Selecting adhesive for extruded polystyrene foam.

Extruded polystyrene foam is a reliable insulation material for walls, facades, floors, and ceilings; it is often used in construction. Penoplex is a capricious material, and not every glue is suitable for it: some adhesives can destroy the structure of extruded polystyrene foam. Choosing the right adhesive for extruded polystyrene foam will help you quickly and reliably repair your home. Today we will introduce you to the features of extruded polystyrene foam and tell you why it is considered the best insulation for houses.

We will also advise how to glue extruded polystyrene foam.

Features of installation of polystyrene foam

Extruded EPS is a high-density foam material. It is this indicator that distinguishes it from ordinary polystyrene - polystyrene foam. The density increases during the production process when passing through the extruder, this seriously increases the thermal insulation characteristics of the material. The final slabs consist of polymer and small air bubbles.

Due to the smoothness of EPS boards, they have very weak adhesion to the adhesive composition. This is the main problem when gluing. It can be solved by selecting special adhesives that themselves have high adhesion to any surface. Also, some products can partially dissolve the foam top of the slabs by being absorbed into them.

The specifics of installing polystyrene foam boards are as follows:

- if the material was purchased as floor insulation, it is laid on an expanded clay pad or on a pad made of other low-density material and filled with concrete;

- to insulate the foundation, the slab must be glued to the concrete of the base and secured with mounting fasteners;

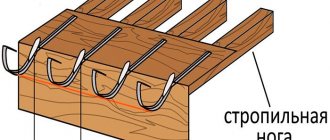

- material is laid on the roof, then a layer of bitumen is placed or PPS is laid between the ribs of the rafters inside the roof layers;

- When insulating the ceiling in an apartment on the top floor, polystyrene foam is laid on the attic side with glue, then concreted or covered with crumbs, gravel, expanded clay.

Scheme of application of various brands

The following key types of expanded polystyrene are produced, differing in density and other characteristics:

- PSB-S-15, the density of this brand of foam is up to 15 kg/cu.m.

- PSB-S-25, from 15 kg/cu.m. up to 25 kg/cu.m.

- PSB-S-35, from 25 kg/cu.m. up to 35 kg/cu.m.

- PSB-S-50, from 35 kg/cu.m. up to 50 kg/cu.m.

The thermal conductivity component of foam plastic, expressed in digital values, refers to the range 0.037 W/mK - 0.043 W/mK. The indicated value can be correlated with the thermal conductivity of air, which is equal to 0.027 W/mK.

Use of polystyrene foam PSB-S-15

Polystyrene foam PSB-S-15 can be used for insulation of house facades. This type of insulation is practically not used in construction. It is used in structures that are attached to structures. These can be open balconies or verandas that serve a decorative function. Using PSB-S-15 foam plastic, shapes for facades are formed, and this allows:

- frame the corners of the house, windows;

- separate floors by creating cornices.

What is PSB-S-25 suitable for?

Plates with a density of 25 are used to insulate the facades of a house. The standard is foam plastic, the thickness of which is 5 cm. This type of insulation is used for many purposes. Its thickness can be changed - this will depend on consumer preferences.

Polystyrene foam of maximum thickness can be used to insulate walls that are exposed to atmospheric agents. They can also be used to insulate walls, since such material perfectly prevents the appearance of fungus.

Based on the designation of the material, it is used in various construction structures, and this does not impair its quality characteristics.

Application of polystyrene foam PSB-S-35

Before choosing insulation of the required thickness, it is recommended to find out in advance how much gas pipe is available, because under no circumstances should it be covered, as this may disrupt the aesthetics of the appearance of the building. In this case, it is advisable to prefer PSB-S-35 material with a thickness of 5 cm over material with a density of 25 and a thickness of 10 cm, especially since their prices are practically the same.

Insulation with a density of 35 can be used to insulate the slopes of windows and doors, and the facades of buildings. As a rule, it costs twice as much as the same polystyrene material with a density of 25. With a thickness of 5 cm, it can be used to insulate non-residential structures and garages. With a thickness of similar insulation of 7 centimeters, it can be used for thermal insulation of residential premises.

