For installation below the ground surface, it is advisable to use plastic containers that are specifically designed for this purpose and have additional reinforcement.

Situations are different, and sometimes some other container is already available. When installing it, it is important to observe the following rules:

- The concrete base must be level and sufficient in area for the entire container to rest on it.

- The pit must be of such a width that it can prevent direct contact of the soil with the container and pressure on its walls. To avoid deformation, it is placed in an insulating box or lathing.

Important! Filling the tank with soil, sand, or other external pressure is unacceptable!

Underground installation of such containers with backfilling into the ground is strictly prohibited

for the following reasons:

- due to compression by groundwater, due to the pressure of the surrounding soil, the product may be damaged;

- If damaged, there is no information about possible leaks.

Accessories and components

Depending on their functionality, tanks can have a variety of accessories and components.

Many tanks are equipped with a stand and a large diameter screw cap. They may have special holes on the side surface - they are used to connect to the water supply system. This accessory allows the tank to retain its original shape. This is especially true when it comes to plastic tanks. In addition, many containers are equipped with a float valve - it allows you to fill the tank with water automatically.

When filling a storage tank in an autonomous water supply system, a hatch is traditionally used, located on top or connected through the wall in the upper part of the pipeline tank. Bottom connection of pipes to the storage tank is allowed - in this case, a check valve must be installed on it. If necessary, you can order a tank with shut-off valves and other equipment.

Diaphragm accumulator instead of accumulator

A hydraulic accumulator with a membrane is a high-tech descendant of conventional accumulators. His cost is not very humane, but he solves all issues with the supply, supply of water and ensuring pressure independently. The membrane tank is a metal container divided inside into two parts by an elastic bag-like membrane partition. Air or nitrogen is pumped into one part of the tank. Traditionally, the gaseous medium has a pressure of 2 atmospheres, but it can be adjusted.

When the pump operates, water fills the second part of the container, stretches the membrane and compresses the gaseous medium, which, when the tap is opened, pushes water to the points of consumption. When the hydraulic accumulator is filled according to the specified parameters, it automatically turns off the pump. When the container is emptied and there is a concomitant drop in pressure in the reservoir, the automation turns on the pumping equipment again.

The membrane tank is installed in front of the pipeline branches. It can be installed in a well caisson, in a well pit or directly in a bathhouse. At the entrance to the container there should be a check valve to prevent the pumped water from flowing back into the source, and at the outlet there should be a pressure gauge to check the pressure. To remove air from the system, the hydraulic accumulator is equipped with an automatic valve. The membrane container operates in dynamic mode, so you don’t have to get carried away with its internal volumes being too large.

A membrane-type hydraulic tank is a very useful thing in the household, but not cheap. You should not undertake its installation and configuration without having experience in this matter. Incorrect pressure setting may cause diaphragm rupture. The fastening of a device that vibrates during operation must be very reliable. Without knowledge of the technological intricacies of connection, the tank will disturb you with a rather unpleasant sound. But the manual installation of a conventional storage tank for supplying water to the bathhouse is highly recommended and economically justified.

Manufacturing technology

The cost of plastic products compared to steel ones is significantly lower. However, plastic is inferior to steel in strength. The technology used, called rotational molding, helps to obtain seamless products with the same thickness in all places. This technology helps to give products such properties.

- Resistance to temperature changes.

- Chemical neutrality.

- Immunity to UV radiation.

Stiffening ribs give additional strength to the products. Some horizontal models have “legs”, which allows you to install the container on a not entirely flat surface. If necessary, the tank can be buried in the soil, provided that a good crate is made.

If necessary, additional holes can be made in the side of the tank. This makes it possible to simplify the drainage of water and avoid stagnation in the summer if the shower is not used for a long time.

Pros and cons of a storage device

The main advantages include:

- operates at low power, so there is no need for separate wiring;

- you can use hot water from both the kitchen and the bath at the same time;

- ease of operation;

- can be installed at a certain distance from the water intake point;

- the presence of a protective function against overheating; when the extreme temperature value is reached, the automation is triggered;

- to obtain the required temperature, there is no need to change the pressure, since a mixer is included in the package.

Among the disadvantages are:

- dimensions that can take up a lot of space, which must be taken into account when planning housing;

- Once the water is completely used up, it will take time to heat the next batch.

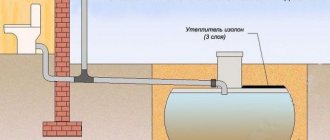

Requirements for septic tanks

Autonomous sewers must meet a number of requirements regulated by legislative documents SNiP and GOST. Errors during the installation process can lead to very disastrous consequences. If sewage flows out due to overfilling or cracking of the tank, the entire area will be filled with a fetid odor, and soil and groundwater will be contaminated. To avoid such troubles, you need to carefully study the requirements for septic tanks.

