Thanks to modern equipment, a private homeowner has the opportunity to set up an autonomous water supply system at will. For seasonal living in a country house or dacha, a pumping station without a hydraulic accumulator is quite suitable, although this solution is used less and less due to its impracticality.

Let's consider the principle of operation, the pros and cons of a system that operates directly from a well or well to water collection points. We will evaluate the feasibility of such a solution, and also present options for organizing water supply without a hydraulic accumulator.

Is it advisable to abandon the hydraulic accumulator?

When designing a water supply system for a house, it is necessary to take into account factors such as the number of consumers, the volume of pumped liquid, and the resource of a well or borehole. If water is required on an ongoing basis and in large quantities, then you simply cannot do without a hydraulic accumulator.

A pumping station with a hydraulic tank ensures a continuous supply of water to the house, and if a power outage suddenly occurs, the supply of liquid is enough to finish your business. The volume of the tank is selected based on needs.

The average volume for domestic use is 25-50 liters, but for frequent use it is better to immediately purchase a 100-200 liter tank or include a storage tank as an addition to the circuit.

The hydraulic accumulator performs several important functions: it stabilizes the water pressure in the system, protects equipment from water hammer, and increases the service life of the pump.

The water supply system can operate without a hydraulic accumulator. In essence, it is a pump connected by a pipeline to water collection points. The main disadvantage of such a system is the rapid wear of pumping equipment.

In a system with a hydraulic tank, the pump is turned on only when necessary, but here it will turn on every time someone opens a water tap or wants to water the flowers. Due to frequent activation, the engine fails faster, and the pump has to be repaired or replaced more often than usual.

Connection diagram for a pumping station without a hydraulic tank. A surface pump is installed in the basement, water is supplied through a suction pipeline lowered into a well (well) (+)

However, manufacturers have not abandoned models without a hydraulic tank, because they are in demand. Most often they are of interest to owners of summer cottages who use the water supply system only in the summer - for recreation, growing vegetables or flowers.

Let's consider situations in which you can get by with one pump, without a hydraulic accumulator:

Image gallery

Photo from

Watering lawns or flower beds

Caring for garden beds

Drip irrigation system

Summer house for seasonal stay

Thus, if there is no need for a large amount of water, which must be supplied stably, constantly and have a reserve, you can get by with an ordinary automatic pump. In other cases, a hydraulic accumulator is required.

Correctly setting up a new device

The new hydraulic tank should be checked to see what its internal pressure level is. It is assumed that it should be 1.5 atm. But during transportation of the product from the place of production to the warehouse and during storage, a leak could occur, which reduced this important indicator at the time of sale. You can check the pressure by removing the cap on the spool and taking measurements.

To measure pressure, you can use different types of pressure gauges:

- Electronic. These are expensive devices. Their performance may be affected by temperature and battery charge.

- Mechanical. They are produced in a metal case, otherwise called automobile ones. If this device has successfully passed the test, then you couldn’t find it better. To get the most accurate value, since you will only need to measure 1-2 atm, it is better to buy a device with a large number of divisions on the measuring scale.

Inexpensive pumping stations and automatic pumps are most often equipped with pressure gauges in a plastic case. The error in the readings of such Chinese models is too great.

If there is less air in the tank than needed, water will take its place. This will affect the water pressure in the water supply. At high pressure, the pressure will always be high. Higher pressure will provide less water in the membrane bulb, so the pump will have to turn on more often. If there is no light, the water supply may not be enough for all needs.

That's why sometimes it makes more sense to sacrifice pressure to achieve other important goals. However, it is better not to reduce the pressure below the recommended values, nor to exceed the maximum characteristics. Lack of pressure can lead to contact of the bulb surface with the tank body, which is undesirable.

You can use different devices to measure pressure, but the optimal one is a relatively inexpensive automobile pressure gauge with a metal body and a fairly comprehensive scale of measurement results.

Operating principle of a system without a hydraulic tank

Equipment pumping water works the same way: it takes liquid from a source - a well, a well - and pumps it into the house, to water collection points. The pump can be either submersible or surface pump.

The role of connecting lines is performed by pipelines made of polypropylene pipes or flexible hoses. In the same way, water is supplied to the bathhouse, garage, summer kitchen, and swimming pool.

So that water can be used in autumn or early spring, it is recommended to insulate the well and bury the pipes to a depth of 70-80 cm - then the liquid will not freeze even during frosts

The difference concerns the use of additional devices, such as a hydraulic accumulator, pressure switch, etc. Installing pumping equipment without means of control and adjustment is extremely dangerous - primarily for the equipment itself.

