The reliability and service life of the building depend on the correctly chosen type of foundation. One of the most durable and inexpensive is a foundation on piles; thanks to this technology, construction can be carried out on water and unstable soils.

A house on screw piles can withstand even slight ground vibrations in seismically unstable areas. In this article, we will look at the types of piles used for arranging the foundation, their advantages and disadvantages, as well as how to build a house on screw piles with your own hands.

Types of piles

Before building a house on screw piles, you need to decide on the type of supports, material of manufacture and method of deepening. Piles are divided into types depending on the following factors:

- Use of material in the production of supports: reinforced concrete, concrete, dense bentonite or local clay, steel (pipes, rails, etc.), soil (clay), wooden logs, a combination of several materials.

The type of piles is chosen depending on the type of structure and the nature of the soil - Support shape: round, square, trapezoidal, prism-shaped, with an extended lower edge.

- Depth, weight, diameter thickness depend on the freezing point of the soil, the proximity of groundwater, and the weight of the building. Solid 12-20 m products are used, composite, spliced from several parts using clamps or welding. The shape of the bottom edge is made open or closed with a special tip.

- According to the method of redistributing loads on the soil, they are divided into vertical (they transfer the entire load from the building to a dense layer of soil located under an unstable layer), hanging ones are installed obliquely (the load is transferred through the friction of the earth on the uneven surface of the pile wall).

The choice of piles for foundation construction depends on many factors; the reliability and service life of the house depends on how correctly the choice is made.

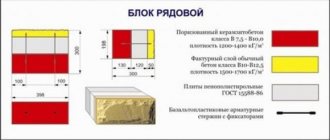

Advantages of foam concrete and aerated concrete blocks

Foam concrete is concrete with a cellular structure. Cement, sand and water are mixed with special foam. The mixture is poured into molding containers. After hardening, the molds are disassembled and ready-made foam blocks are obtained. Large blocks are produced by sawing volumetric monoliths.

Foam concrete blocks

The density of foam concrete is three times less than the density of brick, and accordingly its weight is three times less. Possessing high thermal insulation, waterproofing and strength properties, foam concrete compares favorably with other types of building materials.

Considering the low load-bearing capacity and fragility of the material, foam blocks can only be used in the construction of low-rise, small residential buildings.

In terms of their quality characteristics, aerated concrete blocks are not much different from foam blocks. Aerated concrete is obtained as a result of a chemical reaction of cement, sand and various fillers. A significant disadvantage of aerated concrete is its poor resistance to moisture. Therefore, masonry made of aerated concrete blocks requires enhanced waterproofing.

Masonry walls made of foam concrete and aerated concrete blocks are built in the same way as brickwork with cement mortar.

Types of pile foundations

Piles are placed singly or as whole pile bushes.

Piles are long vertical elements immersed in the ground in order to transfer the load-bearing load from the building to them.

A pile foundation includes a group of piles interconnected by a grillage, ensuring uniform load distribution.

Depending on the location of the piles, foundations are divided into types:

- the ribbon arrangement includes supports located along the entire perimeter of the building and united by a grillage;

- single piles support light frame buildings;

- pile bushes require a group arrangement and are laid in the form of columns, pillars, or individual supports;

- pile fields are multi-storey structures and may include elements from the above types.

The piles are laid below the freezing point of the soil, this protects the foundation from deformation during soil heaving.

Design options and their structure

A pile-grillage foundation for a house made of aerated concrete consists of two parts that are monolithically connected to each other and take up the load: the grillage and piles.

Types of grillage

Grillage is the upper part of the base, which is a monolithic strip that unites the pile heads and passes under all the load-bearing walls of the building. The purpose of the grillage part is to absorb the load from the aerated concrete house and distribute it evenly to the underlying pile supports. Depending on the material, a grillage for a gas block can be of two types:

- Reinforced concrete. Monolithic concrete structure. Structurally, the reinforced concrete grillage strip is similar to a traditional strip foundation, only without being buried in the ground. This is a universal type of grillage that can be applied to any piles.

- Metal. Beams made of steel with high compressive strength. Used primarily for screw piles, but can also be used with concrete piles. The cost of a metal grillage is significantly higher than a monolithic one. It is chosen when the construction of an aerated block house needs to be completed as quickly as possible (the monolith gains strength within 28 days).

