Having bought a walk-behind tractor, its happy owner solves most of the problems associated with cultivating the site.

A rich set of attachments allows you not only to plow the soil efficiently, but also to cultivate it, harvest potatoes, clear snow and pump water.

You can always buy a trolley for a heavy walk-behind tractor, which will turn it into a mini-truck.

What should the owners of medium and small walk-behind tractors, which are not structurally suited for transporting goods and performing other “tractor” work, do?

One thing can be firmly said: you shouldn’t sit back and wait for a miracle. Anyone who understands the mechanics of cars can make many interesting cars out of a walk-behind tractor.

What is the speed of the walk-behind tractor?

The speed of the walk-behind tractor depends on several parameters:

- walk-behind tractor class

- engine type

- availability of attachments

- type of gearbox

- wheel size

- the terrain in which the walk-behind tractor operates

As a rule, the class of a walk-behind tractor is associated with the type of engine; light models are equipped with gasoline engines with a power of up to 5 hp, medium ones with gasoline engines of 6-12 hp, heavy models with diesel engines with a power of 12 hp or more. Diesel engines are more powerful, so equipment with such engines will have greater speed.

Among budget models of mid-class walk-behind tractors, the common type of gearbox is 2 forward, 1 reverse; more expensive models have 6 forward and 3 reverse gears. The more gears, the higher the speed available.

The size of the wheels is important: the larger the wheel diameter, the faster the equipment moves.

Attachments such as plows and mowers can contribute to slower speeds. The speed of a walk-behind tractor with a trailer will also be lower, although the speed with a cart can be accurately calculated only by taking into account the speed and weight of the walk-behind tractor itself, as well as the weight and type of cart. Typically, the speed of a walk-behind tractor with a trailer does not exceed 10 km/h.

The more difficult the terrain, the more the speed decreases. For plowing in virgin lands, it is recommended to use weights that provide cross-country ability and help maintain speed. However, it is worth remembering that plowing heavy soils at increased speed is not recommended, as the quality of tillage decreases.

Increasing the power of the walk-behind tractor

You can increase the speed of the walk-behind tractor in the following ways:

- replacing a gear pair;

- installation of wheels with a large diameter.

Increasing speed in the first way is a rather complicated process. Therefore, without knowledge and skills in this area, it is better not to do this yourself and contact a special service center. If you have the necessary skills, you can make the replacement yourself. Just like any other equipment, the walk-behind tractor has several speed modes controlled using gears. The walk-behind tractor moves at a speed of 2 to 15 km/h. The larger gear usually has 61 teeth, and the small one – 12. To increase the power of the walk-behind tractor, the gear pairs of the gearbox are replaced. Maximum speed can be achieved by increasing the number of teeth on the gear.

When replacing a gear, be sure to select the correct pulley. If the pulley is selected incorrectly, the walk-behind tractor may stop working.

How to make a walk-behind tractor go faster by changing wheels? Motor cultivators have a standard wheel size of 57 centimeters.

To increase the speed, you can install tires with a diameter of 70.4 cm; such a replacement will help speed up the walk-behind tractor several times. If the arches in which the tires are placed allow the installation of wheels with a larger diameter, you can try to increase them by a few centimeters.

The lineup

It is worth distinguishing two categories of technology:

Specialized equipment is represented by brands:

- Laski TR50;

- OJSC "Mikhnevsky RMZ";

- Kwik-TrenchEarthSaw;

- GroundHog T4;

- TKMG-1200;

- Sable /BS/50/;

- Vermeer RT60;

- Barreto 912HM;

- GroundHog T-4 Trencher.

Motoblock trenchers are represented by the TrenckIt model, which is produced by the manufacturer QuickAttah. This equipment is connected to both gasoline and diesel walk-behind tractors, the engine power of which ranges from 8 to 15 horsepower. For ease of work, tracked or wheel-driven equipment can be used.

How to increase the speed of MTZ

The article will tell you what characteristics a conventional walk-behind tractor has, as well as what needs to be done if there is a need to resolve the issue of how... Rating is available when the video has been rented. ... Which wheels are better to put on a trailer for a walk-behind tractor to make it go faster? Also…

More and more gardeners today are asking the question: how to tune a walk-behind tractor with your own hands? After all, if you turn to specialists in this matter, this can entail large financial costs. Ultimately, remaking a walk-behind tractor can even cost much more than purchasing a new unit.

