Refusal to use centralized heating and water supply lines, the creation of autonomous heating systems and hot water supply at home is becoming commonplace.

This is convenient for owners of private houses or apartments; it allows them to independently make decisions about the beginning and end of the heating season or home heating modes.

Retail chains offer a wide range of gas boilers, on the basis of which the most efficient and economical heating systems are created.

European companies are considered confident leaders in the production of heating equipment, but their colleagues from Southeast Asia have achieved considerable success.

Let's consider the brightest representatives of heating equipment from South Korea - Arderia gas boilers.

Error codes

If the slightest malfunction or problem occurs in the operation of the device, a certain error is shown on the electronic display.

To properly troubleshoot a problem, you need to know the content of all possible equipment errors.

- Error A1 - failure of the air pressure sensor. This probably occurs due to blockage or icing of the inlet.

- Error A2 - reduced fan speed, as a result of which the boiler does not heat the water well and is also noisy. The cause may be either poor contact, problems with connecting the wires, or foreign objects getting on the fan blades. This may be the cause of the noise.

- Error A3 - the circulation pump is broken, the pressure drops. This problem can occur due to dirt getting into the pressure sensor, or if it turned on before the pump.

- Error A4 - an increase in the temperature of the device, which knocks out both fuses at once. This can happen if the shut-off valves are screwed down, the heating filter is clogged and the valve is leaking, the pump is faulty, the three-way valve is not working, or the water flow sensor is damaged.

- Error A5 - coolant pressure decreases. It may occur due to a decrease in the amount of water in the system, the appearance of air, pump failure or a decrease in its speed, or wear of the pressure sensor.

- Error A6 - no ignition, the boiler does not ignite and goes out. Occurs due to blockage of the chimney, low gas pressure, inoperability of the gas valve, breakdown of the transformer, or blockage of the gas duct.

- Error A7 - the gas valve is broken, as a result of which the unit does not start. This breakdown occurs due to the relay closing, errors in the control system.

- Error A8 - flame extinction. This happens due to the presence of a residual flame when the gas valve is turned off, damage to the gas valve diaphragm, or failure of the control unit.

- Error A9 - freezing. Occurs as a result of a decrease in coolant temperature to 5 degrees Celsius.

- Error AA - boiling. It happens if the heating circuits are faulty, the filters are clogged, the circulation pump does not work, the three-way valve is damaged or worn out, or the hot water supply sensor is damaged.

- Error AB, AC - thermostat failure. Possible due to an electrical short in the thermostat or poor connection of contacts in the device itself.

- Error AE - chimney blocked. Appears due to foreign bodies entering the gas outlet or its deformation.

- Error E0 - problems with the anti-freeze mode. Occurs when the temperature drops to 1 degree Celsius. In this case, the boiler will not work until the temperature rises above this mark.

- Error E1 - failure of the ionizing sensor, lack of combustion. Occurs when the flame goes out or ignition is poor. Within an hour, the boiler itself will try to correct errors in the system. If this does not happen, then you need to contact specialists.

- Error E2 - error in the sensor responsible for air pressure. Occurs when there is reduced draft or a faulty fan. If after 15 minutes the device does not work, it is better to contact the customer service center.

- Error E3 - occurs when the thermostat overheats. This may occur due to the absence or improper circulation of coolant. It is necessary to drain the hot water, check all valves, and press MODE to unlock.

- Error E4 - failure or overheating of the temperature sensors. May occur if the pump breaks down.

There are also cases when no error is displayed on the display, but the boiler operates with complaints.

Such cases include the following.

- The fan turns on, but the burner does not light. The problem may arise due to a clogged chimney, leakage of combustion products, or breakdown of the current stabilizer.

- Change of flame color to red or yellow. Occurs due to contamination of the burner, failure of the gas valve settings.

- Hot water begins to flow after a long period of time. This is most likely not an error or breakdown - this phenomenon is associated with the gradual heating of the incoming water.

How to set up a boiler yourself

Why do you need proper adjustment of equipment:

- To save resources.

- To make the room comfortable, use hot water.

- To extend the life of the equipment.

You need to start with the right choice of boiler and its power. Consider the features of the room: the number and area of windows, doors, quality of insulation, wall materials. The minimum calculation is based on heat losses per unit time. You will learn more about this in the article “How to calculate the power of a gas boiler.”

Gas boilers are divided into single-circuit and double-circuit. The latter perform heating on the heating and hot water supply (DHW) circuit. Single-circuit units provide heating only. Therefore, to obtain hot water, indirect heating boilers are installed.

