Siding is a modern material that captivates with its practicality, reliability and beauty. It is easy to install and create a completely new design or repeat the one you saw in the photo. It is easy to care for, will not require replacement for many years, and is inexpensive. When it is necessary to cover a façade and protect it from the destructive influence of the environment, there is no better material. But where there are advantages, there are always disadvantages. There are many types. Which to choose?

Wood siding

In order for the repair to be successful and what you are looking for to be found, let’s look at all the pros and cons, the main characteristics of different types of this material, and find out the opinion of professionals.

What to choose from

What types of siding can scientific and technological progress offer today? There are relatively few of them.

- Wood.

- Vinyl.

- Metal.

- Steel or galvanized.

- Siding made of zinc.

- Cement (fiber cement).

Siding always looks good. Knowing the features will perhaps convince you or broaden your horizons and help improve your country house, any extension, or fence. Only positive reviews from home owners and professional builders indicate the quality of the invention. This is a small victory of scientific and technological progress over corrosion and inflation, which nothing will erase from history.

Installation nuances

Installation of PVC plates is a kind of composition of sheathing panels by fastening them to each other and at the same time to the sheathing.

Installation begins with a starting strip, which is attached in a horizontal position to the bottom of the facade . Depending on the direction of the slabs, installation can be horizontal or vertical.

Next, the corners are mounted , under which strips of siding are then inserted.

Setting obtuse angles

Tight butt fastening of the panels is done thanks to special locks on the panels , which snap into place during installation.

Windows and doorways should be decorated additionally: for this purpose, panels are cut out specifically for the window opening and decorated with finishing components.

The penultimate row of sheets should be decorated with a finishing strip.

IMPORTANT!

When attaching the main sheets of siding, it is necessary to leave an additional joining gap of 1-2 mm, as well as a gap between the fastening cap and the material.

This is necessary so that during compression and expansion there is no deformation of the facing surface . Due to temperature changes in the material, joints should not be treated with sealants to avoid distortion of the cladding.

Installation of finishing strips

Features of wood siding

This kind of cladding costs a lot. Wood is an expensive, natural material. Accordingly, wooden siding requires expenses. But each strip ensures 100% tightness of protection, protects the walls from rain and severe frosts, and allows you to create a luxurious, bright design. Puttying and painting are necessary maintenance.

There are several options for wood siding:

- false beam;

- block house;

- ship plank;

- wood-cellulose.

The false beam looks like a regular wooden beam. It is neat, has rich color, smoothness, and a pleasant texture. A block house can create the illusion of a wooden hut. Compared to a wooden house, cladding is more economical. The ship's plank has a special relief and looks good from a distance. An illusion of three-dimensional walls arises. The house may seem smaller. Coming closer, the traveler will be pleasantly surprised. This is a very beautiful decor that is worth paying attention to.

Wood-cellulose siding is the most practical option. It is inexpensive and does not require painting or varnishing. You can only periodically change the damaged areas. It is made from wood fibers. The pros and cons of wood siding come down to one thing - whether a person likes wood. A wooden house will last for many years. More than a hundred is quite likely, and with proper care even longer. You can always hear only positive reviews about such a house. It’s easy to forget about the hassle with it, living in beauty. The pros and cons of siding a wooden house are a healthy balance between the need to restore the building and build a new one.

Stone siding

Is it difficult to install siding on a house?

Not difficult. Siding installation is very simple. Even a person who does not have special knowledge in the construction industry can cope with this work. The main thing is to have the right tool and strictly follow the manufacturer's instructions.

When fastening, it is also necessary to remember that under the influence of temperature, siding can expand or, conversely, contract. It is recommended to leave a gap of 2-3 millimeters. You cannot cut siding if the temperature is below -10 degrees. To do this, it is better to do this in a heated room.

For installation you will need the following materials:

- short galvanized self-tapping screws without a drill;

- tar nails;

- lathing (in case of uneven walls).

For the work to be successful, you must follow the plan:

Preparatory work

Remove all protruding parts. Seal all cracks. To do this, you can use cement mortar or foam. Clean the walls from dirt. If necessary, use an antiseptic to protect wood from fungus.

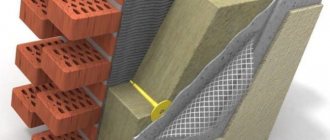

Working with the sheathing

The sheathing is made of slats. They can be metal or wood. Before using the slats, you need to treat them with an antiseptic. Then they are attached to the walls. It is important that the slats fit tightly. To do this, you can use dense foam or pieces of wood.

You also need to waterproof it using a moisture-proof membrane.

Fastening of guide elements

The work begins with installing a drainage system. Next, the corner profiles are attached. Next, using self-tapping screws, you need to mark starting J-profiles around the building. For convenience, you can stretch a rope or bright thread between the screws.

