Depending on the slope angle of the sewer pipe:

- for a pipe with a diameter of 100 mm - at least 2 cm per meter

- for a pipe with a diameter of 50 mm - at least 3 cm per meter

At what height is the sewer line for plumbing fixtures installed?

For a wall-mounted toilet 160-190 mm (depending on the manufacturer and model), local fitting will give the most correct answer.

In other cases:

- for wall-hung toilet 220-240 mm from the floor

- for shower cabin with tray 60 mm

- for washbasin 500-550 mm

- for bath 100-150 mm

- for kitchen sink 300-400 mm

- for washing machine and dishwasher 600-700 mm

If, for technical reasons, the sewer outlets for the bathroom (shower stall, toilet) are made higher, then under the bathtub (shower stall, toilet) you can make a podium to the required height. This podium can also play a decorative character.

Cold and hot water is discharged at a height of:

- for a wall-mounted toilet 400-600 mm (depending on the water supply to the tank - bottom, side or rear), local fitting will give the most correct answer

- for a shower cabin with a tray 1200 mm from the bottom of the tray, and shower heads - 2100-2250 mm (from the bottom of the shower head to the bottom of the tray)

- for bathtub 750-800 mm from the floor

- for washbasin 550-650 mm

- for kitchen sink 500-600 mm

- for washing machine and dishwasher 700-750 mm

Distance between water outlets:

- for shower cabin and bathtub 150 mm from the central axes

- for washbasin and kitchen sink 100 mm (not so rigidly tied, as they are connected with flexible hoses)

The bathtub is mounted at a height of 600 mm, the washbasin is 850-900 mm. These sizes can be changed and depend on the height of family members. And they drag along with them the adjustment of other sizes (output of water outlets).

And do not forget also that the floor level in toilets and bathrooms should be 15 - 20 mm below the floor level in adjacent rooms, or the rooms should be separated by a threshold.

It is advisable to purchase all the plumbing before the installation of plumbing communications begins. This will simplify the plumber’s task and also reduce the risk of mistakes.

During the renovation process, a lot of questions arise. I will highlight the most common ones that arise when renovating bathrooms.

What is the slope of the sewer pipe? – for a pipe with a diameter of 100 mm – at least 2 cm/meter – for a pipe with a diameter of 50 mm – at least 3 cm/meter

At what height is the sewage system installed... - for a wall-mounted toilet 160-190 mm (depending on the manufacturer and model), local fitting will give the most correct answer - for a wall-hung toilet 220-240 mm from the floor - for a shower cabin with a tray 60 mm - for a washbasin 500-550 mm – for a bathtub 100-150 mm – for a kitchen sink 300-400 mm – for a washing machine and dishwasher 500-650 mm

If, for technical reasons, the sewer outlets for the bathroom (shower stall, toilet) are made higher, then under the bathtub (shower stall, toilet) you can make a podium to the required height. Perhaps this situation will upset someone, but on the other hand, this podium can play a decorative character.

At what height is cold and hot water discharged... - for a side-mounted toilet 400-600 mm (depending on the water supply to the tank - bottom, side or rear), local fitting will give the most correct answer - for a shower cabin with a tray 1200 mm from the bottom of the tray , and shower heads – 2100-2250 mm (from the bottom of the head to the bottom of the tray) – for a bathtub 750-800 mm from the floor – for a washbasin 550-650 mm – for a kitchen sink 500-600 mm – for a washing machine and dishwasher 500-750 mm

The distance between the water outlets... - for the shower cabin and for the bathtub is 150 mm from the central axes - for the washbasin and for the kitchen sink 100 mm (not so rigidly tied, as they are connected by flexible hoses)

The bathtub is mounted at a height of 600 mm, the washbasin is 850-900 mm. These sizes can be changed and depend on the height of family members. And they drag along with them the adjustment of other sizes (output of water outlets)

And do not forget that the floor level in toilets and bathrooms should be 15 - 20 mm below the floor level in adjacent rooms, or the rooms should be separated by a threshold. And also do not forget about waterproofing in the bathroom and toilet.

It is advisable to purchase all the plumbing before the installation of plumbing begins. communications. This will simplify the plumber’s task and reduce the risk of mistakes.

How to calculate the optimal sink height

According to building codes, sinks in residential areas must be installed at a height of 80-85 cm, but studies have shown that this is not the most convenient location.

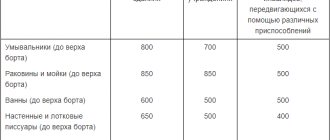

In this case, most people have to bend over a lot to wash their hands, so it is better to be guided by the anthropometric parameters of men and women. Optimal washbasin installation height (from floor to side) for men, women and children

| Men | 94-102 cm |

| Women | 81-93 cm |

| Teenagers | 65-80 cm |

| Children | 40-60 cm |

If the sink will be used by several people of different ages and genders, it is better to choose an average height - 86-93 cm from the floor, and for children, install a special stand or a second washbasin. True, such an arrangement is only possible for models with the ability to adjust the height - for “tulip” type washbasins or those that cut into cabinets, SNiP parameters are usually used (80-85 cm).

In addition, there are certain technical standards that regulate the location of the sink in relation to other interior items.

| Interior element | Distance to sink, cm |

| 25 | |

| 30 | |

| 25 | |

| 30 | |

| 20 | |

| 60 | |

| 60 |

The distance from the side wall to the edge of the washbasin should be at least 20 cm, and the free zone should be about 70 cm (if the sink is installed in a niche, this figure increases to 90 cm).

Before installing a sink in the bathroom, you need to carefully measure the room, consider the optimal placement of plumbing fixtures and furniture, and then draw a detailed diagram of the interior indicating all measurements. When purchasing a model, it is important to pay attention to the fact that the model’s fastenings correspond to the water supply system. Another important aspect is the choice of a faucet, which is best purchased together with a sink, since they may have a hole for the faucet or be blind.

Tulip-type sinks are equipped with a base of standard length, but it is possible to change the height of the sink at your discretion (though only if its design and configuration are quite simple). To do this, you need to cut the base of the sink or install it on any stand - the main thing is that so that it is reliable and stable. When installing plumbing, it is necessary to take into account the distance between the drain and the siphon: if the siphon is located below the level of the drain, the use of the washbasin can lead to serious problems.

If you plan to place a washing machine under the sink, its height should not exceed 70 cm, since there must be a fairly large gap between the appliance and the washbasin

When spinning laundry, the machine may vibrate, and if its edge touches the edge of the washbasin, the plastic coating of the appliance or the sink itself may be damaged.