Types of pile supports

For pile-grillage foundations for a house made of aerated concrete, three types of supports are used:

- Reinforced concrete driven piles. These are standardized products with a square section with a pointed lower head, produced at the factory. To drive piles into the ground, special equipment is used - pile driving machines. On soft soils they use a mini-copper, whose services are cheaper. The minimum length of finished concrete products is 1625 mm, so a trawl truck is needed to deliver them. Transportation costs and rental of pile-driving equipment increase the cost of construction, so this support option has not found widespread use in private housing construction.

- Bored piles. These are reinforced concrete products that are poured directly on the construction site. Simplicity of execution and low cost make this option the most preferable when installing a pile foundation with a grillage for aerated concrete. We will discuss below how to calculate a pile-grillage foundation with bored supports.

- Screw piles. Factory-made metal supports with a screw on a claw, with which they are screwed into the ground. To construct a pile field from screw supports, no special equipment is required, and the absence of concrete work makes this option acceptable for those who want to complete construction as quickly as possible. In soils with high groundwater level and an aggressive acid-base environment, it is necessary to use screw piles made of alloy steel with an anti-corrosion coating. Such supports have a relatively high price - from 3,500 rubles per piece.

Selecting the type of supports

Reinforced concrete piles can support the weight of a multi-story building.

In heaving, water-saturated soil with a significant freezing depth, laying a pile foundation is considered the best option.

The material for making supports is used depending on the type of soil and geological features of the area.

Wooden logs installed in fresh water or in soil at a depth below the water table will last more than 50 years without changing their load-bearing capacity. But with frequent changes in humidity (they are either moistened or dried out), the wood begins to decompose and loses its qualities within a short period of time.

Metal supports can be installed in any type of soil and on water. A prerequisite is treatment with anti-corrosion compounds and installation at a depth below the freezing point of the soil. It is more economically and technologically advantageous to install hollow screw piles.

Reinforced concrete supports can support the mass of multi-story buildings with large numbers of floors. If the installation technology is followed, the service life is more than a century.

In soils subject to horizontal shear, the use of a columnar foundation is not recommended, since the movement of the soil can push and overturn the building. If the construction site has an uneven surface, it is necessary to install a rigid reinforced concrete pad between the supports to prevent lateral movement of the structure.

Comparative characteristics of strip and pile-screw foundations

Safety precautions

When installing a pile-boring foundation for a house made of aerated concrete, you must follow safety precautions. Safety standards for concrete and piling work regulate:

- SNiP 12-03-2001. Occupational safety in construction. General requirements;

- SNiP 12-04-2002. Occupational safety in construction. Construction production.

A pile foundation with a grillage for aerated concrete is one of the best options in terms of the ratio of bearing capacity and monetary costs. On weak-bearing soils, swampy or rough terrain, this is the only way to make a reliable foundation for a structure made of aerated concrete.

Comparative characteristics of strip and pile-screw foundations

| Types of jobs | Strip foundation | Pile-screw foundation |

| Excavation | required | not required |

| Construction duration | 28-45 days | 1-5 days |

| Construction on unstable soils and difficult terrain | impossible | Maybe |

| The ability to immediately build a house and fully load it | the foundation must be stable | You can immediately mount the walls |

| Possibility of arrangement of basements and ground floors | There is | No |

| Construction only in the warm season | Yes | can be built at any time of the year |

The screw method of driving piles allows you to solve complex construction problems. It is based on a special support design, which is buried into the ground by screwing.

How to build up piles

Sometimes the standard length of piles is not enough, so the design assumes the ability to extend them. This is especially necessary when houses are built on slopes with height differences of more than two and a half meters.

Extension of screw piles

To build up, two pipes are connected to each other on a pre-fitted section of pipe of smaller diameter and welded. After pouring concrete into the cavity of the pipe, the top of the pile is covered with a steel head, which is popularly called the “heel,” and is also welded to the metal pipe.

