Interfloor stairs are most often made from common materials such as wood, steel or concrete products. Each of them has some pros and cons that should be taken into account in specific conditions. Metal has several technological properties, thanks to which the staircase can take any shape. At the same time, it will have aesthetic appeal, strength and reliability.

When constructing metal staircases with one flight, the work is not very complicated, so almost anyone can do it. When erecting a structure, you will need to use a welding machine, which requires certain skills. A two-flight staircase on metal stringers is more difficult to perform.

Primary requirements

During work, certain principles should be observed:

- In country houses, the structure must have a width of at least 90 cm.

- Fence posts should be spaced at a maximum distance of 150 mm from each other. If there are children in the family, this figure drops to 120 mm.

- The steps should have a height of 160 to 180 mm.

- The slope of the stairs should not change along its entire length.

- It is recommended to make steps with a depth of 27 cm.

Such features of creating metal products are taken into account first of all.

Types of metal products

Stairs made of metal can be forged or welded. They also differ in design:

- On the stringers. Such products are among the most popular. In these products, the steps are mounted on special elements.

- On one stringer. Despite the minimum of parts, products of this type are highly resistant to loads.

- On pain. These products do not have a frame. The steps are mounted to the wall.

- On the bowstrings. Support elements are mounted on the side of each step.

- Screw. The supporting element of such stairs is a supporting pillar. It is mounted centrally.

Important! Each of these types of structures is quite simple to perform, except for the screw version.

If you decide to make the structure yourself, you should choose a simple one-flight staircase structure.

Construction of staircases

Width of the stairs according to GOST.

To move along the stairs, you need to make platforms using previously installed beams. Work is carried out in 2 ways:

- ready-made reinforced concrete slabs are laid on top of the site metal structures by crane;

- a durable monolithic floor is installed.

The first method is simple, but requires the use of lifting equipment. The finished slabs are placed on the beams, their embedded parts are welded to the I-beam. Finally, a leveling screed and a suitable floor covering are laid on the slab.

Pouring a concrete platform involves assembling panel formwork, knitting a frame from periodic profile reinforcement and laying a concrete mixture. The disadvantage is that you have to wait at least 28 days for the concrete to harden.

Carrying out calculations

When contacting a design organization, the work is carried out much faster. First, specialists create a design model in the program. Thanks to this, it is possible to adjust the parameters of the staircase taking into account the specific conditions of its installation. Then, after making certain changes, the product begins to meet the customer's needs. When executing the final model, the sizes and shapes of individual elements of the staircase change. When all the parameters are determined, the program calculates a complete drawing of a metal staircase.

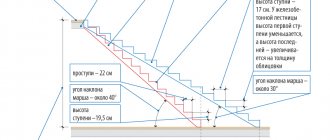

The simplest design option is a single-flight staircase. Standard requirements have been developed for it, according to which the length and width of the structure, as well as the height of the steps, are determined.

To complete the drawing, you will need to make certain measurements. To do this, determine the length of the flight along the finished floor from the beginning to the end of the structure. This value is conventionally designated “a”. In addition, you will need to know the height between the finished floor of the first floor and the second. This indicator is denoted by the letter “b”. For example, you can take the following values: a = 400 cm, b = 250 cm. Now you need to determine what the length of the stairs will be. It should be remembered that the optimal tilt angle is from 30 to 45 degrees.

The unknown characteristics of the product are determined using the right triangle formula. If we take into account that the height between the floors and the projection of the staircase onto the floor of the first floor are legs, the length of the structure will be the hypotenuse. By taking the square root of the sum of the squares of the known sides, we obtain the desired indicator. The length of the stairs in this example is 472 cm.

Now you can select the number of steps. With the indicated height, their number is 14. You can make 15. Each of these options is acceptable according to established standards. If you select 14 steps, you can check the depth of each of them. To do this, you need to divide 400 cm by 14. The result is 28.6 cm. This depth is optimal.

Important! Steps should be calculated taking into account the overhang. Typically, these elements are made in sizes from 30 to 40 mm.