Installation of the sink must be done using a level, and it is best to use a laser level, as it allows you to carry out work more accurately.

The easiest option for installing a washbasin for beginners is the overhead model, as it does not require special skills and knowledge. If the dimensions of the room allow, you can install two washbasins side by side. The distance between them should be 94-109 cm, and between the taps - 90 cm.

The correct choice and installation of a sink is the guarantee that the plumbing fixtures will serve its owner faithfully for many years.

Basic principles of container installation

Before installation, the height of the bowl is determined based on knowledge of the height of the youngest person living in the house. The installation height is affected by the material used to cover the walls. If a tiled coating is used, then it is worth considering the tiled parameters. When installing a bathtub with a height of sixty centimeters, tiles are laid in several rows on an area with the same area, without leaving a residue.

Main installation requirements:

- Maintaining the horizontal position of plumbing fixtures. Inspection is carried out using a building level, guided by the side of the container, which is attached to the wall.

- The wall with the side of the bowl should form a right angle. Using a large triangle, this parameter is periodically checked.

Attention! The installation of the bathtub on the floor covering must be level. Next, the bowl legs are adjusted, a siphon is attached, and the drain system is set up.

Metal spacers, which are plates measuring 100 x 100 x 5 millimeters, ensure the horizontal position of the sides of the container. Installing a gasket under the plumbing supports is a prerequisite when performing installation work on a base that is softer than the screed. For example, on laminate or parquet, wood flooring.

Without metal gaskets that form rigidity under the base, the structure will sag over time.

Reference! In Russia they produce bathtubs of standard sizes 1.5 by 0.7 meters, or 1.5 by 0.5 meters. Imported products are made in a larger format, usually 1.8 by 0.8 meters.

Determining the height of the bowl of the structure ensures the normal operation of the siphon, with a built-in water seal; for this it needs a space equal to 15 centimeters.

Dimensions for installing bathtubs and showers

The shower cabin and bathtub are connected to the sewer using specially designed corrugations and pipes or tees with a diameter of 50 mm (see photo below). The level of the outlet from the wall of a pipe with a diameter of 50 mm should be 60 mm (from the level of the floor tiles to the axis of this pipe):

If this distance is higher, then you will have to build a podium for the bath.

By the way, the sequence of all repair measures depends on the type of bathtub. If the bathtub is ordinary, then first it is installed itself (details about installing a cast iron, acrylic or steel bathtub), and then the room is tiled. If the bathtub has a hydromassage device, then everything is done the other way around: the bathtub is installed last.

Installation of bathtubs made of different materials

The installation height of the bowl should be determined in advance. To do this, you need to focus on information such as the height of the smallest member of the family.

General installation rules

This parameter is also affected by the type of wall cladding. If you choose tiles, then it is advisable to know the size of the tiles. At a height regulated by SNiP, 2 to 3 rows can be laid on an area of 0.6 m without any residue.

Correct installation of the font involves:

- Its position is strictly horizontal. This is controlled using a level placed along the side of the bathtub in contact with the wall.

- The angle created by the side and the wall should be 90⁰. Therefore, a large triangle will be required to constantly check that this condition is met.

It is easier to ensure that the sides are horizontal by using metal spacers in the form of plates with parameters 100x100x5 mm.

Their presence under the supports is mandatory if the bath is installed on a base that is less hard than the screed. It can be a wooden floor or parquet, laminate. In this case, without additional rigidity elements, the container will sag during operation.

Domestic manufacturers most often use the format 1.5x0.5 and 1.5x0.7 m. Products from foreign companies have slightly larger sizes - 1.8x0.8 m

When choosing the height of the bathtub, you should also remember that a siphon with a water seal will be located under its bottom. For its normal functioning, a free space of about 150 mm is required.

The nuances of installing cast iron plumbing

It is especially important to select the height from the floor before installing a cast iron bathtub. Since its weight is quite impressive, it is difficult to adjust this parameter after installation. The legs of such a bowl are usually solid and often have an exquisite design.

A cast-iron bathtub with legs of an ornate shape with engravings or ornaments is a classic option. She can stand on lion paws or supports in the form of petals or vines. The supports are attached rigidly to the body. They are fixed with complete metal wedges or coupling bolts.

A designer cast iron bathtub is a decoration for the room. It should be placed at a distance from the walls

If the cast iron bathtub includes non-adjustable stands, then the height is adjusted by trimming them and then sanding them.

The surface on which the product is installed must be strong and level. If the floor is not hard enough, metal pads with a diameter of 5 cm and a thickness of at least 5 mm are placed under the legs.

When installing the container on a slippery floor, its supports are secured with waterproof polymer glue. If the design of the legs allows for height adjustment, the parameter is adjusted using adjusting screws and then tightened with fixing nuts. Correctly align the bowl on one side and one end.

If a cast iron bath comes into contact with a steel pipeline, it must be grounded. This important work can only be performed by a professional electrician.

A modern cast iron bathtub on one of the legs or on its bottom has a special eyelet for connecting a grounding wire. If this element is available, then you will need to strip the insulation so that the cable fits tightly at the connection point. Then all that remains is to attach the conductor using a bolt.

Models of the old image cannot be grounded using such a simplified scheme - they do not have a special ear. At the time they were produced, grounding was natural - the bath was connected to the ground by a cast-iron water supply.

Since many people have replaced cast iron with plastic, natural grounding has ceased to function. Therefore, for grounding, make a hole yourself in the area where the legs are attached to the bottom of the container. It is necessary to use a building level during installation to ensure that the sides of the bowl are parallel to the floor.

If, after final adjustment, the product needs to be moved, this can be done by gentle tapping. Perform manipulations only with those supports that are closest to the others in relation to the points of movement.

Adjusting the height of the steel bath

While a cast iron bathtub can be installed even in the middle of the room, a steel bowl must be adjacent to the walls. Before installing it and leveling it in height, you need to tiled the walls. Of the existing methods of fixing steel bathtubs, supports with self-adhesive linings are considered the safest and most reliable.

Often, when installing a bathtub, they are guided by design rules. This is not entirely correct - if you change the height for the sake of beauty, the consequences can be sad. The standard exists to prevent possible errors.

When installing legs with tightening bolts, enamel peeling may occur both when tightening the fasteners and during operation.

Self-adhesive, adjustable, following the contour of the bottom of the bowl, the legs are always paired. They have a channel shape and a slight deflection at the base. The fasteners are located here—adjusting screws equipped with plastic tips.

Particularly reliable legs for a steel bowl are short, but have long bolts for adjustment. The bath itself is installed against straight walls, which are not yet finished, pre-impregnated with a moisture-proofing agent.

