There are many formulas on the Internet that can be used to initially calculate gas consumption, but experts say that the result will be an average indicator that has errors in one direction or another.

What affects the gas consumption of a gas tank?

Depending on the climatic conditions of a particular area and time of year, gas consumption during autonomous gasification can vary within a fairly significant range. First of all, this is determined by the evaporation mirror that appears in the gas tank. As a result, the choice of this equipment is best left to specialists, because in other cases, it is optimal to use a vertical tank as opposed to a horizontal one and vice versa. This parameter can also be adjusted, giving preference to underground installation of the gas holder tank, which protects it from the effects of environmental temperature conditions. But in some cases, above-ground installation is recommended to ensure greater performance of the autonomous gasification system.

Also important factors affecting gas consumption are:

- the quality of insulation of the external walls, foundation and roof of the house, which determines the amount of heat loss of the building;

- wind rose in a specific area;

- set temperature regime;

- building area, number of windows and doors;

- number of people living in the house;

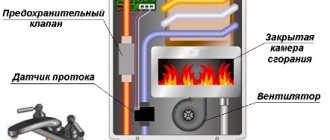

- technical features of the boiler;

- permanent or periodic residence;

- use of additional and auxiliary equipment.

How long does it take to refill an autonomous gasification system?

Our company has made its own calculations, based on practical observations, according to which 20–30 liters of gas are consumed daily per 1 m² of area for permanent residence on average per year.

That is, one refill of a gas tank, the tank volume of which is 4800 liters, is enough for 160-240 days. As a rule, owners order the next refueling before the start of the heating season, because... in summer, consumption decreases significantly.

Gas consumption by a gas holder depending on the area of the house

Again, we carried out observations in residential buildings, where our specialists carried out work to create an autonomous gas supply. Therefore, you should take into account not only the basic set of equipment, but also additional modules, such as heated floors, the number of radiator points, etc.

| House area, m² | 100 m² | 250 m² | 500 m² |

| LPG consumption, l/month | 190 - 250 l | 400 – 600 l | 1,000 – 1,250 l |

* The table shows average data during the heating season.

You can also find information on the topic:

It is well known that gas tanks are increasingly used for heating houses and cottages with permanent or long-term residence. It is also undisputed that a large share of the budget for heating a house is the cost of fuel. In our case it is liquefied gas.

Therefore, a prudent home owner must know how to correctly calculate the gas consumption from a gas tank for heating and be able to predict the intervals between refills. This is also relevant because gas delivery, as a transport service, has its own quite significant price.

We will help you in an accessible manner to independently calculate the consumption of liquefied gas for heating your home in gas supply systems with a gas holder. This knowledge is relevant when designing the construction of a new house and planning the reconstruction of an existing heat supply system. Correctly carried out calculations will allow you to control gas consumption and reduce gas costs.

Factors affecting gas consumption

The gas holder has the form of a volumetric tank that is filled with liquefied petroleum gas (LPG). This is a mixture of two gases - propane and butane.

Storing gas in such tanks, with its further use for heating the house, may be due to the following factors:

- the inability to tie into the main gas pipe or the high cost of such a connection;

- constant and unresolved by gas services problems with gas pressure in the central pipeline.

For normal operation of most gas boilers, the gas pressure in the pipeline must be at least 35 mbar. This standard is often not maintained in main gas pipelines and ranges only from 8 to 22 mbar.

To determine the volume of liquefied gas in a tank, there are mechanical level gauges or more modern remote telemetry systems. Such equipment can be supplied complete with the tank or purchased separately. The average daily gas consumption can also be determined by the difference in gas meter readings, if available.

But a more accurate answer to the question of how much gas in a gas holder is enough to heat a home, what its consumption is and how to minimize costs for it, mathematical calculations will help. And this despite the fact that objectively such a calculation will be of an average nature.

It should be taken into account that gas consumption is influenced by the following factors:

- climate of the region and wind rose;

- square footage of the house, number and degree of thermal insulation of windows and doors;

- material of walls, roof, foundation and the degree of their insulation;

- number of residents and mode of their stay (permanently or periodically);

- technical characteristics of the boiler, the use of additional gas appliances and auxiliary equipment;

- number of heating radiators, presence of heated floors.

