Updated: 02/19/2021 18:45:21

Expert: Konstantin Borisovich Polyakov

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

A hydraulic accumulator is a container for storing water, which is equipped with a rubber membrane surrounded by compressed air. The design performs four functions at once: it provides water supply in case the central supply is turned off or the pump breaks down, it protects subsequent wiring and fittings from water hammer, reduces the frequency of pump operation, and maintains stable pressure in the system. Let's consider how to choose such a device and take a more detailed look at the advantages and disadvantages of the most popular models. This will help you make your choice and not regret the money spent.

Recommendations for choosing and installing a hydraulic accumulator

Which hydraulic accumulator should you choose: horizontal or vertical?

There are 2 ways to install a hydraulic accumulator: horizontal and vertical .

If the dimensions of your room allow the use of both methods, then you should pay attention to the fact that over time, some of the dissolved air in the system will accumulate in the cavity of the accumulator. Removal of this kind of air plugs can only be done using an air release valve located in the upper part of the accumulator (for a vertical accumulator), or using an additional section of pipeline, which consists of an air outlet nipple, a ball valve and a drain into the sewer (for a horizontal accumulator). Only large-volume hydraulic accumulators (100 or more liters) are equipped with an air-separating nipple; air is removed from small-volume hydraulic accumulators by periodic complete emptying: an additional ball valve can be provided in the pipeline diagram or the power supply to the installation can be periodically turned off and the air bleed through any one closest to the hydraulic accumulator water point. For greater effectiveness, this procedure must be repeated several times.

What size accumulator should I choose?

If your house only has a water tap, a shower, a tap for irrigation and up to 4 people live, then you will need a standard water supply installation with a 24-liter hydraulic accumulator, even if you increase the number of water collection points, you can additionally install another hydraulic accumulator 24 liters to any point in the water supply system. If the number of water points is more than three, a hydraulic accumulator with a capacity of 50 liters is sufficient. But when calculating individual houses equipped with sewerage and various equipment that consume a large amount of water, you will have to resort to the international calculation method UNI 9182:

1. Fill out the table below to determine the total water consumption coefficient Cy by compiling a list of distribution points in the house and indicating the number of each type of equipment.

Type of equipment

Frequency coefficient of use of each type of equipment, Cx

Number of each type of equipment, n

Product (Cx) x (n)

Faucet in the sink

Dishwashing machine

Irrigation tap

Total coefficient Su=

2. Based on the value of the total coefficient Su, determine the value of the maximum water flow required for your home (see table below):

Su

Max. performance

(l/min)

3. To determine the volume of the hydraulic accumulator, it is necessary to decide how many times per hour the hydraulic accumulator can be turned on at maximum consumption intensity. 10-15 times per hour is considered normal. It is also necessary to assign response thresholds for the pressure switch of the water supply station. The lower threshold Pmin for two-story houses is usually 1.5 bar, and the upper threshold Pmax is 3 bar. Then, to determine the volume of the accumulator, you must resort to the following formula:

Calculation of air pressure in the accumulator

To calculate the minimum air pressure value, you need to take the height in meters from the lowest point (where the accumulator is installed) to the highest point of your water supply system, then add 6 to this value and divide by 10. You will get the required value in atmospheres. For example, for a two-story house 7m+6=13/10=1.3 atmospheres. This is the minimum value of air pressure in the accumulator. As a rule, the air pressure is already set at the factory at 1.5 atm, but it may be different, so you should initially check it with a pressure gauge, connecting it to the accumulator nipple and, if necessary, increase it using a car pump.

Recommendations for assigning response thresholds for pressure switches in water supply systems of an individual home

The difference in response thresholds Pmax - Pmin determines the volume of water supplied by the accumulator of the water supply system. The greater this difference, the more efficient the operation of the accumulator, but in this case the membrane is more heavily loaded and may rupture. The Pmin value is determined based on the hydrostatic pressure (water height) in the water supply system, 10m=1 bar.

What should the minimum pressure value Pmin be? The air pressure in the backpressure chamber of the hydraulic accumulator must be equal to hydrostatic pressure, i.e. in our case 1 bar. The lower response threshold pmin should then be slightly higher (0.1 bar) than the air pressure in the accumulator. But, since we need the system to work stably, and the most critical point is the high point of disassembly and the tap works normally if the pressure drop in it is at least 0.5 bar, therefore, the pressure should be 0.5 bar plus the value of the hydrostatic pressure of this points. That. , the minimum value of gas pressure in the hydraulic accumulator is 0.5 bar plus the value of the reduced hydrostatic pressure at the location of the hydraulic accumulator (the height distance between the upper point of disassembly and the point of location of the hydraulic accumulator). Then, if the accumulator is located at the lowest point of the water supply system, then the minimum gas value in it is 1 bar + 0.5 bar = 1.5 bar, and the pump response threshold Pmin = 1.5 + 0.1 = 1.6 bar. If the hydraulic accumulator is located at the top point and the pressure sensor at the bottom, then the gas pressure in the hydraulic accumulator should be set to 0.5 bar, and the pump activation threshold Pmin = 1.6 bar.

When assigning an upper threshold for operation of an automatic water supply system, it is necessary to take into account, first of all, the pressure characteristics of the pump. The pressure value in meters divided by 10 will show the maximum pressure value, but the following should be taken into account:

Therefore, we recommend setting the upper response threshold value 30% lower than the maximum pump pressure value.

However, the initial consideration when determining the upper alarm threshold is the height of the water supply system. To determine the value of the upper threshold, add 20 meters to the height of your water supply system and divide by 10. You will get the pressure of the upper threshold, in bars. In domestic water supply systems, it is recommended to set the difference between the lower and upper response thresholds in the amount of 1-1.2 bar.

Criterias of choice

For long-term use, experts recommend purchasing models with a bulb. Membrane accumulators are more susceptible to corrosion, since the membrane is not able to isolate the walls of the housing from the effects of water. However, for models with a pear, repairs are more complicated than for membrane analogues. When choosing a storage tank, you also need to take into account future water consumption.

If the number of permanent residents in a house or apartment is no more than three people, and there are a minimum of plumbing fixtures, then a 24-liter container is sufficient.

If there are more users, then an appropriate hydraulic accumulator is required. Please note the following before installation:

- number of users;

- number of water points;

- number of household plumbing fixtures;

- presence of heating elements.

If the preliminary calculations did not turn out to be final, for example, another person appeared in the family or the number of plumbing fixtures increased, the best solution would be to install a larger tank or install an additional tank.

Both procedures have approximately the same complexity and comparable equipment costs.

Do you need extra capacity?

Many people believe that one of the purposes of a battery is to create a water reserve. However, this is not the case and the functions of the device are completely different. Of course, a small reserve of capacity is needed - there are times when water consumption may increase. In addition, a slightly increased volume will have a positive effect on the operation of all equipment.

However, given the price, there is no need to pay extra money for additional capacity. For these purposes, special plastic tanks are designed that are built into the water supply system.

Moreover, if you plan to increase consumption points in the future, you can buy an additional hydraulic tank. Their total volume will be summed up. For example, if two devices of 40 and 80 liters are installed in the system, then the total operating power will be 120 liters.

Optimal pressure

In order for the GA to cope well with its tasks, the pressure must be set correctly. In general, the calculation of the required value is made based on the fact that for every 10 meters of rise, 1 atmosphere is required. In addition, another atmosphere ensures normal pressure in the water supply system.

For example:

- the hydraulic accumulator is installed in the basement, and the distance to the highest point is 6 meters;

- thus, 0.6 atmospheres will be required to raise the water and another one for operation;

- i.e., the operating value will be 1.6 atmospheres.

During installation, you must immediately check this value, and if it is below normal, then pump air into the tank. Also, you need to correctly configure the pressure switch. After all, the frequency of turning on the pump and the water pressure in the system will depend on this.