Before installing a new steel bathtub, try on self-adhesive legs to the places where they join the bowl. In this case, the first one is installed at a distance of about 30 mm from the drain hole. The second - on a flat surface at the opposite edge. Before this, the contact points are wiped with alcohol or a solvent containing acetone for the purpose of degreasing.

Adjust the height of the bath to the required level by turning out the studs. All manipulations related to attaching the legs are easier to perform when it is in an inverted position

The overlay is slightly warmed up with a hair dryer. Then, having removed the protective film, install the supports exactly according to the markings and press tightly. Place clamping nuts on the adjusting pins and carefully drive them into the plastic tips until they stop. The nuts are moved close to the tips. The assembled unit is connected to the supports.

After the bathtub is installed in a permanent place, it is first leveled in terms of level and height. Next, proceed to precise alignment. To do this you will need 4 wooden wedges. They are driven between the walls and the side of the bath so that the edges protrude slightly.

The side is covered with paper tape. Then the resulting gap is foamed using a balloon with a narrow nozzle. After the polyurethane foam has hardened, remove the wooden wedges using pliers. All that remains is to cut off the remaining foam and eliminate the play by unscrewing the adjusting pins.

Proceed to the next stage - finishing work. Cover the bowl with a protective film, lay tiles on the walls and floor. After this, the legs are manually pulled in such a way that the bathtub adheres very tightly to the wall.

Clamp the nuts, twisting them tightly to the supports. To check the correct height adjustment of the bathtub, measurements are taken at four points from the side to the floor. The difference in measurements should not exceed 4 mm. If this condition is violated, the adjustment is performed again.

Features of mounting an acrylic model

Acrylic bathtubs are often equipped with a metal frame. There are adjustable legs here, with the help of which you can easily select the height of the polymer bowl. The supplied set includes different-sized metal profiles, which already have mounting holes, 4 legs, 4 stud-shaped stands, 4 thrust bearings, 16 nuts, self-tapping screws.

The installation work begins with the assembly of the frame. Do this according to the instructions using long screws

At the beginning of the installation of an acrylic bathtub, the assembled frame is installed in the middle of the center of the bottom of the bowl, which is located upside down on the floor. The legs are attached to the frame. Two supports are secured under the bottom, three along the front edge, and two more along the wall. Adjust the legs to the required height.

The bath is turned over and checked for horizontality using a level. If there are no deviations, connect the siphon. The next step is to attach the edge of the bathtub to the walls. This is done using special hooks or corners. Finally, a decorative screen is installed.

When there is no metal profile frame, the bowl is installed on bricks, from which a podium-like structure is made. Sometimes, in order not to overload the ceiling, columns are made of brick instead of this bulky structure. There may be two or three of them - it all depends on the length of the model.

Hydraulic testing of pipes

After all water and sewer pipes have been laid and all requirements for the placement of water outlets have been met, it is imperative to test the pipeline or, as experts call it, pressure testing.

Pressure testing must take place under increased pressure of 10 atmospheres using a special press. To do this, all water outlets, except the farthest one, are closed with plugs (they will later protect the pipes during finishing), and a ball valve is screwed into the farthest water outlet.

The system is filled with water, then shut off and a special crimping press is connected to the tap. The tap opens and a pressure of 10 atmospheres is injected into the pipeline using a press (all pressure testing machines are equipped with pressure gauges).

If the pressure does not drop within several hours, then the system can be considered sealed and can be safely walled up. If not, then you should find the leak, fix the problem and test again.

CONCLUSION

After laying the pipes and carrying out hydraulic tests, you can begin finishing – tiling the bathroom with ceramic tiles. The installation of plumbing fixtures should be carried out at the final stage.

Properly done piping in a bathroom using modern pipes and technologies will serve its owner for decades.

What dimensions should sewer outlets have to install different plumbing fixtures? Dimensions of sewer pipe outlets for plumbing connections

In previous articles, the rules that must be followed when installing plumbing were discussed. Now let’s figure out what sizes of sewer pipe outlets

.

The shower cabin and bathtub are connected to the sewer using specially designed corrugations and pipes or tees with a diameter of 50 mm (see photo below). The level of the outlet from the wall of a pipe with a diameter of 50 mm should be 60 mm (from the level of the floor tiles to the axis of this pipe):

If this distance is higher, then you will have to build a podium for the bath.

For a washbasin (sink), the height of the sewerage system from the floor (pipe outlet from the wall) should be 530...550 mm from the level of the clean floor to the axis of the pipe:

For an attached toilet – 180…190 mm (depending on the model):

For a wall-mounted toilet – 220…240 mm.

For a kitchen sink without a chopper – 300…450 mm.

For a kitchen sink with a chopper – 300…400 mm.

For washing machine and dishwasher – 600…700 mm.

(all distances are given from the level of the clean floor to the axis of the pipe)

Let me clarify: the above values are common, standard, but with today’s variety of companies and models, it is necessary to approach each case personally.

If you want to install some new, exclusive plumbing equipment, then you should first look at the technical map of installation and connection dimensions specifically for this equipment. This must be done earlier than supplying water and laying a drainage ditch - so as not to have to redo it, therefore it is better to purchase the desired plumbing fixtures in advance (if there is space for storage).

By the way, the sequence of all repair measures depends on the type of bathtub. If the bathtub is ordinary, then first it is installed itself, and then the room is tiled. If the bathtub has a hydromassage device, then everything is done the opposite: the bathtub is installed last.

How many bathrooms are needed? If we are talking about an apartment with an open plan, then first you need to impartially assess the dimensions of the place, as well as the locations of the risers to which all plumbing equipment will be connected. As a standard, it is better to equip two separate bathrooms - a guest and a master (again, if space allows). The guest room will only have a toilet and sink.

Naturally, residents living in houses with a standard layout do not have the ability to make several bathrooms, so you just need to decide the question: is it really necessary to bother with remodeling the bathroom or should you just limit yourself to replacing plumbing equipment and cosmetic repairs?

In the following article there is still little information about installing plumbing fixtures with your own hands.

in the light of water supply and sewerage design. Namely, about electronic sockets in the bathroom.

Accessories for installation of sewer pipes

Let's look at the various corners and joints for plastic sewer pipes used for installation.

Tee 90 degrees, diameters: 32, 40, 50, 110 mm. One of the main and frequently found spare parts. Used to organize drainage to the toilet and in other solutions. You often hear from “very experienced” plumbers that the toilet outlet should not enter a horizontal bench (pipe) at an angle of 90, otherwise there will be constant blockages. I can say with full responsibility: this is not so - in my practice there are a great many toilet connections with such a tee and during operation there is no hint of blockages.

