When constructing a multi-story building, a flight of stairs is required. This design is easy to manufacture and is an excellent option for a private home or cottage. Having basic construction skills, it is quite possible to build a lift to the next floor yourself. However, do not forget that the design must be safe and comfortable. To avoid unpleasant consequences, there are certain norms and standards for installing a structure of this type.

Considering practicality, experts advise giving preference to a two-flight staircase. The advantages, features, as well as the technology for self-construction of this structure are further in the article.

In this article you will learn how to make a similar staircase

Calculation of stairs

We start by determining the rise of the step h by dividing the height of the staircase H by the estimated number of rises n: this is the distance from the floor of the first floor to the floor of the second floor H = 2,976 mm (Fig. 1).

With the selected number of lifts n = 16 h = 2,976:16 = 186 mm. Since the staircase is two-flight, with a platform in the middle, there will be 8 ascents in each flight. Reference by topic: DIY spiral staircase

Next, we measure the length A of the opening from the edge of the platform to the edge of the upper floor - this is the so-called travel line. For my opening A = 1,596 mm. We divide it by the number of rises to get the depth of the tread.

In my version, it was very important to make the staircase as compact as possible. Therefore, as the last step, I used the upper floor slab (for the lower flight - a platform), attaching a “nose” to it in order to save one step rise

Tread width a = A: (n – 1) = 1,610: 7 = 230 mm.

We check the comfort of the staircase using Blondel’s empirical formula, according to which the condition 600 is satisfied for a comfortable staircase

We add a “nose” to the tread - a protrusion 40 mm long and we get a step width of 270 mm.

Template for marking steps on a string

To make the bowstring, we need to make grooves 15 mm deep into it, into which we will insert treads and risers. To prevent the staircase from becoming skewed, precise marking of these grooves is necessary. Therefore, you will need templates that allow you to make each bowstring in the same way. We will make a template from a rectangular sheet of plywood (Fig. 2) for marking the position of the steps on the strings, that is, drawing lines of treads and risers.

Rice. 2. Marking the position of the steps on the string. 1. Template for marking the position of the steps on the string. 2. We make steps and mill tenons on them.

These lines will then serve as a guide for selecting grooves for both treads and risers. On one side of the right angle we set aside the height of 2 risers, and on the other - the width of 3 treads. By connecting these points to each other, we get a reference line 4, and then at a distance of 50 mm from it we draw line 5. We nail two slats 6 to the plywood sheet on both sides, the edges of which should coincide with line 5, indicating the edge of the bowstring behind the slats.

3. We cut out the first, so-called invitation step, with a jigsaw.4. Then we process it according to the template using a router with a copy sleeve. 5. We saw off the balusters at a given angle to size using a miter saw. 6. We make a groove in the pillars into which the bowstring spike is inserted. Rice. 3. Template for making grooves on the string for treads and risers.

The template allows you to accurately mark the position of the steps on the string. The line of the first tread will coincide with the base of the bowstring - its supporting platform, and its intersection with line 4 serves as the beginning of the riser line. The corner of the template will be the beginning of the second tread line. The intersection of the line of the second tread with the reference line 4 serves as the beginning of the line of the second riser. And so on.

7-8. After manufacturing and fitting all the parts, we assemble and tighten the march “dry” with clamps for fitting. 9. Having disassembled the march, we coat each part separately with oil. I used Osmo oil with hard wax. Apply the first color layer with a brush. Immediately wipe off any stains with a lint-free cloth swab and dry. The next day, apply a second layer of transparent oil in the same way.

We file the upper part of the bowstring (including the tenon) along a line parallel to the line of the last riser, and the lower part along the line of the first tread (also known as the floor line). We mark the second string in a similar way, but so that the markings on it are a mirror image of the markings of the first string.

10. After fitting, we disassemble the fence, remove the balusters, apply a coating and dry it. 11.. It turned out to be more convenient to assemble the upper flight on the second floor, and then carefully “roll” it down from above onto the landing. The march stood up well, since the walls were smooth and the tiled floor was horizontal. I did everything myself, I tried! 12. The assembled march is very heavy, but the four of us lifted it, placed it vertically and carefully lowered it into the opening onto the platform. 13. We finally assemble the balusters, handrail and mount them assembled on the string. We make “fungi” plugs and cover all the mounting holes with them. When assembling, we use silicone sealant so that if a defect occurs, we can easily disassemble the structure and replace the damaged part.

