The operating efficiency and service life of an air conditioner largely depends on the quality of its installation. So, it is fundamentally important to choose the right pipes for the freon main and carefully install the connections.

Copper pipes are intended for air conditioning systems. The requirements for them are specified in the ASTM B68 standard. It is fundamental for all domestic metallurgical companies. Foreign manufacturers are guided by DIN and ISO standards.

In addition, each manufacturer, in the documentation for the equipment, gives recommendations on what material should be used during the installation process. If the installation regulations are not followed, the equipment may be voided from warranty.

Laying a freon line is a responsible and labor-intensive process on which the performance of the system depends

How to disassemble and wash the indoor unit

The cleaning process is proposed to be considered using the example of a Korean Daewoo split with a power of 18 kBTU or 5.3 kW. What you will need for work:

- flat and Phillips screwdrivers;

- alkaline-based cleaner Carlyclean or similar in a container with a hand sprayer;

- a special polyethylene cover with a water drain, made to fit the dimensions of the indoor unit;

- latex gloves;

- another hand-held sprayer to rinse off the cleaner.

Location of fastening screws

To thoroughly clean and disinfect all parts of the internal module, you need to disassemble it in the following order:

- Unplug the air conditioner, remove the filters and wash them. Remove the plastic blinds by carefully bending the ends out of their slots.

- Unscrew all screws located on the front panel. They hold the electrical compartment cover, the panel itself and the condensate tray. Some of them are located under decorative plugs.

- Pull the front panel towards you and tilt it up to disengage the 4 top latches. Do not remove it until you have disconnected the LCD connector located on the right side.

- Mark with a marker the position of the servos that rotate the blinds, then unscrew and remove them. Release the retainer of the condensate tray (held by its left end) and disconnect the drainage tube. After this, the element can be easily dismantled.

- Pull out the temperature sensor inserted between the evaporator fins and bend it towards the electronic unit. Protect the latter from water with a plastic bag, as shown in the photo above.

Cover with drain prevents wallpaper from splashing

If you are servicing your home air conditioner for the first time, the disassembly procedure will take approximately 1.5-2 hours. This gives you access to the fan turbine and the cavity behind it, which also needs to be cleaned. Then everything is simple: pull the cover over the module, sliding its edges between the wall and the body, then start cleaning the “split”:

- Wear rubber gloves and thoroughly apply cleaning fluid to the heat exchanger, fan drum and internal cavities. At the same time, rotate the turbine with your free hand.

- After 5-10 minutes, take a water sprayer and wash off the product along with the dirt. You need to spray until clean water runs out of the block.

- Wait until all the water has drained out of the indoor unit, then remove the cover and let the unit dry.

- Wash the removed panel, bath and filters and dry them. At the same time, try not to wet the foam seals. After drying, the air conditioner can be assembled.

This is what the turbine and heat exchanger look like after flushing

Watch this video on YouTube

Production

Copper is a very ductile material, and copper pipes are made without welding.

Industrial methods for the production of seamless pipes: drawing, rolling, pressing, combined methods. Very rarely, thick-walled products are produced by welding. In practice, rolling and drawing are most often used.

Large-sized products are produced in several stages with intermediate heat treatment. After manufacturing, the pipes are necessarily annealed (heated, held for a certain time and cooled together with the furnace). After annealing, the structural stresses that appeared as a result of manufacturing disappear in the metal.

How to clean the indoor unit of an air conditioner

How to remove an air conditioner from a wall (and is it necessary to do so)

As a rule, there is no need to completely remove the air conditioner from the wall when cleaning. It is enough to remove its individual parts - the top covers, the fan - to gain direct access to the heat sink and other “internals” and clean them. As mentioned above, it is advisable to use a special service package or any other package of suitable size and strength so that all debris and dirt fall into it during cleaning and not onto the floor and walls.

How to remove the cover

Before you begin disassembling the indoor unit, you must disconnect the air conditioner from the power supply. To open the front cover, study the design of the case, there are three main options:

- Clips at the bottom. With this option, the lid tilts up. The most common option.

- Clips on top. Quite a rare option.

- Clip-free design. The front panel tilts forward and then the lid lifts up.

How to disassemble the indoor unit

- After the outer cover is removed, we take out the coarse filter (looks like a lattice mesh), then proceed to the body of the internal device. The block has self-tapping screws underneath the blinds; most often they are located under decorative plugs. We unscrew these screws.

- Under the cover of the indoor unit, where the filters are located, there may also be screws or clips - unscrew/snap them off. Carefully open the lower part of the case.