The simplest example of equipment for providing dacha residents with water in the summer is the AL-KO garden pump. You can use it to water plants, organize a shower, or fill a pool with water.

If a large amount of water or a more stable supply is needed, another important element is included in the scheme - a storage tank. First, the water flows into it, and only then to consumers.

When using household pumps, the liquid volume is usually from 2 to 6 m³/h. This amount is usually enough if the station is connected to a well or borehole and serves a country house.

When choosing a unit, it should be taken into account that the absence of a hydraulic tank accelerates the wear of parts, so the equipment must be durable - with a steel or cast iron body coated with anti-corrosion paint.

The pump functions are controlled using a pressure switch, which is responsible for regulating the pressure. For control, the easiest way is to install a pressure gauge, which is usually equipped with automatic pumping stations.

In the absence of a hydraulic accumulator, the pressure switch is connected directly to the pumping station or integrated together with a dry-running relay into the pipeline

In addition to equipment for pumping water, you will need an electrical cable, a connection point to the network and grounding terminals. If the ready-made solution does not satisfy your needs, the station parts can be purchased separately and then assembled at the installation site. The main condition is the compliance of the system elements with characteristics.

Specifications

| Specifications | |||

| Capacity in liters | Water pressure | Length Width Height | Connector size, inches |

| 14 | 8 | 373x240x261 | 3 x 4 |

| 18 | 403x260x282.2 | ||

| 24 | 450x270x290 | 1 | |

| 50 | 540x350x375 | ||

| 100 | 10 | 450x450x840 | |

| 200 | 600x600x1020 | 1 by 1/2 | |

| 300 | 650x650x1110 | ||

| 500 | 650x650x1715 | ||

| 750 | 800x800x1920 | 1 to 1/4 | |

The company provides competitive prices for its products.

| Products | |

| Model | Price, rub. |

| 6 VP | 700.00 |

| 6 V | 700.00 |

| VP 80 | 4700.00 |

| At 80 | 4700.00 |

| 10 VP | 800.00 |

| 10 V | 800.00 |

| 14 GP | 950.00 |

| 14 G | 950.00 |

| 18 G | 1050.00 |

| 24 GP | 1300.00 |

| 24 G | 1300.00 |

| 35 G | 2300.00 |

| 35 GP | 2300.00 |

| 50 G | 3300.00 |

| 50 GP | 3300.00 |

| 150 VP | 9000.00 |

| 150 V | 9000.00 |

| 50 V | 3300.00 |

| 50 VP | 3300.00 |

| 100 V | 6000.00 |

| 100 VP | 6000.00 |

| 200 V | 12500.00 |

| 200 VP | 12500.00 |

| 300 V | 15500.00 |

| 300 VP | 15500.00 |

| 400 V | 17500.00 |

| 400 VP | 17500.00 |

| 500 V | 23000.00 |

| 500 VP | 23000.00 |

| 750 V | 65000.00 |

Water supply without accumulator

If you exclude the hydraulic accumulator from the water supply scheme, then two options are possible:

- using a pump to supply water directly to water collection points;

- connecting a storage tank.

Both options are actively used, but the first is optimal for irrigation systems with a small volume of liquid, and the second is most appropriate when you need to provide water to a shower, kitchen faucet - that is, consumers inside the house.

Option #1 - connecting the pump directly

There are many interesting solutions, but the most practical and economical are automated irrigation systems. They work only during periods when there is no rain, and are installed wherever regular watering is necessary - in the garden, near flower beds, on lawns.

One of the options is an expanded irrigation system for a personal plot. It is fully automated. To set the on/off time, connect the controller. Solenoid valves can be installed on each individual line so that they can be operated separately.

Approximate scheme of automatic watering of a summer cottage. Transportation of liquid from a well or well is carried out through pipes with a diameter of 19 mm (central) and 16 mm (branches) (+)

The rain sensor makes the irrigation system more efficient: during rainfall, the pump does not function.

The procedure for installing the irrigation system:

- we place the pipes on the surface of the earth according to a pre-designed diagram and connect them with fittings;

- we install sprinklers, drip systems, watering hoses;

- we equip a pumping group - a surface unit and a pressure switch;

- connect the water supply, test the system for leaks;

- if all is well, we dig trenches 30 cm deep, build a drainage cushion from crushed stone and sand, lay the pipeline and fill it up;

- We carry out repeated testing to check the tightness, check the performance of all lines;

- connect the controller and rain sensor;

- We check the operation of all elements of the system.