These and other conditions make the calculation of fuel consumption from a gas tank a relative value, which is based on average accepted indicators.

Monitoring the actual level of LPG consumption in the autonomous gas supply system of a private home

Of course, in a real situation, the above gas consumption figures may change in one direction or another. To ensure control of the current level of liquefied gas in the tank (including the option of remote control), there is a special device - telemetry, various versions of which can also be purchased profitably from our company, both as part of equipping a gas tank purchased on a turnkey basis, or separately.

Current gas price

- Minimum order - 2000 l;

- In winter, gas delivery is carried out only if there are cleared access roads;

- If the distance from the gas carrier stopping place to the gas tank is more than 50 m, inform the manager about this at the time of order.

| Delivery region | Price of 1 liter of gas, rub. | Propane content, % | Manufacturer |

| Moscow and Moscow region | from 27.5 | 85 | GazProm Surgut |

Current cost of gas tanks

| Volume, cube | Heated room area | High pipes, rub. | |

| SpetsGaz | 2,7 | up to 150 m2 | 220 000* |

| 4,3 | from 150 to 250 m2 | 2450 000* | |

| 5 | from 150 to 250 m2 | 265 000* | |

| 6,2 | from 250 to 350 m2 | 290 000* | |

| 6,6 | from 250 to 350 m2 | 295 000* | |

| 7,3 | from 250 to 350 m2 | 330 000* | |

| 8,1 | from 350 to 450 m2 | 370 000* | |

| 9,1 | from 350 to 450 m2 | 390 000* | |

| 10 | from 450 to 650 m2 | 410 000* | |

| 12 | over 650 m2 | 485 000* | |

| Bear | 2,2 | up to 150 m2 | 135 000** |

| 3,1 | up to 150 m2 | 140 000** | |

| 4 | from 150 to 250 m2 | 150 000** | |

| 4,95 | from 150 to 250 m2 | 155 000** | |

| 5,7 | from 250 to 350 m2 | 165 000** | |

| 7,4 | from 250 to 350 m2 | 200 000** | |

| 9,2 | from 350 to 450 m2 | 270 000** | |

| 11 | more than 500 m2 | 290 000** |

* It is possible to additionally equip the gas tank with a neck. The cost of a high neck is 30,000 rubles.

** It is possible to additionally equip the gas holder with a neck. The cost of a high neck is 45,000 rubles.

Current cost of gasification

| Volume, cube | Heated room area | High pipes, rub. | |

| SpetsGaz | 2,7 | up to 150 m2 | 190 000* |

| 4,3 | from 150 to 250 m2 | 200 000* | |

| 5 | from 150 to 250 m2 | 200 000* | |

| 6,2 | from 250 to 350 m2 | 230 000* | |

| 6,6 | from 250 to 350 m2 | 240 000* | |

| 8,1 | from 350 to 450 m2 | 300 000* | |

| 9,1 | from 350 to 450 m2 | 320 000* | |

| 10 | over 450 m2 | 340 000* | |

| Bear | 2,2 | up to 150 m2 | 195 000** |

| 3,1 | up to 150 m2 | 200 000** | |

| 4 | from 150 to 250 m2 | 210 000** | |

| 4,95 | from 150 to 250 m2 | 215 000** | |

| 5,7 | from 250 to 350 m2 | 225 000** | |

| 7,4 | from 250 to 350 m2 | 260 000** | |

| 9,2 | from 350 to 450 m2 | 330 000** | |

| 11 | more than 500 m2 | 350 000** |

* It is possible to additionally equip the gas tank with a neck. The cost of a high neck is 30,000 rubles.

** It is possible to additionally equip the gas holder with a neck. The cost of a high neck is 45,000 rubles.

Calculation of gas flow from a gas tank

Calculating the heating consumption of the mixture from the gas storage used in the heating system of the house has its own characteristics and differs from calculating the consumption of main natural gas.