Cleaning the filter

After the filter is removed, it must be washed with cold running water; if the dirt has become too ingrained, you can place the filter in warm soapy water and let it soak for half an hour.

Afterwards, rinse with cool running water again and let dry naturally. It is not recommended to dry filters using a hair dryer, heater or other devices.

Radiator cleaning

The function of radiators is to change the temperature of the distilled air. Visually, it is one large plate consisting of many smaller ones. Dust between them can be removed with a soft brush; for deeper dirt it is better to use a vacuum cleaner. It happens that grease mixed with dust accumulates on the radiator, which can be cleaned with a stationery knife, but everything is done very carefully. Then you need to rinse the radiator with water.

Cleaning the fan

There is a fan under the radiator. This is a shaft with a blade that supplies air to the room. Severe contamination can lead to failure of the entire device.

To avoid this, you need to spray a special detergent onto the fan cavity.

After waiting for some time, the fan turns on at low speeds, the dirt mixed with the product begins to blow out, so it is important to use the service package. Next, remove any remaining dirt with a brush. When cleaning the fan, you need to be extremely careful not to damage its blades.

When cleaning the fan, you need to be extremely careful not to damage its blades.

Cleaning the heat exchanger

This is one of the most important parts of the air conditioner. For good heat transfer, the plates must be in contact with air flows; contamination of these plates significantly worsens this contact and, as a consequence, heat transfer. To clean a not very dirty evaporator, it will be enough to remove dust from the plates; for more complex situations, you will have to use a steam cleaner or vacuum cleaner.

Types of pumps

There are many different types of sump pumps on the market. Each of them is designed for a specific air conditioner. Most of them have a similar structure:

- condensate collection tray;

- drainage route for transporting liquid;

- drain pump for air conditioning, designed for pumping liquid.

Devices equipped with a special container for condensate, equipped with a pump and a level sensor, are called “bulk”. They are a unit with an installed level sensor and can work autonomously as the container is filled.

Liquid flows into bulk (storage) pumps by gravity, so they must be installed in any convenient place slightly below the level of the drain tank.

One such device can be used to service several air conditioners located close to each other. Equipped with large capacity storage tanks.

Peristaltic devices are devices that are capable of pumping water directly from the fan coil drainage tank.

Such devices use powerful pumps that can lift liquid from a level lower than the unit itself. Such devices are called “membrane” or “peristaltic”.

Separate pumps are pumps consisting of several compartments connected to each other by control lines and pipelines. They consist of a pump, a water level sensor communicating with a storage tank and, in some cases, a control device. Some devices are not equipped with a level sensor and to turn it on you need to use the “cold” mode on the air conditioner.

Split pumps, due to their unusual design, provide more options for their placement. So, they can be installed on a hose, drainage pipe or inside storage trays.

The standard place for its installation is considered to be a separate block connected to a flexible tube or storage tray.

Built-in pumps are a mandatory element of the standard structure of cassette or duct split systems and air conditioners from leading manufacturers.

They are installed directly inside the drain container on the drain hose for the air conditioner or the outlet pipe. Such a pump includes a control device, a level sensor and a pump located at the water level or slightly lower.

Purpose of the drain pipe in the air conditioner

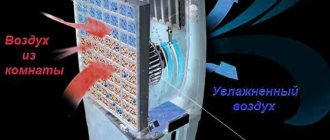

Condensation is an integral part of the effective operation of an air conditioner. Its appearance is explained by the operating principle of the split system itself. In summer, when the air temperature is high, air conditioner owners try to cool their houses and apartments with the help of air conditioners. The split system itself, or other types of equipment, effectively copes with its task with the help of refrigerant. Most often it is freon.

The operating principle of an air conditioner is based on air cooling. It is with the help of freon, which circulates in the compressor-condensing unit along copper lines, that the temperature decreases. Since the condenser part with the heat exchanger of the equipment is always located outside, this is where the collision of “hot” with “cold” occurs. Droplets of liquid actively accumulate on the surface of the condenser, which can harm the operation of the air conditioner if they are not properly disposed of.

It is important that condensate disposal does not disturb other people (in multi-storey residential buildings). The tube should be located away from windows and walls, as it can damage the integrity of the structure itself

And the best option is to connect the drainage to the sewerage system. But this method has no disadvantages. But only owners of private properties can organize it.