Metal stairs: diagrams, production, application

The scope of application of metal stairs in modern construction is wide. These are both internal inter-level structures and external street ones.

The latter can be welded with your own hands, having minimal welding skills. The material can be a steel corner. But the stairs inside the house must be made by a high-class specialist. They are subject to high demands on design and reliability.

What kind of metal stairs can there be?

Internal metal stairs are made according to preliminary measurements and drawings. This is a special design project. The materials for the manufacture of components are chrome-plated steel pipes and metal structures coated with durable powder paint.

The design of flights of stairs can be very different - straight with a platform in the middle of the flight, rounded, helical. The steps in interior metal stairs are equipped with decorative wooden planks or plastic inserts, and even marble tiles.

Interlevel stairs are often installed in offices with a large number of visitors, in institutions and in industrial premises. The main task of designers and builders in this case is the strength of components, long service life, traffic safety, and high throughput.

These structures are much lighter and more elegant than the usual wooden or concrete stairs. They create a feeling of free space and do not darken the room. Neutral colors suit any design solution.

Staircase drawing

Drawing of a staircase with a landing.

Installation of flights of stairs Having determined all the necessary dimensions, you can complete the drawing by drawing the stairs on paper in accordance with the scale. It is better to carry out the drawing in design or graphic programs, which are usually used today for such purposes. The electronic version of the drawing is easier to correct and edit.

If you need to make changes to your diagram, the advantage of the computer format will become obvious.

Do-it-yourself work will help turn an idea into a real product. Even an elementary staircase, a little more complicated than a stepladder made of metal or wood, requires quite complex calculations and enumeration of solution options. Designing spiral staircases is much more difficult because it changes configuration in three dimensions. For this purpose, special design programs are usually used, which save a lot of effort and time, while avoiding errors.

Materials for production

Just a few years ago, the choice of two-flight staircase structures was limited to wooden products made according to one pattern. Today there is no problem of selecting materials; you can make the frame yourself or use the services of specialists.

Almost all types of building materials are suitable for making stairs:

- Different types of wood. This classic option is in wide demand due to its low cost, ease of installation and aesthetics. Pine is not suitable for constructing wooden stairs because of its softness.

- Metal base. This is the optimal and most durable type of construction. Steel products have a shelf life of up to several decades, do not deform (like aluminum) and do not oxidize (like brass and other metals).

- Glass steps and railings. It’s hard to imagine a more stylish option than a mirrored staircase in the center of the living room. However, this solution also has a number of disadvantages: glass does not tolerate mechanical loads well, even a hardened coating quickly loses its original appearance and requires constant maintenance.

- A natural stone. Steps made of marble look very original and, due to their unique structure, retain their original appearance for a long time without wear. The stone is also non-slip and easy to maintain.

The most budget option is to make a medium-sized wooden staircase. It is recommended to use metal blanks made of steel for the steps, then the structure will serve your family for decades.

If we are talking about a major renovation of a two-level apartment, made in a modern high-tech style, then we recommend that you pay attention to glass stairs. You should choose either hardened or laminated). But be careful when subsequently processing this material and try to minimize the number of decorative elements on the site in order to reduce mechanical stress.

Whatever the shape of the staircase opening, the installation of all structural elements must be carried out in accordance with safety rules according to the classical standard. In the case of non-standard opening parameters, it is better to entrust the construction of the site to professionals, although it will cost you a little more.

You can calculate the required amount of materials using special online calculators. This will allow you to save money and time at the first stage of work.

Rotate 90 degrees

Calculation of the size of staircase steps in a house

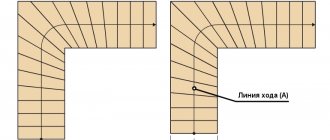

Stairs that change their rotation by ninety degrees are also called L-shaped or L-shaped. The length of the march should not be more than thirteen to fifteen steps, otherwise it will be difficult to climb such a structure. The areas between flights of stairs, which are at right angles to each other, should be slightly wider than the flight of stairs. If there is more free space, the platform can be made larger by half or the full width of the step.