Advantages

Building a country house on stilts has many advantages:

- the ability to build on unstable, waterlogged soils and complex terrain;

- minimal land work;

- the possibility of construction in seismically unstable areas;

- fast turnaround time;

- used for buildings in permafrost;

- when building a house on high stilts, a parking lot or utility room can be installed underneath it;

- Possibility of use in the repair and reconstruction of already constructed buildings, and in densely built-up areas.

Previously, hollow screw piles were used for lightweight construction. Currently, supports are produced that can withstand heavy loads and have a long service life.

Construction of the frame

The construction of the frame begins with the installation of the frame. It is made from timber, which is laid on a head or grillage.

It is strengthened by a rod. The angle of attachment can be different, but usually it is made with a lock.

Strapping and fastening in a frame house on stilts

The posts will be attached to the harness, first the corner ones, and then the intermediate ones. It is necessary to ensure that they stand exactly vertical and the angles are 90 degrees.

In addition to vertical posts, the structure is strengthened by horizontal jumpers, which make the frame more rigid and less movable.

At the corners, struts are installed to secure the corner posts.

Fixing the frame wall

In places where there will be windows and doors, racks are not installed accordingly, however, it is extremely important to assemble the window frame correctly.

The window opening is formed by racks, there are usually three of them, and they are located end to end.

- The opening beam lies on the first window post; this post is the shortest.

- On the second rack lies the board of the load-bearing crossbar of the opening.

- On the third rack lies the framing beam of the house itself.

Window diagram in a frame house

Additional shortened step racks are placed under the opening beam. They perform a supporting function for the beam.

Shortened step racks can be installed not only from below the window, but also from above, if the height of the house allows.

In this case, they will distribute the load on the load-bearing crossbar of the opening much better.

Window beams in the frame of a house

Do not forget: all wooden elements must be carefully treated with fire protection, and when installing the frame, the wooden elements must not come into contact with iron. Otherwise, the tree will begin to collapse.

Read about the advantages of frame houses here.

Flaws

Almost all types of pile foundations are designed to withstand the load from low-rise buildings (1-2 floors). When building an apartment building, it is better to choose a different type of foundation. For information on when it is worth using a pile foundation, watch this video:

The strength and durability of a house depends on the quality of the material used; cheap materials may have low load-bearing capacity.

Metal pipes that are used as screw piles are subject to corrosion over time (especially at welding points), even when treated with protective agents.

The lower part of a house built on screw piles requires high-quality insulation.

Disadvantages of using piles for home

Pile foundations also have disadvantages, which you should also know about in advance, so as not to encounter unexpected surprises later. A pile foundation is limited in its load-bearing capacity: it is usually used for one-story and two-story houses that do not have much weight.

The construction of such a foundation requires the most accurate calculations at the preparatory stage. In order not to make mistakes in the parameters, it is better to seek help from specialists. In addition, despite the speed and ease of installation, installation of piles usually requires special construction equipment. This is especially true for the construction of foundations on heavy reinforced concrete piles.

If metal piles are used, they must be provided with a protective layer, otherwise the material will corrode over time.

A pile foundation is suitable for any type of soil, but it is almost impossible to install it in rocky terrain. There you will have to choose a different type of base. Sometimes a ground floor or basement is made inside a pile foundation, but such a planning solution is fraught with many difficulties that are taken into account at the house design stage.

Houses on screw piles

A screw pile for a home is a hollow pipe with a pointed tip and having helical blades.

Before starting to build a house on screw piles, it is necessary to develop a project that takes into account all the features of this type of foundation.

When choosing a support, you need to study the relationship between the type of soil and the load-bearing load of the pile depending on its diameter and length.

The data is shown in the table.

| Soil type | With a diameter of 76 mm | With a diameter of 89 mm | With a diameter of 108 mm | With a diameter of 133 mm |

| Clay | 3.5 m | 2.5 m | 2.5 m | 2.5 m |

| Loam | 3m | 2.5 m | 2.5 m | 2.5 m |

| Peat | Determined by test drilling | Determined by test drilling | Determined by test drilling | Determined by test drilling |

| Sand | 3m | 2.5 m | 2.5 m | 2.5 m |

When building a house on screw piles, it is necessary to correctly calculate the number and diameter of supports depending on the area and weight of the building.