The tube must be routed as far as possible from the walls of the house

Areas of application

There are several situations when it is better to choose this material:

- The current option for installing a heating system made of copper pipes is connecting to a solid fuel boiler. This is due to the fact that such systems are exposed to prolonged exposure to high temperatures (over 100 degrees Celsius).

- Compared to other materials, copper is better if it has a complex shape.

- Installation will be 100% justified if the owner of the house has enough money and wants to get the highest level of durability.

When considering other options, you need to pay attention to plastic or stainless steel

Drained air conditioning system – Cold at home

29.05.2019

Repairing air conditioners requires special knowledge of the principles of operation of the internal components of the structure.

Proper operation of the units is ensured, among other things, by the air conditioner drainage system, which is designed to remove condensed moisture from the air.

The air conditioner drainage system is a soft corrugated tube through which moisture flows into the drain pan, into the street or into the sewer.

If there is excessive accumulation of moisture, the pan overflows and the room smells of stagnant water. Often, in order to reduce the likelihood of breakdown, the drainage pipe is placed outside, but in this case water gets onto the facade of the building, window sills and passers-by.

Therefore, it is better to direct the tube into the sewer using a special drainage pump. To ensure natural water flow when installing a drainage tube, a slight slope of 5-10 mm is used. If tilting is not possible, drainage pumps are used.

Air conditioner repair: faulty air conditioner drainage system

A malfunction of the drainage pipeline leads to a malfunction in the air conditioning system. Repair of air conditioner units from which water flows consists of reinstalling the entire drainage or replacing the pump and its components. The cause of a leak may be clogging with dust, pinching or rupture of the drainage pipeline.

Clogged pipes are cleaned with powerful pressure or high pressure using special equipment. To prevent blockages, the drainage pipe must be equipped before the onset of cold weather with a heating device or heating cable, the power supply of which is continuous and independent of the main circuit.

The pump is equipped with a self-diagnosis system, which, when the water level is exceeded, sends a signal to turn off the air conditioner, which greatly facilitates its repair.

Air conditioner repair: evaporator icing

Repair of air conditioners in case of icing of the evaporator and penetration of ice into the drainage hole begins with identifying the causes of icing. It can be caused by a decrease in freon pressure in the system and its leakage. Dirty fan and filters lead to insufficient air flow to the evaporator.

In these cases, repairmen clean the fan, evaporator and filters, and fill the freon leak. Incorrect drain configuration and increased levels of air pollution also lead to clogged drainage systems.

Specialists flush the drainage channel and clean it with antibacterial and antifungal agents, and there is no need to disassemble the air conditioner.

How to clean an air conditioner drain pipe: clogged and cleaned

How to clean the air conditioner drain pipe

Many owners of split systems have encountered such a problem as air conditioner leakage. Water usually drips from the indoor unit of the device. It’s good if it just leaked onto the floor and didn’t spill over your expensive furniture or equipment.

Another problem that can occur due to condensate leakage is a short circuit if water gets into an outlet or a switched-on household appliance. What does this come from? Most likely, your air conditioner drainage system is dirty. Water cannot flow out through the tube and therefore flows inside, into the apartment.

In this article we will cover in detail the question of how to clean the air conditioner drain pipe and the entire drainage system.

How to properly clean your air conditioner drain system

Most modes of household air conditioners and split systems operate in a fully automatic mode and do not require user attention, with the exception of the drainage system

Drainage system, how to use it and how to maintain it

The operating principles of any refrigeration unit, including a household air conditioner, imply that in the process of cooling the air a certain amount of condensate, that is, water, should be formed.

And water, as you know, tends to seep into any openings, and is also an excellent conductor of electricity.

To collect accumulated condensate, a special plastic bath is provided in the internal block of the split system with a drainage tube connected to it, through which the water naturally flows, according to the laws of gravity, into the sewers or directly onto the street.

Pipes for air conditioners made of copper - sizes, diameters

Currently, copper pipe manufacturers offer a wide range of products that differ in various geometric parameters. The main characteristic for choosing the required product is its diameter. It is this indicator that determines how quickly the refrigerant will circulate through the air conditioning system. In addition, a competent choice of tube cross-section makes it possible to significantly reduce pressure losses in air-cooling units.

In construction markets and stores it will not be difficult to find copper pipes with a cross-section ranging from 6 to 100 millimeters. For air conditioning systems, the following product size standards are usually used:

- 3/8 inch (9.52 millimeters).

- 1/4 inch (6.35 millimeters).

- 3/4 inch (19.05 millimeters).

- 5/8 inch (15.88 millimeters).

- 1/2 inch (12.7 millimeters).