Many finishers recommend making stairs at least seventy centimeters wide so that there is space for a person to freely ascend or descend. As for the number of steps, the most normal option would be the one where there are three of them. And the width of the step should not be more than one meter. The ease of use of the span in the future and its stylish appearance depend on the accuracy of the calculations.

Then this circle is divided into two equal parts, where the middle line is drawn. As for the middle point of the step, it should not be made more than seventeen to twenty centimeters, and the width of the step should be at least approximately equal to the size of the leg. When measuring and obtaining the length from the floor of the first floor to the floor of the second, three meters, two flights of one and a half meters each fit on this segment. It turns out that there are twenty steps, then naturally they will not fit into one march. This amount must be divided into two marches. It turns out to be ten steps. But keep in mind that there will be one less tread - nine each, because from both flights one at a time is removed onto the platform. Therefore, it turns out that the width of the march will be only two meters and seventy centimeters.

Rotate 180 degrees

Each staircase must have a certain height and, for safety reasons, should not be too steep. This implies a limitation on the minimum length of the site. An attempt to reduce the space occupied by a flight of stairs leads to an increase in the angle of its inclination, and the angle, on the contrary, makes it too long. One solution to this problem is a staircase with a one-hundred-eighty-degree turn, or U-shaped. The calculation of such a design mainly coincides with the calculation of the opening at an angle of ninety degrees.

In most cases, instead of reducing the length of a flight of stairs to a minimum, it is enough to simply reduce the space occupied by the low-lying parts of the stairs. For example, the first march can be short, up to one meter high. The calculation in this case is that the part of the second flight protruding beyond the lower steps will be located higher and will not interfere with walking or the placement of furniture.

You can further reduce the size of the stairs using winder steps. Then the rotation is performed in the form of several steps in the form of a fan. In a turn of one hundred and eighty degrees, it would be better to place five steps, and this is as much as half a meter of height, “taken away” from the marches, which at the same time become shorter. In general, the calculation of a flight of stairs consists of several points, namely it is necessary:

- calculate the angle of inclination;

- display the optimal parameters of the steps;

- determine the best march width;

- calculate the height of the passage;

- create a design for turning sections;

- work out the desired fences;

When you carry out the work slowly, thinking through all the details, you will end up with a stable and strong structure for your home, which will become an ideal addition to your interior, which will last for many years and will delight you with its compactness.

The main stages of the construction of a two-flight composition

The general erection process looks approximately the same for any type of raw material and includes several steps.

First, a drawing of the future building is drawn up, precise calculations are made for marking, calculating the required number of consumables, and the size of the stock.

Once the paperwork is completed, the procurement phase begins. It is better to purchase products after consulting with an experienced craftsman, since the risk cannot be excluded that the sales consultant will sell the item he needs.

The next step is to prepare tools, clothes made of thick fabric that you don’t mind ruining, and closed shoes to protect your toes.

Workwear

Now they begin preparatory work, the task of which is to clear the space, apply markings, and cut wood.

After this, the structure is completely assembled according to the drawings. First, the turning zone platform is constructed, then the lower steps. Particular attention is paid to fasteners. And then they make the top elements.

When the assembly process is completely completed, you should wait a day or two before finishing, and if we are talking about a concrete monolith, then the time frame is much longer.

It is important to screw the fasteners tightly so that there are no gaps between the planes.

Pros and cons of double-flight stairs

Like any construction project, double-flight wooden stairs have both advantages and disadvantages of use. If we compare this design with outdated marching models, they have significantly more advantages.

Experts attribute the following to the advantages of this type of design:

A two-flight staircase with a transition platform saves free space, which is especially important for small rooms. This is due to the possibility of marches turning at different angles (the right angle is used the least often).

Due to the different angles of the marches, the inclination of the stairs can be reduced. Thus, moving between floors will be much more convenient and safer. We recommend that families with small children avoid single-march climbs.

The design consists of two staircases, which can be connected in different directions and at a suitable angle (depending on the characteristics of the room and safety requirements).

Where do the marches lead?

Not everyone fully understands the true meaning of creating staircase objects, which are distinguished by a certain complexity of implementation. A person who does not have any special knowledge in this area would prefer to build a simple span to the second floor. However, the ceiling height significantly affects the steep rise of the device. There are possibilities for designing a flatter product. In this case, the staircase structure with one flight will start from the door, and its end will lie on the ceiling of the other end of the room, as shown in the photo. However, such a project is not very convenient to use. In addition, experienced specialists do not recommend building it. Therefore, the design of marches is very relevant.

