A beautiful, stylish kitchen-dining room is a necessity for every family, but it requires careful cleaning. The times when the kitchen was simply whitewashed and repainted every year are gone. The cooking process is always accompanied by the release of moisture and combustion products that settle on the walls, furniture, and ceiling. A hood helps get rid of this problem.

But another problem arises: the hood and exhaust pipe in the kitchen do not look very aesthetically pleasing, they try to disguise them and make them as compact as possible. We welcome our dear regular reader and offer an article on how to select and install an air duct from a range hood with your own hands.

Use of ventilation pipes in everyday life

Residential buildings must have ventilation. In the process of breathing, a person emits carbon dioxide and moisture, cooking - moisture, soot, fat, carbon dioxide, sanitary appliances - a lot of moisture. Moisture settles on walls and furniture, which leads to the formation of mold. Carbon dioxide and combustion products, odors from cooking lead to rapid fatigue, irritation of the respiratory tract, deterioration of well-being, and decreased performance. Some of the substances formed during frying are carcinogens.

In old Soviet-built houses with small apartments and loose doors, ventilation in the kitchen and bathroom simultaneously removed some of the air from the living rooms. Ventilation ducts were built into the building structure. In private houses, ventilation was not provided at all - the situation with carbon dioxide was saved by a stove with a chimney: the air for firing the stove was taken from the house and removed, along with the products of fuel combustion, outside the living space. Fresh air entered houses and apartments through leaks in wooden windows and doors. The smoke and soot simply settled on the walls and ceiling - they had to be whitewashed every year.

In apartments there are ventilation ducts in kitchen hoods, additional ventilation in bathrooms and toilets.

In modern houses, in addition to the hood, additional ventilation systems are often installed - exhaust and supply and exhaust. In passive and energy-efficient houses, supply and exhaust ventilation with heat recovery is a mandatory component of the house design.

Functional purpose and technological features

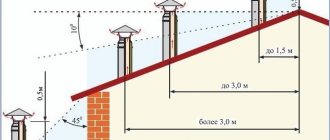

The task of any ventilation system is to maintain a fresh atmosphere in the house, remove foreign odors and substances that do not meet sanitary standards. Forced ventilation is rarely used in residential buildings. And for the natural movement of air to work correctly, it is necessary to create good draft in the exhaust air line. It is ensured by the optimal location of the outlet pipe above the roof and the correct calculation of its height.

Complete ventilation of the house should perform the following tasks:

- ventilation of all rooms in the building;

- air removal from household appliances (gas stoves and boilers);

- sewer line ventilation.

It is optimal for each task to create a separate ventilation circuit with its own exit to the roof.

Functions of home ventilation

Differences between a kitchen exhaust system and ventilation

A kitchen hood is a local exhaust ventilation system with artificial impulse and is fundamentally no different from ventilation. There are differences from general indoor ventilation: general ventilation in apartment buildings is designed with natural impulse and operates without the participation of fans. In addition, general ventilation serves to ensure air exchange throughout the entire apartment, and the hood removes polluted air in a specific place and only when necessary.

Increased ventilation system performance

The best way is to create forced air flow using roof fans. But it is very expensive and difficult.

At the same time, passive additions to the pipe can lead to improved air movement. Here are some of them:

- Deflector. Special attachment for the upper part of the ventilation pipe. Its internal structure, under the influence of wind, creates an area of low pressure at the very outlet of the air duct. This leads to increased traction.

Roof deflector

* - Protective caps and droppers. They are attached to the top of the ventilation pipe and prevent precipitation from entering it. The absence of moisture in the system maintains its performance and reduces the risk of corrosion.

- Roof aerators. Devices designed to improve ventilation between the roof itself and its thermal insulation. They do not directly affect the microclimate in the house, but prevent the formation of condensation.

Practice shows that protection from moisture and installation of a deflector can increase the draft in the ventilation pipe by 10 - 30% in different weather conditions.

The importance of kitchen ductwork

The existing general ventilation does not remove combustion products and evaporation specifically from the stove; it serves to replace air throughout the entire volume of the room.

Modern housewives are not happy with this situation. We want high-quality and durable repairs in the kitchen; a working woman does not have time to regularly wash the walls, ceiling and furniture. Demand creates supply - local ventilation units have appeared above kitchen stoves - hoods. But polluted air must be removed outside the room, and air ducts perform this function.