The predicted volume of gas consumption is calculated using the formula:

V = Q / (q × η) , where

V is the calculated volume of LPG, measured in m³/h;

Q—calculated heat losses;

q is the smallest specific value of the heat of combustion of the gas or its calorie content. For propane-butane this value is 46 MJ/kg or 12.8 kW/kg;

η – efficiency of the gas supply system, expressed in absolute value per unit (efficiency/100). Depending on the characteristics of the gas boiler, the efficiency can range from 86% - for the simplest ones, to 96% - for high-tech condensing units. Accordingly, the value of η can range from 0.86 to 0.96.

Let's assume that the heating system is planned to be equipped with a modern condensing boiler with an efficiency of 96%.

Substituting the values we accepted for calculation into the original formula, we obtain the following average volume of gas consumed for heating:

V = 9.6 / (12.8 × 0.96) = 9.6 /12.288 = 0.78 kg/h.

Since the LPG filling unit is usually considered to be a liter, it is necessary to express the volume of propane-butane in this unit of measurement. To calculate the number of liters in the mass of a liquefied hydrocarbon mixture, it is necessary to divide kilograms by density.

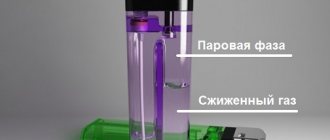

The physics of the transition of LPG from liquid to vapor (working) state is as follows: propane boils at minus 40 °C and above, butane - from 3 °C with a minus sign. Accordingly, a 50/50 mixture will begin to transition into the gaseous phase at a temperature of minus 20 ° C.

For middle latitudes and a gas tank buried in the ground, such proportions are sufficient. But, in order to protect yourself from unnecessary hassle, it is optimal in winter conditions to use a mixture with at least 70% propane content - “winter gas”.

Taking the calculated density of LPG as 0.572 t/m 3 - a 70/30 propane/butane mixture at a temperature of -20 °C), it is easy to calculate the gas consumption in liters: 0.78 / 0.572 = 1.36 l/h.

Daily consumption with such gas selection in the house will be: 1.36 × 24 ≈ 32.6 l, during the month - 32.6 × 30 = 978 l. Since the obtained value was calculated for the coldest period, adjusted for weather conditions, it can be divided in half: 978/2 = 489 liters, on average per month.

In the area we took as an example (Moscow region), this period averages 214 days.

Gas consumption for heating during the year when calculated will be: 32.6/2 × 214 ≈ 3488 liters.

Gas boiler power calculation

The main share of fuel consumption is heating. An important parameter of any house or apartment that affects the amount of gas spent on heating is the heat loss indicator. The task of heating is precisely to correctly compensate for these losses, creating conditions for comfortable living.

In order to calculate the need for liquefied gas, it is necessary to determine the amount of heat loss at home or the thermal power required for full heating. The rated power of the heating system - gas boiler - depends on this indicator

As a standard for calculations, we will take a house located in an area with an average climate, in satisfactory condition and insulated in accordance with technology. The area of the house is 80 m2.

The average values of heat loss and boiler power can be determined by the quadrature of the area.

The formula looks like:

Q = S × Рр /10 , where

Q—calculated heat losses (kW);

S is the area of the premises that are heated (m2);

Рр - specific power of a gas boiler (kW/m2) - power for every 10 m2.

The specific power for heating an area of 10 m2 has already been approximately established, taking into account adjustments for regions with different climates. For our reference house, located, for example, in the Moscow region, Рр = 1.2 - 1.5 kW.

Taking into account a house area of 80 m2, the optimal power of the heating system will have the following value:

Q = 80 × 1.2 / 10 = 9.6 kW.

Although simplified, this formula reflects the most accurate results.

Often, for convenience in carrying out calculations, unit is taken as the value of specific power. Based on this, the power of the heating system is taken at the rate of 10 kW per 100 m2 of heating area.