If there is sufficient free space, it becomes possible to build a front swing staircase with several flights. The material for constructing such a structure can be marble or noble wood. This design will certainly become the main element of the interior, as can be seen in the photo.

The species diversity of two-flight staircases is quite wide. Designs with straight marches have several forms:

- Parallel, which lie in the same geometric plane;

- L-shaped. A similar structure is located on adjacent walls;

- Swing. With this design option, its first span is in the free zone, and then it diverges in different directions.

The straight design is distinguished by the fact that its marches are separated by a platform. In this case, the rotation of the structure can be 90 or 180 degrees. If instead of a platform the product has winder steps, this design is called a rotary flight staircase.

Calculation of step width

Stair steps must be positioned strictly horizontally and parallel to the floor. This requirement does not apply to stepladder type stairs, but for all others it is mandatory. The width of the step should be sufficient for the foot to be firmly fixed on it. In ordinary flights of stairs, this distance is usually 27 centimeters.

If the staircase connects the upper floor and the attic, there is no need to strictly adhere to this size. But it is advisable to take this dimension into account. Reducing it to fifteen to twenty centimeters will slightly worsen performance characteristics.

Scheme and drawing with dimensions of staircase steps

It is very important to consider that the steps should not overlap each other in width. Otherwise, there will be a real threat that a person will trip over a step located above the one on which his foot stands.

This is a real danger that cannot be ignored.

Calculation of a C-shaped staircase with a 90-degree turn and a corner intermediate platform

A C-shaped staircase is a design with a continuous radius turn. Such a staircase can be installed as an alternative to a two-flight staircase, and just like on a two-flight staircase, an intermediate platform can be installed on a C-shaped staircase.

C-shaped staircase

A C-shaped staircase is also sometimes called a U-shaped staircase and is characterized by the following advantages:

- Significant space savings with other advantages inherent in double-flight staircases.

- When installing a staircase with winder steps, space is not only saved, but also visually expanded.

- The C-shaped staircase gives unlimited freedom in choosing a design solution.

Certain difficulties include the following nuances:

- When moving along a C-shaped staircase, you will only have to walk along the outer radius, because it creates a subconscious feeling that there is nowhere to put your foot in the narrow part of the step.

- A complex design leaves no room for error, because... any, even the slightest, mistake in calculations, even if not visually noticeable, can ultimately lead to discomfort when using the stairs and injuries.

When calculating the design of a staircase, one should not forget about two features that are characteristic of C-shaped staircases - when calculating a staircase structure, the distance between the flights should be set to a value equal to one quarter of the width of the step, and the distance between the opening and the flight of stairs should be at least two meters.

Calculation of the design of a C-shaped staircase

In order to mark a drawing of a staircase, you need to determine the central bend point of the flight of stairs. Then the number of steps on the turning section of the staircase is determined; as a rule, there should be at least 5, but the more there are, the more convenient it is to use the staircase.

The width of a stair step can be calculated using another technique, for this you need to know the step length of an average person - it is approximately 65-75 centimeters and in order to calculate the optimal step height, you need to divide this figure by 4, you get a step height of 16-18 centimeters, comfortable for lifting.

Calculation of the width of steps

If you significantly reduce the height of the steps, then when walking along such a staircase there will constantly be a subconscious desire to step over a couple of steps and the staircase will occupy a significant space.

But if you decide to save space and make the steps too high, then using such a staircase will cause discomfort due to the need to make significant efforts.

A C-shaped staircase can be installed with a platform; such a staircase looks more familiar, but takes up much more space and, accordingly, requires a more impressive investment of funds for design and installation.

C-shaped staircase with landing

But despite the material costs, such a ladder will be much more convenient to use and, importantly, much safer. The intermediate platform conditionally divides the staircase into two parts, which makes the ascent less tiring and energy-consuming

Despite the fact that formally a c-shaped staircase takes up more space compared to other analogue staircase structures, but as a rule, if this type of staircase is chosen, then when designing a house, a so-called staircase is laid out, which does not occupy the living space

The intermediate platform conditionally divides the staircase into two parts, which makes the ascent less tiring and energy-consuming. Despite the fact that formally a c-shaped staircase takes up more space compared to other analogue staircase structures, as a rule, if this type of staircase is chosen, then when designing a house, a so-called staircase is laid out, which does not occupy living space.