Sufficient volume. It is highly desirable that the septic tank container holds liquids 4 times larger than the daily surge. Capacious tanks allow residents of the house to freely use the sewerage system, and also provide high-quality sewage treatment. Reliable design. Mechanical loads to which a septic tank is exposed during operation can lead to cracks and damage to the tank. The consequences are very unpleasant. High degree of wastewater treatment. Only wastewater that is 90-95% purified can be disposed of in the soil. Otherwise, soil contamination may occur. Install not one, but two or three wells, arrange a filtration field or drainage well. High temperature resistance. Hot waste coming from the washing machine or dishwasher

It is important that they do not have a destructive effect on the material from which the tank is made. Possibility of operation in the cold season

To prevent sewage from freezing in the sewer in winter, during installation the depth of soil freezing in the region should be taken into account. It is also important to insulate the well. Easy maintenance. Storage-type sewers need to be cleaned as they fill. If you set up a bioseptic tank or a septic tank with soil purification, you will have to call sewer trucks to pump out sludge no more than once every six months.

If you decide to install an autonomous sewer system at your dacha or in a country mansion, do not try to save on everything. This may negatively affect the performance of the septic tank. You can save money once, but the inconvenience will persist for decades, because the sewer system is designed for long-term operation.

How the system works

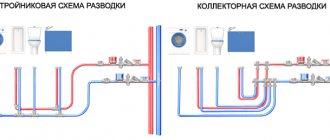

When drawing water from the central main, shut-off valves 23, 24 must be closed, and valves 20, 21, 22, 25 must be in the open position, and the voltage to the pumping station must be cut off by an automatic switch. Water flows through the primary filter and float valve into the tank. When a certain level is reached, the valve closes, and to prevent leakage that may occur if the valve is broken or clogged, the water supply is shut off by valve 25.

When the water supply to the house is stopped, shut-off valves 20, 21, 22, 25 are closed and taps 23, 24 are opened, and electrical power to the pump is restored.

When the mixer is opened, water flows from the receiver, and when the pressure drops to the lower limit (1.8 bar), the automation unit turns on the pump, which supplies liquid from the reservoir to the pipeline and membrane tank. The pressure switch will turn off the pump when the pressure in the discharge system reaches 2.8 bar. Liquid consumption is a cyclical process, and the appearance of water in the city energy network will be signaled by pressure gauge 17.

We will consider in detail the important components of the storage device to determine the installation method and criteria for selecting equipment.

How to choose?

The expert advice is multi-faceted and covers different aspects that need to be taken into account when purchasing this type of product.

For example, recommendations for choosing black or dark blue barrels for storing and transporting water are due to their ability to prevent the liquid from blooming, and if the surface has reflective properties, there will be no overheating from the sun's rays.

The second important recommendation is to purchase containers made of multilayer plastic.

It has greater strength due to the fact that a special stabilizer is added to the top layer, prolonging the period of optimal operation. Considering that barrels can be of different weights, you need to pay attention to this indicator of the product. Sometimes the cost of transporting goods increases due to the weight of the container - additional load on the vehicle, payment of duties at customs and the work of loaders. Based on the labeling, you can choose a type that does not emit toxic compounds.

As for the displacement and design, you need to look for them in the assortment of the outlet depending on the product or drink, your own or production needs.

Operating principle of an electric storage water heater

Equipment of this type operates according to a special principle. The water is mixed inside the storage heater. According to the laws of physics, the warmer liquid rushes up the reservoir. Cold or less heated water accumulates at the bottom; this is the heating zone where the heating element operates. Passive fluid shear ensures periodic activation of the equipment, that is, heating until ready.

For your information! The device has a permanent connection to the network. The load on the heating equipment is controlled through thermostat contacts. Their task is to open the circuit when the water reaches the required degree of heating.

To block inversion (recirculation), a check valve operates in the equipment system. It is this that prevents the heated water from moving in a different direction. Water distribution fittings operate on the outlet line (to the consumer). After distribution by the pipe, the pressure inside the boiler system decreases. The response to this is to open the fill valve to fill the tank with cold water from the tap.

Note! The divider is of decisive importance for the efficiency of an electric water heater. It controls the water mixing process by limiting the speed

Types of tanks

Plastic

Plastic tanks can be given any shape. These can be round barrels or flat containers with a volume of up to 200 liters. They often even carry water in them: the tanks are very light.

The following are the features of plastic containers:

- the water in them remains clean and fresh for a long time;

- they are absolutely resistant to corrosion;

- environmentally friendly;

- UV resistant;

- tolerate temperature changes from -30˚С to +60˚С;

- have a long service life (up to 40 years);

- easy to transport due to low weight;

- quickly installed.