The choice of the optimal pipe width depends on the performance of the cooling system or, in simple terms, its power. The higher the performance of the air conditioner, the more refrigerant will circulate through the pipes. Accordingly, for more powerful equipment you need to choose wide designs. If you are installing a small air conditioner to cool a room, then small-diameter products are suitable for you.

The standard wall thickness of copper pipes does not exceed 0.7 millimeters. The length of the products can be completely different, although most manufacturing companies cut the products into two-meter lengths before selling them to the buyer, and then pack them into coils of 25, 15 or 50 meters. Note that at the ends of the pipes, two-meter parts of the pipes have plastic plugs designed to protect the pipes from small debris and moisture getting into them during transportation.

Installation of a condensate drainage system

This process is very simple.

It is necessary to remove the lower fasteners from the air conditioner body so that it can rise. In the lower part, under the fan that blows the evaporator, there is a tray for collecting condensate. There is a pipe on its side, and it is to it that you need to attach the drainage pipe for removing condensate from the air conditioner using a clamp. The indoor unit housing is lowered and installed in place

In this case, it is very important that the corrugation passes through it through a special hole made in the side wall. The fasteners are screwed into place.

Now all that remains is to remove the attached corrugated hose either to the sewer or to the street

If the withdrawal process is associated with the installation of a drainage route, then you must first decide how easier and more convenient it is to carry out the entire process. As mentioned above, the best option is to make grooves into which to lay the hose. The most important thing is to maintain an inclination angle of at least 3%.

Now all that remains is to remove the attached corrugated hose either to the sewer or to the street. If the withdrawal process is associated with the installation of a drainage route, then you must first decide how easier and more convenient it is to carry out the entire process. As mentioned above, the best option is to make grooves into which to lay the hose. The most important thing is to maintain an inclination angle of at least 3%.

Basic drainage problems

The most common malfunction of the condensate drainage system from the air conditioner is a clogged hole in the bath. Dust and dirt with condensation settle to the bottom of the pan, where sludge forms. It grows and covers the pipe. The consequence is the flow of water over the edges of the bath. The liquid begins to drip onto the floor and leak down the walls.

And other malfunctions:

- If the air conditioner works for heating in winter, then often the drainage pipe on the street simply freezes.

- The slope of the drainage route was set incorrectly.

- If the pump fails.

- If the amount of refrigerant in the system has decreased, which leads to icing of the evaporator and supply pipes, so the ice begins to melt along the entire length of the route, pouring water onto the floor.

- The evaporator may become covered with ice if the pressure regulator stops working. If the temperature outside the window begins to decrease, this can lead to a decrease in the freon temperature due to a drop in its pressure.

Cleaning the drainage system

You can clean the condensate drainage system from the air conditioner with your own hands only if the bathtub pipe is clogged. To do this you need:

Remove the filters located on the device body in front of the evaporator. They must be washed thoroughly. The air conditioner housing is raised. The drainage tube is disconnected from the pan. The latter is removed and washed

Pay special attention to the hole. If the tube is clogged in the same way as the drain hole, then it must be blown out

If that doesn't work, you'll have to replace it with a new one. All other steps for assembling the condensate drain system are performed in the reverse order.

Experts recommend using a chlorhexidine solution to disinfect drains and the condensate drain pan. Although any household detergent that contains chlorine will easily cope with the task.

For other malfunctions associated with the failure of one or another device or part, it is better to call a specialist. Independent actions can lead to irreparable consequences.

https://youtube.com/watch?v=L-4-BgJKNoo

Adviсe

Let's look at how to properly cut copper pipes. Accuracy and accuracy are very important here. To do this, as mentioned above, you will need a pipe cutter: at the very end you need to install a pipe and slowly begin to rotate it in the opposite direction from the stroke

As a result, the cutting angle should not be more or less than 90 degrees. If soldering is used for pipe installation, it is very important to observe the temperature conditions during soldering and ensure sufficient ventilation of the room, since cadmium vapors and fluoride compounds released during heating can be hazardous to health! When using the option of connecting copper pipes with fittings, the most important thing is to thoroughly clean their edges from burrs. When tightening the nut during installation with compression fittings, it will be enough to stretch it 1-2 turns from the initial stop. To prevent the pipeline from freezing or overheating (in other words, to create insulation), it is sometimes placed in a special sleeve made of polyethylene or foam rubber. This also improves the energy efficiency of the structure.

To learn how to install an air conditioner, watch the video below.