House project with a C-shaped staircase

Due to their design, turning staircases with an intermediate platform are flatter, but at the same time maintain a symmetrical graphic line that structures the space.

U-shaped staircase with intermediate platform

Design features

A two-flight staircase with a landing is installed to cover the distance between the first and second floors. A distinctive feature of such structures is the presence of separate spans, the so-called system of steps, united by one staircase (these sections have clearly defined parameters). The product consists of two flights connected to each other by one horizontal platform.

The main component of the structure is the horizontal platform. Its task is to differentiate the levels of the first and second floors; it also plays the role of an auxiliary element. Selecting a free area allows you to introduce modern features into the interior design and place comfortable furniture or decor.

This solution is especially suitable when planning the construction of a country house or in the process of arranging a two-level apartment. Externally, the design looks stylish and gives the room logical completeness.

Double-flight stairs can be either with a platform or with winder steps. It is worth noting both the comfortable climbing angle and the height of the steps according to traditional options.

Three-flight staircase

This option is the most interesting from a design point of view. It is used in private houses with high ceilings and large distances between floors for lifting to the floor with a 180-degree turn.

The staircase to the second floor with two landings is a grandiose, massive structure that will emphasize the size of your home and organically occupy the space.

There are several types of three-flight stairs:

- S-shaped;

- U-shaped;

- T-shaped.

If you need a staircase with two landings and a 180-degree rotation at your dacha, then it is best to choose a project with a U-shape and a short middle flight.

Calculation of staircase dimensions

Calculation of staircase dimensions

The calculation of the dimensions and dimensions of each element of the staircase is made depending on the height of the floor (the distance between the surfaces of the finished floor of the first, second and subsequent floors), the type of staircase - marching or spiral, the configuration of the staircase in plan and the area of the staircase.

In the simplest case - a staircase with one straight flight - the step height is first outlined, including the height of the tread and riser, then the floor height is divided by the step height, as a result the number of steps is determined. In this case, the restrictive requirements of building codes and regulations must be taken into account. Next, the width of the steps, the width of the flight, the length of the stringers or bowstrings are calculated, based on the dimensions of which each element of the staircase structure can be determined and manufactured.

Manufacturing of staircase elements

Stair elements

When you build a wooden staircase with your own hands, all the individual parts are made at the construction site from blanks. At the same time, to ensure the proper quality of staircase construction, the following conditions must be met: finishing has been completed, including painting the walls, carpentry and installing finished floors; windows and doors installed; During the cold season, heating is turned on to maintain the temperature at least 18 degrees.

Making staircase parts on a workbench

Each element of the staircase is manufactured from wooden blanks according to previously made calculations, sketches and drawings using power tools. They start with load-bearing elements - stringers, bowstrings and pillars.

Marking should be done each time from the initially calculated template so that measurement errors do not accumulate. Small parts - treads and risers - are cut out from blanks using a single, specially made template made of plywood or metal.

Marching staircase: production of stairs on a metal frame

It’s enough to simply make a metal frame with your own hands. Having decided on the option, you need to create your own drawing indicating all dimensions. Next, you can begin installation work.

Any such self-made product must be made according to the following scheme:

- Be sure to follow the specified dimensions when cutting parts;

- It is better if the welded structure is made of channels or profile pipes, because such material eliminates vibration;

- Next, you need to weld the corners to the resulting frame;

- Steps (you can use wood or sheet metal) should be fixed directly to the metal frame.

When installing steps, be it an external or internal staircase, you can use a convenient method.

Some craftsmen prefer to weld additional corners to the frame, creating an additional frame on which the steps are installed. Or you can do without such a frame, instead you should place the steps directly on top of the “kerchief”.

A metal frame is an excellent choice for making a reliable and durable product. In addition, such a design, in addition to its practicality, can decorate the interior of the house. However, in order for a metal staircase to last for many years, it is important to take care of the correct installation of the structure in compliance with all instructions.