Since the gas supply system of your home includes not only heating, but also water heating and other equipment, the boiler power is determined by adding 20-25% of the reserve to the calculated heat losses

The second option, but accepted with a greater degree of error, is to calculate the cost of thermal energy for the heat loss of a building by cubic capacity - the volume of heated premises. Depending on the climate zone, 30 - 40 W are allocated for heating one cubic meter of a room with a ceiling height of up to 3 m.

Selecting the optimal gas tank for consumption

A gas tank is expensive equipment that is purchased and installed for more than one year. Not only the efficiency of the home heating system largely depends on its correct choice. Heating costs may indirectly depend on the type and type of liquefied gas storage facility.

Comparison of above-ground and underground gas tanks

An above-ground gas holder is a cheaper option for autonomous gasification. Such tanks are usually smaller in volume and their installation does not require expensive excavation work.

But, when using above-ground gas tanks for heating needs in winter, it is necessary to take into account that the evaporation of the propane-butane mixture during this period will be reduced and problems with gas pressure are possible.

It is possible, of course, to reduce the temperature threshold for the transition of LPG into the gaseous phase of fuel due to a higher content of propane in the mixture. But this will entail additional costs, since such gas is more expensive than butane.

Underground gas tanks are the most popular storage facilities for LPG.

How to pay less

There are several ways to reduce fuel consumption and increase the efficiency of the system used to reduce payments. First of all, we recommend:

- Insulate the facility;

- Optimize consumption volumes by adjusting heating and other equipment;

- Contact specialists to properly design an autonomous system, taking into account the nuances of its operation.

You can find out more and order gasification services by contacting our company. We will provide consulting assistance on any issues.

Tips for saving gas

You can reduce gas consumption from a gas tank by performing the following energy-saving measures:

- insulation of walls, roofs, attics, basement floors;

- replacing old window units with modern double-glazed windows with frost-free profiles;

- optimal setting of boiler parameters;

- installation of an energy-efficient condensing-type gas boiler for heating;

- the use of a collector heating system, which has a higher efficiency and the ability to regulate the coolant supply on each heating device;

- equipping heating radiators with thermostats.

A good gas saving effect is achieved through the installation of controllers that automate the process of heat supply control.

Moreover, modern controllers are, as a rule, smart devices with which you can remotely control the boiler from a mobile phone.

An inexpensive alternative to such remote-controlled devices are programmable or daily thermostats, which also allow you to save energy.

A modern solution for saving gas from an autonomous storage facility is the “smart home” system.

The climate control function in the house can be installed separately or integrated into a general set of “utilities”.

Such technologies make it possible to economically use gas for heating throughout the day in individual rooms. You can configure the system to operate in heating mode when there are no residents and turn on full heating remotely before arriving home.

The main problem with implementing a “smart home” climate control system is the relatively high cost of the issue and the need for design before installation of the heating system.

Pros and cons of an autonomous gas holder for the home

Among the advantages of using a gas holder in private gas supply, the following are worth highlighting:

- Independence from the main gas pipeline.

- Liquefied propane-butane has greater efficiency than conventional natural gas.

- When connecting a gas generator, the gas holder can also serve as a reliable source of electricity.

- Problems with pressure drop, as is often observed with centralized gas supply, are eliminated.

- When burned, propane-butane does not form gas, and much less harmful substances are released.

- When leaking, LPG evaporates and does not get into the soil.

- Owners can start and end the heating season whenever they see fit.

One of the disadvantages of an autonomous gas supply is that the price of equipment and installation averages from 500,000 rubles (excluding the cost of the boiler and generator), and you need to pump fuel 1 or 2 times a year.

Conclusions and useful video on the topic

An interesting method for calculating gas consumption for heating and tips for reducing gas costs:

Expert advice on economically feasible choice of gas tank volume:

9 tips for reducing gas consumption used to heat your home:

It is necessary to understand that all the calculations that we propose to use when using gas from a gas tank are rather arbitrary. Even a specialist cannot determine and predict exactly how much liquefied gas will be consumed over a specific period.

But the presented methodology, based on the practice of operating autonomous gas systems, displays reliable average gas consumption values.