How to clean an air conditioner at home

How to clean your air conditioner yourself at home? - Many people ask this question. In fact, this is not difficult to do at home. You can do this yourself no worse than a real master if you follow our recommendations. Plus, you'll save quite a lot of money!

It is not difficult to clean the air conditioner in an apartment or private house yourself. This does not require special tools or consumables. Just read this post and get started.

How often should you clean your air conditioner?

Experts recommend cleaning the indoor and outdoor units of the air conditioner twice a year - before summer and after the end of the season. If you use a split system for heating, you will need to clean it before and after cold weather.

It is also worth cleaning the air conditioner if the following symptoms appear:

- The blowing speed has decreased;

- The air conditioner has become noisy or extraneous sounds have appeared;

- There was a bad smell in the room;

- Water is dripping from the indoor unit;

- The device became worse at cooling or heating.

If the outdoor unit of the air conditioner is located at a level of 10 meters (4th floor) or lower from the ground, it must be cleaned once every 2-3 months throughout the season. At low altitudes, it quickly becomes clogged with dust, insects, and leaves.

It is enough to clean the outdoor unit at a height of up to 25 meters (11-12th floor) once every two years. It is well blown by the wind, and pollution does not accumulate in it as much.

If the outdoor unit is installed above 25 meters, it is enough to clean it once every 5 years. But only on condition that the air conditioner operates normally, does not consume a lot of electricity and produces enough cold or heat.

7 dangers of a dirty air conditioner

- Dust accumulates on the radiators of the indoor and outdoor units, forming a kind of “fur coat”. Because of it, the heat exchange between freon and air deteriorates. This causes the compressor to wear out quickly and the air conditioner to no longer heat or cool effectively.

- When the radiators are dirty, the air conditioning compressor starts to turn on more often to ensure the desired temperature. You may not notice it, but it works hard. But this is the most expensive and important part of any climate control equipment!

- The main energy consumption is for the compressor.

The more often it turns on, the more you have to pay. Hence the conclusion - the cleaner the air conditioner, the more economical it is. - Dust and particles of pollution clog the filters and impede air access. At first, the air conditioner just starts blowing weakly. You, of course, increase the blowing power and everything seems to be fine. But at the same time, electricity consumption increases, and fan motors work to the limit.

- Condensation constantly forms in the indoor unit, which accumulates in the form of drops on the parts. When the air conditioner is turned off (for example, at night or while you are at work), the room temperature rises. And water and warmth are the best environment for fungus and mold. They, in turn, cause bad smell in the room.

- In addition to fungal microflora, microorganisms feel quite confident in the air conditioner. They establish entire colonies there and multiply, and when the fan is turned on, the air flow carries them throughout the room. And many of these microbes are disease-causing. Because of them, asthma can worsen, allergies, and various skin diseases can occur.

- Dust tends to get into small crevices and impede the operation of air conditioning mechanisms. This leads to the appearance of extraneous sounds - the fans begin to creak or crackle, the plastic case begins to rustle.

Step-by-step instructions for cleaning the indoor unit

In order to clean the indoor unit of the air conditioner you will need:

- Vacuum cleaner;

- Basin with water;

- Dish detergent;

- Container with clean water;

- Soft rags (preferably lint-free);

- Toothbrush (or any other);

- Soft brush (painting brush will do);

- Crosshead screwdriver;

- Thin rope, wire or easily bendable wire (40-50 cm).

Disassembling the indoor unit

Be sure to unplug the air conditioner! Open the indoor unit of the air conditioner. To do this, press on the plastic clips that are located on its side walls (see photo). Take out the mesh filter.

Advantages of copper products

Due to their performance properties, copper pipes are widely used for transporting various liquids. Among the advantages of such products are:

- Plasticity and strength. Copper products have high strength and ductility. At low temperatures, these properties increase significantly. This makes it possible to use a copper pipeline for transporting non-freezing liquids.

- Resistant to sudden temperature changes. Copper pipes do not lose their performance properties at extreme temperatures. This also applies to high blood pressure. Such pipes can withstand a load of 400 atmospheres.

- Slight thermal expansion.

- The versatility of the material. For the construction of one or another utility line, you can use pipes with a small wall thickness. So, for example, if we take steel or plastic analogues, then to solve a similar problem we needed products whose wall thickness was several times greater.

- Resistant to chlorine and other chemicals that may be contained in the transport fluid. Upon contact with copper, an oxide is formed, which extends the life of the product.

- Copper pipes are not afraid of ultraviolet rays, chemically aggressive substances and corrosion. Thanks to these properties, the service life of the pipeline can reach 100 years or more.