Buy or rent

If you are involved in an activity that requires the regular use of the described units of special equipment, then it would be more advisable to purchase it than to lease it. However, it should be borne in mind that a manual small-sized trencher can cost you 150,000 rubles. minimum. The maximum cost reaches 500,000 rubles.

If you are purchasing a trencher to solve a specific task, then it is better to rent it. The machine is selected individually, and the leasing cost usually includes the operator’s labor, as well as the cost of additional materials.

Increasing cross-country ability and improving the walk-behind tractor

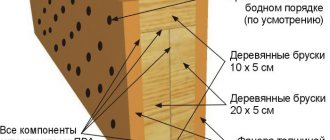

So, how to improve a motor cultivator with the help of weights. You can buy them or make and install them yourself. Weights are installed on the frame and wheels. Wheel weights are made of solid profiles and steel wheels. The body is weighted using special removable frames and a corner. Loads with different weights and configurations are attached to the frame.

So, sometimes you need to make a motor cultivator quite heavy, you can use reinforced concrete products.

Such loads can load the walk-behind tractor quite well. With the help of such simple devices, the range of application of technology is significantly expanded.

You can increase the capabilities of a walk-behind tractor and turn it into a snowmobile using tracks. To do this, you just need to install an additional axle with wheels and buy wide rubber tracks. Stoppers are attached to the inside of the tracks to prevent them from sliding off the wheels. Such a snowmobile will be useful on the farm in winter, when it is difficult to drive a car through huge snowdrifts, and in spring, when the ground is still too wet and the terrain is impassable for other equipment.

A homemade snowmobile can be equipped with a sled to transport property or feed for animals, or go fishing or hunting.

Converting the Mole cultivator into a walk-behind tractor

Some craftsmen turn the Mole cultivator, which has very modest characteristics, into a walk-behind tractor for plowing virgin soil. The power of this model is only 2.6 hp, and the total weight with the cutter does not exceed 50 kg.

So, let's look at the stages of remodeling:

- Dismantle the original engine and install a more powerful one (6 hp will be enough). The single-cylinder, four-stroke, air-cooled engine can be removed from any old walk-behind tractor, or purchased at a garden equipment store.

- To install the engine, weld 2 steel angles to the body of the unit and make 3 holes in them to which the unit will be attached. Fasteners in different places are needed so that the motor can be moved relative to the axis of rotation of the cutter to change the center of gravity during different jobs.

- Replace the belt tensioner with a wider one, and the pulley with a double-lane one.

- The Mole's steering wheel needs to be strengthened and lengthened for ease of operation. This is achieved by welding pipes of a suitable diameter onto the racks, and between the handles a crossbar from the same pipe or angle should be welded.

- Install a rotating plow on the frame to make the future walk-behind tractor maneuverable and easier to control.

- Modify the installed cutter by welding segments of homemade “crow’s feet” along the edges, 2 on each side. Such a device is capable of plowing virgin soil and crushing large clods of earth. Thanks to this modernization, the working width increases by 25 cm, and the productivity of the machine increases significantly.

The Mole, converted into a walk-behind tractor, despite its size and low weight, is capable of “raising” virgin soil with amazing speed, but has a significant drawback - it is difficult to control.

Do it yourself

How to make a creeper for a walk-behind tractor with your own hands? The design of the mechanism is very similar to a gearbox. Including it in the operation of the walk-behind tractor redistributes part of the traction force to additional attachments. The work on manufacturing the device can be divided into several stages:

- Preparatory activities. At this stage, the body for the future mechanism is selected, metal pipes, bearings, gears, steel sheets and screws are prepared.

- Shafts are made. The main material is round rolled hardened steel. Using machines, the workpieces are turned to the exact size, and grooves are also made. Shafts transmit torque, and radial bearings hold them.

- Install chains and sprockets. It is better to purchase this material in a store.

- After assembling the creeper housing, it is tested. If any extraneous sounds or creaks occur, work is suspended and the violations are corrected.

Advice. You should only undertake the manufacture of home-made devices if you have experience and, when assembling, strictly adhere to the algorithm of necessary operations.