Depending on the type of placement, equipment can be floor-mounted or wall-mounted. Units placed on the floor have greater power. Therefore, they are used for large areas (from 300 m²). Installation is carried out only in separate rooms (boiler rooms). These are models Baxi (“Baksi”), Buderus (“Buderus”), “Navien”, “Kiturami”.

Attachment appliances (Neva Lux, Arderia, Daewoo, Ariston, Bosch) fit perfectly in small apartments in the kitchen. Therefore, it is important to take into account all the nuances of the location. The comfort of residents, as well as the durability of the boiler, depend on the correct selection of parameters.

Power setting

The heating power depends on the modulation of the gas burner. If you choose an electronically controlled device, then it includes a thermostat that connects to a room thermometer. The adjustment occurs automatically: the thermometer measures the temperature in the room. As soon as it drops below a comfortable level, he gives a command to start the burner or increase the flame power.

In normal mode, the thermometer monitors the temperature in only one room. But if you install valves in front of each radiator, control will be in all rooms.

You can adjust the burner manually by operating the gas valve. This is true for atmospheric boilers with an open combustion chamber. Thus, in the Protherm “Cheetah” and “Protherm Bear” models, the valve is controlled by an electric motor. To change the settings, you need to go to the service menu. Most often, this is done by a specialist, and the user follows the steps specified in the instructions.

But we will still tell you how to call up the hidden menu for adjustments.

Before going into the menu and making settings, do this:

- Unscrew the taps on the batteries.

- Set the room thermostat to maximum values.

- In the user settings, set the maximum temperature that you use in severe frosts. The burner always turns off when the readings reach 5°C above the set values. For example, at +75 degrees, a shutdown will occur when it reaches 80 degrees.

- Cool the coolant to 30°C.

For Protherm Gepard:

- Hold down the Mode key on the panel. Once the display shows “0”, set the value to 35 by pressing “+” and “−”.

- Press Mode to confirm.

- As soon as d lights up on the screen. 0, enter the line number in the menu. Do this using “+” and “−” d.(number). To set the maximum burner power, select d.53, the minimum - d.52.

- Use Mode to move to parameter selection. Change it "+" "−".

- The installation receives automatic confirmation.

- Return to the original menu - hold Mode.

While adjusting using the panel, monitor the flame change and temperature rise.

For Proterm Panther the actions are different:

- Press Mode for about 7 seconds.

- Using keys 2 (see the picture above), enter code 35.

- Confirm your entry.

- Once d.00 appears on the left side of the screen, use the 2 buttons to enter the number.

- You can change the parameter on the right side of the screen using keys 3.

- After confirmation, press mode to exit the menu.

For Electrolux Quantum models:

- Unplug the device for a few seconds.

- After turning on the controller, hold the red button for 15 seconds.

- As soon as P01 lights up on the display, press the red key until P07 appears.

- If after P07 the number 1 flashes, then 38°C-85°C is maintained. If it lights up 4 - 60°C-85°C, 7 - 38°C-60°C.

- Use the “+” “−” knob to adjust the desired value.

- Turn off the boiler for a few seconds. Now it will automatically support the specified parameters.

How to program Viessmann equipment, watch the video:

For Eurosit 630:

All the steps described above are used to configure the device in heating mode. Many users encounter a problem when, in DHW mode, water comes out of the tap at an unstable temperature. To fix this, use our recommendations.

Changes in hot water temperature

To regulate the water supply to comfortable levels, you need to reduce the burner power.

- Open the mixer to switch the boiler to DHW mode.

- Set the temperature to 55°C.

- Go to the service menu as described above (for “Proterm”).

- Select option d.53.

- Click Mode.

- After this, the maximum power will appear in the line. For example, let's take indicator 17.

If you experiment and immediately select the minimum value - 90, then the temperature of the water from the tap will not be comfortable. We set it to 80 and get an increase in water temperature. Increase the values little by little until you are satisfied with the DHW supply. In our case, the water reached +50 degrees, and the setting was 80. This despite the fact that the factory setting was 17. That’s the difference.

SIT valve adjustment

The automation of some units provides for the presence of a SIT type gas valve. It is found in the Vaillant and Proterm models. The adjustment is made by rotating the bolts on the valve. To change power, you need to change pressure. Values of 1.3-2.5 kPa are considered normal.

To reduce pressure, turn the bolts counterclockwise. To reduce the pressure in DHW mode, you need to rotate the adjustment nut. More details are shown in the video:

Bypass valve

If the radiators in the room warm up unevenly, increase the coolant circulation rate. To do this, turn the bypass screw clockwise.