- Copper inhibits the development of bacteria, which makes the pipeline safe.

- The inner walls of copper products have a smooth surface. Thanks to this, pipes with a small diameter can be used to construct the pipeline. At the same time, throughput is at a high level.

- Dismantled copper pipes can be reused to construct a new heating or water supply system pipeline.

- Copper pipes have an attractive appearance. This makes it possible to abandon the installation of decorative boxes. The products themselves can be used as a decorative element.

Due to the presence of such advantages, copper pipes are especially popular among professionals and are used in various fields.

Main causes of breakdowns

The indoor unit filter is clogged. This problem leads to disruption of normal air flow, resulting in loss of power. If the system has threaded connections, this may cause refrigerant leakage. In turn, this will lead to overheating and further breakdown of the compressor.

The heat exchanger of your device's indoor unit is clogged. This can happen due to the ingress of poplar fluff, as well as coarse dust, into the heat exchanger. In this regard, heat exchange is significantly disrupted. In this situation, this will lead to a disruption in the operation of the compressor and its further breakdown.

Freon leaked. There are two types of leakage of this substance - normalized and non-standardized. In the first case, you cannot influence the leakage process. It occurs in all devices without exception. In the second case, during poor-quality installation of equipment, gas can leak out in a very short time (a couple of days or months). Fortunately, this is not fatal to those around you, but it can significantly hit your budget. To fill the system with this gas, you need to call a specialist. And so, with proper installation of the air conditioner, gas is refilled every couple of years.

Advantages and disadvantages of copper pipes

Copper elements that are used to make heating systems have strengths and weaknesses. Advantages:

- Service life up to 50 years.

- Withstand pressure over 30 atmospheres.

- The material does not react to ultraviolet radiation and is resistant to corrosion under natural conditions.

- No air leaks through the walls.

- Copper does not emit harmful substances. Has antibacterial properties.

- Light weight.

- It is possible to defrost the system 3 times.

- The material can withstand prolonged exposure to active chemicals and does not release any additional elements.

- Deposits do not accumulate on the inner surface of the products.

- Low rate of thermal expansion, which does not require the installation of expansion joints.

Flaws:

- High price when compared with other materials.

- The connections are permanent, which may cause difficulties during installation.

- Galvanic corrosion can occur if you try to combine copper with other metals.

- If the room has a high level of humidity, corrosion may appear on the surface of the products.

- High electrical conductivity contributes to the deterioration of the walls of products.

- To reduce heat loss in the walls, it is necessary to use additional insulation.

Maintaining the drain pipe guarantees the longevity of the air conditioner

Improper installation of the condensate drain hose may result in excess water inside the outdoor unit of the air conditioner.

Therefore, it is important to do everything correctly. But not always, problems overtake the owner of the equipment precisely for this reason

So, the drain hose may simply become clogged. But this will not happen when the technology is being monitored. It is the care of the air conditioner that guarantees its effective operation. Since the external unit of the split system is located outside, it is constantly exposed to natural factors. Dust and debris are brought inside, which get there with the help of precipitation and wind. If signs of an air conditioner leak appear, it is not difficult to find the problem area.

Every owner of a split system knows where the drainage system pipe is located. If it is it that is clogged, then the problem can be solved with a couple of quick actions. The hose can be blown out or cleaned by hand using any thin oblong tool. But hose clogging rarely occurs. Another important element of the drainage system, the water tank, suffers more often. It is to this that the drain tube is connected through a small drain hole. If this vessel becomes clogged, water fills its full volume. And the owner of the air conditioner can only observe the consequence of this - flooding. When the water begins to overflow the edges of the bath, it ends up at the bottom of the block itself. As the liquid accumulates, it looks for an easy way to remove it through any cracks and holes.

How does the drainage tube depend on the operation of the device itself?

The main cause of blockages or poor drainage tube capacity most often occurs due to human error. Only inattention and neglect of household appliances can change the quality and efficiency of the air conditioner. But there are also exceptions. These include:

- Defective or missing pressure sensor. It is this element that can cause some problems with the drainage system. When the temperature in the evaporator decreases due to a sharp change in climatic factors, the water in the bath and hose may freeze, which will lead to flooding of the external unit of the air conditioner.

- Freon leak. A decrease in the volume of this gas in the compressor-condensing unit can cause a decrease in the temperature in the evaporator. So, the water freezes, blocking the drain hole of the drainage hose.

