Every day, owners of private houses or summer cottages are increasingly asking themselves the question of drilling a well or a well on their territory. But in addition to drilling, it is also necessary to somehow supply the extracted water to the house, and here the owners are stunned, and a lot of questions arise in their heads. Which well pump to choose? What should its performance be? Choose an expensive model or save money? Let's consider the domestic well pump Vikhr SN-100, because they have proven themselves to be reliable and inexpensive products. Over the many years of the company's existence, the range of pumps has become very large, since each operating condition requires an individual tool.

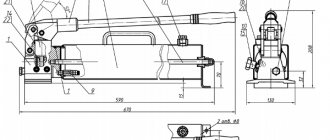

Devices and main components

Currently in Russia you can find hydraulic equipment from manufacturers in Italy, the USA, Germany, France, Denmark: ZDS, PEDROLLO, CALPEDA, WILO, Busch, GRUNDFOS, Tapflo and others; Russian companies Gilex, Ampika, Pinsky OMZ, GMS Livgidromash.

Submersible pumps are designed to pump water from wells, wells or basements of buildings and, if necessary, supply it to a collapsible water supply network. At the same time, their working area is immersed in liquid, which is why they are called that.

There are several types of these devices:

- Centrifugal, in which the main element is an impeller (impeller) or a screw. Examples of them are “Vodomet”, “Aquarius”, “Whirlwind”, “Octopus”.

- Vibrating ones, which are headed by a piston. An example of them is the “Kid” pump.

- Vortex pumps are similar to centrifugal pumps, but are distinguished by a higher circular velocity of the fluid. An example is the “Vikhr” vortex pump.

Note: centrifugal units are divided into rod-type, when the hydraulic part and the electric motor are located in different places and are connected to each other by a rod, and rodless, when the electric motor is combined with hydraulics.

The main components of centrifugal apparatuses include:

- impeller or screw/auger;

- electric motor;

- barbell;

- stuffing boxes;

- couplings;

- bearings.

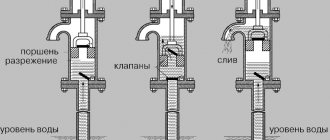

The main components of vibration devices include:

- working part body;

- drive unit;

- electric coil;

- piston;

- diaphragm;

- valve

- shock absorber;

- emphasis;

- coupling

Pump selection criteria

- Depending on the diameter of the well, the size of the pump is selected, taking into account the fact that it must fit into the pipe with a gap (at least 10-15% of the diameter of the well);

- The operating capabilities of the pump are selected in accordance with the depth of the well.

Advice! It is better to take a more powerful pump due to the fact that over time, the abrasive agents present in the water will weaken the device;

- The required amount of water and its pressure are determined by the power of the pump. Thus, in the line of Vikhr models there are units with a capacity from 1500 l/h (CH-90V) to 3600 l/h (CH-50N).

Important! As the pump immersion depth increases, its performance decreases;

- Regardless of the pump model, it must have automatic protection. For example, all models of Vikhr pumps have a thermal relay in their arsenal, which is activated when the device heats up to a temperature of 110 degrees. Some models also have anti-clogging protection.

The video below shows:

Review of the CH-100V pump:

Problems with the Whirlwind pump – vibration:

Repair of the Whirlwind pump:

Breakdowns of the deep apparatus, causes and solutions

Let's consider possible breakdowns of centrifugal units

- It hums, but does not pump water (or flows weakly). Reason: wear/destruction or silting of the impeller; increasing the gap between the screw and the device body; clogging of the coarse filter with debris; spontaneous unwinding of the nut securing the impeller to the shaft of the working part; breakage of the key connecting the impeller to the unit shaft, drop in mains voltage. Solution: clean/replace the impeller/screw, restore the fastening of the wheel to the shaft, clean the filter from debris, install a current stabilizer.