Advantages and disadvantages

There is only one advantage of the air duct: it is impossible to remove carbon dioxide, water and soot without it.

Disadvantages of air ducts:

- They take up space.

- They spoil the kitchen interior.

- Poor installation results in increased fan noise.

- They require regular washing on the outside and periodic cleaning on the inside.

Is it always possible to install a hood?

There may be situations when installing a hood is prohibited by the operating rules for gas appliances.

If there is a gas water heater (boiler) or a gas heating boiler with an open combustion chamber in the same room as the hood, a hood with air removal (circulation) cannot be installed. Removal of combustion products from the boiler occurs without force; when the exhaust fan is turned on, the draft may overturn and toxic combustion products may be thrown into the room.

It is allowed to install a flow-through exhaust device only if a boiler with a closed firebox is installed (with a coaxial chimney and combustion air intake from the street).

You can install circulation-type devices with filters that clean the air from grease and soot.

Is it possible to do without an air duct?

Hoods are produced as flow-through and circulating:

- Flow-through systems remove exhaust air from the room.

- Circulating filters purify the air without removing it from the room.

Circulating hoods are installed above the stove; the air passes through a housing with a carbon filter and is cleaned of grease. These devices do not require air ducts; they are compact and easy to install. But they have other disadvantages - the need to frequently change filters, insufficient air purification, and lack of removal of moisture and carbon dioxide.

Connection options when assembling ventilation ducts

Air ducts are assembled from individual parts. Docking is carried out using flanges or other connecting elements.

Angular flanges are installed at the ends of the sections being connected. Holes for mounting bolts are drilled on them. Sealing gaskets are placed between the flanges.

To ensure the strength of the flange connections, the bolts are carefully tightened using nuts and a suitable wrench. The nuts are on one side of the connection. When installing vertical pipes, the nuts are located on the side of the lower flange.

The disadvantages of such a connection are the significant weight of the structure, high consumption of metal, and high labor intensity of the work.

A sealing tape is placed between the flanges of the parts to be connected. Its edges should not extend into the inner space of the pipe and cover the holes for the bolts. To make the oil seal, dense or porous rubber or foam rubber is used.

Lighter flanges are made from galvanized profile strip. The Z-shaped flanges are connected using a C-shaped rail and a seal.

The connecting rail resembles a collapsible flange. It is made of a galvanized metal profile in the shape of the letter G. The length of the larger side is from 20 to 30 mm. The kit includes a seal and a corner. The advantages include low labor intensity and low financial costs.

Among the wafer connections used for assembling round air ducts, the most commonly used are:

- nipple;

- bandage.

The thickness of the nipple should not be less than the thickness of the pipes.

The nipple is inserted inside or put on top of the joining elements so that its width covers both sides of equal length for the pipe diameters:

- 100 - 315 mm - not less than 50 mm;

- 355 – 800 mm – not less than 80 mm;

- 900 - 1250 mm - not less than 1000 mm.

Instead of the name nipple, the term coupling is often used.

The tightness of the nipple connection is ensured by the rubber gasket included in the delivery set. In its absence, the fastening is sealed with adhesive tape with a polymer or reinforced coating. Every 200 mm of circumference, the coupling is tightened with rivets or self-tapping screws with a diameter of 4-5 mm. The number of fasteners should not be less than three

The bandage connection is considered a connection with a high degree of strength and reliability. The edges of the straight and shaped parts of the air ducts are folded back and combined. Then a bandage filled with sealant is applied to the pipes at the seam and tightened.

When connecting air ducts, the seams are sealed:

- elastoplastic tapes such as “Guerlain” at temperatures up to 40 degrees;

- non-hardening mastic based on synthetic rubber (for example, Buteprol), silicone and other sealants that can withstand heating up to 70 ° C.

The seam of the pipe or box is located at the top.

When moving an air mixture with a temperature above 70 ° C, elastic strands made of polyisobutylene, bitumen mastic (BTU) and other fire-resistant non-combustible materials are used as a seal.

Before joining the channel elements with thermal insulation, carefully bend the insulation at both ends. The sections are hermetically connected and the insulating layer is returned to its place. The seam in the thermal insulation is sealed with aluminum tape or clamps.

Types: materials and characteristics

For the installation of small home ventilation systems, the industry produces a wide range of pipes and components.

Air ducts for domestic ventilation are divided into:

- By material - plastic, aluminum or galvanized steel.

- Shape: square, rectangular, round.

