A pile foundation is a supporting structure used in all situations where the bearing capacity of the soil is too low.

These include flooded areas in swampy areas, loose and unstable soils, peat bogs and other areas with problematic construction conditions.

Piles provide support on dense underlying soil layers that have appropriate parameters and are located at great depths.

The operating conditions of the supports are very complex; all possible types of loads and negative impacts are present.

One of them is close contact with soil moisture.

Protection of foundations from soil water

Scheme of waterproofing a foundation with a basement.

The work can be done with your own hands. In this case, certain features should be taken into account. Types of wall waterproofing, technology for applying protective layers, their density and thickness depend not only on the saturation of the soil with soil water, but also on the aggressiveness of the environment. Moisture may contain salts with various acidic residues; active chemicals of technical origin and natural reagents may be dissolved in it. Some compounds are capable of destroying Portland cement, others - metal reinforcement, and still others - bitumen-containing coatings.

Types of foundations and construction procedures, types of foundation waterproofing are regulated by State Standards (GOST) and Construction Norms and Rules (SNiP). In general terms, these issues are grouped and set out in the Recommendations for the design of waterproofing of underground parts of buildings and structures, published by the Central Research Institute of Industrial Buildings in 1996. According to regulatory technical documents, pressure and filtration types of water loads on the walls of structures are distinguished.

Problems in the absence of insulation

Whatever the design features of the piles, the option and technology of their installation, this type of foundation has many disadvantages:

- Cold underground, causing significant heat loss during frosts through open space.

- When the grillage is reinforced concrete, it forms a significant cold storage tank. If you do not constantly heat the room, it is not easy to restore a comfortable microclimate in it.

- Freezing of pipelines laid underground is possible.

- Piles anchored in the frost layer can be pushed out. They are an excellent conductor of cold. When insulation measures are not carried out, concrete or metal pillars become the cause of local heaving.

- If some piles are located at points with low soil density, uneven shrinkage of the building occurs.

- Aesthetically, an undecorated foundation of this type looks unattractive.

- The underground space will certainly become littered, so it has to be cleaned periodically.

Classification of methods for protecting foundations from groundwater

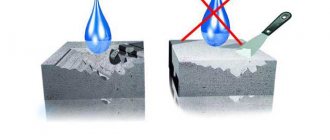

To protect construction projects from the damaging effects of soil moisture, appropriate types of waterproofing are used, which differ in the arrangement of water-protective layers. The foundation is separated from the pressure of surrounding groundwater using water-repellent coatings that are applied to the walls. This is vertical waterproofing.

Horizontal waterproofing has a different function: it prevents the capillary spread of water up the concrete and masonry. Lay horizontal insulation on two levels. The first is created under the base of the foundation strip, the second - on the base to protect the walls of the first floor from moisture. There is a third type - floor waterproofing, which regulatory documents classify as a separate type of protection. However, due to technological similarity, installation is often combined.

SNiP2.02.01-83 considers in detail all the requirements for the construction of foundations, including:

- types of loads to which the foundations of houses are exposed;

- soil types;

- characteristics of groundwater;

- depth;

- design features depending on influencing factors, including groundwater.

Calculation

To make the calculation, you need to collect all the information about the territory on which the structure is planned to be erected.

For calculations you need information about:

- physical and geographical conditions;

- geological structure;

- hydrological conditions;

- physical properties of the soil.

Based on this information:

- grillage parameters are determined;

- loads are calculated;

- the depth of placement is calculated;

- the required number of supports is determined;

- the diameter of the piles or pillars is calculated.

It is advisable to entrust this work to specialists, since the slightest mistake in calculations leads to disastrous consequences.

Methods for waterproofing foundations

An example of cement-based plaster waterproofing.

The type and type of protection are provided at the design stage of the structure. In this case, the humidity conditions of the premises are taken into account. Under normal conditions, in accordance with SNiP II-3-79, humidity is limited to 75%. Rooms in which this characteristic does not exceed 60% are considered dry.