| Base dimensions, m | Number of supports, pcs | Diameter of supports, mm |

| 10 x 10 | 25 | 89 |

| 9 x 9 | 16 | 89 |

| 8 x 8 | 16 | 89 |

| 7 x 7 | 16 | 108 |

| 6 x 6 | 9 | 108 |

| 5 x 5 | 9 | 108 |

| 4 x 4 | 9 | 108 |

| 3 x 3 | 4 | 108 |

Preparatory work

Let's look at how to build a house on stilts with your own hands. Screw piles for building houses can be used on any soil except rocky and rocky soil. The parameters of the supports depend on the design of the house and the load-bearing load. To determine the location of the piles, you need to draw a drawing according to the house design.

The building plan is divided into rectangles, after which their size is calculated. There should be a support at each corner of the rectangle and in the middle of each load-bearing wall. Then the distance is divided into equal intervals, at which the installation of piles is also provided.

Site marking

According to the drawing of the location of the piles, the construction site is marked. We mark the locations of the supports with pegs, between which we stretch a rope along the perimeter and diagonally. We check that smooth rectangles are formed, the perimeter of which is located strictly along the line.

Do-it-yourself pile installation

The support must go into the soil strictly at the level.

To lay the foundation of houses on screw piles, you need to invite several assistants. Three people are enough to complete the full cycle of work.

Stages:

- At the location of each support, a hole 500-700 mm deep is drilled with a manual or mechanized drill.

- A lever for rotation is inserted into the hole located at the upper end of the pile. When screwing in the support through several turns, check that it fits exactly in line. If the supports are installed at an angle, their load-bearing capacity will be significantly reduced.

- The upper ends of the piles are cut so that they are in the same horizontal plane.

- For greater reliability, durability and corrosion protection, hollow supports are filled with cement mortar.

The last stage is the installation of a grillage, which serves to evenly distribute the load from the building.

Price list

Piles with a cast tip 133 mm Piles with a cast tip 108 mm Screw piles 133 mm Screw piles 108 mm