Accumulator volume

Do not buy a hydraulic accumulator based on what your friends or neighbors in the country have installed. Perhaps this model will not be effective for you. The volume of the hydraulic accumulator (like all other equipment!) should be selected only on the basis of the results of hydraulic calculations. The number of models on the market is quite large.

Is there an optimal hydraulic tank volume? As we have already said, only a hydraulic calculation can accurately indicate a specific model of hydraulic equipment that is optimally suited to your conditions. But the number of typical volumes for various models of hydraulic tanks is not so large. That is, if, according to the calculation results, you need a tank with a volume of 51.5 liters, then you will not be able to find such a tank on sale. You will be advised to purchase a 60 liter hydraulic tank. Extra liters of volume will not harm, and will even slightly increase the water supply and reduce the number of pump starts.

The experience of engineers selecting and installing water-lifting equipment tells us the following:

- A hydraulic accumulator with a volume of 25 liters can be installed in a water supply system for three consumers with a borehole pump productivity of 2 m3/h.

- in a system with a number of consumers of 4-8 and a pump capacity of 3.0-3.5 m3/h, a hydraulic tank with a volume of 60 liters is optimal.

- if the number of consumers is more than 10 and the pump capacity is 5 m3/h, then the optimal tank volume will be 100 liters.

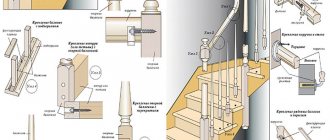

Connection methods and configuration of the hydraulic accumulator

In what part of the system is it installed and how to connect the accumulator to the pumping station

There are many variations of water supply systems. In complex systems with a well depth of more than 100 meters, for example, the pump power may not be enough to supply water directly to the house, or the size of the pumping unit with the required power exceeds the diameter of the well (the pump simply will not fit into the well). This system is supplemented with a surface pump. In this case, you will need two hydraulic devices, one is installed in the well pit immediately after the deep pump, the second is installed in the house after the surface pump. These factors prove that the most important part of the cold water supply system is the pump and, based on its characteristics, a suitable hydraulic accumulator and the entire water supply system are selected.

Sample with surface pump in well pit

With a standard scheme, where water comes, for example, from a well or shallow well, the power of a conventional pump is quite enough to supply water even to the second or third floor. In this case, the system does not cause any difficulties and the hydraulic device is installed indoors.

An example of a simple water supply scheme from a deep-well pump

What is required to assemble the entire hydraulic accumulator group

In addition to the pressure switch, the hydraulic tank group includes a pressure gauge.

Pipeline pressure measuring device

For ease of connection of all components, a five-pin fitting is used.

Five-outlet valve for hydraulic tank

When assembling the entire group, it is recommended to use American cranes. For trouble-free removal and replacement of any device in case of breakdown. That is, to the outlet to the battery, to the pipe leading to the pump and to the distribution to consumers. If you assemble a group without “Americans”, in the event of a minor breakdown or replacement of the membrane, for example, you will have to drain the water from the entire system.

An American faucet allows you to cut off the system from any component

Is it possible to increase the volume of the hydraulic accumulator?

Incorrect hydraulic calculations, changes in water or electricity supply parameters may require an increase in the volume of an already installed hydraulic accumulator. This can be done quite simply by installing one or more hydraulic tanks in addition to the main one. This is possible because the volumes of all hydraulic accumulators in the system are summed up. That is, two tanks with a volume of 50 liters are approximately equal in efficiency to one tank with a volume of 100 liters.

several hydraulic tanks in one water supply system

Rating of the best hydraulic accumulators for water supply

| Nomination | place | Name of product | price |

| Review of the best hydraulic accumulators for water supply with a volume of 50-200 l | 1 | Reflex DE 200 200 l | 8 663 ₽ |

| 2 | Wester WAV 100 100 l | 5 403 ₽ | |

| 3 | STOUT STW-0003-000080 80 l | 3 908 ₽ | |

| 4 | GILEX Crab-T 50 | 5 004 ₽ | |

| 5 | UNIPUMP 86832 50 l | 6 000 ₽ | |

| 6 | WWQ GA 50H 50 l | 3 101 ₽ | |

| Review of the best hydraulic accumulators for water supply with a volume of 8-25 l | 1 | Reflex DE 25 | 2 135 ₽ |

| 2 | Wester WAO 24 | 970 ₽ | |

| 3 | WWQ GA 24H 24 l | 1 474 ₽ | |

| 4 | STOUT STW-0001-100020 20 l | 1 211 ₽ | |

| 5 | Reflex DE 8 | 1 450 ₽ |

Optimal pressure in the accumulator

The air pressure in the hydraulic tank in the absence of water is one of the main operating parameters. This parameter is different for each hydraulic accumulator and is indicated in its technical data sheet. Small fluctuations from the nominal value are allowed, but significant excess or decrease in pressure should be avoided, as the service life of the rubber cylinder (membrane) is reduced. For the water supply system to operate, the pump activation pressure must be at least 0.5 bar higher than the operating air pressure in the accumulator.

The nominal pressure may be affected by the number of storeys in the building. For example, if the accumulator is located in the basement of a two-story building, then the minimum pressure in the water supply system should be 2 bar. 1 bar of pressure is needed to raise water to a height of 10 m, another 1 bar is needed to create the required water pressure in the consumer’s tap. In our case, 10 m is the average height difference between the basement and the second floor. Taking into account the pressure of 0.5 bar created by the well pump, the operating pressure in the accumulator should be equal to 1.5 bar.

simple pressure gauge and automatic control units

The values of the pressure to turn on and off the well pump can be set programmatically in the automatic control unit. The sensor is a pressure switch. Correctly set pressure values will reduce the frequency of pump activation and maintain the required pressure in the water supply system. Effective operation of the accumulator occurs if the difference between the pressure on and off the pump is from 1.5 to 4.5 bar.

Principle of working with a well, components

Here's how a hydraulic accumulator works step by step:

- water is pumped into the bulb, which expands, thereby displacing air - a buoyant force is created inside

- After reaching the required pressure value, a special relay turns off the operation of the electric pump

- Compressed air forces the liquid from the membrane into the system. Thus, when the tap is opened, water flows from the hydraulic tank

- After reducing the amount of liquid in the bulb, the pressure decreases - the relay records this indicator, turns on the supercharger until the desired value is reached, and so on in a circle

The principle of operation of a hydraulic accumulator is to generate a buoyant force inside its body, which compensates for the pressure in the system. The empty space inside is filled with air. In this case, the compression force reaches about 2 bar. It pushes the required amount of liquid from the “pear” into the pipes to stabilize the pressure according to the indicators of the pressure switch.

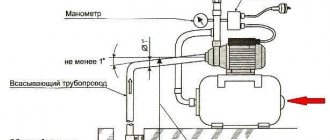

A hydraulic accumulator for a pumping station with a well works according to the following scheme: an electric pump pumps water from the well, it goes through a pipe coming out of it through a pressure pipeline. On its way from the source to the water supply system, a HA is inserted, and a pressure switch and pressure gauge are located near the connection point. The liquid first enters the unit and then flows further to the water intake points.

Hydraulic accumulator device:

- oval (thick balloon-shaped) metal body with legs

- inside – a water-filled “pear” made of food or industrial rubber

- at one end there is a valve or pipeline to bleed air, at the other there is a connector (flange) for connecting to a tee

- flexible hose or rigid pipe for connection to the house pipe

- a tee on which a pressure control relay is attached with a nipple for a pressure gauge (sometimes you need to buy it in addition)

- fastening and strapping if the container is attached to the wall

The scheme consists of the following elements (in order):

- Well: submersible pump with electric cable, hose, pipe, lifting cable

- Pipeline with a check valve coming from the pump (laid to the house underground below the freezing point)

- Hydraulic accumulator

- Endpoints: taps, household appliances

Balloon or membrane?