Terms and Definitions

To avoid confusion in definitions, we first provide a small glossary (dictionary) of terms:

Ladder and its composition

- staircase - a limited space in the plan intended to accommodate stairs;

- march - a component part of a staircase connecting different levels, including stringers or bowstrings and steps;

- step is the main supporting and load-bearing element of the staircase. The steps can be straight - rectangular as part of straight flights, and winder - trapezoidal or sectoral (in the form of a circle segment) in shape as part of stairs of complex shape;

- tread – the upper, horizontally located working plane of the step;

- riser - support for the tread, the vertical part of the step;

- riser height – the distance between the working planes (treads) of adjacent steps;

- height of the stairs - the difference between the floor marks of the lower and upper floors;

- stringer - an inclined beam carrying a flight of stairs, support for stair steps;

- bowstring - a supporting beam to which the steps are adjacent on the side;

- bolt - a metal element for fastening the steps of frameless stairs in the form of a bolt or strand;

- fencing - a structure that encloses the side of the staircase, includes balusters and a handrail;

- baluster - a fence post made in the form of a carved columnar figure.

Types of stairs

By design, the following types of wooden stairs are distinguished: on bowstrings, on stringers, on rails and stairs with a spiral structure.

Staircases on stringers have the form of a series of steps resting on top of stringers - inclined wooden beams that are attached to supports in the floor structure, to horizontal beams of intermediate platforms and platforms of higher floors.

The difference between ladders on bowstrings and ladders on stringers is that the steps in this design are located between the support beams and are attached to them from the side.

In a staircase on rails, the steps rest on metal vertical elements - rails or bolts that fasten them together, and are also attached to the walls like consoles.

Spiral staircases have the appearance of spirals in plan or can have a more complex curved shape. The steps of a spiral staircase, triangular or trapezoidal in shape, rest at one end on a central metal or wooden post, and on the other side can be fastened with bolts and bowstrings.

What tools are needed

High-quality assembly of a structure can only be achieved with thorough preparation. The set of tools depends on what exactly the construction will be made of.

Basic items will be needed regardless of your choice:

- roulette;

- building level;

- abrasive paper;

- a simple pencil;

- self-tapping screws;

- saw;

- ladder;

- hammer.

To assemble the frame, metal blanks and profiles are needed, and the adjustment of treads and risers is carried out with special corners.

Metal corners

If a monolithic structure is assumed, then you need to prepare everything for pouring the solution: boards for formwork, thick plywood, reinforcing rods, a welding machine. For the solution you need to find a large enough clean container, clear water, a construction mixer or a special attachment with an electric drill.

Set of tools

Additionally, construction adhesive, mastic, impregnating compounds, primer, brushes, gloves, respirators, etc. may be required.

U-shaped staircase. Basics of mathematics.

Published 10/31. by admin in Useful articles // 0 Comments

It is quite difficult even for an experienced craftsman to independently make and install a U-shaped staircase in a house. However, with some experience and to save the family budget, such a task is quite doable. Let's try to calculate the dimensions of a U-shaped staircase, which will have two platforms at different levels, which will allow us to make such a staircase from purchased blanks.

First, we take measurements of the room and all dimensional restrictions (window, boiler, etc.), and display the result on a sheet of paper. We got a floor plan on an arbitrary scale. If the staircase is designed with two landings that are connected by a step, we set the width of the interfloor opening. If the size of the step is 300 x 1000 mm, and the width of each platform is equal to the step (1000 mm), we derive the width of the opening using the formula: 2 multiplied by 1000 mm (the length of the step) and add 300 mm (its width). We take into account the overhang of the upper platform by 35 mm, subtract this value and ultimately get 2265 millimeters.

A lifting height step of about twenty centimeters is quite comfortable and financially acceptable. To calculate the length of the opening, we measure the height of the room to the floor of the next floor. Let's say we get a figure of 3 meters 20 cm. In our case, we will place the platforms at half the height (3200/2 = 1600 mm). We divide the resulting height of the first flight of stairs (1600 mm) by the lifting height (200 mm) and find out the number of required lifts (8). Since it makes no sense to install the step flush with the platform, we have (8-1) 7 steps.

For comfortable use, we determine at what stage the ceiling will begin to interfere with climbing the stairs for a person, say, two meters tall. Subtract the height of the person (2 m) from the height of the room (3 m) and divide the resulting result by the accepted step height (0.2 m).