Stainless steel tanks

No matter how good plastic is, many summer residents dream of a tank made of food-grade stainless steel. The shape of the container is like a large flat box. The design for filling water includes fittings and a technical cover.

The drain is located on the side or bottom. A hose and sometimes a faucet or shower head-spray is attached to it. Install the device vertically. This container will last about twenty years.

Undoubted advantages:

- the strength of the material allows its thickness to be reduced down to a millimeter;

- This tank looks solid;

- if the product is coated with a layer of chrome, then the steel is protected from rust;

- The water is fresh, does not “bloom”, and does not acquire an iron taste.

Galvanized steel tank

Steel coated with zinc is very beautiful and is memorable for its original surface pattern.

Zinc reduces the likelihood of corrosion, but not one hundred percent: it is better to paint the product. The configurations are different: rectangular, flat and round.

It holds 40-200 liters of water. Galvanized tanks are usually inexpensive.

They are equipped with a ball valve. Sometimes fittings are installed under the hose.

Black carbon steel tank

Positive aspects of this material:

high strength;

durability;

availability; Dark-colored steel heats up faster on a sunny day.

But all this is covered by one big drawback: black steel is susceptible to corrosion. Rust will eventually damage the faucets and degrade the quality of the water itself. Over time, reddish pieces of rust will begin to appear in the water.

Attention! It is almost impossible to remove rust from clothes. Such water should be used for washing only after settling.

In what cases will a storage tank help out?

For a modern person, it is not enough just to have water in the house. It is necessary that it flows from the tap, and with good pressure for the normal operation of water taps. And in some cases, only a storage tank for water supply built into the system can ensure such work.

What are these cases:

- When there are no sources of water supply on the site or near it, and their installation is impossible. In such a situation, the only possible water supply is a storage tank, which is periodically filled from a tanker.

Water supply scheme with imported water

- When the house has a centralized water supply from a city or village network, but water is supplied with frequent interruptions or according to a specific schedule.

In case of frequent outages, water supply from storage tanks will help out

- When you have your own well or well, but they have a low flow rate and cannot meet your needs at any time, because the water in them disappears during long-term continuous intake.

Scheme of water supply from a well with insufficient flow

- When there are frequent power outages, without which no pump can operate.

In this case, there is only one way out: a gravity water supply system from a storage tank installed on a hill

In any of these situations, the supply of water accumulated in the tank earlier will allow you not to experience discomfort from its absence from several hours to several days. This depends on the volume of the container, the number of users and the usual consumption.

Reasons for the formation of condensation on the tank

So, why does condensation form on the tank in the first place? Everyone knows that the appearance of condensation is typical not only for toilet tanks, but also for glass on windows, drinks in the refrigerator in glass containers, etc. And the reason for this in many cases is the same - warm and/or moist air in contact with a cold surface.

As a result, the air, cooling, loses its ability to hold the water vapor it contains. As a result, steam falls onto the cold surface in the form of moisture and is condensate.

Poor ventilation in the bathroom is one of the main reasons for the accumulation of moist air and the formation of condensation. When normal air circulation is restored, the problem will disappear by itself.

Below is a table showing a clear dependence of the appearance of the dew point (the moment when condensation forms) on the parameters of air temperature and humidity, as well as the temperature of the surface on which moisture collects.

Table of dependence of the appearance of condensation on humidity and temperature in the room

For example, if the air humidity in the bathroom is 75% and its temperature is 25 degrees, condensation will appear on the tank, whose temperature is 20 degrees or lower.

Norms for the distance of treatment facilities on the site

According to SNiP, treatment facilities and pits must be located at a considerable distance from the house, water well and other engineering facilities.

- From a residential building - at least 5 m to a septic tank, VOC, cesspool to avoid unpleasant odors entering the room. And also prevent in advance the possible disastrous consequences of the influence of a humid environment on the foundation of the house.

- It is 30-50 m to a water well. Of course, it is very difficult to follow this rule, since the size of the plots is very limited. It is still necessary to remove the septic tank from the water supply system as much as possible, to the extent technically possible.

- To the borders of the neighboring plot - at least 2 m.

- From the collector to plants and trees - the location is 2-4 m if the tree roots are large.

Why does strong condensation form?

Condensation on the toilet flush tank appears as a result of condensation of water vapor that is present in the air. It condenses on surfaces that have a temperature lower than the dew point temperature. This happens because the air, when cooled, can no longer hold the same amount of water vapor in a gaseous state and condensation occurs. In addition to temperature, the relative humidity of the air has a direct influence on the condensation process. As humidity increases, the risk of condensation increases. Unfortunately, determining the humidity value is difficult to predict at the design stage of a bathroom ventilation system.