- Knocks out plugs when turned on. Cause: short circuit of the stator winding or armature of the electric motor, breakdown of the power wire, jamming of the device by foreign particles between the impeller/screw and the housing, low voltage in the network. Solution: disconnect the electric motor from the hydraulic unit, check it for functionality, rotate the shaft , if necessary, clean the unit from blockages, check the serviceability of the electrical wire, find out if there is supply voltage, if necessary, install a stabilizer.

- The pump overheats and vibrates strongly. Reasons: foreign particles get between the impeller/screw and the housing, which leads to friction of these particles, causing the latter to heat up. Vibration of the device is possible due to partial destruction of the blades or wear of the bearings. Reasons for overheating of the electric motor: foreign particles entering the hydraulic part of the device and rubbing them against the body, which creates additional load on the engine, causing it to overheat; reduced supply voltage; liquid entering the motor due to seal failure; oil leak (dry running). The reason for vibration of the electric motor is wear of the bearings. Solution: cleaning the hydraulic unit, replacing the oil seals of the electric motor, bearings, installing a voltage stabilizer.

- Low fluid pressure, the pump barely pumps. Reasons: silting of the impeller/screw; increased clearance between the impeller/screw and the housing due to wear of the impeller/screw; filter clogged with debris; low voltage in the network. Solution: clean the filter, impeller/screw or replace the worn impeller; install stabilizer.

- Noises during operation. Causes: loosening of the nuts securing the impeller to the unit shaft, wear of the impeller key, bearings, coupling. Solution: check the fastening of the impeller on the shaft, replace the bearings and coupling.

- Mechanical defects. This type of malfunction of submersible hydraulic units includes defects in manufacturing, assembly and installation. They also include wear of the working body, bearings, and stuffing box seals. Defects in the manufacture of device parts, assembly and installation appear immediately. In this case, the device can be replaced by the seller. Worn parts are replaced.

- Voltage surges. During surges, cable damage occurs, the stator or armature winding burns out, and possibly both windings. Solution: use a voltage stabilizer for frequent current surges in the network.

- Siltation. The working part of the installation can become silted, that is, become covered in silt or sand. Moreover, if it does not work constantly, then silt or sand can cake/compact, thereby jamming the electric motor, which, the next time the unit is turned on, can lead to the plugs being knocked out or the electric motor burning out if they do not work. If the installation operates constantly, then silt or sand may stick to its working element, which will lead to a decrease in its performance. Solution: use a device with an upper suction pipe; promptly clean the location of the unit from silt or sand; Periodically remove the device, disconnecting it from the power supply, for cleaning.

- Cable rupture. Causes of mechanical damage: fracture, pinching, extreme cable tension. Solution: laying from the connection source to the pump through pipes, hose armor, cable channels for protection from mechanical damage; use sufficient length.

Rewind the reel

If you need to rewind the vibration pump coil, prepare the following consumables and tools:

- wire brand PETV;

- set for replacing epoxy compound (epoxy resin, plasticizer, hardener);

- electric stove;

- winding machine (can also be done manually);

- soldering iron;

- hammer.

While rewinding the coil, you will need to melt the epoxy compound. It is toxic, so carry out the work outside or in the garage. Place the filled electromagnet on the tile and wait until the epoxy heats up to 165 degrees. This will be visible from the toxic haze that appears.

Carefully knock the electromagnet out of the housing on a wooden object, while the electromagnet looks straight down. When the magnet changes its position, remove it. We clean the heated body from epoxy resin, using a screwdriver or a metal brush.

We knock the electromagnet out of the coil with a wooden wedge.

We do not clamp the coils in a vice, we only hold them with our hands.

Once the magnet is removed, unwind the coil, removing all the epoxy.

Using a winding machine, wrap the spool completely. Here you can do without a machine, but it will take longer to wrap it by hand.

Solder the ends of the wire to the main part, now we mount the electromagnetic core into the coil body. We solder the power cable to the beginning of the new winding. It is permissible to “seat” the coils by lightly tapping the core.