- According to the degree of flexibility - flexible or rigid. Flexible boxes are made of corrugated aluminum or galvanized steel. Rigid air ducts made of metal are not used due to the complex installation and complexity of manufacturing galvanized pipes of small sizes (from 100 to 150 mm in diameter or section side length). Aluminum pipes of suitable sizes are expensive, there are no special advantages in their installation, so they are also not used for kitchen hoods.

Plastic

Plastic air ducts are round, square and rectangular with a smooth surface. They come in white and painted in different colors - it’s easy to choose a shade that matches your furniture set or wallpaper.

Plastic boxes are very smooth - they are easy to clean, and less grease and soot accumulate inside. Smooth walls provide the least air resistance - therefore, such pipes vibrate and make less noise. Plastic boxes are the quietest compared to corrugated boxes.

.

Made from flexible corrugated aluminum pipe

A very practical option for an air duct is a corrugated aluminum pipe of round cross-section. The flexible pipe is easy to install; it does not require rotating elements - it can simply be bent. An aluminum pipe is durable, but it is very difficult to clean it from grease and soot deposited on the walls. The corrugated inner surface creates great resistance to air flow; the pipes make more noise when the hood is operating.

Metal

The corrugated pipe can be made of galvanized steel. This pipe is a little stiffer and stronger, but otherwise its installation is as simple as for aluminum corrugation.

Places with a damaged zinc layer rust, the rigidity of the pipe complicates its installation, so steel corrugation is rarely used for internal household ventilation systems.

By degree of flexibility

Aluminum corrugation is more ductile than steel, it is easier to bend, stretch and compress.

Plastic air ducts are used only for rigid ones; corrugated plastic pipes are not suitable for transporting hot air.

How to choose the diameter?

If you are thinking about what diameter of the air duct to choose, remember a couple of nuances. The ideal diameter of the air duct should coincide with the ventilation channel and the outlet under the pipe in the hood.

The diameter size is very important, since incorrect selection can lead to increased noise, as well as possible damage to the hood.

The diameters of the ventilation hole and the hood may differ; in this case, transition structures are used, but the efficiency of the air duct will naturally decrease.

Be sure to measure the dimensions of the exhaust and ventilation openings.

Manufacturers offer round air ducts in the following sizes: from a minimum of 80 mm to a maximum of 300 mm. In everyday life, pipes with parameters of 180 and 200 mm are usually used.

There are noticeably fewer rectangular air ducts. Most often you can buy products with dimensions of 50x100 mm and 80x150 mm.

Advantages of plastic and metal air ducts

Advantages of plastic boxes:

- Little air friction and power loss when air passes through pipes.

- Easy to clean; Less grease and soot settle.

- Fits beautifully into the interior.

- There are many varieties of components available that allow you to assemble a system of any configuration.

Advantage of metal corrugation:

- Fewer adapters and angles required; smooth turns reduce the efficiency of the system less.

- The ability to stretch and contract makes installation easier.

- Small price.

Which option is better

Plastic boxes are better - they have less resistance to air flow, they fit better into the interior and are washable.

But in some cases, when laying hidden, flexible corrugated pipes are necessary.

Types of kitchen hoods with ventilation outlet

The devices are installed directly above the stove. They differ in the method of fastening and installation location.

Island

Another name for the products is hanging. Such instances are used if the stove is not against the wall, but in the center of the room. Then the equipment is suspended from the ceiling above it. Such models look very stylish and original, but they are only suitable for large kitchens.

Original and stylish island hood

Mounted

One of the most popular devices. They are mounted on the wall, in many cases under the kitchen shelf. They allow you to save space, which is convenient for small rooms. Installation of such installations does not cause any particular difficulties. They look attractive, are inexpensive and do their job perfectly. They have a low noise level.

The mounted option is one of the most popular. Interesting! Attachments can be flat or dome. Recently, manufacturers have begun to produce inclined models that fold and unfold when necessary.

Built-in

This option is the most convenient and visually attractive - specimens look advantageous in any interior, even in the smallest kitchen. When choosing, special attention should be paid to the dimensions; the hood must fit into the dimensions of the kitchen unit and correspond to the dimensions of the stove. Typically, the depth of the exhaust system is 60 cm; many products are produced with a sliding visor, which allows for even more space saving.