- Freezing of water in the hose due to exposure to low temperatures outside. Often, this problem appears when using equipment in cooling mode.

- Other problems that may arise with the drain pipe during operation of the air conditioner arise due to the installer of the equipment and its owner. Often, the zigzag structure of the hose becomes an additional clogging factor. Also, the tube can burst when the material from which it is made is of poor quality.

If the drain pipe for the air conditioner is connected to the fittings, then gaps and cracks may appear at the joints. They also cause some problems

Therefore, it is important to pay attention to the quality of the hose used. And if the tube included with the air conditioner does not have the positive properties that are necessary, then it is better to purchase a new element

Tube repair or replacement: what to choose for a car air conditioner

Repair or buy new? Every person asks himself this question when a car air conditioner breaks down at the most inopportune moment. A new spare part costs from 5,000 rubles for budget cars and from 10,000 rubles for business class cars. And you still have to wait almost a month for the part to be delivered. After all, these are not typical consumables that are available in every car shop. Tubes for car air conditioning repair will have to be ordered separately and there is no guarantee that they will be delivered on time. In most cases, repairing will be many times cheaper than ordering an original spare part or looking for a non-original one from other manufacturers. A complete repair with restoration of car air conditioning tubes at the Autoclimate Vostok car service center (Moscow) will cost from 500 to 3,000 rubles.

Grinding a new “tip” to replace the damaged one.

Instructions for cleaning the drainage system

First of all, you should know that clearing a clogged tube using wire or other folk remedies gives a positive result, but not for long. Most often, before a person has time to rejoice at the solution to the problem, the dust accumulated on the heat exchanger again clogs the drainage system and the air conditioner begins to flow again. That is why experts recommend cleaning the drainage system and at the same time cleaning the filters and the heat exchanger of the indoor unit of the air conditioner.

- The first thing you need to do is turn off the power to the device.

- Then remove the cover and coarse filters. They should be washed and dried thoroughly.

- Remove the condensate tray while simultaneously disconnecting the drain hose. In some models this is quite difficult to do, so use the instructions.

- Rinse the tray thoroughly and clean the condensate outlet.

- Blow out the drain pipe with a vacuum cleaner. If the clog is quite dense, then use a syringe to fill it with air conditioner cleaning liquid, which can be purchased in specialized stores.

- After 15-30 minutes, you can remove dirt using a vacuum cleaner connected to the drainage system hose.

The last step in cleaning is to disinfect the system. To do this, it is necessary to treat the condensate collection tray and coarse filters with chlorhexidine, which is sold over the counter in any pharmacy. It’s a good idea if you pour a certain amount of the drug into the drain tube to disinfect it. After 15 minutes, rinse the tube with plain water. It will remove any remaining dirt and medication, and you will also be able to make sure that the drainage system is clear of blockages and will operate normally.

Next, using a soft brush and a vacuum cleaner, clean the heat exchanger from dust and assemble the split system. As you can see, in some cases, solving the problem of “crying” climate control equipment is not at all difficult. In this article, you learned how to clean the drain pipe of your air conditioner at home if it is dirty.

There are many reasons why climate control equipment leaks. It is better if professionals undertake diagnostics and troubleshooting.

Material characteristics

Copper is a very ductile and at the same time durable metal. Due to their high ductility, copper pipes can withstand impacts and bends even at subzero temperatures. Copper does not corrode and is chemically inert. The strength of copper is lower than that of steel, but higher than that of plastic. Copper tubes can have very thin walls. Copper has high thermal and electrical conductivity.

In many cases, plastic and plastic piping systems can be replaced with copper, but the widespread adoption of copper is hampered by its price and somewhat more complex installation compared to plastic systems.

Copper tubes are very widespread in the manufacture of refrigeration equipment, household appliances, appliances, household heating systems, and automobiles. Air conditioners are traditionally installed with copper pipes - more compact, reliable pipelines have not yet been invented.

Draining the condensate

Ordinary water, which is condensate, can cause a lot of trouble and inconvenience. It is a by-product of the space cooling process. The amount of condensation directly depends on the temperature and humidity of the cooled air.

Some of the condensation evaporates naturally; “advanced” models of air conditioners use some of the water to maintain natural air humidity, but a significant part of it has to be removed outside the room.

In this case, the drainage of the air conditioner, or rather condensate, occurs through the drainage system, which originates in the internal units of split systems, continues with a connection to the drainage pipe (with the possible participation of a drainage pump), and ends with discharge into the sewer or outside the room (through a window or wall).