After mixing the epoxy with the plasticizer and adding the hardener, we pour it into the vertically fixed body of the device. Fill the compound to the top of the electromagnet, wait 10 minutes and add the compound again (after filling all the cracks, it will settle). After 24 hours, we assemble the pump and check its functionality.

How to disassemble correctly

First, turn off the power, then dismantle, disconnect the pressure pipeline and disassemble it:

- remove the coarse filter;

- disconnect the motor part from the hydraulic part.

Disassembling the hydraulic unit:

- the hydraulic part is clamped with a vice onto the pressure pipe;

- the housing is unscrewed;

- All parts are removed from the shaft;

- if necessary, replace worn or broken ones;

- the parts are washed and then assembled onto the shaft.

Important: in order not to confuse the parts, they must be placed in the order of disassembly or put on any axis/rod without changing position.

Motor disassembly:

- it is installed with the lid facing up;

- unscrew the lid and remove the sealing gasket;

- oil is drained;

- using a press, the lower motor cover is pushed down, the locking ring is released, and then removed;

- with light blows of a mallet on the end of the shaft, the bottom cover with the rotor is knocked out;

- the engine rotor with bearings is removed;

- if replacement is necessary, remove the bearings from the shaft and the oil seal from the top cover of the motor;

- windings are checked; if necessary, the stator is sent for repair. Assembly is carried out in the reverse order.

Vortex

In vortex submersible pumps, water is taken in and expelled using a single impeller with blades, which is located in the upper part of a vertically suspended housing next to the outlet pipe. To reduce hydraulic losses, the design provides for a very small distance between the side edge of the vortex wheel disk and the working chamber - this makes it impossible for vortex devices to operate in an environment with sand particles.

Vortex-type devices have good pressure characteristics (the height of liquid rise reaches 100 m) and average pumping volumes (about 5 m3/h).

Although vortex electric pumps are rarely used in everyday life, there are Belamos TM, Sprut, Vikhr, NeoClima, Pedrollo Davis models on the market.

Rice. 7 Vortex submersible pump - design and appearance

Centrifugal

Centrifugal devices have achieved such widespread popularity due to the following properties:

- Their efficiency factor (efficiency) is the highest of all analogues; in large-sized industrial units it reaches 92%, in household models it reaches 70%.

- Structurally, the working chamber is designed in such a way that the liquid enters the central part of the centrifugal wheel and is pushed out through the side pipe. This makes it possible to make multi-stage centrifugal devices in which the ejected liquid is fed to the axle of the next wheel, which further increases its pressure. Thanks to the use of several centrifugal wheels with separate working chambers (stages), it is possible to obtain pressure parameters in the system that are several times higher than those of other pumping equipment (in household models, the pressure does not exceed 300 m).

- Centrifugal types are capable of pumping liquid in large volumes at high pressure; for domestic use, this figure rarely exceeds 20 cubic meters per hour.

- Centrifugal-type units are less susceptible to the effects of small sand particles on the working mechanism; they are widely used in sand wells, choosing a model to work with the appropriate particle size specified in the passport.

- A significant advantage of centrifugal types is their high level of automation; the world's leading manufacturers of pumping equipment (Grundfos, Pedrollo, Speroni, Dab) equip their devices with units with frequency control of the impeller rotation speed. This innovation allows not only to significantly save energy when operating the electric pump (up to 50%), but also to significantly increase its service life.

If we list all the manufacturers of centrifugal pumps that present their products on the domestic market, the list will be quite lengthy, so we will limit ourselves to the leading global manufacturers listed above. Among the domestic brands, the most famous are Aquarius, Gilex Vodomet, Vikhr, Belamos, Caliber, Unipump.

Rice. 8 Centrifugal submersible pumps - design and materials using the example of Grundfos SBA

Do-it-yourself repair of downhole equipment parts

To repair downhole devices, they are first de-energized, then removed upward and disconnected from the pressure pipe.