Built-in model

Fireplace

They are expensive, but they look incredibly beautiful and luxurious. They are installed in designer luxury kitchens, where every detail is thought out to the smallest detail. For the device to operate effectively, a high-quality modern ventilation system is necessary, and complex installation requires the participation of specialists. The equipment is able to cope with large volumes of contaminants.

The fireplace hood looks luxurious

Oblique

A modern option for compact spaces. Takes up little space and looks very stylish. Fits perfectly into a designer interior. She copes well with her duties and is not picky in her care.

An inclined hood is suitable for a compact room

Corner

Designed to be placed in the corner of the kitchen. Mounted to the wall, they come in various shapes - T-shaped or dome. The angular location of the stove is a non-standard solution that allows you to intelligently manage the space of a small room. They require installation near ventilation due to the design features.

Corner hoodHelpful! The corner hood must match the dimensions of the slab or exceed its dimensions. This will make it possible to effectively and quickly remove dirty air and unpleasant odors from the room. In stores there are models with sizes from 50 to 90 cm.

Tips for choosing

When choosing a pipe type, they are guided primarily by aesthetic considerations. Before making a choice, it is determined whether the box will be mounted openly or covered with furniture, a box, a false wall, or a suspended ceiling.

Corrugated shiny pipes spoil the kitchen interior; more often, when laying air ducts openly, smooth plastic pipes are chosen - they are easy to clean and can be painted in the desired colors - white or colored to match the ceiling or walls. Rectangular and square boxes fit better into the interior; round plastic boxes have minimal resistance to air flow.

When laying hidden, corrugated pipes are chosen - they are easier to install, no adapters or corners are needed, they are easier to bend when avoiding obstacles and for turning. Masking metal pipes will require additional costs. If problems arise, it will be difficult to get to the hidden pipe.

Diameter and shape

The diameter of the round pipe should be equal to the diameter of the outlet pipe of the kitchen hood.

Round boxes provide minimal resistance to air movement.

The ideal shape for an air duct is straight. Sharp corners when installing air ducts are unacceptable.

Dimensions and cross-section

The cross-section of a square or rectangular pipe must be equal in area to the cross-section of the round hood pipe. Narrowing the cross-section will lead to deterioration in system performance, fan overload, increased noise, vibration and loosening of fasteners. It is better to take a pipe with a slightly larger cross-sectional area. A large excess of the cross-section will lead to increased costs and difficulties with masking the pipe.

A slight narrowing of the cross-section is permissible only if the fan power is taken “with a reserve” and the hood is rarely turned on at maximum power.

Optimal duct length. If the duct length is longer, the fan power must be increased.

Diameters of corrugated pipes used in domestic ventilation: 100 mm, 125 mm, 150 mm.

Dimensions of plastic boxes: 80×80 mm, 100×100 mm, 125×125 mm, 55×110 mm, 50×120 mm, 60×204 mm, 90×220 mm.

Diameters of plastic pipes: 100 mm, 125 mm, 150 mm, 200 mm.

Calculation of the minimum required size

Calculation of the cross-section of the hood duct is not necessary. The cross-section should be equal to the cross-section of the hood outlet pipe. If the hood was purchased with a power reserve and it is not planned to turn it on at maximum power, then the cross-section can be narrowed.

The minimum cross section is calculated using the formula:

Smin=Srab *(QrabQmax), where

- Smin is the minimum possible cross section.

- Srab is the nameplate section of the exhaust pipe.

- Qwork is the required volume of air removed.

- Qmax - maximum volume of air removed (according to the hood's passport).

- Qwork is calculated using the formula:

- Qwork = kitchen volume x 12 times x 1.3 per m³.

In accordance with sanitary standards, 12 is the air exchange coefficient (the air in the kitchen should be changed 12 times per hour), 1.3 is the power loss coefficient in the air duct and ventilation shaft.

Duct requirements

All technological conditions are specified in regulations, for example, in GOST 12.4.021-75 SSBT “Ventilation systems”. And they can also be developed separately by designers for the immediate home. The main task is to remove exhaust air. The performance of air channels in this case consists of three components: the strength of the air exhaust pipe, its configuration and diameter. The air distribution system must pass the required amount of air subject to certain requirements:

- pipe tightness;

- minimal air leaks;

- speed of exhaust air in accordance with SNiP;

- noise level is not higher than sanitary standards;

- thermal insulation (if necessary).

And also during installation it is necessary to minimize the space in which the exhaust duct is installed. The pipe shape, material and diameter are then selected based on the influence of immediate conditions.