Hydraulic accumulators are divided into two main types - membrane and balloon. The principle of operation of both types is similar - an elastic film of rubber expands or contracts under pressure from water and compressed air. The main difference is that in a membrane tank, water coming from the well comes into contact with the metal walls of the tank, which can potentially lead to corrosion. In a tank with a rubber cylinder, water comes into contact only with the cylinder itself, without touching the metal walls. The absence of conditions for the development of corrosion extends the life of the balloon accumulator.

hydraulic accumulators with a membrane and a cylinder

An additional convenience is that the cylinder, unlike the membrane, is a replaceable part. Carrying out the replacement will not cause any difficulties - even a non-specialist can do it. As a result, servicing a hydraulic accumulator with a cylinder will be cheaper. Taking into account the above factors of practicality and reliability, cylinder accumulators are the optimal solution for individual water supply.

An important factor when choosing a hydraulic accumulator is the cost of spare parts. Please note that some manufacturers may unreasonably inflate the price of components. For example, a rubber cylinder can cost half or even more of the cost of the entire hydraulic accumulator.

Accumulator classifications

The hydraulic accumulator, as a concept, has many areas of application. It is used in all types of mechanical engineering and heavy industry. In this article we will look at hydraulic tanks used only in domestic water supply. The most popular units in this industry are pneumatic units. They are divided into two types:

- Disposable membranes. Samples in which the membrane is enclosed in a retaining ring in the center of the tank;

Disposable water accumulator

Cutaway disposable water accumulator

- Water accumulators with the ability to replace the membrane.

Hydraulic accumulator with membrane change function

Sectional view of a hydraulic accumulator with a replaceable membrane.

Each of these types has a different design:

- Vertical;

- Horizontal.

Samples with vertical and horizontal orientation

Related article:

Pump to increase water pressure in an apartment or private house. In the article we will look at how to solve the problem of insufficient water pressure, which complicates the adoption of water procedures and the operation of auxiliary household appliances, how to choose the right pump, and what to pay attention to.

Vertical or horizontal?

From the point of view of the physical processes occurring in the accumulator, its vertical or horizontal orientation does not matter. Choose a vertical or horizontal form factor based on the convenience of placing the equipment in a house or caisson. According to statistics, horizontal hydraulic accumulators are more often chosen for pumping stations due to ease of mounting. For borehole pumps - vertical, as they take up less space when installed in a caisson.

hydraulic accumulator horizontal and vertical

Types of hydraulic accumulators

The hydraulic accumulator is a tank made of sheet metal divided into two parts by an elastic membrane. There are two types of membrane - diaphragm and balloon (bulb). The diaphragm is attached across the tank, a pear-shaped cylinder is secured at the inlet around the inlet pipe.

According to their purpose, they are of three types:

- for cold water;

- for hot water;

- for heating systems.

Hydraulic tanks for heating are painted red, tanks for water supply are painted blue. Expansion tanks for heating are usually smaller in size and lower in price. This is due to the membrane material - for water supply it must be neutral, because the water in the pipeline is potable.

Two types of hydraulic accumulators

Depending on the type of arrangement, hydraulic accumulators can be horizontal or vertical. Vertical ones are equipped with legs; some models have plates for hanging on the wall. It is the elongated upward models that are most often used when independently creating water supply systems for a private home - they take up less space. The connection of a hydraulic accumulator of this type is standard - through a 1-inch outlet.

Horizontal models are usually equipped with pumping stations with surface-type pumps. Then the pump is placed on top of the tank. It turns out compact.

Differences between cheap and expensive hydraulic accumulators

Taking into account the operating conditions of the hydraulic accumulator - constant pressure and contact with water, more expensive models provide not only increased tightness and reliability of all components, but also environmental friendliness.

- a well is drilled to obtain drinking water. Therefore, the rubber cylinder of the hydraulic accumulator must be made of high-quality material that will not cause harmful substances to enter the water. Only if you plan to use water exclusively for technical purposes, you can not specify what exactly the cylinder or membrane is made of.

- the flange on the cylinder can be made of stainless steel or cheaper galvanized metal. Stainless steel will not only last much longer, but will also not become a source of chemical compounds harmful to humans.

The rubber bladder and flange are easily replaceable elements. Therefore, if you doubt the reliability of the information about the quality of the materials used in the accumulator, you can replace these parts yourself.

Operating principles, design and advantages of a hydraulic tank in water supply systems

What does the hydraulic tank consist of?

Sectional view of the unit with a description of the key elements

- The body of the device is most often made of ordinary steel. There are stainless steel samples. They are more durable, but are less common due to their high cost;

Samples made of stainless steel

- Rubber membrane. It is made of elastic material, which ensures long-term operation;

- The operating pressure is controlled through the spool using a conventional machine pump and pressure gauge;

- A coarse filter is installed in the housing, in addition to a separate filter built into the circuit.

The group of battery equipment also includes a pressure switch - this is an automatic sensor for starting and shutting down the pump unit.

Pressure switch

The advantages of pneumatic equipment are:

- Simplicity of design;

- Possibility of membrane replacement;

- Easy connection to the pumping station;

- Compact dimensions;

- Light weight;

- Affordable price

Let us briefly describe the operation of a water accumulator

When water is consumed at any water intake point, the pressure switch turns on the pump unit. Water entering the hydraulic tank stretches the membrane. Then, when the tap is closed, the pump continues to work. The membrane, stretching, increases the operating pressure of the unit. When the pressure rises to the maximum value, the pressure switch turns off the pumping unit.

Operating diagram of the hydraulic accumulator

“Choosing a hydraulic accumulator”, BC “POISK”, tell your friends:

A hydraulic accumulator is a metal vessel, in one part of which there is water, in the other - compressed air, which allows you to accumulate hydraulic energy and release it into the system at the right time.

In other words, it is a device that creates pressure in the hydraulic system and allows water to flow out under pressure when you open the tap.

There are two types of hydraulic accumulators - membrane and balloon.

A balloon accumulator is a metal tank with a rubber cylinder inside, and the distance between the walls of the metal tank and the rubber cylinder is filled with compressed air. It is into the rubber cylinder that water is collected. When filled with water, a rubber cylinder expands, the air on its outside is compressed and the pressure on its walls increases. When the pressure in the hydraulic system drops or when you open a faucet, the compressed air begins to put pressure on the rubber cylinder containing water in the tank and pushes the water into the hydraulic system. When the pressure drops to a certain level, the automation turns on the pump and pumps water into the rubber cylinder of the hydraulic accumulator.

A membrane accumulator differs from a balloon accumulator in that the space of the metal tank is divided into 2 parts by a rubber elastic membrane. In this case, water is pumped into one part of the tank, and compressed air is stored in the other. According to the principle of operation, a membrane accumulator is no different from a balloon accumulator - compressed air, when the pressure decreases, pushes water into the hydraulic system.

Membrane or balloon. Which type should I choose?

The fundamental difference between these two types of hydraulic accumulators is that in the cylinder type the water comes into contact only with the rubber cylinder, and in the membrane type with the inside of the metal tank - this creates a threat of corrosion. In addition, balloon accumulators last longer and are easy to maintain. It seems the choice is obvious.

Horizontal or vertical accumulator? Which to choose?

There is no difference in the horizontal and vertical arrangement of the accumulator in technical aspects. Therefore, when purchasing, be guided by the size of the room where you will install it, i.e. Buy the type that fits more conveniently into your interior.

What volume of hydraulic accumulator is preferable?

The most common hydraulic accumulator volume is 50 liters. It is enough for a family of 3-7 people. The pump productivity should not exceed 3.5 m3/hour.