If, when you turn on the heating, the liquid in the radiators makes noise, then reduce the speed of the coolant by turning the screw in the opposite direction. To set up and measure, use a pressure gauge or digital differential pressure gauge. It will indicate the nominal pressure, which should not exceed 0.2-0.4 Bar.

Startup problems

During the startup and operation of Bosch, Ariston, Ferroli, and Oasis gas equipment, problems may arise.

Boiler clocking

If the power of the equipment is incorrectly selected, excessive cycling occurs. This means that the device’s burner often turns on and off, and the radiators do not have time to warm up. Firstly, this leads to rapid wear of components and parts of equipment. Secondly, a large amount of fuel is used.

To eliminate the phenomenon and reduce cyclicity, two methods are used:

- Reduce burner flame.

- They increase the heating power by including additional radiators in the circuit.

We described above how to complete the first point. Sometimes you have to install additional batteries, although this is a rather expensive method.

Igniter does not work

If attempts to ignite at Immergas, Korea Star are unsuccessful, inspect the igniter. It could get clogged. The problem can be resolved by cleaning the part. You can wipe it with a dry cloth or use a solvent.

Inspect the combustion block. Soot often accumulates there. Lightly tapping the gas supply pipe to the burner removes soot.

The igniter worked, but still no ignition. Diagnostics required:

- thermocouples;

- supply valve;

- thermostat;

- solenoid valve.

No DHW heating

When the mixer is opened, water flows with low pressure and the flow is cold. Inspect the heat exchanger for blockages caused by scale deposits. Clean the tubes with reagents. Use a pump to bleed. After the procedure, rinse the unit with running water. To keep temperatures comfortable, install cleaning filters. They reduce the likelihood of scale formation.

Recommendations from the manufacturer can be found in the instructions. Proper connection and adjustment of equipment is the key to its effective and long-lasting operation.

Source

Features of Arderia equipment

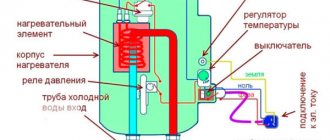

Security and full automation are the main areas on which all efforts of developers are directed. That is why the design provides several additional protective devices. In general terms, the Arderia boiler has the following design advantages:

- Arderia double-circuit boilers are equipped with two independent heat exchangers. A copper heat exchanger is used for the heating circuit. A stainless steel heat exchanger is installed for the DHW system.

- Installing a pressurized burner allows the automation to independently control the power of the generated thermal energy. This also involves a forcing fan, which provides the necessary amount of air for stable combustion.

- Simple and clear automation control: you can adjust and set the required temperature values for heating and hot water in just a few clicks.

- Connecting a room thermostat allows you to control the boiler operating modes remotely.

- The modern wall-mounted arderia boiler has an electronic display, which displays current values and error codes in the event of a malfunction.

Adaptive Design Features

In addition, gas boilers of the arderia brand are fully adapted to operating conditions in Russian systems. For this purpose, the design of the device provides the following additional elements:

- The main breakdown of volatile double-circuit boilers is voltage surges, which happens quite often in our country. The manufacturer took this into account and the Arderia boiler has a built-in voltage stabilizer. The reliable operation of such a stabilizer is maintained at values from 150 to 285 volts.

- The design also includes a special gas valve and reducer, which are capable of ensuring operation of the burner when the gas pressure drops to 4 Bar.

Such design features were duly appreciated by domestic consumers, which is confirmed by positive reviews on forums and the manufacturer’s official website.

Performance characteristics

Let's look at the main technical characteristics indicated by the user manual:

- A closed combustion chamber, in addition to its efficiency, increases the safety of gas equipment, since combustion products cannot leak from it.

- A coaxial chimney with a forced fan ensures stable and reliable removal of exhaust gases in all weather conditions.

- Protection against voltage surges and anti-freeze system.

- A powerful, yet compact circulation pump ensures pumping of coolant through a heating system of any complexity and configuration.

- Electronic system for automatic ignition of the burner. In addition, the electronics provide smooth start-up and control over the flame.

- The control module has an electronic display, thanks to which the Arderia boiler is easily adjusted to the required comfort indicators.

The pressure in a double-circuit boiler either drops or rises, what to do?

Hi all! The author of the site Blogvp.ru, Vitaly, is in touch! I think you will agree that it is not a very fun experience to be left without heating and hot water on winter days. And this prospect came up several times in my house. I want to tell you how I struggled with this and what knowledge I acquired in this matter.

In my house, for about six years, a gas double-circuit wall-mounted boiler ARISTON CLAS 24 FF has been working to create comfort. Undoubtedly, the thing is extremely convenient; anyone who used, for example, geysers from the early nineties will understand.