During construction and renovation, we widely use insulation to reduce energy losses caused by changes in the temperature of the transported medium, when the ambient temperature differs from the temperature inside the system. In the case of devices with average temperatures below ambient, such as a toilet flush cistern, insulation has another very important function - it prevents condensation from forming on the surface of the device.

Optimal operating mode of an electric boiler

Setting the temperature to the minimum permissible is highly not recommended for the following reasons:

- Reduced efficiency of water heating equipment;

- Liquid temperature 30-40⁰ C is an ideal environment for the formation and proliferation of bacteria and mold, which inevitably end up in the water;

- The rate of scale formation increases.

These devices are often equipped with an economy mode option, designated by the letter E. This operating mode means heating the liquid inside the capacitive tank to a temperature of +55⁰ C, which allows you to extend the period of use before maintenance. That is, at a given temperature regime, scale forms the slowest, and accordingly it is necessary to clean the heating element less often. This does not apply to energy savings.

Varieties

Storage tanks are classified according to several criteria:

- container shape: round, cylindrical, rectangular, non-standard;

- design: open and closed;

- material: plastic, stainless steel, metal, polypropylene;

- internal capacity: 7, 20-30, 50 liters, as well as large containers of 80, 100, 200, 250, 500 l;

- purpose: for hot water supply with electric water heaters, for cold water supply, for heating and irrigation systems;

- installation method: vertical and horizontal placement, indoors and underground, wall-mounted.

Shape and volume

When calculating the capacity of the storage tank, the following factors must be taken into account.

- Liquid consumption rate: everyone consumes water differently, so it is impossible to recommend specific values. For approximate calculations, you can take average values.

- Productivity of the main water source. Much depends on the amount of liquid that comes from the source.

Materials

The storage tank is made of stainless steel or food-grade plastic. The material must be of high quality, otherwise drinking water will contain various toxic chemical elements harmful to human health.

Installation methods

Installation of the storage tank is carried out in stages:

- preparing the base for a water tank;

- installation of a storage tank on the base;

- installation of a float valve;

- making holes for pipelines;

- insertion of shut-off valves;

- installation of an overflow pipe, which is discharged into the sewer and secured to the walls of the tank;

- the connected tank is checked for leaks;

- insulation of the tank using polystyrene or mineral wool.

Let's take a closer look at the design features of the tank.

- The suction pipe must have a float valve. In the event that liquid is pumped from a well, a float switch is used.

- If the float breaks, an overflow pipeline is cut below the suction pipe, which leads to the sewer system.

- A filter element is installed at the suction. They are available in several types: mesh, centrifugal filter-pumps and cyclones. A mesh filter is installed when pumping exclusively clean water, while others are used for dirty water. It is recommended to install a mesh on the discharge line.

- In tanks with opaque walls, level gauges are installed to determine the remaining volume of water.

- Care must be taken to remove sediment. Underground tanks are cleaned through the top hatch. Top-mounted tanks have drainage pipes that cut into the bottom of the vessel.

- The reservoir is filled using a shower head or watering can, which will avoid mixing clean water with sediment.

- A ventilation pipeline or blowhole is provided at the top of the container. It is bent in such a way that the inlet pipe is located at the bottom. A mesh is installed at the inlet of the blowhole to prevent clogging from entering the tank.

Classification by purpose

Typically, the location and installation option is determined precisely by the purpose of the water.

Liquid reserve capacity

The reservoir can be installed in any part of the dacha area where water supply is most often needed. This can be a special container for drinking water, which is located near the house, or a container for liquid, which is used for watering, car washing, laundry and cleaning, etc.

Rainwater container

A more highly specialized product that does not necessarily have to be of very high quality. Similar products are installed near houses or other country houses, where a drainage roofing system collects rainwater and directs it through gutters into a special compartment or an entire tank. The purpose of water in this case is very diverse - washing, watering ornamental plants, and so on.

Storage capacity

These can be iron, steel, plastic and other tanks that are installed near greenhouses. The purpose is clear to everyone, because if drip irrigation or ordinary watering does not work for certain reasons, the plants will not need to wait for the system to be repaired or the water supply to be restored, because watering can always be organized from such a storage facility.

Tips for choosing

When choosing tanks for a shower, for a dacha, or just for a garden plot, you should take into account their size. They are available in volumes of 50, 55, 100, 128, 150, 160, 200 and 250 liters. The most popular options are 100 and 150 liters.

When choosing a tank, it is worth taking into account the heating rate of a certain volume of water. Here we should also assume that an adult will need approximately 50 liters. It is clear that smaller tanks heat up faster than larger tanks.