In general, plumbers have a rule: if possible, do not make 90 angles on the “ditch”, it is better to put two 45 angles

. This is indeed true and it is worth adhering to this rule, however, in the case of a toilet, in 9 out of 10 cases it is technically more convenient to make the connection with a 90-degree tee. And there’s nothing wrong with that!

Transitional eccentric coupling 110-50 mm.

, popularly called “bottle”. Designed for transition from the 110th pipe to the 50th. In the bathroom sewer, it is used, as a rule, after organizing the outlet to the toilet - then the 110th diameter is unnecessary and installation continues with the fiftieth.

In the photo above we see the assembly: cross 110-110-110-50

and "bottle". This is how the outlet to the toilet is organized, the continuation of the D50 lounger to the left and the D50 outlet up. The upper outlet in the example above is used for the drain of the washing machine.

When purchasing crosspieces, you need to be careful: they differ in left and right.

Errors made during the installation process that can cause pipes to become clogged

Pipes from sinks, sinks and other plumbing fixtures must be mounted on a connection at a right angle of 90 degrees. If two devices are installed and the drains are drained towards each other, a blockage may occur in the tee of the pipe, which goes directly into the drain pipe. In this case, it makes no sense to clean the pipes from the side of the sink or washbasin using a spiral or hydrodynamically using a hose. If it comes to two sinks connected next to each other, then it is clear that from one sink the hose will pass to the second sink, but it will not be able to turn in the direction of the main drain pipe

One way or another, it will be quite difficult to clean the sewer. Another important mistake is that the drain pipe coming from the washbasin or sink is too high in the bathroom. As a result, the process of draining wastewater into the sewer pipe becomes difficult.

Many people decide to move pipes and plumbing fixtures, which include bathtubs, sinks and sinks, to another location that is not provided for in the project. If pipes are changed, the main problem may be that the outlet to the device will be rigidly tied to the outlet of the pipe in the riser, and the situation is very difficult to change. When connecting sinks and sinks, everything should be fine, since there is a certain height reserve, taking into account the fact that plumbing fixtures are suspended at a height of approximately 90 cm. But despite this, many inexperienced installers may not take into account or think through such a detail. It is easier to make a mistake with the height when connecting a bathtub and shower. Often the drain is located above the floor surface. It is quite difficult to lift a heavy bathtub yourself, so a simple solution is to install the drain pipe above the siphon outlet. Thus, the pipe is often laid without the required slope, which can also cause clogging of the sewer. You can often encounter a problem in which pipes that are supposed to be attached to the wall from the outside are not fixed correctly. Products may sag, and counterslopes and other practically irreparable cases often form. Of course, this does not in any way affect the proper functioning of the sewer system, but this feature can cause blockages, which will require frequent cleaning of the pipes.

Types of mechanisms

Today there are three types of faucets: herringbone, single-lever and thermostatic. A herringbone is a pair of crane axle boxes located in one body. They are made with a ceramic disc or with a rubber gasket. Valves control water flow, pressure, and regulate temperature.

Single lever mixer

Herringbone mixer

Thermostatic mixer

When purchasing such a design, it is necessary to examine the quality of the connection of the parts: it often happens that bad installations do not completely block the water or have valves that circle in different directions without meaning. The second designs contain a pair of polymer plates or layers; the interval between them can be adjusted using a lever.

Thermostatic designs for bathtubs and showers are the most expensive; they allow you to adjust the required temperature, and this does not depend on the pressure and heat of the water. Such devices have a safety system that prevents the water from being very warm or cold.

The most reliable and reliable material for producing the body of a structure can be called brass, which is made from an alloy of copper and zinc. A galvanic layer is often placed on top of it. It is better to buy other spare parts from stainless steel - it is not heavily exposed to unnecessary sediment that accumulates in the pipes.

Schemes and standards for the placement and installation of plumbing equipment and appliances

Previously, waste and overflows were used in bathrooms, but then they became widespread for sinks.

Flat sink drain

In the case where the sink needs to be installed above the washing machine, as a rule, it has a flat shape. This saves space and is the most suitable option in this case.

Such a sink, which is called a “water lily,” must have a special flat drain. It must be included in the package, since it is almost impossible to select it separately.

In addition, the “water lily” is a sink with a side drain. Its peculiarity is that the hole for water drainage is located on the side, and not at the bottom. This may cause some inconvenience as the water may not drain completely. To avoid siphon blockages, you will need to remove the liquid yourself by soaking it with a rag.

If you are willing to put up with these shortcomings, this will allow you to free up additional space in the bathroom.

Therefore, the choice of sink drain should be given special attention as it will ensure the efficient operation of the system. Plumbing measures in the home can be divided into three types:

Plumbing measures in the home can be divided into three types:

- Maintenance work, for example, fixing a leaking faucet or clearing a clogged shower drain;

- Work to replace pipes or broken equipment;

- Installation of new plumbing and pipeline communications.

Routine plumbing repairs are not regulated by any regulations or standards. However, measures to replace pipes or install new plumbing equipment will necessarily entail the need for coordination with the relevant organizations, which will require strict compliance with the rules for installing plumbing fixtures in accordance with current standards.

The motivation of bureaucrats is simple and clear:

- The transfer of utility networks and the installation of plumbing fixtures in a new location is called redevelopment, which may entail changes in the configuration and size of the room, requiring changes to the apartment’s registration certificate;

- Relocating plumbing fixtures is also a remodel.

Naturally, it is easier to do everything according to the letter of the law, then the preparation of technical documentation for housing will not cause problems.

- SNiP 2.08.01−89* “Residential buildings”;

- SNiP 2.04.05−91* “Heating, ventilation and air conditioning”;

- SNiP 3.05.01−85 “Internal sanitary systems”;

- SNiP 2.04.01−85* Internal water supply and sewerage of buildings.

The modern market of plumbing equipment is represented by a wide range of bathtubs, showers, sinks and sinks, toilets and bidets, valves and mixers. Despite all the variety of devices in terms of functionality and methods of controlling their operation, the methods of connecting household sanitary equipment with residential pipeline communications are completely unified and “submit” to the requirements of GOSTs and SNiPs.

It is recommended to install household plumbing after installation of utilities before finishing the room. Water connections for installing appliances must end with water sockets, which are a mandatory attribute of a home’s water supply system. Water outlets are specially rigidly fixed to protect the water supply system from vibration effects that occur during the operation of connected household plumbing fixtures.