Due to the normal level of density, it is possible to use a heat insulator with a minimum thickness, which does not imply a deterioration in the quality of insulation. If the polystyrene foam heat insulator turns out to be harder, then it can be used to provide ideal insulation of basement walls and foundations.

Selecting adhesive for extruded polystyrene foam

How to glue polystyrene foam? To fasten the slabs, you can use different means that have different components. But there are specifics to using mixtures. So, it is better to use one for gluing to a concrete base, another for attaching to a brick wall, and another for winter work. There are adhesives that combine the properties of fastening material and insulation and have low thermal conductivity.

Before purchasing, it is important to clarify that the product contains no substances that corrode polystyrene foam. This:

- acetone;

- alcohol substitutes;

- toluene;

- esters;

- other solvents.

The ideal option is to purchase specialized formulations, because their manufacturers have already taken into account all the important points. There are three main types of products that are suitable for gluing material. This is a plaster-adhesive mixture of different brands, polymer adhesives and bitumen glue (mastic).

People often use “liquid nails” in a bottle, silicone sealants, frost-resistant tile adhesives, drywall and tile products for gluing materials. Can I use them? Experts say that the use of such adhesives is possible, especially if additional fastening of the structure with dowels is planned. But the cost of the work can be much higher, so it is better to buy products designed for XPS.

How to glue foam

Before gluing the foam, it is determined what is best for this type of plane. Technologies differ for street and home processing. It is necessary to choose products that have the greatest adhesion, are resistant to negative factors, are economically beneficial, and are also safe for humans.

Before starting work, it is recommended to carefully study the instructions, which are usually located on the packaging and are duplicated in the attached documents; they describe in detail how to glue foam plastic to a wall or floor.

To the foam

Novice craftsmen are interested in how they can glue foam plastic together and which option is better. Any solution is not suitable for this.

Specialized brands such as Styroglue are most often chosen. A neat, invisible seam is formed. From available means, PVA can glue the foam onto itself, apply it to both plates, then connect and hold for some time until bonding.

To concrete

They are glued to the concrete base with bulk mixtures diluted to the desired state. The surface to be treated is cleaned, degreased, and primed if necessary. The powder is poured into a bucket, diluted with water, and mixed with a construction mixer until the lumps dissolve.

Then it infuses for 10-15 minutes and swells. The mixture is applied to the polystyrene foam block along the edges and evenly in the middle, pressed tightly horizontally or vertically, and apply pressure.

Excess adhesive is removed immediately with a damp cloth. Having figured out what kind of glue to glue polystyrene foam, you can achieve the best results.

To metal

To attach the foam sheet to the metal, you will need burlap. It is laid to increase adhesion. In this case, any adhesive products are used; the best option for Eps is foam in spray bottles.

The mixture is applied in dots to the polystyrene foam block. Strips are made using diluted dry mixtures.

To the tree

Before gluing the foam to the wood, preparation is carried out. Before installation, it is thoroughly cleaned, greasy stains and unevenness are removed, and the paint is removed. Then it is treated with a primer and antifungal drugs, since mold will grow on it due to dampness.

The cracks are sealed. The adhesive product is spread in strips onto the sheet with 2 cm indentations from the edges. It is desirable that the product has fungicidal components. Expanded polystyrene attaches well to wood.

Plaster and adhesive mixtures

Such mixtures are suitable for gluing EPS to plasterboard, brick, concrete, and cinder block bases. You need to breed them yourself, since they are sold in the form of dry mass. The composition includes mineral components, plasticizers, Portland cement, and a number of auxiliary additives. The mixtures are suitable for exterior work and interior decoration; they will hide all the unevenness of the base. The downside is the need for preliminary deep priming of the surface.

Ceresit CT-83

"Ceresit ST-83" is widely used for pasting building facades. It has excellent frost resistance and adheres well to wood, concrete, plaster, and brick. After drying, ST-83 is breathable. Consumption per 1 sq. m is small, because it is enough to apply the mass 1 cm thick (this is done with a notched trowel).