Connection rules for all types of pipes

Recommendations:

- The duct must be carefully sealed at all joints.

- The system must contain a minimum number of adapters, turns, and narrowings - they lead to a decrease in efficiency.

- The boxes must be securely attached to the walls and ceilings using special clamps. If the boxes are moving, the system will vibrate, the noise level will increase and the seal will be broken.

Rules for laying the air duct from the hood to the ventilation shaft opening

For proper installation of the air duct, it is necessary, if possible, to select the shortest path from the hood to the hole in the ventilation shaft. If the air duct is too long, you need to consider another possible way to remove polluted air - for example, to the street.

The shape of the air ducts should have a minimum of turns. . If possible, it is necessary to smoothly rotate the pipe using two 135° bends or different-angle bends (see 6 in the figure). You cannot turn the box at an acute angle - this will completely stop the movement of air in the pipeline.

If the length of the air duct is too long, it is necessary, with the help of specialists, to recalculate the power losses in the air duct and the required fan power.

Features and nuances of do-it-yourself installation

Installing ventilation pipes from a hood is a simple task, quite feasible for a home craftsman even with little experience. If you carefully follow our advice, the installation of ventilation ducts will go without problems.

Required tools and materials

To complete the work you will need:

- Drill.

- Screwdriver.

- Hacksaw or grinder.

- Sealant.

- Boxes, bends, adapters of the required section.

- Check valve.

- Ventilation grille for connecting ducts to the ventilation shaft.

Indoor air duct installation

To install the boxes, it is necessary to carefully mark and measure the entire route of the system. The grate on the hole in the shaft is dismantled, and if necessary, the shaft is cleaned of dust, soot and cobwebs.

After installing the exhaust equipment, connect the box to the exhaust pipe. All joints are coated with sealant. Heat-resistant sealant is not needed - the temperature of the exhaust air is not too high.

Then the system is assembled by inserting individual elements into one another. The pipes are shortened to the required length by cutting with a hacksaw or grinder. The box is fixed to the wall using special holders or clamps. The distance between fastenings is no more than 500 mm.

The grate is attached to the shaft wall with dowels. It is more practical to use a grille with a hole for the box and a hole for natural ventilation. A check valve must be installed in the system - if the hood is not working, it will prevent air from flowing back into the room from the ventilation shaft.

To install the system, only industrially produced pipes, adapters and connectors are used - there is no need to reinvent the wheel, the industry produces fittings for any geometry of ventilation ducts and transitions from round to rectangular pipes.

After installation of the system, it is tested:

- If a leak is detected, coat the gap with sealant.

- If rattling occurs when the system comes into contact with any structures, in this case it is necessary to lay a gasket made of polystyrene foam or polyethylene foam.

Thermal insulation of pipes in the attic

Water must not enter the air ducts. If water gets in, the fan will quickly fail. In order to prevent moisture from settling on the walls of ventilation pipes and ducts, it is necessary to provide insulation. For this purpose, slabs of polyurethane foam or mineral wool are used. The insulation is covered with roofing felt or fiberglass on top and secured with wire.

How to hide equipment

The hood can be covered with a decorative screen or an imitation of a kitchen hanging cabinet.

How to hide pipes from the kitchen hood

There are several options for hiding pipes:

- Covering suspended ceiling structures.

- Route through kitchen cabinets.

- Laying over cabinets and covering with a decorative screen.

- Painting or decor to match the color of the walls and ceiling.

- Closing with decorative boxes.

- Covering with a screen that imitates a wall, for example, made of plasterboard.

When installing boxes behind a false wall or suspended ceiling, you should take into account the fact that disassembling and cleaning or repairing the system will not be easy - you will have to disassemble the wall or dismantle the ceiling structures.

Installation of a hood without a duct

Circulation-type hoods are more compact than flow-type hoods, and their installation is simpler. A hood without pipes is simply attached to the wall or suspended from the ceiling (if the stove is placed in the middle of the kitchen on the island).

Video

All the details of installing a hood box can be seen in our video:

Installation of a pipe for an exhaust hood in the kitchen

The diameter of the exhaust pipe should not exceed 3 m.

When laying, the trajectory of the main line and its length are taken into account, which is not recommended to be more than three meters. The hood and air duct are not placed opposite the ventilation hole in the ceiling or wall. Each extra meter of length, as well as a turn at an angle of 90°, reduces efficiency by 5 - 10%.