The distance between the axes of the outlet fittings provided for hot and cold water must be strictly 15 cm.

Instead of sockets, it is allowed to use elbows, tees, couplings or manifolds for connecting mixers or other types of taps.

Another general requirement for the installation of plumbing fixtures is to ensure free access to the equipment, for which SNiP stipulates the size of the free space around each type of fixture (bathtub, washbasin, etc.).

The height of placement of plumbing fixtures is regulated in clause 3.11 and clause 3.15 of SNiP 3.05.01−85 “Internal sanitary systems”, and pipeline fittings to the devices are installed in accordance with clause 10.5 of SNiP 2.04.01−85* “Internal plumbing and sewerage of buildings."

Installation features

Actually, most of the information has already been told, all that remains is to assemble the purchased components in accordance with the design idea.

Pipes are assembled from the riser (inlet pipe) towards the consumer. In other words, the pipes that are closest to the drainage point into the common house riser are installed first.

At each connection, the pipe should fit into the socket of the previous one by approximately 50 mm. If the cuff in the socket is too tight and you cannot insert the outlet, then you need to lubricate the cuff with liquid soap or detergent - things will go much easier.

Plastic pipes are cut using any available means: a grinder, a hacksaw. You can even do the cutting with a regular wood hacksaw. The main thing is to clean the cut edge from all kinds of burrs - burrs inside the pipe will cause blockage, and burrs on the outside will prevent the parts from being assembled properly.

Some craftsmen practice applying silicone (sealant) to the cuffs of assembled parts - supposedly the joint becomes even more airtight. The effect of silicone is very doubtful, because polypropylene (which is what plastic drainage systems are made from for indoor use) is a chemically resistant plastic and silicone does not stick to it properly.

“Correct” pipes should be assembled together with some effort and not leak without additional sealants. However, it happens that parts are assembled together too easily - components from different manufacturers, used parts, etc. In this case, of course, you can use silicone sealant. The main thing during assembly is to apply it not to the cuff (because part of the sealant will get inside the pipe), but to the pipe along the outer diameter.

In some situations, it is necessary to secure two parts together so that during operation one does not come out of the other. This should absolutely not be done using self-tapping screws, which some craftsmen screw into the end of the socket. The sharp tip of the screw sticking out inside the pipe will collect hair and cause a blockage. If for some reason the assembled unit experiences mechanical stress to “undocking”, both parts need to be secured using brackets or other fastening techniques.

To form and control the required pipe slopes, it is very convenient to use a laser level. Having built a horizontal beam slightly higher than the horizontal beam, you can control the slope by placing a tape measure on the controlled areas and comparing the distances from the pipe to the beam.

That's basically all. We have covered the main points of installing a sewer system in a bathroom, and perhaps I will add something over time.

Dimensions for connecting non-standard plumbing equipment

Let me clarify: the above values are common and standard, but with the current variety of manufacturers and models, it is necessary to approach them individually in each case.

If you intend to install some new, exclusive plumbing equipment, you should first look at the technical map of the installation and connection dimensions for this particular equipment. This needs to be done before supplying water and laying a sewer system - so as not to have to redo it, so it is better to purchase the desired plumbing fixtures in advance (if there is space for storage).

Sink drain

The sink drain is a necessary element for its installation. It performs important functions, namely: it protects the room from the smell of sewage and prevents the pipe from clogging with solid particles that penetrate through the hole in the sink.

How a sink drain works

The sink drain design consists of the following parts:

- curved siphon;

- sewer pipe.

When the water is flushed, the liquid enters the siphon, passes along the bend, rises up the curved elbow, and then falls down into the general drain. In this case, the water remains in the lower part of the curved elbow. This promotes the formation of a water seal, which prevents odors from entering the room. In addition, small objects and solid particles remain in the elbow part of the pipe, which can fall into the sink. To remove them, this part of the pipe is periodically removed and cleaned.

Sink drain diameter

Depending on the diameter of the sink drain, the siphon holes have the following dimensions:

- 32 mm - designed for washbasins with one hole and small diameter sewer pipes. This is the most common option;

- 40 mm – designed for large sewer pipes.

Sink waste and overflow

Recently, sink drains equipped with an overflow system have become very popular. The advantage of such designs is that the water does not go beyond the edges of the sink. A special overflow hole is installed at a certain level.

Causes of incorrect height ratio

The main reasons for the discrepancy between the levels of the tee and drain holes should be considered:

- errors made during installation or reconstruction of the system;

- the use of modern types of plumbing that require a different system configuration;

- re-equipment of kitchen or other premises, requiring installation of sewerage under the floor covering.

Owners of cafes or bars that open in unprepared premises often face similar problems. They constantly have to solve plumbing installation issues. For example, how to install a toilet if the sewerage system is higher than the drainage elements. In addition, many modern appliances are equipped with a floor outlet, which requires the assembly of a separate line.

Also read: Do-it-yourself homemade sewer pump - vacuum pump

Errors made during the installation process that can cause pipes to become clogged

Pipes from sinks, sinks and other plumbing fixtures must be mounted on a connection at a right angle of 90 degrees. If two devices are installed and the drains are drained towards each other, a blockage may occur in the tee of the pipe, which goes directly into the drain pipe. In this case, it makes no sense to clean the pipes from the side of the sink or washbasin using a spiral or hydrodynamically using a hose. If it comes to two sinks connected next to each other, then it is clear that from one sink the hose will pass to the second sink, but it will not be able to turn in the direction of the main drain pipe

One way or another, it will be quite difficult to clean the sewer. Another important mistake is that the drain pipe coming from the washbasin or sink is too high in the bathroom. As a result, the process of draining wastewater into the sewer pipe becomes difficult.

Many people decide to move pipes and plumbing fixtures, which include bathtubs, sinks and sinks, to another location that is not provided for in the project. If pipes are changed, the main problem may be that the outlet to the device will be rigidly tied to the outlet of the pipe in the riser, and the situation is very difficult to change. When connecting sinks and sinks, everything should be fine, since there is a certain height reserve, taking into account the fact that plumbing fixtures are suspended at a height of approximately 90 cm. But despite this, many inexperienced installers may not take into account or think through such a detail. It is easier to make a mistake with the height when connecting a bathtub and shower. Often the drain is located above the floor surface. It is quite difficult to lift a heavy bathtub yourself, so a simple solution is to install the drain pipe above the siphon outlet. Thus, the pipe is often laid without the required slope, which can also cause clogging of the sewer. You can often encounter a problem in which pipes that are supposed to be attached to the wall from the outside are not fixed correctly. Products may sag, and counterslopes and other practically irreparable cases often form. Of course, this does not in any way affect the proper functioning of the sewer system, but this feature can cause blockages, which will require frequent cleaning of the pipes.