Now that the main dimensions of the stairs have been obtained, you can begin to prepare the necessary materials. To make two stringers, you will need to find a profile pipe. The supports for the steps are welded from corners.

Design parameters

Before making calculations, it should be taken into account that metal stringers for wooden and steel stairs are different. To carry out calculations you need to use a calculator. The calculation is performed according to the following scheme:

- the total length of the staircase structure between floors is determined;

- then the step fastening mechanisms are calculated in a similar way;

- the height between adjacent steps is also determined;

- then the width and length of the step are calculated.

Subsequently, after calculating all the values, it is necessary to draw up a rough design plan on metal stringers and transfer all the obtained values here.

An online staircase calculator will help you calculate the parameters of the stairs.

Important. When calculating, it is necessary to take into account the Pythagorean theorem, since an ordinary triangle is formed, in which the size of the hypotenuse (the channel used as the load-bearing support of the entire structure) is calculated.

Equipment and materials

To equip a metal staircase, you will need to prepare certain equipment. The list of required tools should include:

- welding mask, gloves and goggles;

- vice;

- construction pencil;

- grinder and cutting discs;

- inverter with electrodes;

- drill.

In addition, for the job you will need a primer and white spirit. Most operations will have to be performed on a stable table.

You can build a metal staircase to the second floor with your own hands quite quickly. The main thing is to follow certain rules during the work process.

Types of stringers, classification

Stringers are the support of future steps of the staircase, while duplicating their step and spacing. Duplication of positions consists in the parallel arrangement of support elements or in the location of corresponding points (sockets). Structurally, support beams are divided into:

- Straight - one-piece, flat with overlays (cutouts) for steps.

- Broken lines - consist of elements similar to straight lines, but have turns, usually 90 degrees, with or without the removal of platforms.

- Screw - made in a spiral shape. The physical reference goes to a single axis, which can be the central support column. In some designs, with proper reinforcement, this axis is conditional.

Landings are understood as a wide horizontal surface that allows you to beat the stair turn so that the next flight of stairs can reach a given point from above (second floor floor, new landing), maintaining the proportions and parameters of the vertical angle of inclination. Their base is also supported by beams, often reinforced with wall stops, hanging elements or attachment to a rigid vertical (Fig. 2).

Figure No. 2: Staircase on paired stringers with reinforced platform support.

The materials used to create the stringer are selected based on the expected load of the staircase and stylistic preferences. Options:

- solid wood (log, board, timber);

- metal (I-beam, metal profile, profiled rectangular pipe);

- dense polymer materials (metal-plastic, composite plastics containing wood fiber);

- reinforced concrete (factory and home-made elements);

- composite materials (polymer/metal, wood/metal, etc.).

Elements made of wood or metal are more often used due to the ratio of cheapness and reliability. The combination of materials is used in complex assemblies; it is necessary to solve the visualization of a non-standard staircase design.

Reinforced concrete massive structures are laid mainly at the stage of finishing work. The base for them, due to their large weight, is calculated when designing the house and installed parallel to the foundation.

Figure No. 3: Staircase on a reinforced concrete spiral stringer.

Making stairs

During operation, a certain sequence must be followed. In this case, you will need to fulfill certain conditions. The algorithm of actions is quite simple:

- first the workpieces are cut;

- then the fillies perform;

- using a welding machine, the support corners are connected;

- install stringers;

- weld the fence and steps;

- perform grinding;

- prime and paint the finished product.

It is necessary to make fillies from the corners. This is what we call fastenings for steps. During this work it is very important not to make mistakes. If distortions occur, the staircase will be damaged. The fillies should be made identical. They are positioned mirror-image relative to each other.

Making fillies is a fairly simple task. First you need to cut out the samples and join the corners to each other. The result is L-shaped elements. For this staircase you will need 14 pairs of similar elements.

The crossbar is made from a corner. It can be strengthened by welding small scarves. They are mounted at the bottom of the step in the direction of the stringer. Markings are made along the edge of the pipe, which will allow the fillets to be welded correctly. Then you need to attach one stringer with fillies to another and transfer the markings. In this way, the accuracy of the geometry of each element can be obtained.