For a family of more than 7 people, it is better to choose a hydraulic accumulator with a volume of 100 liters, with a pump capacity of up to 5 m3/hour. If you live alone or together, then it will be enough for you to buy a hydraulic accumulator with a volume of 20-24 liters. The pump productivity will be up to 2 m3/hour.

Practical tips for use

When installing a system, there are many pitfalls and operational details. We will try to describe the main ones:

- How to detect a broken water battery;

- A way to save electricity;

- Insurance in case of inattention when the pump is on;

- Tips for replacing the membrane;

- Increasing the volume of the hydraulic device when installing a solid fuel boiler;

- Recommendation when purchasing hydraulic equipment with a volume of more than 100 liters.

Brief explanation for each point:

- When the membrane ruptures, water flows directly into the device body. In this case, when you open any tap, the relay will make clicking sounds. The pump will start and stop frequently even when the tap is opened briefly. There is a possibility of micro-holes forming in the tank body, the pressure in the system will constantly drop, faster and faster over time. Check the air pressure in the water accumulator regularly;

- If possible, install a water tank in the attic or at the highest point of the house. Include it in the water supply circuit. A container with a volume of 300-400 liters can easily provide water for a family of 4-5 people per day. Water from the hydraulic tank is used in the bathroom, when doing laundry, and when operating the dishwasher. Since water is supplied by gravity, you will save energy and extend the operating time of the pumping unit. It is also important to note that if it is necessary to consume a large volume of water, for example, when watering a garden or filling an emergency tank, the pump is turned on directly without the participation of a hydraulic accumulator and a pressure switch. Since the relay will quickly fail under such conditions;

- We all know cases when we turned on the pump and forgot about it. In this case, a dry running relay is installed; when the well is drained, for example, it will automatically turn off the pump. You can also mount an ordinary light bulb in a visible place, which is powered to turn on the pump; a burning light bulb will remind you that the pump is running;

- If you are replacing the membrane, take the old sample with you, as the neck diameter of the pear-shaped membrane may vary. Or measure the distance between the holes on the flange;

Diaphragm fixing flange

- When combining a hydraulic accumulator with a solid fuel boiler in the system, with a hot water supply function, the volume of the hydraulic tank should be increased by 20%. Since the boiler heats the water very quickly, it expands very quickly and the membrane more often fails.

- Water accumulators with a volume of more than 100 liters are less common, for this reason components for them are more difficult to find; it would be more rational to install two or even three hydraulic tanks of a smaller volume.

How to choose a hydraulic accumulator

Each developer, planning an individual water supply system, is faced with the need to choose a hydraulic accumulator. The range of these devices is quite extensive, as is the range of prices for them. So, after all, how to choose a hydraulic accumulator so that later there are no problems with the water supply at home? In order for the choice to be optimal, you need to take into account the main technical characteristics of a particular water supply system and have an idea of what a hydraulic accumulator is, how it works and how it interacts with this system.

Content

What is a hydraulic accumulator Operating principle Horizontal or vertical Optimal tank volume

What should be the pressure in the hydraulic tank?

What is a hydraulic accumulator

A hydraulic tank (or hydraulic accumulator) is a water container with a rubber elastic membrane (resembling a pear) located inside the container and having a sealed connection to the metal body of the tank. This connection is made using a flange with a threaded connection to connect the device to the water supply. The cavity between the membrane and the metal body of the hydraulic tank is filled with compressed air, usually the pressure is 1.5-2 bar. Hydraulic accumulators are used to maintain constant pressure and create a water reserve in domestic or industrial conditions. It is this unit that provides the required pressure in the system when the pump is turned off.

Fig.1. Hydraulic accumulator structure 1 – metal body; 2 – rubber membrane; 3 – flange with valve (passes air); 4 – nipple for pumping air into free space; 5 – cavity for compressed air; 6 – supports; 7 – platform for the pump. More details about the design of the hydraulic tank in the video:

Return to content

Operating principle

When water enters under pressure, the membrane connected to the water supply gradually increases in volume. As a result, the air that is between the membrane and the walls of the metal tank is compressed and pressure is created. As soon as the set pressure is reached, the pressure switch cuts off the electrical power supply to the pump and it turns off. As a result, the air in the hydraulic tank begins to act under high pressure on the internal membrane containing water. When the water supply tap is opened, the air pressing on the membrane forces water out of the tank into the tap. At the same time, as water is consumed, the pressure in the “pear” created by the pump decreases. And as soon as it reaches the set value, the pressure switch will work, closing the contacts, and the pump will start working again. That is, the hydraulic tank always contains water and air in full working order, but separated from one another by a rubber membrane. It is worth noting that during operation, the air pressure contained in the accumulator space may decrease. Therefore, once a year it is recommended to check the air pressure in an empty tank not filled with water. If it turns out to be below normal, it will need to be pumped up through the nipple using a regular car pump. You should know that water never completely occupies the entire volume of the hydraulic tank. Typically, the volume of water contained in a hydraulic tank depends on a number of factors: the shape of the unit itself, the initial air pressure in it, the flexibility and shape of the membrane, as well as the specified boundaries (upper and lower) in the pressure switch, etc.

Return to content

Horizontal or vertical

Depending on the installation method, hydraulic accumulators can be vertical or horizontal. Which hydraulic accumulator is preferable? It is necessary to find out how the device removes the air collected inside the membrane (“pear”). The fact is that in any water supply system there is air dissolved in the water. Over time, it is released from the water and, accumulating, forms air plugs at different points in the system. To remove them, large-volume hydraulic accumulators (? 100 liters) are provided with a fitting with a valve through which the air accumulated in the system can be released from time to time. In vertical type hydraulic accumulators (from 100 l), all air is collected in the upper part of the unit and is easily removed using such a valve. In horizontal hydraulic accumulators, air is removed using an additional section of piping consisting of a ball valve, air outlet nipple and drain. Small volume hydraulic accumulators do not have such a valve. Removal of collected air is possible only when the tank is completely emptied. Typically, horizontal hydraulic accumulators are chosen for installing external pumps on them, and vertical ones are chosen for small spaces and when working with submersible pumps.

Return to content

Optimal tank volume

To choose the right hydraulic tank, you need to decide on its purpose: To prevent the pump from turning on frequently. Since it is advisable to turn on the pump no more than 30 times/hour, you should choose a hydraulic accumulator based on the fact that in everyday life pumps with a capacity of 30-40 liters of water per minute are often used. Taking into account the fact that the water in the hydraulic tank occupies up to half the volume of the tank, a unit with a tank of 80-100 liters will completely solve the problem of frequent switching on. To maintain (when the pump is not working) pressure in the system. The system operates normally even with a small (24 liter) hydraulic accumulator. The installation location of the tank can be anywhere, but the closer it is to the pump, the better the system functions. For water reserve. If you intend to use the hydraulic tank as a backup source of water in the event of a power outage (and the useful volume of the hydraulic tank is from 30 to 50% of the total volume of the tank), it is better to purchase a hydraulic accumulator V ? 100 liters. To compensate for peak water consumption. When choosing a hydraulic accumulator, certain formulas and coefficients are used to compensate for peak water consumption values. But how necessary is this? The fact is that the units offered on the market are made in several standard volumes, therefore, regardless of what volume after calculation using the formulas you get - 32.3 liters or 41.5 liters, you will still have to buy a hydraulic accumulator with a volume of 50 liters. Calculations based on coefficients and the practice of using hydraulic tanks indicate the following - in 95% of the water supply of a private house: for one or two consumers a hydraulic tank with a volume of 24 liters is sufficient, for two or three - 50 liters, for four or more - 80-100 liters, etc. .

Return to content

What should be the optimal pressure in the hydraulic tank?