Self-assembly of the stroke reducer

Having all the necessary spare parts, you can begin assembling the speed reducer with your own hands. In order for the finished structure to cope well with its functions, you should act strictly according to the algorithm described below:

- First, make all the necessary calculations so that the result of the work is a well-balanced design. As a generator, you can take an element from the domestic Ural motorcycle;

- The main thing that is required from the device is high power and stable torque;

- Next, start cutting out the shell of the two bearings that will be needed for the drive shaft. It will start the gear. When working, take into account the diameter of the gearbox;

- Then you need to decide on the bearings. The flange must be located on the opposite side of the gearbox. There should be a metal washer inside it;

- Next, install the driven shaft on which the gear will sit. The product must be connected to the rotary generator shaft and transmission mechanism;

- Finally, you will need to secure the pulley to the driven shaft using a spring nut and washer.

Having made the creeper, it will need to be tested. To check the device, it should be connected to the hitch of the unit, and the wheels for the cultivator should be installed. If you did everything correctly, the wheels will spin slowly, while the cultivator itself will be pressed to the ground.

When choosing wheels for a motor cultivator that will work in tandem with a speed reducer, you need to pay great attention to their diameter. There is no need to choose too large parts so as not to load the unit’s motor. Wheels with a diameter of 25 to 30 cm will be optimal.

If homemade devices are planned to be used in conjunction with other attachments, for example, for a plow, then the creepers must have sufficient power to press the equipment to the soil. Be sure to take this into account when preparing spare parts for the manufacture of the device.

Many farmers are interested in how to increase the speed of a walk-behind tractor. The most common agricultural machinery is a walk-behind tractor. With its help, work on land and personal plots is greatly simplified. Let's look at how you can increase the speed of this technique. With increased speed, the performance and maneuverability of the mini-machine will increase, which can be used in any season and weather.

How to increase the power of a walk-behind tractor using reverse speed

Setting the reverse speed on a walk-behind tractor is another way to improve the walk-behind tractor. The presence of reverse depends on the sizes and models. It can work on any type of equipment, it all depends on the tasks assigned to the equipment, be it a light or heavy walk-behind tractor, or a motor-cultivator. For equipment weighing up to 30 kg, there is no need for reverse speed, but on a heavier unit it is more difficult to weed without it.

Gearboxes are:

- gear;

- reverse gear;

- angular;

- downward

A gear reducer is a transmitter that operates between the wheels and the motor. The reverse gearbox consists of a clutch located between the gears and located on the main shaft. The corner is responsible for the operation of the transmission with the engine, which affects power. The reduction gearbox is responsible for reducing the speed, which helps increase power. The main task of this system is to provide reverse gear. To make this mechanism at home, you first need to make the case. Then select the necessary parts. But it’s better to buy a ready-made gearbox.

Improved engine performance

How to increase the speed of a walk-behind tractor? In this regard, nothing can be radically changed, since it’s all about the engine’s performance. To improve its performance, it is necessary to lubricate the main parts of the engine as often as possible. But the main thing is to change the oil in a timely manner. If you do not do this, the engine (and with it the walk-behind tractor) will quickly fail.

If you often have to work in frost or extreme heat, special attention should be paid to candles. The speed and overall efficiency of the engine largely depends on their quality. In order for the walk-behind tractor to plow more soil in an hour, you should replace the old spark plugs with new ones of better quality. This will make it possible to start the unit faster and protect the car from overheating or freezing.

Required materials and tools

First, you need to accurately determine the technical characteristics of the design: the type of transmission, its gear ratio, the distance between the shaft and the axle of the wheelset. The following tools will be needed for this work:

- welding machine;

- electric drill;

- a set of files and needle files;

- measuring instruments (calipers, ruler);

- yew;

- hammer.

The tool must be visually inspected and checked.

Important! It is strictly forbidden to use a faulty tool to avoid causing accidental injury to yourself and others.

How to remake and modernize a heavy Neva walk-behind tractor with your own hands: we explain point by point

A walk-behind tractor is an indispensable thing for farmers. Increasing the power of the walk-behind tractor allows you to increase the productivity of equipment and speed up agricultural work. You can improve your equipment either with your own hands or by purchasing the necessary equipment.

Design features of a mini tractor

When assembling a mini-tractor from a Neva walk-behind tractor, labor productivity at a summer cottage increases significantly. The advantages of such a unit are that a second wheel axle and a driver’s seat are installed.

Thanks to this, a person does not walk all day long, holding the handles of a walk-behind tractor, but sits in a comfortable seat and turns the steering wheel.