Piston replacement:

- the tightening bolts are unscrewed;

- body is removed:

- the nuts are unscrewed from the rod;

- the valve is removed from the stem;

- a new one is installed;

- tighten the nuts securing the valve to the stem;

- the housing is put in place;

- both parts are bolted together.

Valve replacement:

- the tightening bolts are unscrewed;

- the housing of the hydraulic part is removed;

- the valve mount is unscrewed;

- the old one is removed;

- the new valve is screwed onto the body;

- the housing is installed in place;

- both parts are fastened with coupling bolts;

- The operation of the installation is checked in a container with water.

Coil replacement:

- unscrew the coupling bolts;

- remove the hydraulic housing;

- remove the piston assembly with the diaphragm, clutch, shock absorber and armature;

- heat the compound filling of the electromagnet with a burner or on a hot plate until it softens;

- remove the electromagnet from the motor housing;

- clean his nest;

- remove the coil from the core;

- disconnect the power cable;

- replace the coil;

- solder the power cable and insulate the soldering points with PVC pipes;

- install the coil on the core;

- place the coil with the core exactly in place in the engine compartment;

- fill the electromagnet with epoxy resin according to the instructions;

- after 15-30 minutes, add resin to the upper level of the core;

- Allow the resin to harden overnight;

- install the anchor assembly on the engine compartment;

- put the pump housing in place;

- install coupling bolts;

- Check the operation of the unit in a container with water.

Replacing the discharge pipe:

- to repair deep-well pumps, they need to be de-energized, raised to the surface, then disconnected the pressure pipe;

- unscrew the check valve;

- unscrew the discharge pipe;

- screw in the new discharge pipe, having previously wound the FUM tape or FUM thread onto the thread;

- screw on the check valve, winding the threads with FUM tape or FUM thread;

- connect the pressure pipe;

- lower the apparatus into the well;

- connect power supply.

Engine thermal insulation:

- to replace the thermal insulation of the engine, you need to disconnect the hydraulic and motor parts;

- remove the retaining ring;

- remove the seal and install a new one in its place;

- assemble the unit;

- connect the pressure pipeline;

- lower the unit into the well;

- connect power.

Fluid has leaked from the engine:

- disconnect the motor part;

- install the engine vertically, with the cover up, unscrew the motor cover;

- pour in environmentally friendly non-toxic oil (some experts recommend pouring Vaseline oil);

- check the integrity of the gasket; if necessary, replace;

- screw the top cover;

- connect the motor part to the hydraulic part;

- lower the device into the well;

- connect power.

Owner reviews

Vikhr pumping equipment is often praised, but sometimes there are also negative reviews.

An undoubted advantage of the technology is its price, which is 15-20% lower than other domestic analogues and more than 30-40% lower than foreign ones. Among the negative reviews, one can highlight the increased noise of the device. There are also complaints about weak fastenings and their instability to rust. Anatoly, 50 years old, Magnitogorsk: I have had this miracle of technology for more than 3 years, it works like a charm. At first, after reading reviews on the Internet, I was afraid that something would fall off or that I would break it myself, but over the entire period there were no complaints. Valery, 34 years old, Omsk:

I bought a “Whirlwind” drainage system for my dacha, I thought it wouldn’t last long, since I bought it for a symbolic amount. But after several years, everything works great, only the plastic fasteners began to deteriorate, but I’m completely satisfied with the work. Oleg, 43 years old, Kyiv:

About 6 years ago I acquired a “Vikhr” borehole pump, model SN-50, but when purchasing it I was confused by its price. I thought about saving up some money and purchasing a new imported pump in 1-2 years. But, fortunately, the money was not useful, and the device is still working. True, after two years a slight vibration appeared, and after another year it had to be sent for repairs. As it turned out later, the pump broke down through my fault, but I was lucky that the breakdown was minor and cost mere pennies.