One of the most important characteristics of hydraulic accumulators is their operating pressure, that is, the air pressure in an empty tank (without water). This pressure is constant for each device, and its value is indicated on the device body. In a hydraulic accumulator, it is determined based on the hydrostatic (water height) pressure in the water supply system of a particular private house, and must not be lower than this indicator. For example, if the height of the pipes installed in the house is 10 m, then the pressure of the water column is 10 m or 1 bar. You should know that when the pump is turned on, the pressure must be at least 0.5 bar higher than the operating pressure of the hydraulic tank, and for the most productive operation, this difference between the operating and maximum pressure should be from 1.5 to 3 bar. Based on the above, for example, for a two-story house you will need a hydraulic tank with a working pressure within 1.5 bar and with a maximum? 4.5 bar. Each manufacturer usually sets the air pressure in the hydraulic accumulator to 1.5 bar, but sometimes the pressure in the purchased device is different. Therefore, you need to initially check it with a regular pressure gauge by connecting it to the hydraulic tank nipple. It must also be said that the maximum pressure of the hydraulic accumulator cannot be lower than the maximum pressure of the system, which arose, for example, as a result of a relay failure. Therefore, most hydraulic tanks are designed for a maximum pressure of 10 bar.

Review of the best hydraulic accumulators for water supply with a volume of 50-200 l

Knowing the basic criteria for choosing a hydraulic accumulator, let’s move on to the list of the best models. Experts compiled a review based on an analysis of product characteristics and customer reviews. First, let's look at hydraulic receivers that hold 50-200 liters, which is important for a family of 4-6 people or even a small multi-story building.

Reflex DE 200 200 l vertical installation

Rating: 4.9

In first place is a hydraulic accumulator from the Reflex brand. The structure is made of carbon steel with one weld in the middle. It is welded both outside and inside, which increases the reliability and tightness of the hydraulic accumulator. The dimensions of the case are 634x967 mm. The tank holds 200 l. The expansion tank has a vertical installation on three legs made of metal corners. The vessel stands firmly and does not wobble. Judging by user reviews, the height of the stand is enough to conveniently connect the water supply from below. The 5/4" inlet and outlet threads do not require the use of adapters. The metal of the barrel is painted on both sides with an epoxy coating that slows down corrosion. The rubber partition can withstand temperatures from 0 to 99 degrees, so the accumulator is suitable for both hot and cold water supply.

We placed the product in first place due to the huge liquid capacity of 200 liters. This is enough to supply water to a two-story cottage, apartment building or fire extinguishing system of an office building.

Advantages

- sits stably on three legs;

- withstands pressure up to 10 bar;

- replaceable membrane;

- the metal is painted on both sides.

Flaws

- it is difficult to find space for large dimensions;

- high price;

- weighs 54 kg - it will not be possible to deliver and install it alone;

- Footrests are definitely needed, otherwise they will press through the floor (linoleum, laminate).

Wester WAV 100 100 l vertical installation

Rating: 4.8

In second place is a hydraulic accumulator from Wester. The model holds 100 liters and is installed horizontally on three legs. The subsequent water supply connection is made from below through a threaded connection with a diameter of 1 inch. The dimensions of the device are 787x495 mm. A membrane in the form of a partition is used inside, but the manufacturer has made it of a closed type, so the lower part of the vessel is completely protected from contact with water, which customers like in reviews. The hydraulic accumulator can withstand pressures of 10 bar and temperatures of up to 100 degrees. The product is manufactured directly in Russia. You can carry out delivery and installation yourself, since the device weighs 17 kg.

This hydraulic accumulator is recognized as the best for its stable base. Unlike the previous model, the three supports here are welded not exactly under the bottom (90 degrees relative to the body), but with a slope of 45 degrees, which provides better resistance to accidental shocks. The legs themselves have a profile structure, and not in the shape of a corner, which increases resistance to deformation under load.

Advantages

- the expansion vessel is designed for 100,000 filling and emptying cycles;

- the rubber partition can be replaced;

- Allowed supply temperature from the water supply system is 1-100 degrees;

- housing made of durable steel.

Flaws

- if the liquid in the rubber bulb freezes, the seal may be broken;

- There is no pressure gauge to control pressure.

Recommendations for choosing and installing a hydraulic accumulator

There are 2 ways to install a hydraulic accumulator: horizontal and vertical. If the dimensions of your room allow the use of both methods, then you should pay attention to the fact that over time, some of the dissolved air in the system will accumulate in the cavity of the accumulator. Removal of this kind of air plugs can only be done using an air release valve located in the upper part of the accumulator (for a vertical accumulator), or using an additional section of pipeline, which consists of an air outlet nipple, a ball valve and a drain into the sewer (for a horizontal accumulator).

Only hydraulic accumulators of large volumes (100 or more liters) are equipped with an air-separating nipple; air is removed from hydraulic accumulators of small volumes by periodic complete emptying: an additional ball valve can be provided in the pipeline diagram or the power supply to the installation can be periodically turned off and the air bleed through any one closest to the hydraulic accumulator water point. For greater effectiveness, this procedure must be repeated several times.

What size accumulator should I choose?

If your house only has a water tap, a shower, a tap for irrigation and up to 4 people live, then you will need a standard water supply installation with a 24-liter hydraulic accumulator, even if you increase the number of water collection points, you can additionally install another hydraulic accumulator 24 liters to any point in the water supply system. If the number of water points is more than three, a hydraulic accumulator with a capacity of 50 liters is sufficient. But when calculating individual houses equipped with sewerage and various equipment that consume a large amount of water, you will have to resort to the international calculation method UNI 9182:

1. Fill out the table below to determine the total water consumption coefficient Cy by compiling a list of distribution points in the house and indicating the number of each type of equipment.

Frequency coefficient of use of each type of equipment, Cx

Repair and maintenance of hydraulic accumulator

Even the simplest hydraulic tanks require attention and care, like any working and useful device.

There are different reasons for repairing a hydraulic accumulator. This is corrosion, dents in the body, violation of the integrity of the membrane or a violation of the tightness of the tank. There are also many other reasons that oblige the owner to repair the hydraulic tank. To prevent serious damage, it is necessary to regularly inspect the surface of the accumulator and monitor its operation in order to prevent possible problems. It is not enough to inspect the HA twice a year, as stated in the instructions. After all, you can eliminate one malfunction today, but tomorrow you will not pay attention to another problem that has arisen, which within six months will turn into irreparable and can lead to failure of the hydraulic tank. Therefore, the hydraulic accumulator must be inspected at every opportunity so as not to miss the slightest malfunctions, and they must be repaired in a timely manner.

Causes of breakdowns and their elimination

The reason for the breakdown of the expansion tank may be too frequent switching on and off of the pump, water exiting through the valve, weak water pressure, weak air pressure (lower than designed), weak water pressure after the pump.

How to troubleshoot a hydraulic accumulator with your own hands? The reason for repairing the hydraulic accumulator may be low air pressure or its absence in the membrane tank, damage to the membrane, damage to the housing, a large difference in pressure when turning the pump on and off, or an incorrectly selected volume of the hydraulic tank.

Troubleshooting can be done as follows:

- to increase air pressure, you need to pump it through the tank nipple using a garage pump or compressor;

- a damaged membrane can be repaired at a service center;

- the damaged housing and its tightness are also repaired at the service center;

- The difference in pressure can be corrected by setting the differential too large in accordance with the frequency of pump activation;

- The adequacy of the tank volume must be determined before installing it in the system.

How to choose the volume of a hydraulic accumulator for water supply systems

How to choose the volume of a hydraulic accumulator for water supply systems is not an easy question. But, at the same time, if you figure it out, selecting a hydraulic tank will be easy.

The hydraulic accumulator itself is a storage tank, which is internally divided by a membrane into two cavities - an air cavity and a cavity with water.

The hydraulic accumulator plays a big role in the correct operation of the water supply system. It dampens hydraulic shocks when the pump is turned on. It also stores a supply of water, and based on the pressure in this tank, the pressure switch gives a command to turn the well pump on/off.