It is also important to take into account that the less the tank weighs, the easier it is to install

The weight of the tanks directly depends on the thickness of the walls of the product. If you choose a tank of significant weight, then you will have to install it using special fasteners. Before purchasing, we recommend that you familiarize yourself with the types of containers. The tanks are produced in vertical and horizontal versions, which is important for taking into account the fasteners for an already purchased booth.

There are also ways to heat tanks:

- using central water supply;

- solar energy, for a dark metal base;

- local heating systems;

- electric heating device.

Plastic options are cheaper; these tanks will last at least 10 years with careful care. It is better to remove them before the frosty winter. Of course, metal tanks will last longer, but they absorb more heat during heating.

The criteria for choosing tanks are:

- significant variability in their configurations, materials and dimensions;

- long service life;

- ease of removal from sediments;

- power of heating elements;

- ease of installation;

- strength;

- affordable prices (purchasing from catalogs without extra markups will be more economical).

Expensive imported versions have a special coating that prevents the formation of scale. This coating is applied to the tank heater - the shower is comfortable, but the water becomes harder.

The weight of the tank is important to consider, especially if the tank is supposed to be installed on glass - a combined heating option. You shouldn’t overpay – make a rational choice. If you have a good understanding of the topic and purchase parameters, you can easily avoid mistakes. The force of water spray from the divider directly depends on the configuration of the tanks and their volume

For supporters of slowly flowing water, a plastic tank (up to 40 l) will be a convenient option. This option will be comfortable for swimming in summer in slightly warm water. Vertical tanks of significant volume provide a strong stream due to the significant pressure of the water column. And if the family is large, then you should select a tank with a volume of 150-200 liters. It is worth considering that not all cabins or glass roofs can withstand such weight. The planned consumption volume of water is calculated at the rate of 50 liters per adult, plus another 30-50 liters of reserve (for those who like to splash around). When purchasing a tank, do not forget about the “breathable” lid for it, it will prevent the appearance of “blooming” water. Compact heated tanks are easier to install and easier to clean. Metal containers are popular and can have different configurations - from flat products to round, barrel-shaped, cylindrical and cubic. Metal tanks are stronger than plastic ones; they have a higher level of resistance to mechanical stress. For example, extreme hail can damage a plastic product, but not a metal product. Metal is less aesthetically pleasing, but fully satisfies the needs of consumers.

Steel containers made from metals with different characteristics are more durable:

- carbon steels;

- galvanized alloys;

- stainless steels.

Often products combine combined heating options. The advantage of such devices is that the liquid does not stagnate in them. Their price tag is higher than their plastic counterparts, but they are completely worth the cost.

The dilemma is galvanized steel or ferrous metal. Any bulk container of dark colors lying in the sun heats up the liquid relatively quickly - the physical parameters of dark surfaces are triggered. During warm times, heat is retained in tanks heated by the sun's rays, so they are often produced without heaters.

A dark steel tank located on the roof will be the most economical option since it works autonomously.

Galvanized products usually last up to 6-7 years, during which time there is no need to worry about corrosion. But they also lose their qualities, usually in the seam area. However, during this time they quite manage to justify themselves. These tanks are affordable in price, however, flat plastic tanks provide them with worthy competition. Often, thrifty summer residents give preference to expensive, durable products that can last for several generations.

Indirect heating boiler - what is it?

To heat water, indirect heating boilers use heat from the home's heating system.

A little higher we looked at the design of an electric water heater. Now we will talk about indirect heating boilers. What are they and how do they differ from electric models? Indirect heating boilers operate from heating systems, taking some of the heat from them. Inside them there are coils, characterized by a large area - they provide rapid heating of water. There are also thermostats and thermometers.

Indirect heating boilers are highly efficient and productive, since the area of the heating elements (coils) is quite large, and heating is carried out throughout the entire volume. How to get hot water in the warm season, when heating systems no longer work? To do this, you need to purchase or make an indirect heating boiler with a built-in heating element - it will provide water heating when the heat from the heating system is not enough.

Some indirect heating water heaters do not have complete heating elements, but are equipped with flanges for their installation. The heating elements themselves are purchased separately.

Household indirect heating boilers are highly economical, since in the winter they do not consume electricity, but are powered by heating systems. At the same time, connecting them to heating does not lead to noticeable gas consumption, which is a big plus.

Types of plastic containers

The following types of water storage tanks are distinguished by shape: rectangular horizontal and vertical, cylindrical vertical and horizontal. These shapes allow you to install plastic tanks almost anywhere, even in limited space.

These products are also classified depending on the purpose of their use. The most common categories are:

- With index L. They are located inside buildings, in limited space. They are small in size and light in weight.