Increased service life

Motor inspection/revision

In order for the device to last longer, it needs to be inspected at least 2 times a year. To do this, check:

- oil level in motors of centrifugal and screw units;

- integrity of compound filling in vibration installations;

- degree of bearing wear;

- integrity of the power cable;

- hull integrity;

- cleanliness of the unit surface.

Pump inspection/revision

To do this, check:

- hull integrity;

- cleanliness of the unit surface;

- the amount of liquid pressure;

- filter cleanliness;

- absence of mechanical noise during operation of the installation;

- free rotation of the shaft.

Advice: do not forget to inspect the installation and electrical equipment at least 2 times a year, at the beginning of the summer season and at the end of it.

Experts' opinions

Thanks to its popularity, the “Whirlwind” also interested professional craftsmen, who have seen dozens of variations of submersible and centrifugal pumps in their lifetime.

The Whirlwind pump is often reviewed positively

As a result of this, the following conclusions were made:

- The device is good for home use, but for industrial purposes it will be low-power;

- The pump is not protected from voltage surges, so it is advisable to connect a stabilizer to the switching circuit;

- Cleaning must be done periodically, otherwise the pump risks failing very quickly;

- The best water to use is water with a minimum percentage of solid impurities.

Vikhr pumps are relative newcomers to the market, but they have already managed to win their segment of grateful customers and good ratings from professionals. The main thing is to carefully study the technical specifications before purchasing, do not use the device to the limit and provide it with proper care. And then even an inexpensive “Whirlwind” will be able to serve for quite a long time.

How much will it cost

The cost of repairing a well pump, as well as parts for their repair, may be different in each city. Let's give the average cost for each of the named units and components. The cost of repairing centrifugal, vortex and screw installations will cost from 2000 rubles and more.

Cost of replacement parts

For vibration pumps:

- piston - 34 rubles;

- valve – 33.60 rub.;

- repair kit (piston + valve) – 67.20 rubles;

For centrifugal and screw units:

- oil seal - 100 rubles;

- impeller - from 100 rubles;

- screw - from 550 rub.;

- pump shaft – from 260 rubles;

- starting capacitor - from 300 rubles;

- electric motor – 3500 rub.;

- mechanical seals – 2550 rub.

Thus, we can conclude: restoring the operation of the electric pump yourself will cost much less than purchasing a new unit or using services.

Popular models

The following surface pump models are in good demand among private craftsmen:

- Whirlwind PN-370. The body is made of durable cast iron, which prevents any mechanical damage. The unit has a built-in ejector with Venturi pipes. The permissible lifting height of the liquid is 30 meters with a suction depth of 9 m. The model pumps 45 liters of water per minute. The Whirlwind pump PN-370 is equipped with special protection against overheating and can work with media whose temperature does not exceed +35 degrees.

- Whirlwind PN-900. The power of the electric motor is 900 W. The best option for a summer cottage. The pump pumps 60 liters per minute, while the maximum intake depth for this model is not specified by the manufacturer. The equipment can be used on average at a depth of 10-15 m (more is unacceptable for a surface pump). The unit is equipped with a handle for easy carrying. In operation, the equipment proved to be low noise with a low vibration level. Part of the body is made of durable polymer.

- Whirlwind PN-1100N. The unit body is made of stainless steel. The permissible suction depth is 9 meters with a permissible pressure of 50 m. The motor power is 1100 W. The pump body is equipped with a handle for transportation and a comfortable, stable frame. The pump pumps 70 liters of liquid per minute.

Which brands to prefer?

When choosing a specific brand of pump for a well, pay attention to two things. The first is the number of positive and negative reviews. Only here you need to keep in mind that positive reviews are rarely written - if the equipment works and they don’t remember about it

Only if there were some problems before that the new pump solved. Then there are chances that there will be a positive review. There is a much higher chance of receiving negative feedback if there are problems. So the ratio of positive and negative opinions will be biased. You can simply compare the amount of positive and negative regarding different brands

Only here you need to keep in mind that positive reviews are rarely written - if the equipment works and they don’t remember about it. Only if there were some problems before that the new pump solved. Then there are chances that there will be a positive review. There is a much higher chance of receiving negative feedback if there are problems. So the ratio of positive and negative opinions will be biased. You can simply compare the amount of positive and negative regarding different brands.