But, as they say, nothing lasts forever, and therefore sooner or later, you have to deal with the refusal of technology to perform the intended work.

And although I practiced on my Ariston, so to speak, some faults will be common to any boiler. So, let's get down to business.

The pressure in the boiler slowly drops, you have to periodically add water to the boiler

First, let's look at cases where the pressure drops all the time. This is a fairly common problem - it manifests itself in the fact that the pressure in the heating system slowly decreases and when it drops below normal, some boiler models turn off.

There are two reasons why this can happen.

Leak in the heating system

An elementary coolant leak from pipes or leaky radiators, but most often what is used as a coolant? That's right water!

Believe me! It’s not easy to detect such a leak during the heating season, but the fact is that you won’t see a puddle on the floor, unless of course it’s a serious leak. Most often, these will be just droplets and you will not see these droplets, since they quickly evaporate from heated pipes.

As a result, slowly but surely the pressure will drop. You add water over and over again and this continues to kill the radiators. Because the oxygen released from the incoming fresh water does not benefit them.

How and where to look for a leak

You need to pay attention to radiator plugs, joints or soldering of pipes and fittings. You can often see traces of water leaks in the form of rusty or salt stains. But this depends on the composition of the water in your area.

It is not uncommon for modern radiators, aluminum or bimetallic, to also become unusable, sometimes in extremely inconspicuous places, between the ribs or from below, they begin to dig in due to metal corrosion. Not rust, of course, but various chemical processes also damage them. Radiators must be carefully inspected while searching for leaks.

It will be easier to detect various types of leaks if you turn off the heating for a while, let the radiators cool and add pressure to about 2.5 Bar. After this, you will be able to see drops or puddles on the floor. Carefully inspect the floors under the radiators, pipe connections, and soldering areas.

The boiler can also be the cause of the leak. For example, the primary heat exchanger itself or its connections are leaking. But as long as these are small droplets, you will not notice anything; they evaporate during operation of the boiler. As soon as it starts to leak more actively, you will notice “drops” from the boiler.

Regardless of whether the burner is on or not, the leaking feed taps or emergency relief valve will be clearly visible.

So, the first reason for the pressure drop in the system is a coolant leak.

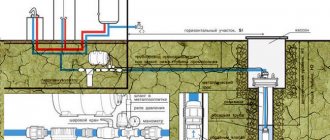

Expansion tank

Another reason is the expansion tank. This is a sealed container divided in half by a membrane, one half of the tank is filled with inert gas or just air, the other is filled with coolant (read water).

Expansion tank

It is designed to compensate for the pressure created during the expansion of the heated coolant.

When heated, the water in the system expands and fills its half of the tank, compressing the gas; when cooled, the coolant is again pushed into the heating system.

This is how temperature expansion in the heating system is compensated.

But sometimes the tank itself may malfunction.

Expansion tank malfunctions

For example, the tank body has lost its tightness and air is escaping from it. This does not happen often, and usually results in a fairly rapid decrease in pressure in the tank, from almost instantaneously to several days.

Also pay attention to the spool so that it does not poison the air either.

The spool (as in a car or bicycle) is located in the upper part of the tank; air is pumped through it, thereby creating the necessary pressure in the expander tank.

Another bad problem with the expander is the rupture of the membrane inside the tank, although it is not so delicate, and you need to “try” hard to break it. But if this happens, then identifying such a problem is not difficult.

In this case, the coolant enters from the heating system into that part of the tank that should be filled with air, and if pressing the spool needle throws water out of the tank, then water has penetrated where it should not be - the tank needs to be replaced.

But most often the pressure in the tank decreases very slowly, due to minor natural leaks. This decline occurs over many months or several years.

At the same time, the pressure in the expander chamber gradually decreases; naturally, it will also decrease in the readings of the boiler pressure gauge.

The behavior of the boiler very much depends on the level of this same pressure in the expander and can manifest itself in different ways. Under the next heading you will find a description of these problems.

The pressure rises and falls - the boiler does not operate stably

From all of the above, it is clear that air comes out from the part of the expansion tank in which it should be or does not have sufficient pressure. And here the pandemonium begins with changes in the operation of the boiler. All this can manifest itself in different ways and depends on the pressure in the air chamber of the Republic of Belarus.

For convenience, we will divide these manifestations into different stages.

FIRST STAGE - The pressure in the boiler drops slowly, about once a week you have to top up the boiler, while there are no obvious leaks in the expander, and there are no obvious leaks in the heating system itself.

