directly in the fire and is heated by the burning gas. The second end of the device is a pair of contacts or a connector for connecting to a solenoid valve.

Measurement error

The correctness of temperature readings obtained using a thermocouple depends on the material of the contact group, as well as external factors. The latter include pressure, background radiation or other reasons that can affect the physical and chemical properties of the metals from which the contacts are made.

consists of the following components:

- random error caused by the manufacturing features of the thermocouple;

- error caused by a violation of the temperature regime of the “cold” contact;

- error caused by external interference;

- error of control equipment.

Types of temperature sensors for gas

Thermocouples of gas stoves differ in the alloy of conductors and the type of connection to the valve. And the main thing here is that each manufacturer of gas-powered equipment uses its own versions of electromagnets with different connection connectors.

We recommend: Circulation pump for heating: types and characteristics, how to choose the right one, review of popular models and manufacturers, their pros and cons

In most cases, it is impossible to move the thermocouple gas control sensor from one tile to another.

The thermocouple must correspond to the model of the gas stove; installing a “left” control device is prohibited for safety reasons

The following alloys and metals are used to create thermocouples:

- constantan + chromel;

- copper + constantan;

- copper+copel;

- nisil + nichrosil;

- alumel+chromel;

- constantan+iron;

- chromel+copel;

- platinum+platinum;

- tungsten+rhenium.

The accuracy of the device and its operating temperature range depend on the alloys used. For example, a chromel-alumel thermocouple is designed to operate at 0–1100 0C, an iron-constant thermocouple at 0–700 0C, and a platinum-platinum-rhodium thermocouple can withstand heating up to +1700 0C.

Household gas stoves usually use thermocouple sensors made of alumel and chromel or constantan and iron. They are inexpensive and quite suitable for the temperature conditions of a gas cooktop.

Differences from temperature sensor

In addition to the thermocouple, a thermal cylinder is connected to the automatic fuel valve of the boiler, which is responsible for turning off the main burner when the set coolant temperature is reached. Externally, the element flasks and copper connecting tubes are somewhat similar. An uninformed homeowner can easily confuse these sensors.

Let us list the main differences between a temperature meter and a thermocouple:

- sensor design - a cylindrical bellows made in the form of a copper flask with a sealed end;

- the thermal cylinder is connected to the gas automatics with a thinner capillary tube than the electricity-generating sensor;

- the heat-sensitive flask itself is installed inside the immersion sleeve or hidden under the casing near the water jacket, and is not attached near the igniter;

- The temperature meter does not detach from the automation at all or the size of the fastening nut differs.

Note. The thermal balloon operates on a different principle: when heated, a special liquid expands inside the flask. The pressure through the capillary is transferred to the automatic valve, which turns off the main burner. The igniter flame does not go out.

Gas control repair manual

If the gas on the stove goes out, then the problem may lie not only in the thermocouple. However, most often this is precisely the problem.

The main sign of problems with gas control is that after igniting the burner and releasing the handle or button to open the “blue fuel”, the flame immediately goes out. This occurs due to the valve closing, since the thermo-EMF to keep it open is absent or insufficient.

The reasons for the noise of gas stove burners are described in detail in the article, the useful information of which is worth reading.

Before purchasing a new thermocouple, you need to determine the reason for the poor operation of the existing device - perhaps the problem is loose contacts on the valve, then you just need to tighten them

You should independently check, repair and replace the thermocouple in a gas stove with your own hands only when the gas is completely shut off. First you need to close the valve on the cylinder with the gas mixture or the methane pipe, and only then begin any work. Also, do not forget about turning off the power supply if the design contains volatile devices.

The thermocouple tip is located directly next to the burner and gas fire. And in the oven you can find it near the flame divider in the upper part of the oven. This tip should be free of carbon deposits, mineral deposits and any damage.

If the working tip of the thermocouple sensor is covered with scale, it must be cleaned off with sandpaper. The more carbon deposits, the less heat reaches the thermocouple, and the less it accordingly creates an EMF. The resulting millivolts may simply not be enough to open the solenoid valve.

How to check before replacing?

The thermocouple usually has one tip for installation near the fire. But there are also options with two or three temperature control tips. They are usually used in ovens, but it all depends on the specific model of the stove.

Thermocouples with several working tips have a peculiarity - if only one of them is not heated or fails, the solenoid valve will be closed. Therefore, in order to accurately find the cause of the problems, such thermocouple devices will have to be checked especially carefully. Only one of the sensors may be faulty.

A working thermocouple for a gas stove, when heated over a candle, produces an EMF of the order of 15–20 mV after 20–30 seconds - if less, then the sensor must be changed

Another point is that the thermocouple conductors in the area up to the valve must be tensioned or dangling in the body of the plate. At the same time, their connection to the electromagnet must be rigid; a connector hanging “on my word of honor” is unacceptable here.

The devices in question are produced with lengths from 40 to 130 cm. You should choose a thermocouple gas monitoring device based on this indicator very carefully. On the one hand, the conductor wire should not be over-tensioned, and on the other hand, it should not lie on heated surfaces or dangle freely.

How to change the device?

Before replacing a damaged thermocouple in a gas stove, you should inspect the device for:

- the presence of carbon deposits on the working tip (if there is any, it must be cleaned off with sandpaper);

- no burnout of this tip (in this case, only complete replacement);

- the rigidity of the connection between the contacts of the thermocouple sensor and the valve (if necessary, tighten);

- serviceability of the thermocouple itself with the output of an EMF at a level of at least 15 mV when heating.

The device in question should only be replaced when it is definitely faulty. In many cases, to get a gas stove to work again, you can get by by cleaning the tip from carbon deposits and checking the contacts.

To replace the thermocouple, you will have to remove the front panel from the gas stove, and also lift the top cover with the burners on it

The working tip of the thermocouple is rigidly fixed near the burner or burner using a nut. If it cannot be unscrewed due to scale, then you should not put too much pressure on the key. This can only break the fastening. It is better to use a solvent first.

The second end of the thermocouple is attached to the solenoid valve using a threaded connector or two crimp contacts. Removing them doesn't seem difficult. The new thermocouple sensor is installed in a similar sequence - one end of it is attached near the burner, and the other to the electromagnet.