Choosing a pump for a well is not easy

The second thing you need to pay attention to is the availability of service centers and warranty workshops in your region. So that if a problem arises, it can be solved quickly and easily, and not have to travel far away

This is also very important

This is also very important

What should I pay attention to (besides technical specifications)? The presence and number of degrees of protection. Good (and expensive) equipment may have the following built-in mechanisms:

- dry-running protection (shutdown when there is no water);

- protection against overloads and electrical discharges (overheating);

- sand removal system;

- from water leaks (check valve, this can be installed additionally without any problems).

From this list, it is very desirable that the well pump has protection against dry running and overloads. These are basic things that extend the life of the unit. Sand removal is, of course, good, but the equipment is very expensive. A check valve can be placed immediately at the pump outlet on the suction hose (pipe).

Pump brands that are considered the best

The opinion of experts does not always coincide with the opinion of users, but it is also worth listening to them. They mostly recommend expensive brands, but for a reason, but because they really work well. So, here is a list of companies trusted by the pros:

- Aquarius. At a relatively low price, quite decent quality.

- Gilex. They work normally - about 5-6 years - with the correct selection of parameters.

- Flow. Chinese-Russian, but they work fine.

- Aquario (Aquario). Normal quality for not very much money.

- Grundfos (Grundfos). Leader in quality, but also in prices.

- DAB Worthy competitors for Grundfos at lower prices.

- ESPA. Good quality. There may be problems with service - not all regions have service centers.

- Willo (Willo). Another one of the market leaders. Good quality at more or less decent prices.

- ZDS. These well pumps have performed well. The manufacturer gives them a 2-year unconditional warranty - replacement if they break down for any reason.

- Acua. The entire hydraulic part is stainless steel, but these pumps are not sized for most wells.

- Water cannon series Prof. Quite decent quality, but repair only at a service center.

This is a more or less complete list of brands recommended by professionals.

Design features of the equipment

All produced pumping stations are divided into industrial and domestic. The former are distinguished by their high power and high efficiency; they are used for water supply to various industrial facilities.

The power of household devices is an order of magnitude lower; in most models its indicators do not exceed 1200 W, which is quite enough to provide water for a country house, outbuildings and watering a garden.

The main structural elements of the pumping station are:

- pumping unit;

- water storage tank or hydraulic tank;

- pressure switch;

- pressure gauge

The most important element of the system is the pump; the functionality of the equipment depends on its characteristics.

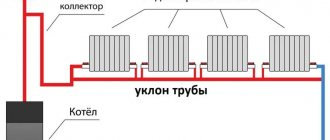

Automated water supply schemes can be equipped with surface units installed directly on a hydraulic accumulator, or submersible ones, which are lowered directly into a well or well.

Surface pumps, in turn, are also divided into several types:

- Self-priming with a built-in ejector, they allow you to get water from a depth of up to 45 meters. However, these units are quite noisy and have a high price.

- Self-priming with a remote ejector, which is installed in the well shaft. The devices can also extract water from great depths and produce minimal noise during operation, but they are sensitive to sand and silt;

- Vortex or centrifugal pumps without an ejector, capable of pumping water from a depth of no more than ten meters. Units of this type are much cheaper than their analogues and operate more economically.

For summer cottages with high groundwater levels, as a rule, the latter is the most economical and inexpensive option for a pumping station. Centrifugal units have a fairly high noise level, so they are usually installed away from residential buildings.

Vortex ones operate almost silently, but can break when frozen; it is better to place them indoors. If the depth of water in the well is more than nine meters, then it is advisable to use a station with a submersible pump.

Pumping stations are equipped with storage tanks or hydraulic accumulators. The first type of tank is equipped with a float mechanism that controls the water level.