The company also produces high-quality adhesive Ceresit CT 85, which is considered universal. High strength and ductility are due to the polymers included in the composition. But this product costs an order of magnitude more than the previous one, so builders prefer ST-83. Both materials are applied in intermittent stripes, slightly retreating from the edge for better air release.

Bergauf ISOFIX

Bergauf Isofix glue is a mixture of minerals, fillers, cement, sand, plasticizers, and special additives. Can be used for any indoor and outdoor use. Average consumption – up to 5.5 kg/sq.m. m, a thin layer (3 mm) is required. After dilution, the mixture is viable for 1.5 hours, it is possible to change the position of the plate on the wall within 25 minutes. The glue is sold in 25 kg bags and can glue extruded polystyrene foam to all types of surfaces.

Overview of adhesives

Adhesive compositions for interior and exterior use differ in composition and characteristics. They can also have different consistencies and be sold as a dry or ready-to-use mixture. The only property that all types of glue have in common is the prohibition on the inclusion of any solvents. Contact of gasoline or acetone with the insulation is unacceptable, because these substances can burn through it.

As for adhesive foam, this type of product is very convenient to use due to its ease of application. The finished composition includes all the necessary components that allow you to quickly and efficiently glue products. However, it should be noted that this glue dries very quickly. It is most often used as a one-time use product.

Dry formulations allow you to use them several times, mixing the mixture in portions as needed.

Foam adhesive for exterior use has a polyurethane base and is sold in cans, which simplifies the application of the composition to sheets of material. Unlike bitumen products, it dries quickly, so there is no need to support the material. The product gains strength within a couple of hours.

Adhesive compositions intended for working with polystyrene foam boards can be divided into two types:

- dry products;

- polyurethane solutions.

The differences between these groups lie in the method of breeding, packaging, appearance, as well as the technique of processing the material.

In addition, products for working with polystyrene foam can be divided into compositions for separate use and universal products. The latter variety has a wider scope. Such compositions can not only perform basic functions, but also serve as a means for reinforcing slabs with mesh. Their disadvantages include average quality characteristics. However, this drawback is justified by the affordable cost of the product. For more reliable installation, you should give preference to adhesive solutions or mixtures of a narrow spectrum of activity.

For outdoor use

The most suitable composition for external work with polystyrene foam boards can be considered bitumen adhesive, despite the fact that it contains a solvent. This component does not pose any danger to the insulation. The products are sold completely ready for application. To glue the surfaces together, bitumen adhesive must be applied to the wall.

The next popular type is cement adhesive, which is perfect for working with brick bases, concrete and cinder block walls, as well as for fixing ceiling tiles. Typically, this mixture is sold dry, and for preparation the powder is diluted with water. The disadvantages of dry products include the fact that it takes some time to dilute the glue to the desired consistency. However, the cement-polymer composition and low cost make the product very popular. It is suitable for cases where extruded polystyrene foam is used as insulation.

In room

When installing expanded polystyrene boards indoors, it is necessary to use compounds that meet the following requirements:

- high level of adhesion;

- absence of toxic substances in the composition;

- resistance to temperature fluctuations;

- quick installation and minimal leakage.

In apartments and houses with a constant positive air temperature and minimal humidity, the slabs can be glued to the surface using PVA glue. In rooms where the humidity level is quite high, it is better to use rubber-based glue. Such products perform well when working with metal, plastic, concrete, wood and ceramics.

Dry gypsum mixture can be used for surfaces with base defects. This group includes Knauf Perflix glue. This is a completely natural product that is intended for interior use only.

When working with decorative elements and ceiling surfaces, you should opt for water-soluble compounds. Such products are white in color, so they allow you to hide as much as possible all existing seams and joints between sheets of material.

Polyurethane products

Any polyurethane adhesive is seriously different from the dry mixtures described above. They are often called “glue-foam”, “foam-glue”, because the compositions are sold in cylinders, and to use them you need a construction gun. They are used in the same way as polyurethane foam. Polyurethane adhesives for EPS are usually used for exterior applications; they have strong adhesion and are easy to use. The products dry quickly, are economical, do not react to changes in weather, and are frost-resistant.