SECOND STAGE - On the boiler pressure gauge, the pressure is constantly “walking” In heating mode it rises above 3 Bar, until the relief valve is activated; in hot water mode, on the contrary, it drops to values less than 1 bar and then the boiler may begin to shut down, the protection is activated. (If it has a pressure sensor)

THIRD STAGE - If there is absolutely no air left in the tank, then the pressure on the pressure gauge drops to zero in a very short time, sometimes in a minute.

There is only one way out for all options! It is necessary to again create the necessary pressure in the expansion tank of your boiler, in its air part.

How to pump up a boiler expansion tank

Diagram of boiler taps Ariston Class 24

A Connection for draining water into the central heating circuit (CH)

B Connection for draining water into the hot water supply circuit (DHW)

C Connection for gas supply

D Connection for cold water supply

E Connection for supplying water from the central heating circuit

S Safety valve outlet

T Drain tap

F Filling tap

How to properly pump air into the expansion tank

We follow the specified order

- Turn off the boiler from the network.

- We turn off all the taps to the boiler, supply, return, and cold water input.

- Open the drain fitting in the boiler. (T) and drain the water completely. (Here is an article about how to drain water from the boiler) The pressure in the boiler should be zero.

- We connect the pump with a pressure gauge to the RB through the spool - the drain fitting is open.

- The pump needs to pump air into the tank until water stops flowing from the drain fitting. At this stage, the main goal is to empty the tank of water.

- We release the pumped air.

- We inflate again, monitoring the pressure with a pressure gauge. The pressure in the expander should be within 1.1-1.3 bar. (See the passport for the boiler - often indicated)

- Close the drain plug.

- We open all the taps to the boiler - everything that was closed.

- We feed the boiler through the make-up tap (F) to a pressure of approximately 1.2-1.5 bar

- Let's start the boiler.

For these purposes, you can use any pump and pressure gauge. There is a car nipple there. I used an auto compressor. True, for this I had to drag the battery home. With an electric compressor, be careful to turn it off in time and not overpump.

Before starting, it will not be superfluous to expel any air that has entered the system.

In Ariston class 24, to do this, press and hold for about 5 seconds. ESK button. The boiler will go into purge mode for 6 minutes, exit this mode on its own, or you can force it by pressing ESK again.

Operating and setting instructions

The initial (basic) setting of gas boilers is carried out at the manufacturer. During installation and first start-up, it is necessary to correct the factory settings in order to combine the existing operating conditions with the needs of the mechanics and electronics of the boiler. These actions must be performed by employees of service centers or warranty workshops.

Independent intervention in the design of gas appliances is prohibited. Operating settings such as adjusting the temperature or turning off the heating for the summer are permissible and must be carried out by the user.

Operation of the units is not difficult

It is necessary to pay attention to the display readings and, if necessary (if an error code appears), call a technician. Clean the housing from dust and dirt, carry out timely technical inspection and other procedures

Before starting work, you should carefully study the instructions and follow their instructions.

Expert advice

- Before you begin repairing the Ariston boiler, you need to press the “RESET” button (translated as reset, playback, zero) and restart the heating installation. Often this helps restore its functionality. As a rule, the occurrence of an error is caused by voltage instability - a typical case in the private sector.

- If an Ariston boiler does not have a display and its indicator lights are blinking, it is not a fact that a malfunction has occurred. This happens when the Comfort mode is turned on. The heat generator is forced to adapt to the microclimate in the room, hence its periodic switching off/on

p, blockquote 3,0,0,0,0 —> Ariston CARES X 24 FF control panel diagram with explanations

Design and principle of operation of Arderia boilers

The Arderia company produces two types of double-circuit wall-mounted gas boilers - bithermal and with two separate heat exchangers. The body is metal, covered with white enamel paint on top. To remove the cover, you need to unscrew the two bolts from below. There is a pressure gauge at the bottom.

The primary heat exchanger is made of high quality copper, the secondary one is made of stainless steel. At the bottom left there is a Grundfos pump with a dry rotor, in which there is no contact of the coolant with the electric motor. This prevents clogging and jamming and also increases the efficiency of the boiler.

Under the burner in front of the combustion chamber there is a fan operating on direct current. This allows it to operate at different speeds and provide the required air pressure at a given moment. The location in front of the firebox means that it does not create a vacuum, but rather a pressurized air.

At the bottom right there is an electronic control board with DIP switches. Additionally, the device is equipped with an SMPS chip, which acts as a voltage stabilizer.

The device comes with a convenient remote control panel with a self-diagnosis function. The temperature of hot water and coolant is set on it.

The Arderia series “B” boilers have a bithermic radiator, which combines hot water supply and heating heat exchangers. Inside the main copper pipe with a round cross-section, a thinner, diamond-shaped one is inserted.