The drives are inexpensive, but have recently been rarely used due to the complexity of installation (they are installed above plumbing fixtures), low performance and large dimensions.

Hydraulic tanks are a completely sealed compact reservoir controlled by a pressure sensor. They have high efficiency, provide stable pressure and good water pressure. Suitable for installation anywhere.

Source: https://ros-tile.ru/nasosnoe-oborudovanie/nasosnye-stanczii-vihr-obzor-model

Pumping station "Vikhr" ASV-370/2Ch

“Vikhr” automatic pumping station, which provides uninterrupted water supply for various purposes. It works not only with surface sources and reservoirs, but also with underground wells and wells.

Advantages:

- asynchronous electric motor;

- self-priming pump, which contains an integrated ejector providing good self-priming height;

- there is a pressure switch - a special relay that reacts to its fluctuations above or below the optimal level;

- built-in pressure gauge – the user can easily monitor the pressure status at a specific time;

- reliable metal receiver, which consists of 2 parts with a membrane partition;

- sealed cast iron body, resistant to impacts and environmental factors;

- thermal protection that operates in auto mode.

Technical parameters of ASV-370/2 Ch:

- Power – 0.37 kW;

- Supply – 2.7 m3/h;

- Head – 30 m;

- Suction – 9 m;

- Hydraulic accumulator – 2 l;

- Weight – 6 kg.

Installation rules

Like all pumping stations, Gilex Jumbo units should be installed only in insulated rooms, because this equipment can operate at temperatures not lower than +1C, but not higher than +30C. The simplest solution is the basement of the house. But everything will depend on the model of the unit used. For example, the same device of the Jumbo 70/50 brand is a very noisy installation, so it is better to install it in a utility room or inside a caisson. Low-power models can be installed in the basement.

And the main requirement for installation is a flat and durable surface. And although Gilex pumping stations use centrifugal devices, they still vibrate

Therefore, it is very important to install the unit level and secure it well.

And one last thing. All pumping units from the Gilex company are inexpensive models that are affordable for any resident of suburban areas. In addition, all equipment is adapted to Russian operating conditions, especially with regard to voltage drop in the supply network. So Gilex will withstand everything.

Adviсe

When setting up a summer house, private house or farm, a person sooner or later faces a water supply problem. An expedient solution to the problem is to install a modern pumping station, which will not only provide water, but also help make a supply of liquid (thanks to a spacious water tank) in case of emergencies or other unforeseen situations.

When purchasing a pumping station, you should pay attention to several key points

- Suction depth. Here, the degree of remoteness of the well or well and the water intake points are taken into account.

- Volume of fluid consumed. On average, for 2-4 people living in a country house in the summer, a tank with a volume of 20-24 liters is sufficient.

- Unit power. A powerful pumping station will allow you to water the area with plantings and make a quick supply of water.

- Material for manufacturing the body of the structure. The most popular are plastic models. This material provides a high level of sound insulation and is not subject to corrosive processes. It is also wear-resistant and does not release harmful substances into the water.

- The presence of an ejector, which improves the functionality of the device as a whole.

- Protective functions of the mechanism that prevent overheating of the system, extending the service life of the station. The higher the electrical protection class, the better the safety of the product in the event of accidental splashes of water or sand.

Regardless of which model of pumping station was preferred, its connection should be carried out by a specialist or person who has the necessary knowledge and experience in this matter.

And in the next video you will clearly see the operation of the VORTEX ASV-1200/24 pumping station.

Where is it used?

The CH-90V whirlwind is used primarily for gardening needs and for supplying water for domestic purposes - home plumbing, bathhouses. It is prohibited to use the unit in the following conditions:

- Pumping out septic tanks.

- Emptying reservoirs during seasonal or natural flooding - basements, storm drains, gutters.

- Emptying containers containing acidic, alkaline or other aggressive chemicals.

From the list we can conclude that the pump is demanding on the quality of water - it should not contain sand or impurities.