Do not bend the pipeline at an acute angle, as this will cause the hood to operate in overload mode. The exhaust hood covers the opening of the ventilation shaft, so care must be taken to organize natural ventilation of the entire kitchen space.

Duct outlet options

There are several options for using and connecting the air duct in the kitchen:

- Connect one or two air intake points to one air duct.

- Take the box outside or into a ventilation shaft.

In any case, general ventilation must operate in the room.

With one entrance

When connecting one air intake point to the ventilation system, the possibility of natural ventilation must be provided. If there are two ventilation shafts in the kitchen, the hood is connected to one of them, and a hole (with a grill) is left in the second shaft for natural ventilation.

If there is only one shaft, then a tee is installed near the entrance of the hood pipe to the ventilation shaft with the ability to switch between the hood and the hole for natural ventilation. There are grilles with holes for natural ventilation and a check valve that does not let air from the shaft back into the room.

With two inputs

If it becomes necessary to connect two air intake points to one system, then check valves must be installed between the tee and the fans, otherwise the fans will interfere with each other’s operation. It is also advisable not to turn on the fans at the same time. A third check valve is installed near the grille.

Outside

If you decide to take the box outside, you need to cover the outlet hole with a grill to prevent birds or animals from getting into the pipe. It is also necessary to install a check valve to prevent cold air from entering the room.

Installation features

The installation of an exhaust system depends on the material it is made of, as well as on the location of the ventilation in relation to the placement of the hood.

- The first thing to consider when installing an air vent: the hood should not be located opposite the ventilation. This is the most inergonomic arrangement, in which it is impossible to ensure normal air removal.

- Second: the closer the hood is to the ventilation duct, the higher the efficiency of air removal will be.

- Third: the absence of sharp corners in the duct design has a beneficial effect on its efficiency.

- Fourth: it is necessary to install additional ventilation (for example, grilles), since one channel will be occupied by the hood.

Select duct size

Hood performance is reduced by two factors:

- The presence of 90 degree turns (sharp corners are not allowed at all).

- Reducing the cross-sectional area of the ventilation tract.

How does what has been said relate to the everyday life in which we live? The ventilation ducts of most buildings traditionally have a diameter of 14 cm. Square shafts are built with a side of 13 cm. It is not difficult to guess that when connecting an air duct with a smaller cross-section, we partially use the passage. Rework will become the bottleneck of the channel. Conversely, an air duct with an excessively large cross-section will not bring much benefit, since the duct narrows further. It would be correct to evaluate the dimensions before choosing a hood. You should buy an umbrella or air ducts after understanding how well the products will work together.

Tip 2: How to choose a hood

Hood design

Hoods, which consist of four main components: a fan unit, an air intake, filters and a housing, differ in appearance from each other. The simplest ones are flat devices. They come in two types: built-in and wall-mounted. The latter are mounted on the wall or bottom of the cabinet above the stove. Built-in units are mounted inside a wall-mounted kitchen cabinet, so before purchasing you need to make sure that a certain model will fit into the cabinet and that the corresponding hole can be prepared in it.

The most common today are fireplace hoods, the name of which goes back to the shape of the devices. They are mounted on the wall above the stove. These models are more productive; most of them are capable of operating in air exhaust and recirculation modes. The range of many companies already includes island hoods, which are attached to the ceiling above the kitchen “island”, and corner appliances, designed for mounting in the corner of the kitchen. To decorate hoods, tempered glass, wood coated with protective varnish, artificial stone and hand-painted metal elements are used.

The most popular hoods are made of stainless steel and aluminum. Models made of polished stainless steel look quite impressive. This surface is easy to clean, but should not be cleaned with abrasives. The disadvantage of this material is that fingerprints remain on it, and manufacturers recommend caring for such products using special compounds. Aluminum units are good because their surface “adjusts” to the color of kitchen items, fitting well into the interior. In addition, aluminum hoods do not leave fingerprints.

Principle of operation

When choosing a hood, you need to decide for yourself how it will remove unpleasant odors - through air exhaust or air recirculation. Both options have their advantages and disadvantages. Most modern devices are designed in such a way that they can operate in both modes, however, if an air duct is not installed, the device can only be operated in recirculation mode.

When recirculating, the fan draws air under the umbrella and, passing it through filters, returns it back to the kitchen clean. Housewives praise such hoods for their low price and ease of installation, but they are often dissatisfied with the low performance and the need to periodically change the carbon filter. For proper operation of the hood, make sure that the air ducts purchased in the store are installed correctly.