Capillary movement of water directly affects the humidity of rooms. The height of liquid rise through the micropores of concrete or brick walls depends on the density of the soil and can reach:

Waterproofing of pile-grillage foundations

- 1.1 m if the foundation is located on sand;

- 12–25 m if the soil is clayey or silty.

Foundations for low-rise construction of all types, regardless of the method of burial, have an upper flat surface: a grillage in pile foundations, a strip or slab in others. In all cases, the horizontal waterproofing mark should be half a meter above the maximum possible groundwater level.

The following types of waterproofing are distinguished:

- painting - a continuous multi-layer coating of bitumen or polymer-bitumen compositions;

- plastering with cement compositions;

- plastering with bitumen mixtures;

- lining - a carpet made of rolled materials - roofing felt or synthetic films;

- facing – fencing made of steel or polymer sheets that are welded (glued) into a single deck.

conclusions

Waterproofing the basement floor requires a thorough and responsible approach. It would be a good idea to involve qualified specialists in the entire process, since each individual case has its own nuances.

There are times when, having studied almost all possible options for protecting the base from moisture, you can easily make a mistake by choosing, for example, a very expensive method. Although basement waterproofing could easily have been much cheaper.

Often you simply cannot do without the help of people who know this matter. Ideally, it would be to completely entrust them with such an important process called waterproofing the basement of a house.

Materials used: Anton Shakalin, “Modern technologies of private construction”, 2005.

More on this topic on our website:

- Basement siding Nailit and Holtsplast - covering the foundation of a house with base siding Before you start building a basement, you need to take into account the costs of its construction and the importance of its use. Buildings with cottages with basements…

- Construction of a blind area around the house - adjoining to the plinth. Plinth - the lower protecting part of the wall, the transitional part of the foundation to the outer walls of the house. The basement is the most vulnerable part of the house. The blind area is concrete or asphalt...

- Making a blind area around the well The main element of the arrangement is the blind area around the well. It will not allow melted snow and surface water to enter the mine, and will also provide a convenient approach to the structure...

- Basement siding Deke - options and designs for covering the base Basement siding Deke is a unique creation created by European specialists. In terms of its structure, the material in question is the highest standard of facade coatings. Speaking of general designs...

Waterproof painting and gluing of horizontal surfaces of concrete structures

Painted or adhesive insulation is most often used as horizontal insulation, since it can be laid with your own hands.

The thickness of the paint coating should be 5±2 mm, applied in 2–4 layers. To install insulation with your own hands, use the following types of coatings:

- Bitumen. They are produced in the form of solutions or mixtures, which, in addition to cracking, include special additives and suspensions;

- Bitumen-polymer. Can be with three types of additives: nairite resin, latex emulsion, crumb rubber;

- Polymer emulsions include mastics containing chlorobutyl rubber mixtures, alkyd, polyurethane, and epoxy additives.

Application of bitumen waterproofing by spraying

With the development of the chemical industry, the list of waterproofing paints has been supplemented with high-molecular compounds, latex cement mixtures and other materials that can be applied either manually or mechanically. Regardless of the manufacturing method, bitumen and emulsions must have sufficient adhesion - bondability with concrete: according to GOST 25591-93, the strength of the joints must be at least 1 kgf/cm2.

Isol, hydroisol, roofing felt, modified polyethylene, complex composite films and others are used as lining films for wall insulation. When choosing a material to create insulation for the base of a house with your own hands, you need to ensure that the waterproof films belong to the foundation group and not to the roofing group. Requirements for insulation design and material characteristics are set out in SNiP 3.04.03-85.

Which product is most optimal for piles and grillage?

The choice of the most suitable waterproofing option is determined by the design and material of the foundation.

Not all types of insulators that are suitable for wood or concrete can be used for metal parts.

At the same time, the traditional application of hot bitumen is suitable in any case, although the process itself poses a fire hazard and due to the possibility of burns.

No less convenient is bitumen mastic, which does not have the disadvantages of hot tar, but does not penetrate the material so deeply and firmly .