Installation of other panels

The first row is attached to the starting bar and continues to the window or roof.

Important installation tips

- The panels are attached from left to right and from bottom to top;

- If you are working on wood siding, use only galvanized nails. This will help avoid wood rotting;

- If vinyl panels are used, a small gap is left during installation. Fasteners are screwed into specially made holes.

Very good and detailed information about the installation of siding, using the example of a metal block house, is written here: https://svitpokrivli.ua/krovelnie-raboti/montazh—metallicheskogo-sajdinga—blok-hausa-. We advise you to read it.

Vinyl siding - all the pros and cons

Plastic or acrylic, the so-called vinyl, is the most popular variety. Attached using self-tapping screws. Almost any person who has reached the age of majority and is not afraid of heights can do this. Professional builders also often recommend plastic or vinyl siding.

Flaws:

- you need thermal insulation of the walls, not just vinyl siding;

- such cladding can be easily damaged by hitting the wall;

- melts upon contact with fire or electrical discharge;

- In case of corrosion, it is impossible to replace a single section; the entire wall will have to be replaced.

The pros and cons of vinyl siding are an explosive mixture of probable fragility and tenderness, proven reliability, and financial benefits. According to statistics, more than 50% of facade cladding materials sold are vinyl siding.

Equipment

Panel covering involves not only the installation of the main panels, but also the additional design of their joints, corners, window and door openings.

Siding components include the following elements :

- starting bar . The element from which installation of the cladding begins serves as the basis for inserting the initial strips of siding;

- J-profile . It is an element for decorating spotlights, framing corners, window and door openings;

- outer corner Gives a finished look to outer corners;

- internal corner . Frames internal corners;

- connecting profile (H-profile). Serves to design the joints of panels;

- finishing bar . Serves to decorate the upper edge of the cladding;

- window slat . Along with the J-profile, it is used for framing windows and door openings;

- platband . Sometimes used instead of J-profile.

NOTE!

All components must be purchased together with the main panels from the same manufacturer.

In this case, they will match in color, their fastenings will match perfectly.

Equipment

Metal siding

The pros and cons of metal siding, unfortunately, are overshadowed by the price. Very rarely this type is chosen for finishing the facade of a residential building. It's too expensive. It is made of aluminum. Metal siding is not rational, although it protects reliably, is easy to install, and does not require additional maintenance. If you choose it, despite the prices, you can create an exclusive, fabulous design and realize the most daring ideas. Metallic shine is the main feature. It is difficult to damage. A strong blow, however, will leave a dent that cannot be straightened out. For commercial buildings it is better suited than all other materials and is often used. The metallic sheen goes well with the transparency of glass and the flawless smoothness of mirror surfaces.

Comparison with other façade materials

Siding in construction is popular due to its unique combination of qualities. Compared to other types of finishing, cladding is preferable.

- A simple way to finish the facade - plaster. The material is affordable, very light, and quite diverse. The plaster conducts steam, so the risk of condensation is minimal. But at the same time, the finish is very short-lived and needs to be updated at least once every 3-5 years. Siding, even cheap siding, is much more durable, and the problem of steam escaping from the premises to the outside is solved by installing it on a frame.

- Sheathing clapboard is also very popular. Wood retains heat, weighs little, and allows steam to pass through. However, it is prone to rotting and damage by fungi and insects. This type of finish needs to be maintained. Wood fiber siding is not sensitive to moisture and frost and lasts longer.

- Facing ceramic bricks and clinker - an expensive procedure. In terms of strength, there is little that can compare with it. However, this method is extremely labor-intensive, time-consuming and costly. Siding imitates brickwork and is much cheaper.

Steel or galvanized

This type can be classified as metal siding, but it is much cheaper and more accessible than aluminum. It has serious flaws. Firstly, it requires regular painting. If this is not done, the facade will begin to rust and quickly become unusable, although it could last 50 years. Secondly, it has a low level of noise insulation.

If you compare the pros and cons of plastic siding with the pros and cons of steel, it becomes obvious that it's all about paint and rust. This is not a problem only for an attentive, caring home owner. Plastic is more practical.

Specifications

PVC panels must meet the requirements for quality indicators, and also contain substances that ensure the safety and quality of the material :

- titanium dioxide . An important component that serves to create the strength of the top coating of the sheet. 10% of the element should be included in the layer. In addition, the element ensures color stability of the coating;

- calcium carbonate . It fills (15%) the inner coating of the panel sheet;

- butadiene _ Helps stabilize the composition of the material;

- modifiers . Helps increase the strength of the panel. The number of these components is directly related to the level of strength of the material and, accordingly, its cost;

- colorful pigment . An element due to which the required color of the sheet is achieved.

IMPORTANT!

When choosing PVC siding, you should correctly calculate their quantity, since the color of different batches of goods may vary slightly.