These calculations and the useful tips provided will make it possible to correctly select the optimal gas tank and plan the frequency of its refills.

If you have experience using gas holders for heating, please share it with our readers. Tell us about the intricacies of using such equipment. Write your comments, ask questions - the contact block is located below.

Video description

For more information about the gas tank and its installation, watch the video:

To control and regulate the process, the system has special automation; if you need to shut off the supply, you just need to turn a special tap. Excess pressure is removed using a special valve. The remaining gas is recorded thanks to a warning system that will warn the owner about the need to refill the tank.

Gas tank automation Source m.mitex-shop.ru

Equipment selection

It is better to place responsibility for the choice of any gas equipment on the designers.

It is they who will be able to not only correctly determine the required characteristics of the gas tank, but also correctly place it on their personal plot.

What characteristics are we talking about?

- Depending on the number of gas-consuming appliances and their unit costs, the total gas demand of the house is determined. Based on this value, experts decide what the minimum capacity of the tank should be.

- Gas tanks can be installed on networks with different gas pressures. Industrial equipment is mounted on high-pressure gas pipelines, while low-pressure gas is supplied to residential buildings.

- The reservoir can be either horizontal or vertical. The choice of design depends on the availability of free space on the site, the degree of landscaping and landscaping, distance from residential buildings and communications.

- Gas storage can be installed underground or above ground. In this case, the ability to comply with the standards for the minimum distance from the equipment to the residential part of the house and organize safe operation is crucial.

How to install a turnkey gas tank

You need to order a turnkey gas holder for a private home only from a specialized company that has the necessary license. You cannot install a gas tank with your own hands - it is illegal.

It is important! The supply of gas to the tank, refueling, connection of the gas holder to the gas boiler and all service work must be carried out only by certified workers from special companies. This is explosive equipment and requires proper maintenance by qualified technicians.

On a note! You can get professional advice on autonomous gasification of a private home directly from specialists

Various volumes of vertical and horizontal gas tanks Source brickandpress.com

Preparatory stage

To properly install the gas tank, you must first carry out preparatory work. All dimensions of the pit and its location relative to the building must comply with the standards and requirements for the installation of gas tanks.

- The pit should be 0.5 m larger than the size of the tank on all sides.

- A concrete slab with fastenings for the tank feet is placed at the bottom of the pit.

- The trench under the highway should not interfere with or intertwine with other communications.

- The depth of the pipeline trench must be at least 1.70 m, and the slope towards the house must be at least 5°.

- The distance to a residential building from the gas tank is at least 10 m.

Delivery of the gas tank to the site for installation Source rosavtonomgaz.ru

Gas and its properties

LPG production complex In production, liquefied gas is obtained by increasing the pressure in the container where it is contained.

As soon as conditions change and the gas enters the open atmosphere with normal pressure and temperature above 0°C, its state of aggregation returns to its original state.

Based on the property of natural gas to change its appearance depending on pressure, the principle of gas supply to a house using LPG was developed.

Refueling vehicles transporting liquefied hydrocarbons to the consumer use hoses to fill the tank with fuel. (You can read about the features of filling gas tanks in this article). Here it is stored and from here it enters the house through a special gas pipeline.

Evaporating from the surface of the liquid mixture, the gas accumulates in the neck of the tank to which the pipe is connected. From here fuel is distributed to house systems and appliances.

Where is the gas tank used?

A gas tank is used for long-term storage of liquefied gas and flammable substances. Its main purpose is to store LPG to ensure autonomous gas supply to the following facilities:

- country houses, cottages, dachas in the private sector;

- industrial enterprises;

- industrial buildings;

- buildings for seasonal use (recreation centers).

Most often, installation of a gas tank is practiced in villages and small towns that are located at a great distance from the main gas pipeline.

This is much more profitable than connecting to central engineering systems.

Environmental influence

Gas tank design Gas consumption may vary depending on the time of year. This is explained by the fact that in different seasons the gas mixture differs in the percentage of its constituent substances.