Wester hydraulic accumulator device

It is important to select the correct volume of the hydraulic accumulator, since a hydraulic accumulator of insufficient volume will not perform its functions correctly.

The role of the hydraulic accumulator in the water supply network

It would seem that the device simply passes water through itself. Could you do without it? In fact, it is with the help of a hydraulic tank that stable pressure is maintained in the water supply system.

The water pump, if present, does not turn on so often, which allows you to use its operational resource economically. In addition, the water extraction and transportation system is reliably protected from water hammer.

If for any reason the voltage in the electrical network is lost, a small “emergency” supply of water in the tank will help solve priority economic problems.

Let us clarify the list of advantages that this fairly simple device provides:

- Premature pump wear. There is a certain supply of water in the membrane tank. It satisfies the primary needs of cottage owners. And only when the supply runs out will the pump turn on. It should be noted that all pumps have a turn-on rate of an hour. If there is a hydraulic accumulator, this figure will not be exceeded, and the unit will last longer.

- Stabilization of pressure in the system. If you turn on two taps at the same time, for example in the bathroom and in the kitchen, pressure changes can affect the water temperature. This is very unpleasant, especially for those household members who are taking a shower at this moment. Thanks to the hydraulic accumulator, such misunderstandings can be avoided.

- Water hammer. These phenomena, which can damage the pipeline, can occur when the pump is turned on. With a hydraulic tank, the risk of water hammer is virtually eliminated.

- Water supply. In a country house, the problem of water supply is especially acute. If there is a sudden power outage and the pump cannot perform its functions, then it is no longer necessary to store a supply of water in a bucket or other container to solve urgent problems. It is available in the hydraulic accumulator tank and is regularly updated.

Obviously, the presence of this device in a water supply system independent of centralized networks is not accidental. It is necessary and useful.

The hydraulic accumulator in the water supply circuit performs a number of significant functions: it protects equipment from water hammer, provides a supply of water, and creates conditions for automating its intake.

When a hydraulic tank is not needed

In irrigation systems, a hydraulic accumulator is not needed, since when the tap is constantly open, the pump will operate without turning off. If there is a storage capacity in this scheme, the equipment will be turned on frequently, which will lead to premature depletion of the resource.

When purchasing a pump with an automatic system that involves smooth engine starting, a hydraulic pump is also not needed. The pipes are not at risk of water hammer, since the fluid flow moves slowly.

Purpose

Before choosing the volume of a hydraulic accumulator for water supply, you should determine the main differences between different models.

Mainly, a correctly selected hydraulic accumulator allows you to:

- ensures optimal pressure in the system (working in tandem with a pressure switch);

- reduces the number of starts/stops of the well pump (maximum wear of the pump occurs at the time of its start-up);

- allows you to avoid troubles associated with water hammer in the system;

- provides low water flow without turning on the pump;

- creates a reserve supply of water in case of interruptions in its supply.

You also need to consider the following features:

- membrane manufacturing material;

- membrane or balloon design of a hydraulic accumulator;

- vertical or horizontal installation is provided for by the design.

Definition and purpose

A hydraulic accumulator (HA) is often called a hydraulic or expansion membrane tank. It should not be confused with a simple storage tank. It looks like an oval-shaped metal sealed can with thick walls and an elastic balloon or partition inside, where two chambers are formed - with water and air - which creates a certain pressure.

To better understand what a hydraulic accumulator is, you need to familiarize yourself with its functions:

- ensures stable pressure in the pipes. When several taps are opened simultaneously, it eliminates pressure drop, compensating for it using its own resources, and also ensures a stable temperature along with the water heater

- protects the water pump from wear, reducing the load on it, as its switching cycles become less frequent. Once the water tap is opened, it will only be activated when the reserve in the tank is depleted. The rate of starts per hour will decrease, thereby creating a reserve and increasing the service life

- eliminates water hammer

- ensures system autonomy for some time after a power outage. Users will always be provided with a supply of water depending on the capacity of the equipment, which is important for private homes

The purpose of the membrane tank is: compensation, leveling, ensuring autonomy of water supply with the creation of a certain water reserve. With this unit, the water supply will function when the power is turned off and in the absence of access to a water source

There are the following types of devices:

- for cold or hot water (blue or red housing, respectively), universal, especially for heating

- industrial or food (differ in membrane material)

- depending on the design: pneumatic and mechanical (load, spring)

Mechanical HAs are rarely used and are difficult to install and operate. The compression force in them is created by a load installed at a certain height, or a spring. Pneumatic samples with a membrane inside are more efficient, more autonomous and easier to operate. They are usually installed for wells.

Value for autonomous sources with pumps

This is why a hydraulic accumulator is needed for pumping stations. The normal operating mode of the pump, ensuring long-term uninterrupted operation, is 20 - 30 starts per hour. Even with a minimal drop in pressure, the relay will turn it on and off when the level is restored. In this case, the leak is compensated by the pump instantly and at the slightest water consumption it is activated, working almost idle, quickly exhausting its resource.

The hydraulic accumulator improves the described operating principle of the system. It forms the required supply of fluid and compensates for its consumption, eliminating idle operation, and also smoothes out sudden pressure surges when turned on.

Vertical or horizontal installation

Products are classified depending on the type of installation. There are devices that are installed horizontally. They are most often used to install a surface pump. For this purpose, a special platform is made on the surface of the tank.

Horizontal hydraulic accumulators are also convenient to mount to the wall. They are inconvenient to use with borehole pumps. Vertical models are suitable for well pumps. Installed vertically. Models of small volumes can be attached to the wall using special fasteners. All hydraulic tanks with a volume of over 35 liters have support legs on which the tank stands stably on the floor.

The mounting holes in the legs allow the tank to be securely fixed to the floor.

Types of hydraulic accumulator tanks

Hydraulic accumulators differ in the type of installation: they are horizontal and vertical. Vertical hydraulic accumulators are good because it is easier to find a suitable place for their installation.

Both vertical and horizontal versions are equipped with a nipple. Along with the water, a certain amount of air also enters the device. It gradually accumulates inside and “eats” part of the volume of the hydraulic tank. In order for the device to work properly, it is necessary to bleed this air from time to time through this very nipple.

According to the type of installation, vertical and horizontal hydraulic accumulators are distinguished. They have some differences in the maintenance process, but the choice is largely influenced by the size of the installation site

Hydraulic accumulators that are installed vertically have a nipple that is designed specifically for these purposes. Just press it and wait until the air leaves the device. With horizontal tanks everything is a little more complicated. In addition to the nipple for bleeding air from the container, a shut-off valve is installed, as well as a drain to the sewer.

All this applies to models capable of accumulating a liquid volume of more than 50 liters. If the capacity of the model is smaller, then there are no special devices for removing air from the membrane cavity, regardless of the type of installation.

But the air still needs to be removed from them. To do this, water is periodically drained from the accumulator and then the container is refilled with water.

Before starting the procedure, turn off the power supply to the pressure switch and pump, or the entire pumping station, if the hydraulic tank is part of such a device. After that, you just need to open the nearest faucet.

The water is drained until the container is empty. Next, the tap is closed, power is supplied to the pressure switch and the pump, and water will fill the accumulator capacity automatically.

Hydraulic accumulators with a blue body are used for cold water, and red ones for heating systems. You should not use these devices in other conditions, since they differ not only in color, but also in membrane material and ability to withstand a certain level of pressure

Typically, tanks intended for autonomous engineering systems differ in color: blue and red. This is an extremely simple classification: if the hydraulic tank is blue, then it is intended for cold water supply systems, and if it is red, it is intended for installation in a heating circuit.