Do not take condensation from air conditioning lightly. Depending on its power, climate conditions and other factors, an air conditioner can produce more than 20 liters of water every hour. There are known cases of water flooding the lower floors of multi-story buildings with condensation from air conditioners. This, of course, is not a heating breakthrough, but it can also cause significant damage.

It doesn’t take much to eliminate the slightest possibility of such an event. Timely prevention of the drainage system is perhaps the cheapest maintenance procedure. One call and everything is cleaned, washed and disinfected. When the “drain” of the air conditioner becomes clogged, the main problem is not that it may someday flood the neighbor below, but that this condition of the split system poses a serious threat to the health of the residents.

If water stagnates in the drainage system of the air conditioner, this means that dirt will accumulate in it, mold will develop and microorganisms, including pathogenic bacteria, will multiply. The most obvious symptom of problems in the drainage system is the appearance of an unpleasant “swampy” smell. This is the last call, reminding us that the air conditioner drainage was last tidied up more than a year ago, when the norm is once every three months.

There is probably no person who has not heard of “legionnaires’ disease.” This is an extremely serious disease that has only recently been discovered to be diagnosed and treated. If dysentery is a disease of dirty hands, then the “legionnaires” got sick from dirty air conditioners.

Since then, disinfection of air conditioners has been one of the most important procedures that must be carried out with each split system quarterly. Several hundred, and maybe thousands, people paid with their lives for this recommendation, but users continue to take it lightly. In Russia, more than a dozen of our fellow citizens die every year from Legionnaires' disease.

Whatever meaning you put into the question of draining the air conditioner, ask it to a service center specialist. This is the case when timely treatment can save the air conditioner from serious damage, or protect your health from major troubles.

It’s even better to sign an air conditioner maintenance agreement and enjoy the excellent microclimate of your home with peace of mind. If you refuse this method, tidy up the drainage system of the air conditioner yourself, just don’t sit idly by - this is the worst thing you can do.

Soldering aluminum

The interest of manufacturers in the development and use of aluminum alloys makes them increasingly popular. Due to the rapid formation of an oxide film on the surface of aluminum, the metal surface is well protected from the effects of the external environment. However, such a film does not make it possible to make a good solder connection. The problem can be solved using fluxes.

The production actively uses aluminum soldering technology using solders and fluxes from Castolin, a leader in its field.

The company has developed solders and fluxes used for soldering copper and aluminum in two modes:

- high temperature (hard soldering);

- low temperature (soft soldering).

Castolin solders are suitable for soldering aluminum and copper, which is especially important when installing air conditioning systems using aluminum refrigerant pipes. At the same time, the seams are smooth and dense.

These solders are also suitable for soldering aluminum pipes that are coated with copper on the inside.

Some solders contain large amounts of aluminum. This allows the solder to approach its characteristics to the base metal and increases its strength. The temperature during the soldering process reaches 440⁰ – 470⁰ C, while overheating of aluminum is avoided and good quality is achieved.

To clean the aluminum surface from oxide film and contaminants, to ensure good wettability and spreading of solder, chemically active substances - fluxes - are used. Without them, good quality soldering is impossible.

Traditionally, copper is used to produce refrigerant transport tubes in cryogenic equipment. Only recently have they begun to replace it with aluminum in order to reduce installation and installation costs. The use of aluminum tubes in air conditioners can significantly reduce material costs without loss of quality thanks to modern technological solutions.

Main manufacturers

Hutterer & Lechner

The leader in the production of siphons for air conditioning systems is the Austrian company Hutterer & Lechner (HL). The products are distinguished by high quality and simplicity of design. The technology of equipping the units with a water seal and a locking ball valve prevents the appearance of unpleasant odors. The company offers siphons of various models:

- HL 136.2 – siphon with water seal;

- HL 138 – built-in system;

- HL 136 N is a unit with a water seal and a ball odor locking device.

Vecamo

The Italian company Vecamo offers a siphon for air conditioning, which is mounted on the wall, providing free access to the inlets and outlets. The kit includes connectors designed for drainage hoses of various diameters. The transparent plastic case allows you to monitor the condition of the internal part.

McAlpine

The self-closing drain valve or dry siphon of the MacValve series from McAlpine is produced in two installation sizes: 32 and 40 mm. The compact plastic case contains a polymer tube that functions as an odor-blocking device. Vertical installation is recommended, but horizontal installation is acceptable. In the first case, the throughput is 1.58-275 l/s, in the second it is lower - 0.7-1.7 l/s.