One type of bathtub faucet is rim-mounted. A built-in faucet is increasingly being chosen when installing an acrylic bathtub, because such a device looks original and modern, and you can install it yourself if you have the necessary tools.

Note! To install a mortise model, the edges of the bathtub must be sufficiently wide: at least 7–8 cm.

Main types of traditional faucets

The two main types of water supply - axle-type faucets and single-lever ones - can also be distinguished by the appearance of the mixers. But there are also differences in the internal structure, which determine the operating features and service life of the product.

The cheapest crane-axle models with rubber cuffs and a metal mechanism are called worm-type. If the rubber rings are replaced, this mechanism will last quite a long time.

But the required pressure is supplied after several turns of the valve, and this prolongs the process of obtaining the desired temperature, leading to excessive water consumption.

Crane-axle mixers equipped with ceramic plates are more expensive, but more convenient to use. Water flows through them in two modes - at turns of 90 and 180 degrees. The valves move easily and silently.

But on ceramic parts, water deposits accumulate, which lead to rapid wear. The mechanism of such faucets cannot be repaired, and their declared service life, in most cases, is reduced due to substandard tap water.

In single-lever faucets, control of temperature and water pressure is combined using the movement of the same ceramic plates in the cartridge. The problem of ceramic wear is also relevant in this case.

Features of drilling through enamel

In addition to the usual tools, such as a marker, tape measure, screwdriver and drill, you will need a special feather drill designed for drilling glass and ceramics, as well as transparent tape and a piece of plasticine. After marking, the drilling site should be carefully sealed with tape.

Then you need to make a round side from a piece of plasticine and stick it around the circumference so that the place for drilling is in the center. The area limited by the plasticine side should be three times the size of the hole for the mixer. It turns out to be a flat round platform with a side. You need to pour water into it.

After this, you can start drilling in the center of the marking. It is recommended to use a drill with a diameter of 6mm at a speed of about 500-600 revolutions. The pressure should be moderate. During such careful drilling, a narrow through hole will appear in the side of the bathtub, through which the water present at the drilling site will flow out.

Now you should make a small cap from plasticine and stick it to the bottom of the side so that the resulting hole is in the center. You need to pour water again and re-drill using a 12 mm drill. The pressure should be light. When the drill goes right through the side, you can remove all the plasticine and evaluate the quality of the work; chips on the enamel should be minimal.

After this, you need to widen the hole to the required size to install the mixer. To do this, new markings are made, indicating the boundaries of the hole. The surface must be sealed again with transparent tape.

The hole should be widened using a grinder using a rubber attachment with sandpaper. The speed should be set to maximum, but the applied force should remain minimal.

Experts do not recommend that beginners make holes in the side of a cast iron or steel bathtub themselves. Problems are caused by the presence of enamel, which performs not only decorative, but also protective functions. If drilling is done incorrectly, there is a high risk of irreversible damage to this layer.

When the hole is wide enough, you can use a nozzle with a diameter of 20 mm. It should be understood that with minimal effort, which will protect the enamel from damage, the work will not progress too quickly. You will have to work with the grinder for more than an hour. When the hole is ready, insert the o-ring into it and install the mixer in the usual manner.

There are other ways to accurately drill into enamel surfaces. Some craftsmen simply glue a metal plate to the enamel and drill through such a “sandwich”. The metal will protect the enamel from damage. Others carefully remove some of the enamel with a grinder before drilling, and then drill with a hole saw.

Finally, there is a way to drill into cast iron with a diamond core cutter using a wood jig. But in this case, the cutter must be cooled quite often by pouring water on it.

Thermostatic mixers

This new program-controlled product is gradually gaining ground in the plumbing market. Water flows are controlled using a panel with an on/off command and temperature and pressure regulators.

These faucets may be equipped with LCD screens, which require an AC adapter or batteries. There are also models with mechanical regulators in the form of valves and buttons.

Shower-spout switching mechanisms

With an eccentric mechanism, switching occurs with a rotational motion. Among its disadvantages are bulkiness and rapid wear of replaceable parts with frequent switching.

A similar cartridge mechanism for a bathroom shower mixer has a modest size, its switching is smoother, but if it wears out, it will require a replacement from the same manufacturer.

The most reliable option is a ball switching system; it is integrated with the main mechanism of the mixer and if it fails, it will require a complete replacement.

There is also a compact mechanism with a cork deviator with up-down switching, which is also not subject to repair.