| Name | Standard | Premium | Zinc |

| Pile with cast tip SVLN-133/350/1500 | 4440 rub. | 4490 rub. | 5780 rub. |

| Pile with cast tip SVLN-133/350/2000 | 5240 rub. | 5310 rub. | 6840 rub. |

| Pile with cast tip SVLN-133/350/2500 | 6010 rub. | 6090 rub. | 7870 rub. |

| Pile with cast tip SVLN-133/350/3000 | 6800 rub. | 6970 rub. | 8920 rub. |

| Pile with cast tip SVLN-133/350/3500 | 7590 rub. | 7700 rub. | 9960 rub. |

| Pile with cast tip SVLN-133/350/4000 | 8370 rub. | 8500 rub. | 11000 rub. |

| Pile with cast tip SVLN-133/350/4500 | 9150 rub. | 9310 rub. | 12030 rub. |

| Pile with cast tip SVLN-133/350/5000 | 9930 rub. | 10100 rub. | 13070 rub. |

| Pile with cast tip SVLN-133/350/5500 | 10710 rub. | 10890 rub. | 14120 rub. |

| Pile with cast tip SVLN-133/350/6000 | 11510 rub. | 11700 rub. | 15150 rub. |

| Name | Standard | Premium | Zinc |

| Pile with cast tip SVLN-108/300/1500 | 3130 rub. | 3180 rub. | 4100 rub. |

| Pile with cast tip SVLN-108/300/2000 | 3750 rub. | 3810 rub. | 4920 rub. |

| Pile with cast tip SVLN-108/300/2500 | 4380 rub. | 4450 rub. | 5730 rub. |

| Pile with cast tip SVLN-108/300/3000 | 4990 rub. | 5080 rub. | 6550 rub. |

| Pile with cast tip SVLN-108/300/3500 | 5610 rub. | 5700 rub. | 7390 rub. |

| Pile with cast tip SVLN-108/300/4000 | 6240 rub. | 6360 rub. | 8220 rub. |

| Pile with cast tip SVLN-108/300/4500 | 6850 rub. | 6980 rub. | 9040 rub. |

| Pile with cast tip SVLN-108/300/5000 | 7480 rub. | 7630 rub. | 9880 rub. |

| Pile with cast tip SVLN-108/300/5500 | 8080 rub. | 8250 rub. | 10690 rub. |

| Pile with cast tip SVLN-108/300/6000 | 8710 rub. | 8890 rub. | 11520 rub. |

| Name | Standard | Premium | Zinc |

| Screw pile SVSN-133/350/1500 | 2860 rub. | 2910 rub. | 3940 rub. |

| Screw pile SVSN-133/350/2000 | 3590 rub. | 3660 rub. | 4870 rub. |

| Screw pile SVSN-133/350/2500 | 4310 rub. | 4390 rub. | 5820 rub. |

| Screw pile SVSN-133/350/3000 | 5080 rub. | 5250 rub. | 6770 rub. |

| Screw pile SVSN-133/350/3500 | 5770 rub. | 5880 rub. | 7720 rub. |

| Screw pile SVSN-133/350/4000 | 6510 rub. | 6640 rub. | 8650 rub. |

| Screw pile SVSN-133/350/4500 | 7220 rub. | 7380 rub. | 9610 rub. |

| Screw pile SVSN-133/350/5000 | 7960 rub. | 8130 rub. | 10560 rub. |

| Screw pile SVSN-133/350/5500 | 8690 rub. | 8870 rub. | 11500 rub. |

| Screw pile SVSN-133/350/6000 | 9430 rub. | 9620 rub. | 12450 rub. |

| Name | Standard | Premium | Zinc |

| Screw pile SVSN-108/300/1500 | 2250 rub. | 2300 rub. | 3140 rub. |

| Screw pile SVSN-108/300/2000 | 2840 rub. | 2900 rub. | 3910 rub. |

| Screw pile SVSN-108/300/2500 | 3250 rub. | 3320 rub. | 4400 rub. |

| Screw pile SVSN-108/300/3000 | 4010 rub. | 4100 rub. | 5470 rub. |

| Screw pile SVSN-108/300/3500 | 4610 rub. | 4700 rub. | 6240 rub. |

| Screw pile SVSN-108/300/4000 | 5190 rub. | 5310 rub. | 7030 rub. |

| Screw pile SVSN-108/300/4500 | 5770 rub. | 5900 rub. | 7790 rub. |

| Screw pile SVSN-108/300/5000 | 6350 rub. | 6500 rub. | 8570 rub. |

| Screw pile SVSN-108/300/5500 | 6930 rub. | 7100 rub. | 9330 rub. |

| Screw pile SVSN-108/300/6000 | 7520 rub. | 7700 rub. | 10120 rub. |

Construction of a foundation made of screw piles

As mentioned earlier, screw piles are steel pipes with a special anti-corrosion coating. The length of the material with a cone-shaped end and blades is from 2.5 to 9 meters. Often a few people are enough to screw the pile into the ground, but in more problematic soils the use of machinery will be required. As for purchasing piles, you need to entrust this to experienced builders or do it yourself by going to a trusted store where they can provide documents confirming the quality of the material. In the optimal case, the seller must present certificates confirming the high quality of the metal and its resistance to corrosion, which determines the durability of the base and the house as a whole.

Before proceeding with the installation of piles, you need to go through preparatory procedures, which include the following steps:

- Creating a plan and drawing.

- Calculation of the depth of piles, calculation of the required number of elements.

- Engineering-geological surveys, during which the features of the relief will be studied.

- Calculating the weight of the future wooden structure.

- Purchasing material of proven quality.

- Preparing the area for work and clearing the soil.

- Marking the territory using ropes and pegs.

To create a strong, stable and durable foundation, screw piles are buried into the ground no less than 1.5 meters (to the depth of soil freezing or deeper to solid ground). As for the number of piles, a calculation is made taking into account that they should be located in the corners and perimeter of the house, in the places where the internal walls adjoin the external frame and along the external and internal walls. Distance between steel supports (1.5-3 meters).

Having installed the piles, it is necessary to cut their upper part to the height of the foundation and pour concrete into the hollow part of the pipe, which will increase the bearing capacity of the supports. After this, you need to weld the heads, on top of which you can attach wooden or metal beams. Having completed the procedure, you can proceed to forcing the walls and further construction work.