Sprayed materials are also suitable for all types of piles and grillages, but their price and application specifics create a significant barrier for users. The final choice is determined by the capabilities and preferences of the home owner.

Self-leveling waterproofing

Self-leveling waterproofing for horizontal surfaces

Horizontal waterproofing of the foundation can be performed using the casting method. This method is used in cases of sealing seams between the base and communications or for filling expansion joints - when the base of the foundation does not consist of a monolith, but of several concrete slabs. The thickness of the layers of cast film for filter insulation of walls should be 7 mm. Perform protection in two layers.

Waterproofing strip foundations

Filling is done cold or hot. In the latter case, the heating temperature of the mixture is limited to 190°C to prevent ignition of the bitumen. A mandatory requirement for painting or self-leveling moisture-proof films: a layer of cement-sand screed must be applied on top of the coating.

Application technologies

Waterproofing coatings are applied to foundation surfaces in two main ways: cold and hot .

The cold method is used when working with ready-made bitumen mixtures or materials that require additional dilution.

The main advantage of this technology is the high speed and safety of waterproofing work. When applying waterproofing layers cold, there is no need to use additional thermal equipment, when working with which you must follow certain safety rules.

Materials are applied with ordinary brushes, rollers, spatulas and similar tools.

Hot technology involves heating rolled, solid or powdered material to a high temperature at which it melts. Molten bitumen is applied to the surface to be treated using tools equipped with elongated holders (to protect against accidental burns).

If sheet material is used, it is heated in small sections using gas burners and the heated fragments are immediately rolled out along the horizontal surfaces of the foundation.

Rolled and pasted

Roll and sheet waterproofing coatings are installed in two ways: with heating and by gluing.

The second option involves the use of additional adhesive mixtures (liquid bitumen mastic can be used as such) or self-adhesive layers.

Before applying roll and adhesive waterproofing, it is recommended to treat the surface with a primer or bitumen primer . This will achieve better adhesion and prevent premature decline in the performance properties of the material.

Penetrating method

To construct penetrating waterproofing, cement mortars containing modifying chemical additives are used.

The technology includes the following stages:

- the surface of the foundation is thoroughly cleaned to remove possible contamination and to open existing pores and cracks;

- the cement composition is mixed with modifiers (if they are not initially included in the material) and diluted with water to the optimal consistency;

- then the surface to be treated is moistened with clean water to improve adhesion;

- the final stage is the application of waterproofing material using a spatula;

- then the protective layer is left until completely dry, which takes several days.

Injection method

This method involves the introduction of waterproofing material into the foundation structure by injection. The bottom line is this: horizontal or inclined holes are drilled in the walls of a concrete structure in small increments.

Special attachments - parkers - are inserted into the prepared holes. They are necessary for uniform distribution of waterproofing material throughout the entire volume of the concrete structure. A composite mortar is then injected into the parkers to provide waterproofing.

Low pressure pumps (no more than 4 atm) are used to supply it, since too powerful pumping equipment can destroy the internal structure of concrete.

Features of horizontal waterproofing of prefabricated concrete structures

An example of sealing a seam between foundation slabs.

The surfaces of floors in basements and the ends of foundations consisting of several concrete blocks (slabs) between which there are joints are additionally protected:

- A board impregnated with resin and wrapped in roofing felt is placed in the opening. The width of the board is chosen such that it covers the gap to ¾ of the depth;

- The top of the joint is wadded with tarred tow, leaving 3–4 cm to the edge of the surface;

- The remaining space is filled with cement mortar;

- If necessary, provide for the installation of metal compensators.

With horizontal insulation, additional roofing felt is applied to the vertical surfaces of pipes, embedded metal profile structures, and other building elements penetrating the foundation. For coatings applied to parts of engineering systems, materials are chosen that would not damage or corrode their surface.

Purpose

The grillage is a structure that has a wide range of applications. Let's look at where and under what circumstances it is used.