Ariston boiler errors Leave a comment

Perpetual motion is found only in the works of science fiction. Any technical device, even of high quality, sometimes fails. Ariston boilers are convenient because error symbols are displayed on their LCD display, indicating a particular malfunction. The article will tell you how to interpret them correctly and give practical advice on how to fix the problem yourself.

p, blockquote 1,0,0,0,0 —>

p, blockquote 2,0,0,0,0 —> Ariston CARES X 24 FF control panel

GAS BOILER ARDERIA ESR 2.13 FFCD

Arderia boilers are wall-mounted gas boilers with a closed combustion chamber designed for heating and hot water supply with a capacity of 16 to 40.7 kW.

Arderia boilers are produced by the leading heating equipment manufacturer in South Korea, Daesung. They combine efficiency, high quality and exceptional reliability.

Quality control at every stage

Daesung uses the Toyota assembly system in which all employees are personally responsible for each boiler produced. By the boiler number you can easily determine who assembled it, what batch the components were from and who carried out the quality tests. Afterwards, all Arderia boilers are tested in operating mode with the connection of gas, a heating circuit and a hot water supply circuit. From each batch of 500 pieces, 2 boilers are selected for more thorough testing in a special laboratory. After testing, the quality inspector puts his personal stamp on each boiler and if a defect is discovered in the future, all personnel will be personally responsible for this.

Built-in voltage stabilizer

Thanks to the presence of a built-in voltage stabilization system, the boiler remains operational during voltage fluctuations in the range from 150 to 286 volts. No additional installation of stabilizer is required.

Minimum operating gas pressure 4 mbar

Arderia boilers are fully adapted to Russian conditions and can operate stably at a minimum gas pressure of only 4 mbar.

Dry rotor pump

Over time, dirt, scale and rust form in the heating system. This leads to breakdown of wet rotor pumps. Arderia boilers use dry rotor pumps, for which this problem does not exist. In pumps with a dry rotor, there is no contact of the coolant with the rotating rotor of the electric motor, thereby the rotor is completely protected from jamming and clogging. It is also worth noting that the efficiency of pumps with a dry rotor is much higher. All pumps for Arderia boilers are manufactured at a plant in South Korea, which is part of the well-known international Grundfos group.

Supercharging with DC fan

Most boilers use AC fans after the combustion chamber. Such fans can only operate at one speed. But chimneys of different lengths require different pressures, and different amounts of air are needed to burn different amounts of gas. Using an old design fan it is impossible to create the necessary conditions for optimal boiler operation.

Arderia boilers are equipped with a DC fan that can operate at any required speed. It provides optimal air pressure at any given moment. Since it is located in front of the combustion chamber, it does not create a vacuum, but a pressurized air. It supplies the combustion chamber with as much air as is needed for the boiler to operate efficiently.

Protection system

Each boiler has a reliable safety system, which includes: ionization flame control, overheating protection, freezing protection and a self-diagnosis function. All necessary parameters are constantly monitored by the boiler automation.

Two heat exchangers

High operating efficiency is ensured thanks to two separate heat exchangers. The reliable copper primary heat exchanger has a long service life and high performance. For hot water supply, an additional stainless steel plate heat exchanger is used, which easily allows you to obtain the required amount of hot water at any time.

Various types of chimneys

Arderia boilers can be used with different types of chimneys (coaxial chimney 100/60 and separate chimney dy80), to change one type of chimney to another it is necessary to change the special flue mounting flanges in the upper part of the boiler.

Guarantee

The warranty period for Arderia boilers is 2 years. For the production of boilers, only proven, high-quality components and materials are used. Arderia boilers are modern equipment that provides a high level of reliability and comfort.

Maris LLC also pays special attention to the service of Arderia boilers; the necessary spare parts are always available.

Series and models

Arderia gas boilers are available in the following series:

Series "B"

“B” series units are manufactured in Russia, at Daesung’s own production facilities . The model range consists of dual-circuit units with a bithermic heat exchanger made of copper.

The power of the models ranges from 10 to 24 kW, which is suitable for heating rooms from 53 to 250 sq.m.

Main parameters of the models:

- modulating burner;

- ability to work with low inlet gas pressure (up to 4 bar);

- silent circulation pump with a “wet” type rotor;

- there is a self-diagnosis and flame detection system;

- availability of frost protection;

- The units have been adapted to Russian climatic and technological conditions.

Gas boilers of the “B” series are reliable and economical . Each unit undergoes a separate quality control inspection. There is multi-stage protection against operational overloads or freezing.