Typically, LPG is produced by mixing butane and propane. The properties of these gases are not the same. They have different boiling points, due to which butane predominates in the gas that enters the devices in summer, and propane in winter.

If the owner of the house intends to live in it all year round, it is necessary to buy gas with a higher propane content for the winter period. This is done to ensure that the gas supply to household appliances is constant and reliable.

The gradual consumption of gas during the cold period leads to more butane remaining in the gas holder. This fact is easy to explain: at low temperatures, butane practically does not evaporate and remains in the storage in a liquid state.

Thus, in winter, appliances consume a maximum of propane. There comes a time when the pressure in the gas tank drops so much that interruptions in the gas supply begin.

How long does a gas tank last if the house is large?

If the area of the house approaches 200-250 m2, the consumption more than doubles. This means that the same 5000 liter gas holder will last for about six months. And you will need two refills per year.

With an area of 500 m2, it is advisable to use a more capacious gas storage facility - up to 10,000 liters in volume. However, you can get by with a smaller gas holder with a capacity of up to 7500 liters.

Operating principle of the gearbox

To supply gas to private houses, gas tanks are often used, the pressure inside of which is quite high, but it is not suitable for supplying gas to the house. Therefore, to reduce it, a gearbox is used. It has a special design that reduces the LPG pressure to controlled values.

The reducer works as follows: a special valve, which is connected to a flexible membrane, periodically opens and closes. Due to the difference in pressure between the lower and upper chambers, the membrane comes into action and passes gas at the desired speed.

Residents of country houses often encounter a problem when the gas tank reducer freezes, and this happens quite often, especially in winter. How efficient will the system be in this case and how can it be repaired?

The problem is that the gearbox is installed openly, so it is often flooded with water, covered with snow, dirt, which causes the device to freeze when frost sets in.

It is important to install a protective cover over the gearbox or cover it with moisture-resistant materials to prevent moisture accumulation and avoid the problem of freezing of the device.

Orientation of the gas tank during installation

- heaters that consume electricity

- additional evaporation tanks

Horizontal orientation of the gas tank

- greater productivity due to increased evaporation area

- minimum additional equipment to ensure the required gas supply parameters

- increased dimensions increase the length of the period between refuelings

- large capacity of underground gas tanks while simultaneously saving useful area of the site

- large footprint for ground installation

- large volume of earthworks

- high cost of equipment with a high neck for deep installation

Is it profitable to install a gas tank?

Autonomous gasification using a gas holder is more profitable compared to connecting to the main gas pipeline or using bottled gas.

The benefits, in contrast to using gas supply through a centralized network, are as follows:

- Autonomy of the heating system. There is no need to worry that the gas may be turned off due to an accident or repair work on the main pipeline.

- Independence from centralized power supply. With a connected gas generator, you can ensure an autonomous supply of electricity to the entire house at all times.

- There is no way to connect to the main line or the pipes need to be laid at too great a distance. Installing a gas tank will cost several times less.

- Gas supply failures are eliminated.

- Accurate individual calculations for specific volumes of gas consumption.

The only caveat is that you need to pump the mixture into the tank in a timely manner.

In comparison with bottled gas supply, the benefits are as follows:

- Provision of gas for cooking purposes only. Not suitable for year-round gas supply.

- Frequent gas refills are required, which incurs shipping costs, especially when there are no gas stations nearby.

- In winter, the mixture in the cylinders only partially evaporates, which entails losses.

- Self-installation and use of used cylinders often leads to emergency situations that are dangerous to the life and health of residents.

The benefits of installing a gas tank are obvious - ease of use, uninterrupted gas supply all year round, safety and cost-effectiveness of the equipment.

Design and principle of operation of an autonomous gas tank

If gas is needed only for the uninterrupted operation of the stove, then one or two gas cylinders of standard capacity will be enough. To heat the house, cook food and generate electricity through a gas generator, you will need to install a tank with a capacity of 2000 to 20,000 liters. The volume is calculated individually according to the needs of the owners.