- With index S. They are installed not only in the building, but also on the street. Used for storing drinking and industrial water.

- With index T. These vertical containers are used in case of high consumption of water resources. Low-density polyethylene is used for their production. They are divided into two classes by volume: from 100 to 750 liters and from 2000 to 10,000 liters.

- With index H. Horizontal tanks, the volume of which reaches 8000 liters.

- For shower. These vessels are used for arranging a shower in a summer cottage. Their volume is only 150-200 liters. They are equipped with fasteners, a valve for air intake, and a fitting for connecting to a shower head.

Plastic water tanks differ in color. The most common colors are blue, black and green. Color has a specific meaning:

- blue shades of the walls prevent the penetration of sunlight, so the chemical composition of the liquid does not change;

- black color, on the contrary, attracts the rays of the sun, providing additional heating of the liquid filling without changing its qualities. Often used to store process water for irrigation. Ideal for summer showers;

- Green shades are ideally camouflaged in the garden without standing out from the overall picture. The properties of the water resource do not change; the sun's rays pass through, but do not attract.

According to the place of installation, plastic containers are divided into two groups: above-ground and underground. Each of these groups has certain advantages and disadvantages:

- Above ground tanks are characterized by their simple shape and ease of installation. However, they take up space on the site, require insulation in winter, and in summer shadow from trees or buildings may fall on them, or they themselves can become a source of darkness for plants. Small vessels can be placed in the attic.

- Underground tanks do not take up site space, do not require insulation in winter, do not create shade, and UV rays do not penetrate into them; therefore, the quality of the water does not change. But they are characterized by the complexity of installation and high installation requirements. For example, to place a product with a volume of 300 liters, you will need to dig a large pit. In addition, the surface for placing the container must be flat and hard, that is, the bottom of the pit must be concreted. A small tank can simply be buried in the ground.

When choosing between above-ground and underground methods of installing a plastic container, you need to take into account the area of the site. If the area allows, it is better to place the above-ground tank

This is easier and cheaper to do.

Features of installing a water tank

In addition to choosing the most suitable water container, its correct installation is of great importance. Incorrect installation of the vessel can cause problems during its use.

- First, determine where to place the container - on the ground or underground.

- Depending on the installation location, choose the type of tank - above-ground or underground.

- If you choose an underground tank, it is better to place it near the water supply system.

- Small volume ground products can be placed on a tower or platform.

- If you want to install a large tank, you will have to mount a durable stand. Alternatively, you can install them in the attic.

Advice! After installing a plastic water tank, you should periodically drain the liquid and clean its walls of deposits using a mild detergent.

Thus, plastic water containers are an easy way to provide your home and site with a supply of technical and drinking water. Such tanks are indispensable in dachas, garden plots, and private homes. They do not corrode, do not interact with liquids, are easy to install and last a long time.

Installation of storage tanks

The container is lowered using lifting equipment

Installing a container made of different materials comes down to one thing: you have to dig a hole. But the installation is slightly different due to the use of different materials:

- To install a container made of metal barrels, dig a hole with a diameter slightly larger than the barrel. To increase the volume of the container, the barrels can be welded vertically with each other. Moreover, you leave the bottom only in the lower barrel. Measure the depth of the pit according to the height of all welded barrels. Place a 10-15 cm sand cushion at the bottom of the hole. As you know, metal tends to rust and rot. Therefore, to protect the structure from exposure to water, cover the barrels with bitumen or paint before installation. Place the finished container in the hole. In the side of the barrel where the sewer pipe will enter, cut a hole to fit the diameter of the pipe. Insert the pipe into the barrel and seal the joint with sealant. Now you can fill the gap between the walls of the barrel with the pit. As the soil is poured, compact each layer after about 25 cm. Cover the top of the container with a lid with a hatch.

- Installation of a container made of concrete rings is carried out on a pre-concreted bottom of the pit. Lower the concrete rings into the hole using a truck crane and seal all joints with silicone or cement-based sealant. Waterproof the outer walls of the rings, install sewerage, and fill the gap between the walls of the container and the pit with earth. Place a reinforced concrete cover with a hatch on top. It should protrude above the ground.

- Installing a plastic container follows the same principle. Dig a hole larger in diameter than the container, about 10-15 cm on each side. Measure the depth to the neck. It should be above the ground. The bottom of the pit can be made of a sand cushion, as mentioned above, but there is one problem - plastic is a rather light material, so in the spring, with the rise of groundwater, the container can be pushed out of the ground. The best bottom option for a plastic container may be concrete. The bottom of the pit is concreted along with anchors. When the concrete has hardened, install the container, tying it with straps to the anchors. Connect the sewer and seal the pipe entrance. Backfilling is done in layers of 20-30 cm. As you backfill, fill the container with water so that the pressure of the earth does not crush the soft walls of the plastic. You can fill it with a mixture of sand (6 parts) and cement (1 part), compacting each layer. Place the lid on the neck of the container and the job is done.