During the renovation process, a lot of questions arise. I will highlight the most common ones that arise when renovating bathrooms.

What is the slope of the sewer pipe?

– for a pipe with a diameter of 100 mm – at least 2 cm/meter – for a pipe with a diameter of 50 mm – at least 3 cm/meter

At what height is the sewage system installed...

– for a wall-hung toilet 160-190 mm (depending on the manufacturer and model), local fitting will give the most correct answer – for a wall-hung toilet 220-240 mm from the floor – for a shower cabin with a tray 60 mm – for a washbasin 500-550 mm – for bathtubs 100-150 mm – for kitchen sink 300-400 mm – for washing machine and dishwasher 500-650 mm

If, for technical reasons, the sewer outlets for the bathroom (shower stall, toilet) are made higher, then under the bathtub (shower stall, toilet) you can make a podium to the required height. Perhaps this situation will upset someone, but on the other hand, this podium can play a decorative character.

An example of a podium for a shower stall.

At what height is cold and hot water discharged...

– for a wall-mounted toilet 400-600 mm (depending on the water supply to the tank – bottom, side or rear), local fitting will give the most correct answer – for a shower cabin with a tray 1200 mm from the bottom of the tray, and shower heads – 2100-2250 mm (from the bottom of the watering can to the bottom of the tray) – for a bathtub 750-800 mm from the floor – for a washbasin 550-650 mm – for a kitchen sink 500-600 mm – for a washing machine and dishwasher 500-750 mm

Distance between water outlets...

– for a shower cabin and for a bathtub 150 mm from the central axes – for a washbasin and for a kitchen sink 100 mm (not so rigidly tied, as they are connected by flexible hoses)

The bathtub is mounted at a height of 600 mm, the washbasin is 850-900 mm. These sizes can be changed and depend on the height of family members. And they drag along with them the adjustment of other sizes (output of water outlets)

And do not forget that the floor level in toilets and bathrooms should be 15 - 20 mm below the floor level in adjacent rooms, or the rooms should be separated by a threshold. And also do not forget about waterproofing in the bathroom and toilet.

It is advisable to purchase all the plumbing before the installation of plumbing begins. communications. This will simplify the plumber’s task and reduce the risk of mistakes.

Standard bath sizes

When choosing a bathtub, it is important to take into account several operational factors, the main one of which is its dimensions. A bathroom of incorrect dimensions will cause clutter in the room, reduce the functionality of the room and, most likely, cause significant discomfort.

The key criterion when determining the size of the structure is whether it is comfortable to take a bath. Convenience is a highly subjective criterion that varies from person to person and depends on body type, height, duration and preferences for taking hygiene procedures. Therefore, the length, width, height and depth for bowls are in the following range:

- length varies from 150 to 180 cm;

- fixed width indicators - 70-85 cm;

- depth and height can reach 65 cm.

Bathtubs are divided into small, medium and large sizes:

- small – from 120 to 130 cm in length and 70 cm in width;

- medium - from 140 to 150 cm in length and 70 cm in width;

- large - from 170 to 185 cm in length and from 70 to 85 cm in width.

Standard bathtub sizes: no matter what calculations

In this case, you should pay special attention to several aspects on which a comfortable position in the bathtub depends:

- It is preferable that during hygiene procedures a person can take a reclining position. To do this, choose a bathtub that can accommodate your outstretched legs.

- The width of the bathtub should also be proportionate: the standard is calculated taking into account the volume of the human body and at least 5 cm to the sides on each side when a person is immersed in water.

- The depth of the bowl will differ for different designs, but the most preferred parameters are 50-60 cm. This bath depth is the standard for safely positioning the body in the water and the head above its surface.

- Bathtubs, similar in appearance, often differ in volume. This is due to the angle of inclination of the internal walls, as well as the presence or absence of armrests and sides.

- Bathtubs that exceed standard sizes not only increase water consumption and the time it takes to fill and drain, but are also considered less safe. Therefore, we recommend installing bathtubs of standard dimensions, which have been tested over many years of use.

The dimensions of bathtubs depend not only on the regulations and standards applied to them, but also on the material from which they were made.

How to choose a bathtub size

First of all, the proportionality with the bathroom is taken into account. The width of the latter should at least correspond to the largest dimensions of the plumbing fixtures plus one centimeter on each side. For small bathrooms up to 4 m², wall and corner tanks are suitable. Round ones are installed in rooms from 8 m². The relevance of the bathtub dimensions for a particular bathroom is determined by calculating the available area. The dimensions of the space for a washing machine and washbasin, toilet, if any, are subtracted from the overall indicator. The resulting result is used to determine the maximum allowable width of the bath along the protruding edges, as well as the largest area it occupies. In square bathrooms, calculating the space for the bowl will not cause difficulties, but in the case of oblong options, much depends on the placement of the sink and household appliances. The length of the plumbing will most likely have to be coordinated with the narrow side of the room.

It will be better if you plan everything in advance: if necessary, the machine can be moved to the kitchen or placed under the sink countertop.

Siphon connection diagrams

Regardless of the design of bathtub sinks and methods of their installation, siphons are traditionally used:

- single-turn;

- double-turn;

- bottle.

The use of a one- or two-turn siphon is typical for “water lilies”, when it is necessary to free up as much free space under the sink as possible to accommodate a washing machine or other household items.

The name “single-double turn” was obtained due to the presence of one or two pipe bends in the circuit. Due to such bends, a hydraulic seal is created inside the line.

Another option, “bottle”, is the most common. It differs from the first in the absence of bends, the functions of which are performed by a special “bottle” with a drain pipe diverted from the top of the structure. This scheme is more convenient than the first when performing maintenance - cleaning the line in case of a blockage. At the bottom of the “bottle” there is a technical cap that can be easily unscrewed.

What determines the installation height of the mixer?

It is important to note that all the figures indicated above are only recommendations. After all, the premises and requirements of different consumers differ from one to another and are unique. For this reason, the installation height of the crane will always be different. This parameter, and the installation method itself, depends on various factors. One of them is the type of mixer.

Each of them needs to be mounted at a different height (as indicated in the previous paragraph). If two taps are installed for the bathtub and sink (that is, for each of the bowls), then the mixer that you will use only for the bathtub can be mounted at a distance of 20–25 cm from its upper edge.

If you plan to use only one faucet (with a long spout) for both devices, then the installation height above the upper side of the bath should be at least 30 centimeters. It is recommended to install the faucet above the sink at a distance of at least 25 cm from its top edge. This height is optimal so that the consumer can easily wash their hands, wash themselves and perform the entire set of hygiene procedures.