A mini tractor can be made in two ways:

- buy a ready-made adapter;

- improve the walk-behind tractor yourself.

In the first case, only cash expenses will be required. The adapter for the walk-behind tractor is a trailed trolley , which is equipped with a driver's seat and attached to the main unit using a rigid hitch.

If necessary, you can purchase attachments and semi-trailers . The disadvantage of this design is the lack of comfort for the operator.

If you improve the walk-behind tractor yourself, you get a mini-tractor that, in appearance and performance, will not differ at all from the factory models. In addition, the mini tractor can be equipped at your discretion and requirements.

Description

A trencher for a walk-behind tractor is an equipment that can make the life of its owner many times easier if he plans to lay communications, carry out gardening and other work where digging long and narrow trenches is indispensable.

Of course, there are special motorized units - industrial-level trenchers, the digging depth of which can reach 1 meter 20 centimeters. Smooth, strong cuts of the cut hold their shape perfectly and do not crumble. This is excellent equipment; its only drawback is its high cost, available only to specialized organizations.

What should owners of private houses and land do when a shovel is not able to help, but they have a walk-behind tractor on the farm? And then a real way to solve the problem appears - an attachment on a walk-behind tractor for digging trenches. Digging trenches with a walk-behind tractor will take much less time and effort, which will also have a beneficial effect on labor productivity.

How to reduce the speed of a walk-behind tractor

To solve certain problems (plowing virgin lands and heavy soils), some models of walk-behind tractors may be too fast, in which case it is necessary to reduce the speed.

Without resorting to changes to the equipment itself, you can use the reduction gear, which is present on many models. This option allows you to reduce speed without reducing power, allowing you to work the soil more thoroughly.

To reduce speed, you can reduce the diameter of the wheels or replace the gear pair in the wheel reducer by changing the gears. Typically, gears of different sizes are installed, with a number of teeth of 61 and 12, in order to reduce the speed, it is necessary to replace them in such a way that the number of teeth on the larger sprocket increases.

What are the minimum and maximum speeds of the walk-behind tractor and how to regulate them?

Today, walk-behind tractors are perhaps the most common type of mini-equipment for agricultural purposes. It happens that users of some models are no longer satisfied with the speed and performance of the unit. Purchasing a new model is quite expensive. In this case, you can try to upgrade your device.

A walk-behind tractor is a kind of mini-tractor, designed for carrying out various agricultural operations on relatively small areas of soil.

Its purpose is to perform arable work on small and medium-sized plots of land, cultivating the land using a harrow, cultivator, and milling cutter. Also, walk-behind tractors can process potato and beet plantings, mow grass, and transport cargo (when using a trailer).

It is also possible to use additional attachments to expand the list of tasks performed by this powerful unit, which is indispensable in many cases: a trailer-trolley for transporting cargo weighing up to half a ton, cutters, harrows, etc.

There are gasoline and diesel varieties of walk-behind tractors. For the most part, diesel units are more powerful than their gasoline counterparts. Gasoline-powered devices win in the price category - they are cheaper. But the choice largely depends on the size of the land plot and the frequency of use of this equipment, because diesel fuel is more affordable than gasoline.

Motoblock devices come in two- and four-wheel configurations. Not all devices have a reverse function.

Does it work

In fact, converting a cultivator into a walk-behind tractor will require the owner to spend significant money and time with an unclear result. Therefore, it is better for summer residents and gardeners to decide at the purchasing stage why they need mini-equipment for cultivating the land, and only after that make the final choice.

To make a snowmobile you will need the following elements:

Below we will look at step-by-step instructions for making a snowmobile from a motor cultivator.

Additional accessories

Walk-behind tractors are sold with a minimum number of components. However, a milling cutter and a standard plow are not enough to perform all agricultural work. How to improve a motor cultivator using scrap materials? With the help of tools that are found in every home, you can expand the capabilities of the walk-behind tractor. Equipment that you can make yourself:

- Installation of a rake on a walk-behind tractor for collecting debris, leaves, and hay. Such a simple device will speed up autumn field work and allow you to clear large areas of debris in a matter of minutes. To make a rake you will need: several meters of reinforcement with a cross section of 8-12 mm and a strip of sheet metal. The reinforcement is cut into pieces 10 cm long and welded to the plate in several rows with an interval of 3-5 cm. To increase maneuverability, the rake can be equipped with roller wheels.