If the manufacturer has not designated its products with one of these colors, then the purpose of the device should be clarified in the technical data sheet of the product. In addition to color, these two types of accumulator differ mainly in the characteristics of the material used in the manufacture of the membrane.

In both cases, it is high quality rubber intended for contact with food. But the blue containers contain membranes designed for contact with cold water, and the red ones - with hot water.

Very often, a hydraulic accumulator is supplied as part of a pumping station, which is already equipped with a pressure switch, pressure gauge, surface pump and other elements

Blue devices can withstand higher pressure than red containers. It is not recommended to use hydraulic accumulators intended for hot water systems for cold water and vice versa. Improper operating conditions will lead to rapid wear of the membrane, and the hydraulic tank will have to be repaired or even completely replaced.

How are calculations carried out?

First of all, we need to know:

- number of family members and approximate water consumption for them;

- the number of taps that residents will use;

- system pressure;

- number of permissible pump cycles per hour.

For example, if 4 people live in a house and they use 3 dismountable points, a 24 liter tank will be sufficient. But, if the number of points increases, you can take a 50-liter tank. If the volume of the tank is not enough, then the easiest way would be to install another one nearby. If you have a small house, then the most common volume of a hydraulic accumulator is 50 liters. It is enough for almost any home.

Tanks with a volume of 80 or 100 liters are installed less often. This is not necessary, but if you have extra money, it will definitely work.

If you need to accurately calculate the hydraulic accumulator, you can choose the capacity using the formula.

The pressure level in the air cavity of the hydraulic accumulator should be 0.1 less than the pump start pressure value set on the relay. For example, if it starts at 1.6 bar, then 1.3-1.5 bar is acceptable in the tank.

How is it different from an expansion tank?

Hydraulic accumulators are often confused with expansion tanks, even despite the fundamentally different problems that these devices solve. An expansion tank is needed in heating and hot water supply systems, since the coolant, moving through the system, inevitably cools and its volume changes. The expansion tank is set up when the system is “cold”, and when the coolant warms up, its excess, which is formed due to expansion, has somewhere to go.

The hydraulic accumulator is needed for completely different purposes: if it is not installed in the water supply system, the pump will be activated every time a tap is opened. If this happens often, then not only the pump, but the entire system wears out faster, since each time the pressure increases abruptly - a so-called water hammer occurs.

As a result, a hydraulic accumulator is installed with the aim of getting rid of water hammer and extending the service life of the system as a whole. In addition, the accumulator has other functions:

- Creates a certain supply of water (useful if there is a power outage).

If there are frequent interruptions in water supply, the hydraulic accumulator can be combined with a storage tank

- Reduces the frequency of pump startup. The reservoir is filled with a small volume of water. If the flow rate is small, for example, you need to wash your hands or wash your face, water begins to flow from the tank, while the pump remains turned off. It is activated after very little water remains;

- Maintains stable pressure in the system. In order for this function to be performed properly, an element called a water pressure switch is provided, which is capable of maintaining a given pressure within strict limits.

All the advantages of hydraulic accumulators make this device an indispensable element of any autonomous water supply system in country houses.

Reliable manufacturers

Before choosing the volume of a hydraulic accumulator, you should familiarize yourself with reliable companies whose products will definitely not let you down. Among the companies that have gained trust: 1. Gilex. Engaged in the production of equipment adapted for operating conditions in Russia. The line includes tanks of almost any volume. There are models with a galvanized or stainless steel body. There are also models with a galvanized or plastic flange. If necessary, spare membranes can be purchased for the tanks. 2. Wester. A very well-known manufacturer of membrane tanks for heating and hydraulic accumulators for water supply. The membrane itself is made of butyl rubber, which is not subject to rotting. If the membrane is damaged, it is easily replaced.

If you want to choose a hydraulic accumulator, we will be happy to help you. Call us now!

Manufacturers of hydraulic accumulators

Product prices

Table of manufacturers and approximate price

| Image | Company name | Manufacturer country | Volume (l) of hydraulic accumulator | Material | Price, rub) |

| Reflex | Germany | 25 | Steel | 2700-3500 | |

| 60 | 5000-8000 | ||||

| 80-100 | 8000-12000 | ||||

| 500 | 28000-51000 | ||||

| Wester | Russia | 24 | 1100-1200 | ||

| 50 | 3200-3400 | ||||

| 80-100 | 4200-5600 | ||||

| 500 | 23000-25000 | ||||

| GILEX | 24 | 1300-1400 | |||

| 50 | 3300-3400 | ||||

| 80-100 | 4700-6000 | ||||

| 500 | 23000-25000 | ||||

| Aquasystem | Italy | 24 | 1500-1700 | ||

| 50 | 4000-6000 | ||||

| 80-100 | 5500-7500 | ||||

| 500 | 24000-27000 | ||||

| Unipump | China | 24 | 1200-1400 | ||

| 50 | 2700-3000 | ||||

| 80-100 | 4300-5300 | ||||

| 500 | 7000-8500 | ||||

| 24 | Stainless steel | 3500-3700 | |||

| 80-100 | 10000-13000 | ||||

| UNIPRESS | 24 | 4200-4400 | |||

| 50 | 7000-7300 | ||||

| 80-100 | 9500-12500 | ||||

| HIDROFERRA | Italy | 24 | 4200-4400 | ||

| 80 | 11500-12500 |

Algorithm for selecting a hydraulic accumulator: simple about the complex

Based on the location of the tank, two types of hydraulic accumulators are distinguished.

- Vertical - suitable for installation in narrow spaces, taking up little space in width even with a large volume. Another feature is the nipple located on top of the body, through which it is easy to bleed excess air from the tank. As a rule, such models are purchased to work with submersible pumps.

- Horizontal - ideal for surface pumps, as they can be mounted on top of the tank. Despite the fact that such a tank takes up more space indoors than a vertical one, this installation method still saves space. The issue of removing excess air is solved as follows: an additional section of the pipeline is installed, which contains an outlet nipple, a ball valve and a drain.

It is worth noting that the air bleed nipple is provided only in large-volume hydraulic accumulators, usually from 100 liters.

If you buy a 24 or 50 liter tank, make the choice in favor of a vertical or horizontal device based only on ease of installation.

Removal of air in such tanks occurs due to complete emptying - a ball valve is additionally built into the system.

Taking pressure into account

The recommended pressure in the hydraulic accumulator is considered to be a value that is 0.1 - 0.5 bar less than the switching pressure of the automatic pump.

So, for example, for a pump with a minimum pressure value when starting the automation of 1.6 bar, the normal pressure value in the tank will be 1.3 - 1.5 bar. This is the minimum air pressure .

Manufacturers also indicate the maximum pressure possible when the equipment is operating. For different models it can range from 6 to 10 bar.

When purchasing a tank, check the pressure in it using a pressure gauge. To connect it, there is a special nipple in the tank body. Some models already have a pressure gauge installed. Make sure that the pressure corresponds to the required value - you need to proceed from the pump activation data.

It is important to understand that water does not enter the tank itself, but into the membrane. If the pressure is less than recommended, the membrane will be filled with water more than it should be - the pump will turn on less often, but this can lead to rupture of the membrane. This is why it is so important to check the pressure in the tank every six months.

If the value is low, you need to pump in air using a car pump. But you don’t need to be too zealous - exceeding the permissible pressure will affect the reduction of the possible water supply in the membrane, which means the pump will turn on more often.

Maintaining the recommended value is the key to trouble-free operation of the water supply system.

Calculating the volume of the tank

This stage is perhaps the most critical. After all, both the efficiency of the water supply system and the money spent on purchasing the tank will depend on the selected volume - the larger it is, the more expensive it is.

In addition, the volume also determines the dimensions of the device: larger tanks require more space during installation.

Thus, you should approach this issue rationally so that there are no installation problems or unreasonable financial costs.