In addition, it should be taken into account that if the panel becomes deformed during installation, it should be replaced with a new one: this factor must also be taken into account when making calculations.

Technical characteristics, in addition to composition, imply compliance with the required indicators of the American Society for Testing Materials (ASTM):

- panel sheet thickness - from 0.9 mm to 1.2 mm ;

- color preservation - according to the standard must comply with D3679, D7251, D6864 ;

- impact resistance coefficient - D256 (individual resistance), D4226 (installation resistance);

- flammability - surface - E84 , general - D635 ;

- smoke generation - D2943 .

In addition, each sheet of siding must be evenly painted, the holes must be located at the same level and be identical, the surface must be matte and free of scratches and microcracks.

Specifications

New – zinc siding

This variety, alas, is rare on the domestic building materials market. It is very expensive. The pros and cons don't cover the costs. In other countries it is also not very popular today. However, it was invented relatively recently. It is too early to draw conclusions. The reviews from those people who chose this material are positive.

You can fall in love with cement siding

Cement or fiber cement siding is made from cellulose fibers and cement. It is truly reliable and practical. The texture and colors are elegant, fill the home with comfort, and evoke pleasant associations. This species resembles wild stone. At the same time, the fiber cement option has the appearance of soft sand, ideal for creating a romantic image. It harmoniously combines with landscape design and its various options, and looks great on its own. It is cheaper than stone, no less beautiful, and durable.

However, the color palette here is limited, and the cost is slightly above average. Upon closer examination, the pros and cons of fiber cement siding indicate that this material is still intended for an amateur.

Classification of siding by purpose

The siding material to some extent determines the purpose .

- Wall – designed for cladding the facade from the base to the roof. The sheathing does not come into contact with the ground. Wall slats and panels are varied and designed for different wind and rain loads.

- Tsokolny – such cladding is mounted close to the ground, and sometimes even comes into contact with it. It is made from materials that are resistant to dampness: metal slats, acrylic. Fiber cement and wood chip materials are not used for cladding the base.

- Soffit - material intended for filing cornices and overhangs. As a rule, the lamellas are perforated, since it is important to provide ventilation in this area. For manufacturing, materials are used that are poorly resistant to water and ultraviolet radiation, since this area is not exposed to rain or sun.

Valera

The voice of the construction guru

Ask a Question

The cladding requires additional elements: corners, connecting profiles, windows. They must be made of the same material as the main sheathing.

Consumer demand

Facade siding is vinyl or metal, which is better, the answer to the question is ambiguous, especially taking into account consumer choice in different regions of the Russian Federation. In most cases, construction companies and consumers prefer vinyl. The trend is most obvious in Moscow and the Moscow region, where about three-quarters of buyers prefer vinyl facade finishing; in the south of the Russian Federation the demand is equally high.

In areas with harsh climatic conditions, winds and cold, and high humidity, the relationship between consumer choice is not so obvious. A much larger percentage of buyers prefer metal siding to vinyl. In some areas, steel panel cladding strips are used by more than half of consumers.

What is siding and its pros and cons

Siding is a facing material that consists of separate plates fastened with special latches. The kit also includes a set of fittings that mask the joints and generally facilitate installation work.

Main advantages of finishing:

- simple and quick installation;

- high strength and performance qualities;

- simultaneously with the sheathing, you can take care of the insulation of the walls;

- a huge variety of models and colors;

- excellent external characteristics;

- care does not require special skills.

When considering the disadvantages, it is necessary to mention the high prices for certain types of siding . We'll talk about the specific disadvantages for each type below.

Vinyl

Single-layer vinyl siding panels are produced by monoextrusion from polyvinyl chloride and a small amount of impurities that are necessary to stabilize the main component. The output is classic cast sheets.

Double-layer profile - a more advanced material . The plastic is additionally covered with a protective layer. The manufacturing method involves the use of a co-extruder, due to which the individual layers are combined at the molecular level.

NOTE!

The cost and color of the cladding are directly related; the richer the shade, the more expensive the material. The nuance is determined by the need to add components that resist ultraviolet radiation.

Advantages:

- affordable price;

- minor deformations that occur during operation can be restored independently;

- plastic is one of the lightest building materials;

- simplicity and speed of installation;

- vinyl is easy to care for;

- a wide variety of shades.

Flaws:

- needs additional thermal insulation;

- direct mechanical impact can cause significant damage to the finish;

- short-lived compared to other types of siding;

- replacing one sheet requires dismantling the entire house cladding;

- flammability of the material, release of toxic substances during combustion.