Series "D"

A series of gas double-circuit boilers with a power of 10-24 kW, capable of heating rooms from 53 to 250 sq.m. Equipped with two heat exchangers .

Primary (main) copper, secondary (for hot water supply) - stainless steel. Parts and materials from the best European manufacturers, as well as the company’s own developments, were used in production.

Specific features of the units:

- possibility of conversion to liquefied gas;

- the gas valve is adjusted via the control panel;

- two options for installing a chimney - separate or coaxial;

- possibility of remote control via an application on a smartphone;

- There are contacts for connecting a room sensor.

The design of boilers in this series is practically no different from the design of the best European models . At the same time, the prices of Arderia boilers are at least two times lower than those of analogues from European countries.

This increases the demand for Korean units and increases their importance in the eyes of buyers.

ESR 13-20 kW

The power of boilers of this series is in the range of 16-18.6 kW . It includes two models - ESR 2.13 and ESR 2.20. In terms of their set of functions, they are dual-circuit units with a closed combustion chamber. Designed for heating rooms from 65 to 200 sq.m.

Manufactured in South Korea, at our own production facilities.

Capabilities of boilers of the ESR series 13-20 kW:

- it is possible to connect to gas lines with low pressure (up to 5 mbar);

- adjustable turbocharging;

- a circulation pump with a “dry rotor” was used, allowing maintenance without draining the coolant from the system;

- a control panel is used that operates at a distance of up to 40 m;

- there is a self-diagnosis system;

- built-in voltage stabilizer that corrects differences from 156 to 280 V.

Units of the ESR 13-20 kW series are adapted for operation in Russian conditions . They are equipped with frost protection

ESR 25-35 kW

This model line includes the ESR 2.25, ESR 2.30 and ESR 2.35 units. Power range - from 12.2 to 40.7 kW . Capable of heating areas from 122 to 407 sq.m.

Equipped with copper primary and stainless steel secondary heat exchangers, a closed combustion chamber, modulated burner.

Main settings:

- electronic flame ignition system;

- the possibility of converting gas equipment to consume liquefied gas;

- automatic maintenance of coolant and hot water heating mode;

- the presence of an ionization sensor that monitors the presence of a flame;

- adaptation of the boiler to Russian conditions.

The units demonstrate reliability, stable operation, and are easy to control and adjust . Combined with low prices, these qualities make them competitive in the market of heating devices.

Main types

The Arderia brand is the property of the South Korean company Daesung. The products of this company are widely known in the world and are in high demand. The main feature of the company is its approach to the production of heating equipment.

Most work operations are performed by automated lines, which eliminates miscalculations or negligence. The Arderia brand was created to place gas boilers on the Russian market, which were produced in the following types:

By type of installation:

wall-mounted Designed for hanging installation indoors (usually in kitchens).

Floor-standing models are not produced, as they require a separate room and are in less demand.

By set of functions:

- single-circuit. Designed only to supply the heating system with hot coolant at a given temperature;

- double-circuit. The units are prepared for simultaneous heating of the coolant and supply of hot water;

The following types of heat exchanger are available:

- with separate heat exchanger. These are boilers in which the primary unit consists of pure copper (99%), demonstrating high resistance to temperature changes and the absence of corrosive processes. The secondary heat exchanger is made of stainless steel, has high heat transfer capacity and shows remarkable performance;

- with bithermic (combined) heat exchanger. This is a “pipe-in-pipe” design. The coolant and water for the hot water supply line simultaneously pass through it without mixing with each other. This design allows you to significantly increase and stabilize the hot water supply at home, but requires taking all possible measures to protect against scale. The complex cross-section of the heat exchanger pipe is very difficult to clean, and replacing a defective unit is too expensive and is not carried out everywhere.

NOTE! The design of the boilers meets modern requirements for the functionality and efficiency of heating technology. The units have all the necessary certificates and can be used in residential and public premises.

Advantages and disadvantages

Advantages:

- efficiency, a successful set of performance qualities;

- the ability to heat the coolant and supply hot water for domestic needs;

- convenient control, there is a remote control and the possibility of remote influence via the Wi-Fi module;

- the presence of a built-in voltage stabilizer capable of correcting drops of up to 150 V;

- boilers are designed for operation in difficult Russian conditions;

- the self-diagnosis system continuously monitors emerging problems and notifies the owner about them;

- there is multi-stage protection against all overloads, coolant freezing, voltage drop, etc.;

- the price of the units is significantly lower than that of European analogues of the same quality.

Flaws:

- need to connect power supply. If there is a sudden shutdown in winter frosts, there is a risk of being left without heating;

- the company emerged relatively recently and has not yet managed to create an extensive network of service centers;

- The power of the units is limited and does not allow their use in large rooms.