Shower faucet spouts

The choice of spout length depends on the bathroom layout. If the shower and sink are close together, choose a faucet with a long spout. In this case, you need to correctly calculate the length (more than 30 cm) and turning diameter. The main advantages of short spouts are their compactness and freedom of choice of installation location.

It should also be taken into account that the cost savings when purchasing a combined mixer for servicing a shower and washbasin can be offset by its rapid wear.

Spout nozzles can be equipped with aerators or a shower-head system. With the first option, the jet pressure increases due to mixing with air, which leads to water saving. In the second, the water flows in small streams without splashing. Shower heads also come with different spray modes, which you should pay attention to when purchasing.

What else needs to be considered

All products are accompanied by full specifications, including:

- Minimum and maximum pressure

- Base diameter

- Spout protrusion

- Weight

It is always recommended to check these specifications carefully to ensure they meet your requirements.

The required size of your new faucet will likely be determined by the surface area around the sink or bathtub. Before purchasing, look at the diameter of your faucet base to make sure it will fit.

Methods for installing shower mixers

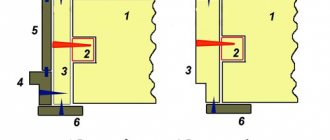

With the traditional installation method, the mixer is mounted on the wall with an indentation upward from the edge of the bathtub. In this case, it is necessary to correctly calculate the mounting location depending on the length of the spout, the shape of the bathtub and other convenience parameters.

It is also possible to install faucets on the side of bathtubs and sinks, for which special holes are provided. In order to place plumbing fixtures without adjacent to the wall, additional stands for faucets are used. A more expensive and time-consuming option is to install a specially designed faucet on the floor.

- Bathroom cabinet - 110 photos of beautiful examples of 2019-2020 using a cabinet in the bathroom

Bathroom accessories - the most necessary popular and beautiful decorative elements (75 photos)

Bathroom cabinet - decor and small tricks when designing a bathroom (85 photos)

Differences between a mortise device and others

Installing all the components in their place (separately) is the main difference between the device embedded in the side of the bath and others. Structurally, it does not look like a monoblock. These are separate parts of one device that function independently. Thus, there is a faucet body to supply the flow of water; the spout and shower head have an independent design. In this case, each unit is fixed on the side with its own fasteners. All this distinguishes the mortise mixer from other models.

What does node separation entail? This allows you to mount the unit in a place that will be comfortable when using it. The arrangement of nodes does not have to be compact. This property is similar to a wall-mounted faucet. Sometimes individual parts of a mortise fixture are combined. For example, one device becomes a spout for a bathtub with a shower.

Pros of installing a mortise structure

The faucet on the side of the bath outperforms the wall-mounted model in terms of its list of advantages:

- The devices are made from high quality materials, which ensures their strength, reliability, and long service life.

- Separate installation of mixer units has increased the flow paths for liquid, which allows you to quickly collect a large volume of liquid.

- Strict lines, unusual shapes, original design - all this influences the interior design.

- The device is mounted in a small space, does not take up much space, compactness is an important quality.

- The static design of the mixer is one of the factors of its long service life.

- The device is easy to adjust and convenient to use.

- Installing the faucet on the bathtub allows you to hide underwater hoses and fasteners. An installation error will shorten its service life.

Disadvantages of installing a mortise model

- The device, built into the side, suffers from rapid wear of the shower hose. This deficiency is often pointed out. When the hose is not in use, it is hidden behind the side of the bowl. When you need to use it, it stretches out. Frequent tightening of hoses leads to wear. When the hose is made of high quality material, it will last 6 years.

- Before installing the faucet on the bathtub, two holes are drilled, which are located close to each other. This installation feature requires careful handling. Otherwise, cracks will appear on the surface of the font. Fastening elements must not be twisted. All actions are measured and performed slowly.

- In terms of price, mortise-type faucets are more expensive than wall-mounted models.

Mixer materials and coatings

Stainless steel faucets offer the best balance between price and durability. Brass and bronze are also reliable and durable, but are more expensive. Ceramic faucets look more stylish and are used in the implementation of design ideas, but, being in a high price range, they are less durable.

Faucets made of silumin, which contains aluminum and silicon, can be considered disposable: they will last a little more than a year.

The choice of faucet finishes is limited to various types of chrome and enamel. In this case, you can be guided by your budget and aesthetic preferences.