In the exhaust mode, air is also taken in by a fan and passed through a grease filter, but does not return back, but is discharged into the ventilation shaft or outside through a special channel. This method of combating odors is more effective, but installation of the air duct is quite labor-intensive. It must be well sealed and have a special valve at the outlet that prevents cold air from entering the room from the street.

Do-it-yourself pipe masking

Work on the construction of a protective box begins with the development of a diagram and calculation of the required amount of material. It should be taken into account that the distance between the walls and the pipe must be at least 10 centimeters.

Materials and tools

In addition to drywall, to carry out the work you need to prepare:

- tape measure and pencil;

- drywall hacksaw (“Fox”);

- screwdriver;

- hammer;

- galvanized screws;

- “quick installation” dowels (size 6x40);

- UD – profile with holes for fasteners.

It is also necessary to take care of eye and respiratory protection from concrete dust generated during drilling.

Work progress

https://youtube.com/watch?v=MsDV9Sicjwg

First, markings are applied to the wall and ceiling in the places where the guide rails will be fixed.

The workpiece is a structure of vertical and horizontal slats connected to each other using self-tapping screws. The distance between the vertical “stiffening ribs” is set to no more than 50 centimeters.

The drywall sheet must be cut according to the required dimensions. This operation is not at all difficult to perform, since the material is thick cardboard, laid in two layers, between which there is plaster.

The sheet is installed vertically, leaning against the wall. First, it is cut along the top cardboard layer with a knife, then the plaster is broken and the cutter is passed along the fold line.

The finished frame is sheathed on top with prepared sheets, screwing them onto self-tapping screws. The joints between the walls are reinforced with an angular profile. The finished box is finished in a suitable way so that it does not stand out against the general background.

Drywall can be plastered, wallpapered, or painted to match the color of the ceiling. Before this, the structure is puttied and coated with a moisture-repellent primer.

Common mistakes

Often, apartment owners, having set themselves the goal of masking communications, wall them up tightly. Meanwhile, gas workers may well consider this a violation if a gas pipe turns out to be hidden.

In the event of a leak, methane will accumulate in a closed space, which can lead to an explosion and fire. Therefore, it is better to hide gas pipes behind single panels attached to the wall.

Choosing a hood

Dimensions play an important role when choosing, that is, width, height and depth. To achieve optimal efficiency from the operation of the exhaust unit, it is required to position it as accurately as possible over the gas stove. Naturally, the size of the hood should match the area of the hob or, to achieve an even greater effect, be 15 cm wider.

It should be noted that built-in models are equipped with a retractable part, which helps to increase the working surface area of the unit; this additional function is an advantageous difference from classic options that do not have such properties. In cases with corner, dome and island hoods, when using non-standard installation methods, the size of the working surface area plays a significant role.

It is very important to determine the desired hood height before purchasing. It is selected taking into account the height of the ceiling, so as not to violate the standards of safe operation, which regulate the minimum distance between the device providing filtration and the hob of 75 cm

You should not try to reduce the distance on your own initiative in order to avoid unpleasant consequences in the form of fire or damage to the device. It is also not recommended to exceed it, so as not to reduce work efficiency.

Correspondence of dimensions of electric stoves and hoods

It is believed that the larger the surface area from which the hood collects air, the more efficiently it works. However, one should not blindly strive for maximum figures: it often happens that the power turns out to be excessive for specific conditions. There will be no benefit in this case. There is an overpayment for a higher power of the device, and extra space is taken up when installing equipment.

As a general rule, the air purifier should be wider than the surface of the stove, or at least the same width. If the hood is narrow or offset to the side so that only part of it is above the hob, the efficiency of the hood is reduced. If the width is insufficient, the following unpleasant moments arise:

- When operating the unit at standard power, food odors may be detected. Smoke, grease, soot particles, and water vapor enter the kitchen area.

- By operating the air purifier at high power, it may be possible to avoid deterioration in the air quality in the kitchen, but under extreme operating conditions, the exhaust mechanism mechanisms will wear out faster. When the fan operates at high speeds, noise is heard.

The dimensions of electric stoves also correspond to the general size range. Minimum width 30 cm for electric hobs. It is designed for models with one burner. For such a stove, an air purifier with a width of 30 cm is required.

If you have not purchased the stove yet, you can use the dimensions of the module designed to integrate the hood into the unit.