- To build a container made of brick or cinder block, dig a hole in the shape of the future container. Concrete the bottom and lay out the walls in a checkerboard pattern. Waterproof the walls with hot bitumen both inside and outside. Make a sewer line and fill the gaps with earth. The top of the container can be covered with sheet metal or knocked down wooden panels.

- A small storage tank can be built from old car tires. When laying them on top of each other, pour bitumen between them to seal.

From tires

Horizontal storage tank Flotenk

As you can see, installing a storage tank is a fairly simple process and can be done by every owner of his own yard. The best option for installation from the containers described above is plastic. It is lightweight, compact, easy to transport, and most importantly, has the longest service life. Watch the installation video provided and follow the instructions to get to work.

What is needed to purchase and install the structure

By and large, it is you who determine this, because when purchasing a tank, you choose the amenities yourself.

You can buy a used container, say 1000 liters, install it near the house and simply take the liquid from there with a bucket or drain it using a tap installed at the bottom of the container.

But there is always an option to make getting water more convenient. For example, install a container in the garage or even in the attic, arrange water intake from the container or its independent drainage (which is cheaper), equip the directions for the flow of liquid, arrange an inexpensive water supply system, and so on.

As you understand, there are no difficulties in choosing the material and shape of the product, as well as in choosing its color; you just need to determine the purpose of the water and choose a container specifically for it.

Manufacturing technology of plastic containers

Thanks to the production technology of polymer containers, they can store technical and drinking water for a long time. Therefore, they are in demand both in summer cottages and for farming in a private home.

Water tanks are produced using seamless technology. The material for production is plastic in sheets, which, according to international quality criteria, is environmentally friendly, safe and durable. It is convenient when creating products, as it is easy to cut and weld.

Plastic water containers, unlike metal barrels, are suitable for storing aggressive substances without additional processing. They are lightweight, practical, durable, do not require periodic maintenance and repair of seams

To make tanks, sheets of plastic are heated, shaped into the desired shape and secured together by seamless welding using welded rods.

The heated material is plastic and easy to mold. Therefore, at this stage, additional parts are installed.

Depending on the purpose of the storage tank, it can be equipped with:

- fittings;

- bends;

- flanges;

- shut-off ceilings;

- pumps;

- handles for transportation;

- drain;

- heating element;

- stiffening ribs;

- legs.

After giving the product the required shape, the finished tank must cool. After hardening, it is sanded in places where sheets are joined and additional elements are installed.

Polyethylene water tanks do not have a negative impact on humans and are safe for the external environment, and their affordable cost is an additional argument in their favor

Polypropylene containers must be purchased in accordance with their intended purpose, therefore, before choosing a container for the dacha or for agricultural needs, you need to decide on the package.

At the customer's request, the tank can be equipped with additional accessories:

- float to visualize the liquid level;

- galvanized metal frame for added strength;

- cover and tray, for outdoor use;

- lid with an air valve to preserve the properties and freshness of drinking water.

Conscientious manufacturers use certified equipment and materials. The consumer, in this case, receives the product without additional seams, from a material of a homogeneous fraction. Such a product will be durable, environmentally friendly and reliable in operation.

The performance properties and service life of plastic water containers depend on compliance with production technology and the quality of materials.

Violation of technology during the production process reduces the service life of plastic tanks. Some products are initially unsuitable for use. To avoid such troubles, the company must issue a quality certificate for the product.

Recommendations before purchasing a water tank

Before purchasing a tank, you need to decide on the purpose, location, volume and material of the tank, and select a manufacturer based on:

- the presence (or absence) of a certificate of conformity of products to the requirements of standards (current) and/or specifications developed on their basis, and ideally additionally – quality management of the ISO 9000 family;

- the presence (or absence) of a portfolio of products delivered to the sites;

- a range of additional services - installation work, transport delivery, information and advisory support, technical support;

- the stated warranty period for the product.

When accepting the tank at the facility or at the point of sale, you need to check the surface of the tank for defects defined in the current GOST 24105 - scratches, cracks, chips, “silvering”, cavities, bubbles, turbidity, uneven texture, burrs, warping, etc. .

Types of plastic tanks

Storage containers for water made from polymers vary in shape, volume, color, material and purpose. When choosing a suitable tank, it is necessary to analyze which characteristics of the product will be optimal for meeting household needs.

Material for production

Light polymers are used to make containers: polyethylene and polypropylene. Polyethylene products are used in everyday life for storing drinking and industrial water.