Tytan Styro 753 GUN

Produced in 750 ml bottles, suitable even for interior work. This polystyrene adhesive is applied in thin strips, then the material is immediately applied to the wall. It can attach EPS to a base made of plaster, concrete, wood, mastic, cement, and is capable of reliably gluing sheets of expanded polystyrene together.

Adhesive foam "TechnoNIKOL"

TechnoNIKOL adhesive is widely used for fastening polystyrene slabs to foundations, walls of houses, roofs, in basements, and on floors. The gaps between the insulation boards are also sealed with glue. The adhesion of the product is high even where there is mold, high humidity, and fungus.

Glue "Penoplex" Fastfix

The product is considered effective for fastening EPS slabs to bases made of concrete, aerated concrete, brick, and ceramic blocks. Packaged in standard 750 ml bottles. It is characterized by high strength, the quality of adhesion to the base is one of the best among analogues. The adhesive is incompatible with bitumen compositions, polyethylene film, and Teflon.

Characteristics and consumption

According to experts, the most economical composition in terms of product consumption is polyurethane foam and paintable adhesive putty for outdoor use.

To calculate the expected consumption of the adhesive composition, you need to have an idea of the average amount of its consumption. This value directly depends on the product, its type, as well as manufacturing technology.

On average, dry powders have a consumption of approximately 500 grams per 1 m2 of material. For a bitumen mixture, this figure ranges from 800 grams or more per 1 m2. Polyurethane adhesive compositions are notable for the fact that they have the lowest consumption - 1 can is usually enough for 10 m2.

Bitumen adhesive Bitumast

Bitumast mastic is similar in properties to a plaster-adhesive mixture, but includes bitumen, which plays a binding role. The advantage of the glue is its excellent compatibility with extruded polystyrene foam; it adheres to the material for a long time without any complaints. The product also has waterproofing properties and protects the joints of external walls from moisture.

You can easily mix Bitumast, it takes a couple of minutes, you don’t need any special tools (you don’t even need a mixer). There is also no need to warm up Bitumast before use. The consistency is liquid, so apply in a thin layer. There is a significant disadvantage - the mastic sets slowly, and you will have to keep the EPP sheets from slipping for a long time.

Requirements

Due to the fact that PS is used for thermal insulation both outside and inside the building, the adhesive product for it must meet a number of requirements:

- Resistance to temperature changes - maintaining properties during sudden temperature fluctuations - from -60 °C to +40 °C. This is relevant for treating walls outdoors, since outside the house the material is affected by aggressive environmental factors.

- Immunity to chemical and biological agents.

- High adhesion.

- Lack of organic solvents (acetone, alcohol, ethers).

- Foam glue must be safe and not have an unpleasant toxic odor.

Polyvinyl acetate adhesives

Polyvinyl acetate is a transparent, elastic polymer produced by the polymerization of vinyl acetate. This glue is considered universal because it can bond any hydrophilic materials. These adhesives do not rot and prevent the appearance of fungus.

"Moment Joiner"

Universal polyvinyl acetate adhesive, widely used in repair work. It is packaged in containers of 0.1-30 kg, so you can easily select the required weight. “Moment Joiner” dries quickly, does not corrode surfaces, and holds expanded polystyrene sheets very reliably.

PVA-MB

Do not confuse the product with regular PVA glue. This material is a reliable polyvinyl acetate emulsion with a number of plasticizing additives in its composition. PVA-MB dries more slowly than Moment, but the seam is considered stronger. You should not buy glues that are too cheap; PVA is often counterfeited.

What is the best way to mount it?

The set of consumables and necessary tools will depend on the chosen mounting scheme and on what can be used to glue Penoplex to the concrete wall.

The most common and well-proven in practice are options for fixing insulation using:

- bitumen-polymer mastic;

- disc-type dowels;

- polyurethane foam.

Let's look at the possible options in more detail.

Mastic

It is considered the most practical and budget-friendly slab fixer. First of all, it is used for thermal protection of the basements of houses with prolonged high humidity.

Bitumen-polymer composition

Refers to materials that are resistant to the effects of reagents that may occur during finishing work and other harmful natural factors.