The operation of an autonomous gas tank consists of the following points:

- A tank is placed near the house. According to safety precautions, the required distance should be 10 m. The distance from the water intake is 15 m. Do not forget about the convenience of access by a tanker truck to refill the gas tank.

- The pit for the tank must be below the soil freezing level. In this case, there will be no risk of LPG freezing in severe frost.

- If necessary, a monolithic slab can be poured under the tank.

- The container is filled with LPG - natural gas, cooled and liquefied under low temperature. Thus, the gas mixture decreases in volume by approximately 600 times. The concentration of sulfur compounds is also reduced. The gas evaporates. Then the gas passes through the reducer, where the operating pressure is 30–50 millibars.

- Gas with this pressure is supplied from the neck of the gas tank into the pipeline. In this case, proper pipe routing must be provided for the boiler, supply to the kitchen for the gas stove, and to the generator.

To ensure an effective evaporation process, you need to take into account the following nuances:

- The container must be supplied with propane-butane no more than 85%.

- The container should not be allowed to cool to a temperature below 0 degrees. In most cases, this applies to ground-based gas tanks. Therefore, it is necessary to provide for insulation of the structure.

- Vertical tanks have a small evaporation area, which means that additional evaporators will have to be installed.

This gas supply technology implies that the tank is not completely filled with the gas mixture, due to which the LPG gradually turns into a gaseous state and is supplied into the pipes under high pressure.

Mini gas holders - a quick solution

The containers are similar in volume to mobile ones. The popular SpetsGas line includes models of 600, 800 and 1400 liters. Manufacturers compare mini-models with “a dozen” gas cylinders.

Small gas tanks are not transported to the gas station, but are installed on the site. This is autonomous gasification in light mode: fast, inexpensive, hassle-free.

When does a mini option come to the rescue?

Requires installation in 2 hours. Place the container on any hard surface near the boiler room. Or prepare the area: remove the soil, fill it with sand, geotextiles, granite crushed stone and make a box from the board.

Next, you need to drill a small technological hole in the wall of the house - 3 cm. Connect the gas pipeline to the boiler and gas stove. The last stage is filling the gas tank to 85%. And no excavation work.

No time for gas stations. A tanker truck delivers gas to the site. Call a gas station and fill the tank. The frequency depends on the heated area of the house, heat loss and container volume.

In a house up to 100 sq. m, seasonal residence and a plot of 6 acres, feel free to choose a mini-format. The 600 liter container needs to be filled every 1.5 months. 1,400 liter tank - a couple of times every six months.

Disadvantages of the solution: it will force the owner to be “more responsible”

Dictates the refueling schedule. The gas tank should contain no more than 85% and no less than 20% of the total volume of the tank. To get into the desired range, you need to constantly remember to fill between 510 and 120 liters.

Gas will have to be purchased at market prices at the moment. Therefore, you won’t be able to add fuel in the summer and save money. Refuel for the year too.

It's always better to have a supply of gas just in case. Even if 1,000 liters is enough for you for the season, it is better to have 1,400 liters available.

Narrows the list of contractors. It is much more difficult to agree on regular filling of a small tank. Not all companies drive a tanker for 500-600 liters of LPG. At Termo Life, the minimum order is 2,000 liters.

As a result, you need a large gas tank to fill a small one. This is not a joke: many negotiate with the owners of tanks over 2,500 liters so that gas stations will stop by their “babies” along the road.

By the way

If you want to know all the risks of mini-solutions in advance, talk to an engineer.

Prepare for risks

Requires insulation. Either the mini-gas holder has a special electric heating system, or in winter the container must be heated manually. Methods “who knows what”: film heated floors, heating cables for water pipes, even the “Good Heat” wall-mounted electric heater.

The problem is related to the above-ground installation: a buried gas holder heats the surrounding soil due to its high heat capacity.

Illustration for the thesis about insulation in the screenshot below. While the propane was evaporating, the heating and water supply worked. When 20% of the mixture remained, the gas stopped flowing. Butane does not evaporate in cold weather. Therefore, an outdoor gas tank needs heating.