Polypropylene tanks are suitable for use in industrial enterprises and factories. Dense, stable containers for technical and chemical liquids are made from polypropylene sheets.

Tanks with smooth, thin walls cannot be called particularly durable, and if you need a structure that is resistant to deformation, choose tanks with thicker walls and stiffeners

Plastic barrels for drinking water are made from pure food-grade polyethylene. This material ensures the preservation of the chemical composition of water and prevents the proliferation of putrefactive microbes and bacteria.

There is a technology where the base material is coated with a special antiseptic coating on the inside of the tank. The inner, white layer protects the liquid from blooms and bacteria, and the outer, blue, creates a barrier to the penetration of sunlight.

To treat double-layer drinking water storage tanks, abrasive cleaning agents should not be used so as not to damage the integrity of the thin coating.

Difference between containers by color

Polyethylene containers are available in four colors: white, blue, green and black.

Blue tanks are universal and are used for storing food and process water outdoors and indoors. Since the dense layer of dark blue plastic does not transmit UV rays, water, even after long-term storage, does not lose its chemical properties and does not bloom.

Green polyethylene containers are similar in properties to blue and dark blue products. The choice of a green or blue tank is based on the personal preferences of the buyer.

Green water containers look harmonious in the front garden, garden and vegetable garden, therefore they are often used for watering

White canisters should be stored indoors without natural light, as light-colored plastic does not protect the liquid from possible reactions. White tank walls have an advantage over colored ones only in that you can control the amount of liquid in the tank.

Black containers are intended for watering or for arranging a summer shower. Such products do not transmit UV rays and get very hot in the sun. Therefore, underground tap water quickly heats up and becomes suitable for bathing and watering garden crops.

Storage volume and shape

Storage containers have different capacities. The smallest ones hold 20 liters of water, the largest ones – 10 tons.

To transport drinking water to the dacha, it is advisable to purchase containers with a volume of 20-50 liters. To equip a summer shower, tanks of 100-200 liters are in demand.

If the supply of tap water is unstable, then a container with a capacity of 1000-2000 liters is suitable for irrigation and domestic needs.

The wall thickness of containers with a volume of 20 to 1000 liters ranges from 4 to 6 mm. For tanks from 2000 to 10000 liters, from 6 to 10 mm

Tanks for 3, 5 and 10 cubic meters of water are used for industrial purposes and for transporting liquid and bulk cargo in special vehicles.

Polypropylene water tanks come in various shapes. Therefore, both the cottage owner and the summer resident will select the best option for the bowl, based on the capabilities and purpose.

Cylindrical tanks take up minimal space, so they are used in bathhouses and homes.

Rectangular universal containers for storing liquids can be located underground and on the surface. A vertically standing rectangular tank significantly saves space.

Cubic tanks have a large volume and a wide neck opening for easy filling. When installing the bottom tap and installing the barrel on the podium, complete drainage of water is possible.

To equip a summer shower, you should purchase horizontally oriented tanks made of black plastic to increase the natural heating surface

Flat elliptical or elongated conical tanks are installed on the roof of a summer shower. The shape, when the lower part is wider than the upper, allows you to increase the pressure of the liquid. For ease of filling, such containers are equipped with a wide neck opening.

This variety will allow you to install a water container in any free corner without losing useful space, even if the country house or plot has a small area.

Installation of the product at the dacha

You can use products of various configurations and technical specifications, but even before purchasing you need to understand where the tank will be installed. The location is selected based on the ease of use of the reservoir.

At the moment, several options are offered - ground tanks, suspended, underground tanks, as well as those installed on special platforms, towers, and so on.

Operation and Maintenance

In order for the barrel to serve for a long time and perform its functions, it must be properly operated and maintained in working condition.

Prevention measures:

- clean from dirt, debris, algae formed as a result of long periods of idle water;

- check for leaks;

- treat metal barrels with an anti-corrosion compound to prevent rust;

- Drain the water before frost sets in so that it does not freeze, as the resulting ice will deform the container.

Advantages

Plastic water containers have the following advantages:

- safety;

- tightness;

- no harm to the environment;

- long service life (up to 30-50 years);

- the ability to store not only water, but also any bulk food products.

In addition, plastic water containers are not subject to corrosion. They are resistant to heavy loads and sudden temperature changes. Plastic tanks are not afraid of severe frosts. They don't need painting or primer.

If plastic water tanks are sealed with metal rings, they can withstand enormous loads. Thanks to modern technologies, plastic containers can be made in different shapes and sizes. Another important advantage of plastic tanks is their low price. For the manufacture of such tanks, depending on their purpose, food or technical plastic is used.