Judging by the relevance and high demand, the shortcomings are not critical and are quite surmountable.

CAREFULLY! Some users note a high noise level or some time lag when supplying hot water. However, such features are typical for all models of gas boilers from European and Russian manufacturers.

Price range

The cost of Arderia gas boilers is significantly lower than that of similar devices made in Europe.

For a Russian buyer they cost 23-36 thousand rubles . The price of the unit depends on its power and additional functions. It must be taken into account that the chimney and remote control devices, room thermostat, etc. sold separately.

IMPORTANT!

You should not skimp on warranty service. The danger of being left without heating in winter is much more serious than the costs of concluding a warranty agreement.

Arderia gas boilers appeared on the Russian market relatively recently. Most users do not yet know about them, although a considerable number of units are already in operation.

They demonstrate stable operation, efficiency, and resistance to external loads . Self-diagnosis prevents boilers from malfunctioning; the built-in voltage stabilizer corrects fluctuations in the network. The quality and low cost of Arderia boilers allow them to take their rightful place among alternative options.

Other faults

Let's consider what to do in case of malfunctions when no error is displayed on the screen:

If you smell a distinct smell of gas, immediately turn off the boiler and all electrical appliances and turn off the gas valve. After this, call the gas service, which will have to check the gas pipeline and the boiler itself. Be sure to open the window and listen carefully, as there is a danger of carbon monoxide poisoning.

After turning on the device, the fan starts working, but the flame does not appear in the burner. The mains voltage may be too low. You can check this with a voltmeter

To eliminate this problem, install an additional voltage stabilizer. It is also important to inspect the chimney for blockages and foreign objects. This can also be caused by a malfunction of the air pressure switch and a lack of tightness in the combustion chamber.

If the flame is red or yellow during operation, the burner is most likely clogged

It is necessary to disassemble the housing and clean the injectors. This effect also occurs when the gas valve is set incorrectly.

If warm water does not flow from the tap for a long time, this does not always mean a malfunction of the hot water supply. Since in the absence of water supply the water in the system cools down, in any case, time must pass before heating. When the boiler often turns off on its own while using hot water, this may be due to the fact that the pressure in the water supply is initially too low. The minimum pressure required for correct operation of the equipment is 1.5 bar.

Each model of the Arderia gas boiler has its own personal characteristics. To avoid most problems during operation, carefully read the instructions for your specific equipment.

Summary

In this article we looked at the most common cases when the boiler does not turn on or ignite. No one anywhere on the Internet will definitely tell you why your boiler won’t turn on; this requires at least an external inspection. This material will help you get acquainted with possible situations in general and is written on the basis of our statistics over several years.

If there is a malfunction, you need to determine the error and read the boiler operating manual. Also, for many boiler models, error descriptions with recommendations are available on our website. Malfunctions can be simple, which the user can fix independently, or complex, requiring qualified assistance and spare parts. We strongly do not recommend performing any actions with the boiler if you do not fully understand its structure and principles of operation, disabling protective devices or changing the boiler’s operation circuit to restore its operation. If there is a malfunction, it must be eliminated! If the cause of the malfunction is not completely clear to you, it is better to call a specialist.

Specifications

Most of the components for Arderia gas boilers are imported. Most often these are Japanese, Danish and German spare parts. It is this detail that is a certain disadvantage of this equipment, as it complicates the maintenance of the units.

For a more detailed look at Arderia boilers, it is necessary to understand their technical characteristics.

- Heat exchanger. The heating performance of the boilers under consideration increases due to the fact that copper heat exchangers are used in the primary circuit. As for these components of the secondary circuit, they are made of stainless steel.

- Monitoring operating voltage in the control circuit. These boilers have a voltage stabilizer. It supports the correct operation of electronics and allows them to operate over large ranges: from 150 V to 290 V and even more. This function allows you to extend the service life of boiler automation. It is worth noting that all Arderia gas boilers are equipped with a good security system. Special systems monitor excessive heating, current status, disposal of combustion products, and also control unexpected gas leaks.

- To improve combustion capabilities and increase the efficiency of boilers, additional pressurization is used, achieved through the use of a fan. It runs on electric current. Using a fan helps increase the service life of the device.

- Using a Grundfos circulation pump operating on a dry rotor reduces susceptibility to current and also improves the operating conditions of the pump.

Arderia heating boilers use a three-way valve. It is installed so that the optimal heating level is achieved and the pipes are heated evenly. This spare part is most often made of stainless steel or bronze. These materials are durable and have positive reviews among owners.