The adhesive is supplied in the form of tubes and is inserted into a sealant gun. It is applied in the center and at the edge of the sheet along the perimeter, and the grooves are also carefully coated with it. The performer presses the sheet against the surface for a short time, after which the insulation adheres independently, and final fixation occurs in 1 hour.

Dry mixes

This is a reliable and simple option for fixing Penoplex to concrete walls. The mixtures are diluted with water according to the manufacturer’s recipe using a mixer attachment for an ordinary electric drill at low speed.

The glue is applied with a notched spatula and the grooves are carefully filled with the material. After applying the adhesive mass, Penoplex is pressed against the walls for 1 minute.

Adhesive foam

It performed very well when performing work on a smooth concrete wall, since it has great adhesion. The foam is applied exactly along the perimeter of the slab. Some craftsmen apply part of the fixative to the center of the sheet to increase adhesion.

Disc dowels

Another popular fixer for Penoplex, usually used for houses with uneven facades or large areas.

To work you will need:

- Boer;

- hammer drill;

- hammer.

Holes are drilled using a hammer drill, with a recess at the base of approximately 50 mm. The holes are filled with simple construction foam and plate-type dowels are driven in. Fungi should not be allowed to protrude above the insulation. You need 5 pieces per sheet. It is allowed to fix adjacent sheets with 1 dowel.

Polyurethane foam

A fairly popular method that ensures reliable fixation of Penoplex slabs. Apply it with a mounting gun, holding the slab until it fully adheres to the walls. The volume of such glue increases over time and breaks down, for this reason this technology is not recommended for external installation of insulation.

Liquid Nails

They are rarely used because they are expensive fasteners and therefore are purchased for small areas. For this mounting option, the wall is first carefully leveled and primed.

The glue is distributed using a construction gun along the center and edges of the slab. After applying the glue, it is pressed for a few seconds, which is enough to attach the structure.

Other gluing methods

Some craftsmen try to use “homemade” methods for attaching polystyrene boards using other methods. This is not always reasonable.

Polyurethane foam

Foam is used to fasten any surface, including EPS. The cost of foam is often cheaper than similar glue in cans. But the disadvantages of this method are obvious:

- slow setting with the base - slabs lying vertically will constantly slide;

- the glue contains special adhesion-improving additives, which makes it more reliable for tearing than foam;

- polyurethane foam tends to grow in volume, and when constructing polystyrene foam this can play a bad role;

- foam peels off the wall faster than glue.

The advantage of foam is the ability to fill the seams between the slabs, so it can also be useful in installation.

Gluing “relatives” together

Bonding foam and extruded polystyrene foam. Sometimes during the production of thermal insulation it is necessary to glue foam insulation onto polystyrene foam. The same compositions are used for this. Since the source materials of both insulation materials are the same. Before gluing extruded polystyrene foam, treat its glossy surface with a needle roller to increase adhesion with the composition used.

Selecting the correct adhesive for polystyrene foam based on the specific situation will ensure reliable fixation of the slabs without loss of insulation quality.

general information

Saving resources is always important, especially when the cold season comes. Thinking about alternative ways to conserve thermal energy, many decide to insulate themselves using heat-insulating boards. Not so long ago, an interesting type of insulation appeared on the market - polystyrene foam, which is a modernized version of the polystyrene foam we are familiar with. Possessing a more efficient heat transfer coefficient, it is used for external cladding, in foundation bases, and in the construction of roofs and ceilings. Expanded polystyrene (PPS) is a material for insulating facades. This is a polymer that is swollen/filled with gas. It has a closed granule structure. Almost one hundred percent gas content in the composition gives it impeccable heat-insulating and sound-absorbing properties. Choosing adhesive for polystyrene foam is not as easy a task as it might seem at first glance. The product you like may have contraindications and incompatibility in use. The main thing is that the glue does not contain substances that can dissolve the EPS structure:

- xylene

- acetone

- toluene

- drying oil

- formaldehyde

- epoxy resin

- polyester resin

- gasoline-kerosene-containing substances

If you are convinced that the composition of the glue does not threaten the integrity of the polystyrene foam, you can buy it.