Advice! If the width of the metal staircase is more than 120 cm, it is better to install the third stringer in the middle of the structure.

With a standard width of 90 cm, such reinforcement will not be needed. Then you need to weld the fillies to the second stringer. The lower end of each stringer is connected to the support platform. It is usually mounted into a concrete base. The upper ends of the stringers are attached to the ceiling. The connection is made using steel anchors. The fillies should be checked for level again.

At the final stage, the steps are connected to the fillets using a welding machine. They can be secured with bolts. The upper step is mounted at a small distance from the wall. The fence is welded to the stairs so that its width does not decrease.

Each structural element in the places where welding was carried out must be ground. It is necessary to completely eliminate burrs, nicks and seams. Then use a brush to sweep away any metal particles that remain. The stairs must be primed and then painted in the chosen color. Wooden steps are installed after the paint has completely dried.

The staircase should be decorated with various elements at the stage of finishing the entire house. No matter how simple the work of installing a metal staircase may seem, it requires a careful approach. If the welding work is done to the highest possible quality, the structure will serve for quite a long time. Applying an anti-corrosion coating will help preserve metal elements.

If the frame is made strong and reliable, after a while it can be finished not only with wood, but also with tiles. Materials are selected according to the taste of the home owners. Even if during the completion of the frame the structure looks bulky and unattractive, after finishing it will take on a completely different look.

Fastening the treads

The method of installing the treads depends on the material from which the stringer is made. First, the gussets are attached to the metal racks, and then the wooden steps are mounted in the secret place using bolts or self-tapping screws. Metal treads are simply welded to the stringer.

Steps are attached to wooden stringers in several ways:

- Cut-out treads are the simplest method, since corners are cut into the supporting beam according to the size of the steps and risers. All that remains is to properly secure all the elements.

- A wooden filly is an additional element that is mounted to the beam using dowels. Then a tread is attached on top of the filly. Such stairs can be open or closed (using risers).

- Steel support - the steps are attached to steel gussets, which are pre-attached to the beam.

- Bolts are used for the rear parts of steps and are attached to the stringer using a dowel.

String stairs are often erected in private houses. If you decide to build such a structure with your own hands, first carefully calculate the dimensions of the structure and select the most suitable materials. A properly designed structure will last for decades.

Spiral staircase made of wood

Anyone can create a visually attractive spiral staircase. In this case, you do not have to contact specialists. Special elements have even been developed for the construction of screw products.

Spiral staircases are especially often erected to residential attics. If all the elements are available, the structure can be assembled within a day. The staircase will look beautiful if it is equipped with steps made of wood. Prefabricated structures are chosen for installation in small spaces. A photo of the spiral staircases taken to the second floor will help you assemble the structure correctly.

Create a drawing

Installation of the structure that will support the stairs is done from above. To avoid distortions, you will need to use a level when installing the first support element. In this case, the stairs will be as level as possible. Correct installation of the structure will increase its strength characteristics. For installation accuracy, you will need to draw a diagram.

The other part of the support is inserted from below into the existing part. Then the structure is leveled in height. The next stage is fixing the elements with screws. One of the main parameters that should be taken into account is the height of the steps. Each subsequent element is mounted in the same way as the previous one. It is necessary to shift the structure from the 3rd stage.

When the metal support is halfway, it is necessary to install special slats under certain parts of it. Only if the structure is securely attached to the floor is it possible to securely fix the stairs. Installing a spiral staircase with your own hands is quite simple. The basic rule is that the fastening of each element should be as reliable as possible.

It is necessary to make holes in the floor into which the dowels will be installed. Attaching the structure to the floor is a necessary condition for its stability. To increase the safety of the ladder, all ends of the metal elements are closed with plastic plugs.

Installation of railings and steps

The instructions for installing a prefabricated structure will help you figure out how to make a metal staircase with your own hands. It is necessary to make an accurate calculation of the sizes of individual elements, as well as connect the individual parts of the staircase as accurately as possible. The steps should be secured so that the lifting ledges are staggered.