Marking, scoring and laying

After choosing the type of wiring, you can begin marking the pipeline routes. For polypropylene and copper pipes, all connections occur at right angles.

And for metal-plastic and cross-linked polyethylene pipes, the grooves can be laid with curves at the corners.

The grooves can be hollowed out with a hammer drill, cut with a wall chaser or a grinder with a diamond disc for stone. This is the dirtiest and dustiest stage of the work.

When laying pipes, it should be taken into account that it is customary to lay the hot pipe on top and the cold pipe on the bottom.

The size of the grooves should be such that the pipes can easily fit into the groove with thermal insulation made of foamed polyethylene placed on them, which, after walling, will compensate for the thermal expansion of the pipes.

In the space under the bathroom, it is not at all necessary to trench the wall for laying pipes; this place is already closed. To fasten pipes in grooves, you can use standard clips, but they take up a lot of space, so dowels and copper wire are often used.

In order to accurately align the water sockets of the bathtub mixer for all types of pipes, there are special mounting strips where the pipe outlets are located at a distance of 150 mm. It is recommended to use them.

When laying horizontal sections of sewer pipes, a slope of 3 cm per 1 meter of length should be observed.

When turning 90 degrees, it is better to use two 45-degree corners, with the exception of the exit to plumbing fixtures.

When assembling sewer pipes, do not forget about the cuffs, which should be lubricated with technical petroleum jelly.

Should I follow the standard?

Most builders, finishers and plumbers are well aware that the standard, optimal height of a bathroom sink is 85 cm.

These standards were developed and tested back in Soviet times, but are still observed, especially when arranging bathrooms in administrative and commercial buildings. When renovating a private apartment, if necessary, you can deviate from the generally accepted installation standard.

In conclusion, I would like to say that inside your apartment, and even more so in a private house, you have the right to install a sink inside the bathroom at any height convenient in specific conditions.

Whether or not to follow installation standards is up to you to decide. However, years of practice and scientific research confirm that, after all, a height of 85 cm is the most optimal option for the convenience of all family members, proven over the years.

Deviations from standards, what height is acceptable

There are some deviations between building codes and regulations. The reference books indicate that the standard height for children's institutions and health care institutions should be 500 mm. It should be understood that all the figures given are not final, and deviation from them will not lead to undesirable consequences.

Height of the rectangular bathtub Aurora

Each owner has the right to set the optimal height and distance for himself based on personal preferences and maximum comfort. Only self-adjusted tests can make it clear what the ideal height should be. Ultimately, this is the only way that bathing procedures can bring maximum pleasure.

At what height should the sink be installed?

An ordinary plumbing fixture in the form of a sink without any auxiliary accessories should be fixed at a height of about 85 cm. At a certain level, it is required to draw a horizontal line corresponding to the level of the highest boundary of the plumbing fixture.

If a support is provided or if the sink is in a cabinet, there is no need to determine the installation height, since it depends on the level of the support or the height of the cabinet.

Features of marking fixation points on the wall

Before installing the fasteners, you need to mark the points on the wall according to a special pattern. There are holes in the sink cavity for fasteners, which must coincide with the markings. The sink is applied to the wall, aligning its upper border with the line that was previously marked on the wall. In this way, the location of future mounting recesses in the wall is determined. It is better to carry out work processes together, as it is much more convenient. During the marking process, one worker will hold the sink at the level of the mark, and the second will fix from below the places where it is planned to fasten.

Installation of fasteners

Installation of fasteners should be done as follows:

- holes in the wall must be made according to clear markings;

- dowels are driven into them;

- special pins are screwed in for fastening.

In the process of connecting a sink in the bathroom and kitchen, the use of dowels and special pins is implied. You may also need nuts and plastic inserts supplied with the plumbing fixture.

When screwing in the studs, you need to monitor the depth of entry. The depth at which you can hang the sink and screw the nut is considered sufficient. In other words, the stud should protrude from the wall to the thickness of the device plus one and a half centimeters for the nut.

Types of baths

There is a wide range of bathtubs on the sanitary equipment market.

Each buyer can purchase a model he likes, made of steel, cast iron, acrylic, or a new sanitary ware product - a quarry product. You can also choose the bathtub volume, width and length. The choice depends on the size of the bathroom, personal preferences and financial capabilities of the consumer. The steel option is considered the most affordable. This bathtub is light in weight and does not cause problems during transportation. The use of steel as a manufacturing material allows the product to be given different geometric shapes. But the service life of such a bath is short, since it does not sufficiently withstand mechanical stress. The product does not hold heat well and makes a lot of noise.

The classic tank is a heavy tub made of cast iron. This product is characterized by reliability and durability. It does not have a wide variety of shapes, but can have an original design. Water poured into a cast iron bath retains heat for a long time. Prices for these products are several times higher than for steel products.

In recent years, the types of tanks described above have been replaced by acrylic bathtubs, which have become very popular. They are lighter in weight, but at the same time retain heat excellently. High-quality acrylic products can last at least 10 years. The height of the acrylic bathtub from the floor is standard.

The advantage of this product is a large selection of colors and shapes. But the presence of numerous intricate lines leads to a decrease in strength indicators. Since there are no pores on the surface of acrylic, pathogenic microorganisms do not multiply in such a bath.

A pleasant novelty on the plumbing equipment market is products made from the composite material quaril, which includes:

- quartz;

- acrylic;

- polymer additives.

The long service life of these baths justifies their high cost. Quaril is a hygienic material with a hard surface and resistance to ultraviolet radiation. Models made from it are heavier than acrylic products - their weight reaches 50 kilograms. The cost of quaril baths is quite high, since they are produced exclusively in Europe.

Video tutorial on installation and connection of a sink on a pedestal

When installing the washbasin and connecting the system, consider a number of points:

When planning to connect a double sink, choose a special siphon that has an outlet to two pipes. The height of the sewer outlet under the bathroom sink should not exceed 500-550 mm

When connecting to a sewer, it is important to reliably seal all joints, otherwise unpleasant odors will appear in the bathroom over time.

If, when checking the tightness of the connections, you notice water leakage, remove the cuff and, after allowing all the elements to dry, lubricate the connecting cuff with sealant and “put” it in its original place.

Installing and connecting a sink is not particularly difficult, but quite labor-intensive work. At some stages of installation you cannot do without an assistant. But in general, if desired, any home craftsman can easily cope with installing a washbasin on his own.