(3000-2000) / 200 = 5

We see that in our example the interfloor opening should start from the fifth step. Then it’s not difficult to calculate the length of the opening: multiply 4 steps by the width (300 mm), add the width of the platform (1000 mm) and subtract 35 mm of the spade.

4 * 300 + 1000 – 35 = 2165

Next, we calculate the number of steps required. To do this, we divide the lifting height by the step we have adopted of 20 cm:

3200: 200 = 16

We get 16 lifts or 16-1 = 15 steps.

Using the principle of budget savings, we opt for steel blanks for balusters. They are attached to each step and provide good rigidity. In practice, balusters are not installed on the first and connecting steps.

15 – 2 = 13 (pcs.)

It is necessary to add the number of balusters to enclose the upper opening of the stairs. If there are small children in the house, balusters should be installed at a distance of 18 centimeters; if not, up to 25 centimeters. Therefore, their number will range from 14 to 23 pieces.

This completes our calculation.

Difficult? Contact the experts and this will be their task.

Mandatory requirements

Before making a choice, you should take into account an important fact - weight. On average, metal and wooden structures on the second floor weigh from 150 to 300 kg. The glass mass will increase to 500 kg (the weight of one stage reaches 33 kg). The weight of a product with steps made of natural or artificial stone will exceed 1.5 tons. Obviously, the last solution for a wooden house is unrealistic.

Staircase with metal railings

Marching staircase in a wooden cottage

Wooden staircase in the house

If reinforced concrete floors were used during the construction of the building, then it is allowed to install metal, wood, and even glass options. Reinforced concrete floors can withstand from 500 to 1000 kg. In houses with wooden floors, additional beams should be installed in the place where the staircase is supposed to be installed. This is especially true when installing a screw model, since the main load-bearing load in this case is performed by the central post.

If for some reason it is difficult to attach to a load-bearing wall, it is possible to implement a cantilever model, since it involves installing steps directly into the wall. Or, as an option, erecting a modular structure on the second floor, since the latter involves support in the floor in only two places. The photo shows a modular rotating model.

Based on the above, the need to design the stairs at the first stage is obvious. The recommendation is also obvious to choose the option with the least weight. Even a novice craftsman can easily make a wooden interfloor structure.

Safety requirements

Depending on the structure, interfloor stairs are classified according to the level of safety. While the steps must be the same height (the only exception is the first step), they must provide sufficient support to the foot. That is, the width of the step should be 35-37 cm, otherwise the risk of slipping and injury sharply increases.

- The direct marching structure to the second floor has the highest level of safety: all steps are the same, sufficient width. A rotary flight with one or two landings has the same characteristics.

- The second place goes to the option with winder steps. A turn where a person is forced to climb wedge-shaped steps increases the risk of slipping.

- A spiral staircase is the most inconvenient to use, since along the line of movement its steps do not reach the proper width. Accordingly, it is also the most unsafe.

Comparisons are given for cases where the march inclination angle of 30-40 degrees is maintained. The greater the angle of inclination, the more inconvenient the design, and the more traumatic it is considered.

Space requirements

The type of interfloor staircase in a wooden house depends on the area of the latter.

- The extensive ground floor will allow you to choose a marching option, and the space below it can be used as a storage room. A very original solution is to install a dressing room or something like a sideboard with compartments for various items in the resulting niche. The photo shows a version of such a built-in “cabinet”.

- If the area of a wooden house is small, then you should make a choice in favor of a rotating interfloor structure: straight or with winder steps. It is recommended to choose the “transparent” option, which preserves perspective.

- The screw model is convenient in that it can be located in any part of the room, if the ceilings allow, and does not block the space of the room.

Design requirements

Wood compares favorably with all other options not only because it allows you to implement almost any design ideas, but also because it makes it possible to realize these ideas with your own hands.

The most common interior options for a wooden house are “chalets”, hunting lodges, and Russian towers. In this case, it is recommended to opt for a wooden flight of stairs. Compliance with the style can be enhanced by the design of balusters and handrails. For example, the “chalet” style does not accept curved parts of the tree, so if the chosen option is rotary, then you should not use a bent bowstring and railings. But in the Art Nouveau style such a project is acceptable and even desirable. The photo shows a product with curved wooden railings.

A wooden house can also be decorated in a style such as the Renaissance, which is very demanding of ostentatious luxury and whimsy. In this case, the manufacturer will come to the aid of an applied thread of the appropriate color.