Quote from user Evgeniy 17 from the ForumHouse forum

Refilling a mobile gas tank

When there is less than 20% gas left in the gas tank, it needs to be refilled. To replenish your gas supply, you can call a gas carrier, or you can take a trailer with a gas holder installed on it to the nearest gas filling station (gas filling station) using your own car. Transportation of such a volume of gas does not require a permit. To refuel a mobile gas tank at a gas station dispenser, a standard refueling nozzle is used. Refilling time is approximately 25 minutes. Gas level control is carried out using a level gauge.

Accessories

In this situation, it all depends on the price, type of model, and manufacturer. But even the purchase of expensive equipment does not guarantee that its components will include a complete set of all the necessary tools for comfortable work.

Here is a list of tools that you may need to comfortably use a laser machine.

- Case for transporting equipment.

- Protective glasses from laser light.

- Sighting targets.

- Laser receiver.

- Remote Control.

- Mount for the device.

- Tripod.

- Magnetic mounts for installing the device on a vertical plane.

- Additional battery.

Although a device such as a laser level is an expensive tool, its characteristics and capabilities easily pay for its cost, making work more comfortable, faster and more convenient.

Options for insulating a gas tank

Owners of houses that are heated exclusively using an autonomous gas supply often think about additional insulation. This is especially true for residents of the northern regions, where the operation of a gas tank is complicated by very severe frosts. But how effective can insulation be with standard insulation, for example, polystyrene foam, for the operation of a gas holder?

As mentioned, butane freezes quite naturally at extremely low temperatures. In view of this, in the northern part of the country, people do not rely on the quality of the winter gas mixture, where there is more propane, but prefer to insulate the container with heat-insulating materials, for example, extruded polystyrene foam.

In those regions where severe frosts do not occur, it is enough that the gas tank is installed at a depth, and on top it is protected by a layer of snow, which does not allow cold air below to pass through.

In warm areas where the ground does not freeze deeply, it is enough to insulate the gas tank around the perimeter with a thin layer of heat-insulating material

As insulation, it is best to use polystyrene foam, both sheets and crumbs, mineral wool, penofol, expanded polystyrene. Their number should depend both on the lowest air temperature in the region and on the depth of the gas tank.

If it was decided to insulate the gas tank, use the following expert advice:

- install insulation on the top of the container;

- carefully cover the neck and lid with heat-insulating material;

- make a high-quality shelter for the gearbox.

Some try to connect a pipe from a heated floor to the reducer and maintain a temperature of about 30 degrees in it.

But not all engineers approve of this solution, so consult with specialists before implementing it. But never connect an electrical cable to a gas container.

Safety measures during installation and operation of gas equipment

All work processes must be carried out in strict accordance with fire safety regulations. The following standards govern installation work:

- Federal Law No. 123-FZ;

- GOST 5172-63;

- SP 62.13330.2011, section 8;

- SP 43.13330.2012, paragraph 6.2;

- GOST 20448-2018.

Key requirements for tank installation:

- The distance from a residential building for underground placement is 10 m, for above-ground placement is 20 m.

- Distance from utility networks and other buildings on the site is 2 m.

- When installing above ground, you should consider thermal insulation of the container so that the propane-butane inside it does not freeze in the winter.

- Sunlight exposure to the tank should be minimal.

- The average depth and width of the pit for the container is 2 m. The length is determined individually - depending on the size of the tank.

- The bottom of the pit should be covered with a layer of sand cushion or a monolithic slab should be poured for ease of fixing the tank with cables and bolts.

- The gas holder fixed in the pit must be filled with sand. It will not retain water, and the soil nearby will not freeze. A layer of soil is poured on top.

- The area covered with earth on top of the gas holder cannot be concreted or laid with tiles. It must be freely accessible so that you can always check the condition of the tank during maintenance or repair.

It is important to remember that any gas tank should be installed only by specialists who have a license and official permission to work with gas equipment. Upon completion of installation, a guarantee must be provided for the list of services performed.

Do-it-yourself installation of a gas holder is prohibited.