It is important to understand that it is not entirely correct to start from the required water supply. Many buyers believe this: the larger the tank, the more liquid is in reserve, therefore, in the absence of electricity and the pump is turned off, this water can be used.

Let's face it: storing water is not the main function of a hydraulic accumulator - there are storage tanks for that. This is only a means of compensating the pressure in the system and reducing the number of pump starts - this is the main goal.

We will carry out calculations precisely from these considerations.

There are rough recommendations for choosing based on several parameters. For example, according to the number of water points: for 1 - 2 points a tank with a volume of up to 50 liters is required, for 3 - 4 points - with a volume of 80 - 100 l, for 4 - 5 points - with a volume of 150 - 200 l.

This parameter is also determined based on the pump power: for 0.5 kW - 24 l, 1 kW - 50 l, 1.5 kW - 100 l. These values are approximate and only reflect the dependence of the accumulator volume on the pump power and water flow.

We offer you a more accurate calculation algorithm.

First, let's determine

the total coefficient of water consumption (Cy) in the house.

To do this, you need to make a list of all water points and indicate their number. To make the algorithm more understandable, we will carry out the calculation using an example. In the House there is:

- mixers – 2 pcs. (sink and shower),

- toilet – 1 pc.,

- washing machine – 1 pc.

We will calculate using the formula: Su = Cx*n , where Cx is the utilization factor, n is the number of water points. Table No. 1 will help you determine the utilization rate .

| Drawing point | Cx |

| Toilet | 3 |

| Shower | 2 |

| Bathroom | 2 |

| Faucet in washbasin | 6 |

| Faucet in kitchen sink | 2 |

| Washing machine | 2 |

| Dishwasher | 2 |

| Watering tap | 2 |

Based on our example, we get the following: Sink = 2, Shower = 2, Toilet = 3, Washing machine = 2. General coefficient = 2+2+3+2=9. Based on this value, we determine the maximum water flow, Amax. Table No. 2 will help with this .

| Su | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 25 | 30 | 35 |

| Аmax, l/min | 12 | 18 | 24 | 30 | 36 | 40,8 | 46,8 | 51 | 55,8 | 67,8 | 78 | 87,6 |

Since for our example the value Cy = 9 and according to the table we can bring it closer to 8, the total water flow will be approximately 24 l/min.

Now let's start calculating the required volume, Vt. To do this we use the formula:

Vt=K*Amax*(((Pmax+ 1)*(Pmin+1))/((Pmax-Pmin)*(Pprec+1))), where

- Vt – hydraulic accumulator volume, l;

- K – coefficient corresponding to the pump power;

- Amax – maximum water flow, l/min;

- Pmax – maximum pressure value to turn off the pump, bar;

- Pmin – minimum pressure value to start the pump, bar;

- Pprec – initial pressure in the accumulator, bar.

Table No. 3 help determine the coefficient K.

| R, kW | 0,47 – 1,5 | 1,5 – 2,5 |

| TO | 0,25 | 0,375 |

The P indicator is the power of the pump, which can be found in its technical data sheet or instructions. Let's assume that in our case it will be 1 kW. Therefore, K = 0.25.

We have already calculated the water consumption, so Amax = 24 l/min.

As for pressure, for calculation we take the following indicators for turning on the automation: Pmin = 1.6 bar, and Pmax = 2.7 bar. You can find them in the passport of the pump or automation unit. Pprec = 1.5 bar.

We get:

Vt=0.25*24*(((2.7+1)*(1.6+1))/((2.7-1.6)*(1.5+1)))=6 *((3.7*2.6)/(1.1*2.5))= 6*(9.62/2.75)=6*3.5=21

According to our calculations, it turns out that the volume of the hydraulic accumulator should be at least 21 liters. You can purchase a 24 liter tank, since models of this volume are widely represented on the market. The above formula helps determine the minimum volume value. Depending on your needs, you can safely increase it by purchasing a tank with a volume of both 50 and 80 liters.

To determine the volume of the tank for your water supply system, use the given algorithm, taking the parameters of your pump, automation, and the number of water points. The example we considered proves that making the necessary calculations is not so difficult. We hope that the information in this article will help you do everything right.

You can buy a hydraulic accumulator in our online store. We offer vertical and horizontal models with volumes from 24 to 200 liters, so you can easily choose the right model. To place an order, use the “Buy in 1 click” service or call the manager at 8-800-333-83-28.

Source: https://www.vseinstrumenti.ru/rashodnie_materialy/sadovaya_tehnika/dlya_nasosov/gidroakkumulyator/articles/1501/

Purpose of the equipment

A hydraulic tank built into the water supply system solves this key problem - it ensures the accumulation of the required volume of water with its subsequent transfer to the pipeline in the event of a reduction in pressure in it.

The formed water supply allows you to eliminate unnecessary pump activation when the tap is turned on for a short time, since the water supply comes from the hydraulic tank.

Ultimately, thanks to the hydraulic accumulator, the number of starts and stops of the pumping system is reduced and the period of effective operation of the pump is increased.

The design of the hydraulic tank is a hollow metal cylinder, made completely sealed. This cylinder contains a special membrane called a “pear”. It is made of special rubber - butyl or synthetic ethylene-propylene rubber is used.

The advantages of these materials are due to their strength, resistance to the action of various microorganisms and compliance with sanitary criteria.

The membrane allows you to divide the internal space of the tank into 2 parts - with water and air, respectively. When the tap is open, under the action of compressed air, water is squeezed out of the first chamber of the hydraulic tank into the pipeline of the house.

The principle of operation of a hydraulic accumulator for water supply assumes its cyclic nature:

- A drop in system pressure parameters when the water in the hydraulic tank is completely consumed leads to the activation of the pressure sensor, followed by the start of the pump, which provides water intake.

- When the “pear” is filled with water, the volume begins to increase while the air is compressed and the pressure in the hydraulic tank increases.

- After the activation of a special relay that sends a signal, the pump stops working.

- Subsequent short-term water consumption comes from the hydraulic tank without the need to start the pump. When the water is completely consumed, the cycle resumes after the pressure switch reacts.

How to use

After the accumulator is installed, it must be properly maintained. About once a month you should check the pressure switch settings and adjust them if necessary. In addition, you need to check the condition of the housing, the integrity of the membrane and the tightness of the connections. The most common failure in hydraulic tanks is diaphragm rupture. Constant cycles of tension and compression eventually lead to damage to this element. Sudden changes in pressure gauge readings usually indicate that the membrane has ruptured and water is entering the “air” compartment of the accumulator. To make sure there is a breakdown, you just need to bleed all the air from the device. If water follows it from the nipple, then the membrane definitely needs to be replaced. Fortunately, these repairs are relatively easy to make. To do this you need:

- Disconnect the hydraulic tank from the water supply and power supply.

- Unscrew the bolts that hold the neck of the device.

- Remove the damaged membrane.

- Install a new membrane.

- Reassemble the device in reverse order.

- Install and connect the hydraulic tank.

Upon completion of the repair, the pressure settings in the tank and pressure switch should be checked and adjusted. The connecting bolts must be tightened evenly to prevent the new membrane from warping and to prevent its edge from sliding inside the hydraulic tank housing. Replacing the accumulator membrane is relatively easy, but you need to make sure that the new membrane is the same as the old one. To do this, install the bolts in the sockets, and then alternately make just a couple of turns of the first bolt, move on to the next, etc. Then the membrane will be pressed against the body equally along the entire circumference. A common mistake made by beginners in repairing a hydraulic accumulator is the incorrect use of sealing agents. The installation site of the membrane does not need to be treated with a sealant; on the contrary, the presence of such substances can damage it. The new membrane must be exactly the same as the old one both in volume and configuration. It is better to first disassemble the hydraulic accumulator, and then, armed with a damaged membrane as a sample, go to the store for a new element.

Operating principle of a hydraulic accumulator