Metal

Metal siding is a stacked profile consisting of several layers:

- main – steel sheet;

- zinc coating;

- anti-corrosion coating;

- primer;

- back surface – varnish or paint;

- the front surface is a polymer coating.

pros:

- high strength characteristics;

- resistance to temperature changes and precipitation, if the protective layer is not damaged;

- long service life;

- ease of care;

- resistance to rot and insect pests;

- sufficient variety of forms;

- aesthetics.

Minuses:

- high price;

- heavy weight and therefore difficult to install;

- complex repairs in case of dents;

- low thermal insulation.

Acrylic

Acrylic panels are a modern solution for home decoration. Key characteristics of the cladding: shape, color, size.

Siding is available in three types:

- ship timber;

- block house;

- vertical siding.

The color range is varied, you can choose the following tones:

- pastel, soft;

- rich, bright;

- imitating natural wood.

IMPORTANT!

Connecting and starting strips are initially available in white. If the customer wishes, the structural elements can be made in color.

Advantages:

- high strength;

- no deformation at high temperatures up to 80°C;

- environmental friendliness of the material;

- resistance to mechanical stress;

- fire resistance;

- the initial color does not change under the influence of ultraviolet radiation;

- does not decompose under the influence of aggressive environments;

- simple installation;

- lightness of the material;

- ease of care.

The main disadvantage of acrylic siding is its high price . In all other respects, the cladding is practically invulnerable if no errors were made during the production of the material and during installation work.

Fiber cement

A relatively new solution for cladding a house, but it has already won a lot of sympathy. The main components of fiber cement panels are cement, sand, natural or synthetic fibers . The front side of the finish is lined with a texture that imitates stone or natural wood.

Advantages:

- long service life;

- high noise insulation and heat insulation qualities;

- environmental friendliness of the material;

- amenable to self-cleaning during precipitation;

- fire resistance.

Flaws:

- fragility of the material, which complicates installation work and transportation;

- tends to absorb moisture, which can lead to deformation;

- the weight forces you to take care of a durable sheathing.

Ceramic

Ceramic siding is a relatively new type of facing material, its quality characteristics are similar to ceramic tiles.

The texture imitates:

- tree species;

- stone or brickwork;

- rock relief;

- plaster.

Profiles are made from clay and silicate fibrous materials . First, the mass is hardened, then several layers of dyes are applied to the surface.

pros:

- resistance to temperature changes, precipitation, sunlight;

- high noise insulation and heat insulation qualities;

- does not fade;

- the cladding is sealed, there is no possibility of water and air penetrating under the cladding;

- durability;

- environmental friendliness;

- fire resistance;

- a large assortment.

Minuses:

- complexity of installation and repair work;

- fragility of finishing;

- heavy weight.

Wood

It was with this that the history of a new finishing material began in the middle of the last century in North America. Wooden panels create coziness and a wonderful atmosphere indoors; from the outside, the building looks presentable and indicates the well-being of the owners .

NOTE!

Despite all the advantages of the material, the popularity of wood siding is falling every year. This nuance is associated with large monetary costs for annual maintenance.

Plus, the technology for making panels has changed; today they are made from wood waste by pressing.

Advantages:

- presentable appearance of the cladding;

- environmental friendliness of the material;

- high energy efficiency;

- zero thermal conductivity;

- high vapor permeability.

Flaws:

- susceptible to rotting;

- afraid of insects, mold, fire;

- needs special, expensive care;

- has low strength characteristics.

Under the stone

The main feature of this finish is that even up close it is difficult to distinguish it from natural stone. Produced in rectangular panels. Each sheet is equipped with locks and fastening holes at the edges for hermetically sealed joining .

During installation work, the joining elements are covered with adjacent profiles, resulting in a single piece of fabric.

Advantages:

- resistant to temperature changes;

- does not rot;

- perfectly resists mold, insects, sun rays, precipitation;

- the material is light;

- does not change the original shade for a long time;

- durable;

- unpretentious in care.

Flaws:

- poor color variety;

- high consumption during installation work.

What type of siding to choose?

The choice of siding depends on financial capabilities, material, condition and location of the house. For example, if the house is located on the sunny side, it is recommended to cover it with acrylic panels - they are more resistant to ultraviolet rays. For homes that are in the shade, vinyl siding is sufficient.

It is better to sheathe buildings that are subject to frequent mechanical stress with metal siding; it is also recommended when used in conditions of very high and low temperatures.

It is better to choose a manufacturer after reading reviews. Thus, there is a greater chance of purchasing high-quality cladding material. When purchasing siding, you should pay attention to the length of the manufacturer's warranty and what defects it covers.

If in doubt, you can ask the store consultants for help in choosing.

Risk of injury

Occurs when working with aluminum siding. When installing, you need to cut the material, adjust it, and you may not notice how you get hurt on the sharp edges. The injury can range from minor to very serious.

Therefore, it is necessary to observe safety measures and wear special protection (glasses, overalls, gloves with a chainmail surface).