1.The construction of the facility is carried out on the following soils:

- clayey;

- peat;

- heaving;

- loess-like;

- silty;

- loamy.

2.The construction of the house is carried out on slopes or areas with ornate relief.

3.The creation of the structure is carried out using frame technology. Piles or pillars will support the object from below.

4. The construction of the structure is carried out in an area where the soil freezes to a depth of more than 2 m.

5. The construction of an object with a base width of more than 2 m is being carried out.

As you can see, the grillage is a universal element.

Protection of underground and above-ground structures from aggressive environments

Protection of the basement from groundwater with a drainage system

To ensure the durability of the foundations, when choosing grades of cement, reinforcing steel, concrete slabs, they are guided by SNiP 2.03.11-85. If necessary, building structures are protected with additional waterproofing. In particular, additional means are used to cover floors lying directly on the ground.

Floors located in an aggressive environment, depending on the degree of its intensity (according to SNiP II-B.8-71), are protected in several ways.

- A painted waterproofing layer is applied if the environment is neutral or slightly aggressive.

- Combined protection - painting with roofing felt or other bitumen films - is carried out in the case of moderately intense chemical exposure.

- Reinforced waterproofing is used to protect the foundation of a house or concrete floors from intense loads. Its composition may include ceramic materials, liquid glass, bitumen, rectlasts.

Types of pile foundations

If a multi-storey residential building is being constructed, which creates a significant load on unstable soil, then the foundation for the house is built using driven piles. They are made of reinforced concrete, which has high strength. Such designs are always created in the factory. Their driving takes place exclusively with the help of special equipment. Private developers practically do not use these mechanisms. It is unprofitable to use special equipment for small volumes of construction. Therefore, it is used exclusively by large construction companies for the construction of large-scale projects.

Work order

Before applying waterproofing compounds, the foundation surface is prepared:

- cut off metal eyes and trimmings of reinforcing wire;

- fill cracks, cracks, remove chips, round corners;

- if you plan to glue the waterproofing layer on the intermediate concrete base of the basement, you need to make straightening plinths from cement mortar in the corners of the room near the walls;

- the joints of horizontal and vertical planes, cracks are covered with strips of fiberglass or waterproofing;

- concrete is washed if it has previously been chemically treated or if any coating has previously been applied to it;

- The surface layer of concrete must be dried to a moisture level of 4%.

Primer for priming the foundation before applying bitumen mastic.

All requirements for surface cleanliness, structure, maximum levels of differences in unevenness, dimensions of overlapping intermediate materials are set out in SNiP 3.04.03-85

Concrete bases are pre-primed: the composition of the mixtures is chosen depending on the type of waterproofing. As a rule, a painting material diluted by 30–40% with an appropriate solvent is used for the primer. Before applying rubber-based compounds, the concrete is primed with glue 88.

The work is carried out with your own hands at positive temperatures in accordance with the requirements of SNiP and TU, technological maps. Between stages, the intermediate layers of waterproofing are dried for the appropriate time at the required temperature. The quality of the work performed is determined by implementing the measures set out in the above building codes and regulations, as well as in SNiP 3.04.01-87.

Necessary materials

There are different types of waterproofing materials. By type of application they are divided into :

- Superficial.

- Penetrating.

- Sprayable.

Surface materials include all traditional materials:

- Hot tar.

- Bitumen mastic.

- Ruberoid.

- Glassine.

They are easy to use and cope with their task, but some types are difficult to apply on curved or embossed surfaces with a large number of transitions or small elements. To facilitate the insulation of concrete bases, penetrating materials are used - impregnation . They clog the capillaries of the concrete, making moisture absorption impossible. For metal parts, these materials are useless, like most exterior types. Steel elements are best protected with sprayed materials :

- Liquid rubber.

- Liquid polyurethane foam.

These insulators are much more expensive than others and require the use of special equipment, but their efficiency is very high, and their service life, if used correctly, is comparable to the service life of the entire building .

2.The construction of the house is carried out on slopes or areas with ornate relief.