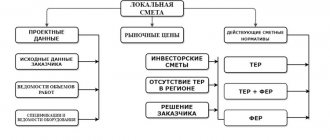

| Name | Europe, mm | Russia, mm |

| Sink | 850 via VK | 850 via VK |

| Mirror over the sink | 1200 according to NK | — |

| Soap stand (sink) | 950-1000 according to Tax Code | — |

| Towel holder (sink) | 800 C | — |

| Toilet paper holder | 750-950 on VK | — |

| Spare toilet paper roll holder | 300 according to NK | — |

| Brush holder | 200 according to VK flasks | — |

| Wall-hung toilet | 400 via VK | — |

| Bidet | 400 via VK | — |

| Towel ring (bidet) | 800 C | — |

| Soap stand (bidet) | 700 C | — |

| Bath | 600 on VK | 600 on VK |

| Hand shower head (bathtub) / hose must not be in the bathtub / hose length 1.25 m / 200 mm from the vertical axis of the mixer | 500 for NK bracket from VK bath | — |

| Inlet for hose (bathtub) / with hose length 1.25 m / 200 mm from the vertical axis of the mixer | 700 C from VK baths | — |

| Soap stand (bath) | 100 according to NK from VK baths | — |

| Bath mixer | 300 C from VK bath | 800 N from the floor surface |

| Overhead shower head (shower cabin) | 2100-2250 according to NK from the surface of the floor covering | |

| Hand shower head on a bar (shower cabin) | 2095 via VK from the pallet area | — |

| Side shower nozzles (3 pcs.) | 600 / 1000 / 1400 N from the pallet platform | — |

| Side shower nozzles (2 pcs.) | 700 / 1300 N from the pallet platform | — |

| Shower faucet | 1200 N from the pallet platform | 1200 |

| Hose outlet (shower cabin) | 1400 N from the pallet platform | — |

| Pen | 1000 according to Tax Code from the pallet platform | — |

| Shower tray | — | 400 via VK |

- Unless otherwise stated, all values are based on the finished floor

. For example, the value “Sink: 850 mm on VK” contains an instruction to install it so that the upper edge of the sink (VK; top of the side) is at a height of 850 mm from the surface of the finished floor (covering). - NK

- the value is indicated along

the lower

edge. - VK

- the value is indicated at

the top

edge (at the top of the side). - C

- the value is given according to the mark of the corresponding

center

line (horizontal or vertical).

When did toilet paper appear in Russia?

We think that you will be interested in learning the history of toilet paper production in our country. Here's what information was published as part of TheQuestion project:

“The production of toilet paper in the USSR began only in 1968, when two English paper-making machines were installed at the Syassky pulp and paper mill (Leningrad region). The launch took place on November 3, 1969, but the first batch of hygiene products encountered zero interest from consumers: Soviet citizens simply did not know what it was intended for. Only after a large-scale advertising campaign (videos about toilet paper from the Syassky plant were shown before screenings in cinemas) did a real boom begin. The personal hygiene product, so familiar all over the world, immediately became in short supply in the USSR and until the 80s it could only be obtained by standing in a huge line.”

So, the need for a toilet paper holder arose relatively recently.

Depending on the slope angle of the sewer pipe:

- for a pipe with a diameter of 100 mm - at least 2 cm per meter

- for a pipe with a diameter of 50 mm - at least 3 cm per meter

At what height is the sewer line for plumbing fixtures installed?

For a wall-mounted toilet 160-190 mm (depending on the manufacturer and model), local fitting will give the most correct answer.

In other cases:

- for wall-hung toilet 220-240 mm from the floor

- for shower cabin with tray 60 mm

- for washbasin 500-550 mm

- for bath 100-150 mm

- for kitchen sink 300-400 mm

- for washing machine and dishwasher 600-700 mm

If, for technical reasons, the sewer outlets for the bathroom (shower stall, toilet) are made higher, then under the bathtub (shower stall, toilet) you can make a podium to the required height.

Mixer installation height

| Device name | Raising the Installation |

| Faucet or sink mechanism | 250 mm from the edge of the sink |

| Faucet or washing device | 200 mm from the edge of the sink |

| Faucet or washbasin device | 200 millimeters from the edge of the washbasin |

| Bathroom faucet | 800 millimeters from the floor in its pure form |

| Common arrangement for bathtub and washbasin | 1000 mm – from the floor in its initial form |

| Shower mechanism | 1200 mm – from the floor in its initial form |

Sink installation height

Installation standards

According to SNiP 3.05.01, developed back in 1985, the standard height of a bathroom sink is 85 centimeters, while during installation a deviation of 20 mm up or down is allowed.

This value is a compromise between a washbasin level that is comfortable for use by men and women, who are traditionally slightly shorter. That is why most Russian and foreign manufacturers produce sinks on a pedestal and cabinets with built-in sinks with a height of 83-87 centimeters.

The correct choice of distance from the floor to the top edge of the sink has a significant impact on the comfort of using the plumbing fixture:

- How convenient it will be for a person to use them depends on whether the plumbing fixtures are installed correctly. If the sink is installed too low, you will have to bend over when washing, which can cause spinal pain. If the washbasin, on the contrary, is too high, then children will not be able to use it.

- The distance between the floor and the sink affects their connection to the water supply and sewerage system. As a rule, under the washbasin there is also a water meter, sometimes filters for cleaning and other devices, the installation of which takes up a lot of space. The need to install additional equipment must also be taken into account when choosing the washbasin level.

How to attach

Installing the mechanism is not particularly difficult for a person who knows this device and knows how to use tools. To install, you need an adjustable wrench and a fully equipped mixer mechanism. The old faucet must be removed carefully so as not to damage the application in the room.

Faucet parts

The mechanism should be installed as follows:

- it is necessary to partially assemble the mixer device, firmly pressing the rubber and other gaskets. When installing, make sure that all parts except the lever and the valve part are stationary;

- Then you need to screw the seal onto the thread. A plastic tape can go behind it. When screwing, it is important that the thread of the nut is aligned with the winding, otherwise depressurization may occur;

- You need to secure the device with pipes with nuts. If nuts are not included with the structure, they can be purchased on the construction market. It is often necessary to use special adapters in the form of small metal parts, which are used for a variety of sizes of water supply and the axis of the structure;

- at the final stage of installation, you need to make sure that the mechanism is tightly installed, and then attach the tap.

Installing a faucet in the bathroom

Then you can open the valves. Do not apply intense water pressure after opening, first wait for a certain time, gradually increasing it to the maximum. If, with the mechanism completely open, the amount of spray is not very large, it means that the installation height has been chosen correctly.