- A trailer and cart will help transport large loads. The cart can be made from scrap materials - channel and old car wheels, metal profiles and boards. The clutch is made standard for both tractors and cars.

- If desired, you can make a potato digger, hiller and harrows, which will not be inferior in quality to purchased ones.

Plows for walk-behind tractors

Another device for cultivating soil using a walk-behind tractor is a plow.

The following types of plows are distinguished:

- The easiest to use is the single-hull one, also known as the Zykov plow.

- Reversible plow for walk-behind tractor: rotary or reversible. The upper part has a curved feather, which turns the soil over during plowing. A universal device that easily copes with plowing heavy soils. Quickly copes with the treatment of areas with clay and marshy soil.

- The rotary plow for a walk-behind tractor has a complex design. Depending on the number of ploughshares, there are two-body and three-body models. Active plowshares dump soil in one direction only, while passive plowshares level the beds and lift them. Tilling the soil with such a plow has a number of advantages: the soil is maximally saturated with oxygen; tire wear and fuel consumption are reduced; after processing there are no large clods of earth left.

- A rotary plow for a walk-behind tractor provides unlimited possibilities. During operation, the axis rotates, and with it the soil layers. It easily plows even very hard soil at a depth of about 30 centimeters. There are paddle, drum, shovel and auger plows. Devices of the first type are equipped with a rigid pusher and can consist of a spring plate or be combined. Units of the second type are equipped with a disk with blades that rotate during operation. A plow with a disc blade for a walk-behind tractor is suitable for work in early spring; it copes well with wet soil.

Any of the above plows can be made independently, taking into account the design features and following the instructions and diagrams. You can also improve an already purchased plow.

A rotary reversible plow for a walk-behind tractor copes with the processing of plots most efficiently, thanks to the optimization of the plowing process. And it is most in demand among agricultural workers.

Thanks to the expansion of capabilities, the walk-behind tractor becomes universal. It can be used to solve a variety of tasks from field work to snow removal in winter.

Motor pump

A homemade motor pump is very close in design to a power plant, the only difference being that instead of a generator, a centrifugal liquid pump is installed

It is important to arrange the design in such a way that when connecting the hoses to the pump, the motor and gearbox do not flood

Homemade products made from the Ural chainsaw indicate its great capabilities. Originally created as a tool for sawing wood, it, in combination with additional attachments produced by the industry, has become multifunctional. However, craftsmen never cease to amaze with their ingenuity, creating new original devices.

Today, industry produces convenient, functional and advanced devices for working with wood. For this reason, still functional Soviet saws became undeservedly forgotten. But as it turned out, new saws cannot be used again, and old ones, on the contrary, open up the possibility of widespread use for other purposes. Most often, Druzhba or Ural brand chainsaws, which were once used to prepare firewood, can be seen in villages. Now savvy minds have adapted the old units for other purposes.

The Ural chainsaw was created on the basis of the Druzhba saw, which for a long time helped lumberjacks cut down trees, and surpassed it in quality and performance. Its main components are a drive with a two-pin or four-pin motor, a cutting bar and a handle. The universal drive allows you to use the saw in various ways. An important fact for variation is its design features:

- engine of sufficient power;

- light weight and compactness;

- ability to withstand extreme conditions;

- autonomy.

The clutch eliminates overload and damage to the working parts due to its leak-tight design.

Thanks to these qualities, the chainsaw has found application in the widest spheres of the national economy. Homemade products from a Ural chainsaw can be made both simple and complex. Simple ones include:

- mowers;

- cultivators;

- walk-behind tractors;

- boat engines;

- pumps;

- winches;

- ice axes;

- Bulgarians.

Complex inventions include the following homemade products:

- snowmobiles;

- snow blowers;

- sawmills;

- snowmobile;

- power plants;

- helicopters.

Rules for driving a walk-behind tractor on public roads

This type of equipment is formally a smaller copy of a conventional tractor. As you know, a tractor is a vehicle, and to drive a vehicle you must have a driver's license and liability insurance. But does a similar rule apply to a walk-behind tractor? Of course, even if the answer to this question is positive, few would think of getting a license to drive across fields and beds. But there are often times when people use a walk-behind tractor to go to the nearest building materials store or simply go to throw out large garbage. Since the route will mainly run along public roads, there is a possibility of meeting a traffic inspector. In this case, the legal issue will be quite relevant.