Each wooden house is a unique creation. And the choice of stairs for him is an opportunity to emphasize his uniqueness.

Do-it-yourself manufacturing and installation

To build a wooden staircase with your own hands, you need to start with design and calculations. You should absolutely not make mistakes, as any deviations in the calculations can lead to difficulties during assembly.

It is recommended to start with designing the main structural elements: steps, stringers and handrails.

The step data can be calculated using the formula: 2A + B = 64 cm, where A denotes the width of the part, and B is the height of the step. On average, the height of the step varies from 13 to 18 cm.

Important! To determine the angle of inclination of the march, you can use the data from the table below.

It is necessary to include in the drawing calculations of the protrusion above each step; usually this figure does not exceed 3-4 cm. With a more significant protrusion, there is a chance that the owners will constantly stumble.

Experts recommend using 0.4 cm thick pine boards when making stringers. It is also necessary to pay attention to the moisture content of the wood; it should not exceed 13%.

It is necessary to strictly follow the steps of creating this staircase

Algorithm for making stringers with your own hands:

- Apply markings to the prepared building material using a pattern. Do not make sharp corners on the teeth.

- Using a hacksaw or electric jigsaw, cut out the teeth along the markings. The first part can be used as a template and all other stringers can be cut out according to it.

- Install the finished structural elements in the place where the stairs will be. Carefully ensure that the ends of the stringers are firmly secured and rest tightly against the floor and ceiling of the floor.

Now you can begin installing the steps, risers and railings, having cut out these parts in the required quantity in advance. It is recommended to start by installing the risers using nails or self-tapping screws. To make the ladder safer and stronger, some connect the parts using triangular shaped fillets. They are fixed with special dowels (for them it is necessary to cut grooves in the stringers).

After installing all the steps, the balusters and railings are installed. The fastening elements are screws and studs.

Finally, the finished staircase structure is varnished several times to prevent the appearance of pests, mold and other unpleasant formations.

Components of a staircase structure

The staircase structure will be “built” from ready-made blocks offered by the program, which can be edited by setting the necessary parameters.

A metal staircase consists of several main elements:

- Staircase steps;

- Area;

- Railing;

- Fencing.

Elements, nodes

In the program, the drawing will be created by compiling and selecting the parameters of each specific element. Thanks to the versatility of such computer software, it is possible to design and calculate in advance absolutely any metal staircase with or without a platform.

https://youtube.com/watch?v=Tr5Ibb8iun4

The entire drawing will be presented in a section so that you can view the selected element more carefully. Each selected and approved element in the drawing is presented not only structurally, but also all the main dimensions of flights of stairs or flights are shown.

Autocad staircase drawing

The set of finished documentation, made in the AutoCad system, will include not only a longitudinal section of the constructed objects, but also a transverse one, as well as a specification with the necessary fasteners and the corresponding GOSTs.

Staircases, staircases

Flights of stairs in the program are carried out in accordance with GOST 9818-85 and can be of the following types:

- Flat without frieze steps - LM;

- Ribbed with frieze steps - LMF;

- Ribbed with two half-plates - LMP.

Flat and ribbed types have one significant difference: some are installed on a slab, while others are installed on a stringer. LMP staircases are larger structures that are joined together by a slab.

Flights of stairs combined with landings

For each type of staircase structure, according to the articles included in the program, a landing is selected, for example, a flight type or a ribbed one.

It is necessary to pay special attention to the rotation of the staircase structure - it can be made in two versions: right and left

Series

The AutoCad program has its own data library, which includes regulatory documents and construction rules. Such documentation, on the basis of which drawings are constructed, is called a series. The series of regulations includes not only the basics of constructing a specific metal structure, but also GOST for the material used, fire safety and rules for basic urban planning.

Data Library in AutoCad

For example, to build metal stairs with a platform, you should take Series 1.450.3-7.94 Metal stairs, platforms, fences as a basis. Issue 2.

Series 1.450.3-7.94

There are issues 0-2, which characterize the material used, so issue No. 2 involves the design of structures from hot-rolled profiles.

Hot rolled profiles

Documentation - series, regulate the basics of construction and installation of steel stairs, railings for them, and the necessary knowledge for their proper installation and operation, as well as a set of additional elements.