Wood products should be prepared in advance for installation on a metal support. To do this, holes are made in them for fasteners. Thanks to this, screwing the ladder to the support is carried out as quickly and accurately as possible.

At the last stage of installing the spiral staircase to the second floor, railings are installed. First, install the U-shaped element. An adapter must be put on one part of the railing. After fixing the fasteners, insert a metal arc into them and tighten it with screws. Wooden spiral staircases are quite popular designs. They have a fairly attractive appearance and excellent functionality.

When making a spiral staircase with high quality, it is important not only to accurately mark the railings, but also to securely fix them. This design detail affects the safety of moving along the stairs. The railing of the screw product should be 90 cm. The steps usually have a width of half a meter to 70 cm.

Types of designs

So, a stringer is a metal support beam that holds the steps rigidly. It rests on interfloor ceilings. In fact, this element for flights of stairs is a load-bearing part.

At the same time, two types of stringers are distinguished - some are called bowstrings, and others are also called stringers. The difference between them is as follows.

Stairs with metal stringers

- Stringers are made in the form of a broken curve, as in the photo above, or they have corners welded to a straight beam. In general, the point is that steps can be laid on top of these elements.

Metal staircase along stringers - powerful channels are used

- The design is very reliable, but more difficult to manufacture, since when welding parts into one element, their dimensions and corner cuts must be precisely adjusted, otherwise the staircase will turn out crooked, which is unacceptable.

Stairs on metal stringers: such structures are also stringers

- We will tell you how to weld a similar element from a steel pipe in the second part of the article - be sure to look at it, in addition to the description, a detailed photo report will be attached.

This staircase with aluminum strings will fit perfectly into the high-tech style

- Bowstrings, unlike stringers, are only 2 pieces in a staircase design and this is due to a design feature.

Interesting to know! There can be any number of stringers near the stairs. Well, not really, of course, but with wide flights of stairs, they can be reinforced with additional elements in the center.

The shape of the bowstrings can also be broken

- The steps to these elements are approached from the sides. They are fastened either through bolted connections at the ends (the fasteners pass through the string and enter the step), or through corners welded on the inside, on which the steps are placed on top and are tightened with screws or clamps.

Metal staircase with glass steps

- A fastening option is also possible when the steps fit into special grooves. However, technically it is very difficult to produce such parts, so this option is practically not used in metal structures, which cannot be said about wooden models.

Bowstrings on a spiral staircase

Interesting to know! Metal bowstrings are ideally combined with screw designs.

conclusions

When constructing a staircase structure, special attention is paid to the marking of elements, their correct location, and fastening features. If the product is created from different materials, you will have to figure out the intricacies of working with each of them.

It is important to properly prepare for work, find all the necessary tools and materials. Only in this case will the work be completed quickly and efficiently. Welding a metal ladder will require the worker to be able to use a welding machine.

If you follow all the recommendations listed, the creation and installation of the staircase will go quickly and without problems. The easiest way is to build a single-flight structure. However, you can also create a spiral staircase. It is attractive, but quite difficult to implement. When choosing a design, you should focus on the size of the room and its design.

Recommended Posts

Wooden staircases to the second floor: the finishing touch to the interior...

Spiral staircases to the second floor of economy class

Canopy over the porch + photo

Canopy over the porch of a private house

Canopy design + drawings

Enclosed porch to the house + photo

Construction of a flight of stairs

When all metal structures are installed in the design position and welded, the steps can be laid on steel stringers. The sequence of work is as follows:

- The first step is placed, starting from the bottom. It is aligned horizontally and relative to the walls, and then welded to the beam from below. For this purpose, the step is provided with steel embedded parts connected to its reinforcement frame.

- A narrow strip of cement-sand mortar is placed on the rear edge of the tread. It does not increase the strength of the structure, but simply closes the gap between the staircase blocks.

- The second and subsequent stages are installed, repeating the steps of fastening and sealing the seam.

This video talks about the nuances of making a staircase.

After completing the installation work, reinforced concrete treads can be lined with any suitable material - porcelain stoneware, marble - or even self-leveling floors can be made.