If the throughput is small, we set up alternate operation of the lines. This is a complex circuit that requires knowledge of how to configure the equipment. The simplest is a regular “Baby” type pump with watering hoses connected to it.

Option #2 – scheme with a storage tank

With the advent of technologically advanced hydraulic accumulator stations, the scheme has become less popular, but is still in use. It is simple and differs in that there is a storage tank between the pump and the water collection points.

Diagram of a water supply system with a storage tank. To ensure the movement of water through the pipes at a certain speed and pressure, an additional circular pump is installed

One of the conditions for operating the system is the organization of water treatment. The first filter is installed on the suction pipe for surface pumps, and on the equipment itself for submersible pumps. The second is at the entrance to the house. It is better if it is a set of two filters, coarse and fine.

After the filtration system, a storage tank is installed, and a pipe (or pipes) goes from it to the water collection points.

Traditionally, the tank is installed as high as possible - for example, in the attic. The high location increases the pressure in the system, which will function even in the absence of electricity

Storage tank - any tank of suitable volume. Previously, they used galvanized metal tanks, now they use plastic containers of various configurations. They are equipped with one inlet pipe for supplying water from a well, and two outlet pipes for distribution to consumers and drains.

The top of the tank is covered with a hinged lid that protects the liquid from debris and dust. By removing the lid, you can analyze the condition of the tank and the water stored in it. In case of severe contamination, the liquid is released through the drain pipe and the tank is washed.

The main controlling element is the float mechanism. As soon as the water level reaches the maximum level, the inlet pipe is closed and the supply to the tank stops. At a low level, on the contrary, the inlet opens and water begins to flow into the tank.

Plastic storage tank installed in the attic. It is lighter in weight than a metal container, so it is much more convenient to install. To prevent the water from freezing, in the northern regions the walls of the tank are insulated

The advantage of using a storage tank: there is always a supply of water, which is supplied under low pressure, even if all pumps are turned off. The downside is that it's difficult to install. Large tanks require space and a base that can support their weight.

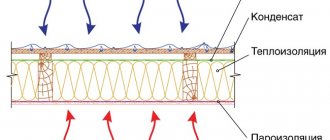

In the case of installing systems for year-round operation, the attic, or at least the tank itself, located in an unheated attic space, must be insulated.

To avoid overflow and flooding of the floors located below, storage tanks must be equipped with overflow pipes. If the permissible volume is exceeded, the water will flow through the overflow hole located in the upper third of the tank through the pipe connected to it into the sewer.

Varieties by type of pump

With built-in ejector

Pumping stations are classified according to the type of working pump, which can be with or without an ejector. The operating principle of ejector modifications (with a built-in ejector) is that water rises due to the created vacuum. They have a higher cost compared to simpler models, but thanks to their special design they are able to supply water from great depths - 20-45 m. Such pumping equipment is characterized by high productivity, but the operation is accompanied by a high noise level. For this reason, such a pumping station should be installed in a utility room and, if possible, outside the residential building. Equipment of this type is most often preferred when running a large subsidiary farm and to satisfy gardening needs.

The design and principle of operation of the pumping station This compact design has a very productive station with a built-in ejector

With remote ejector

In addition, consumers are offered pumps with a remote ejector, which, together with two pipes, is lowered into a well or well. Through one pipe, water is supplied down to the ejector, which leads to the creation of a suction jet. This design is noticeably inferior in terms of its operational characteristics compared to a classic ejector pump. Such pumps are “afraid” of the presence of air and sand in the system. In addition, their efficiency is much lower. But a station with such a pump can be placed in a house without any problems, even if the well is located at a distance of 20-40 meters.

Design and principle of operation of a pumping station Comparative table of operating parameters of a pumping station with a remote ejector using the example of Pedrollo models for a summer residence

Ejectorless designs

When equipping a pumping station with equipment without an ejector, water suction is performed according to a different scheme. In this case, the key role is played by a special multi-stage design related to the hydraulic part. Such pumps operate virtually silently and with less energy consumption. In this article we have reflected only the main options for constructing a classic pumping station. It is these structures that can most often be found in private households. In fact, there are a huge number of pumps on the basis of which the stations are assembled. Everyone can independently assemble such equipment, taking into account their own capabilities and needs.

Positive and negative feedback

How good a system without a hydraulic accumulator is in practice is best judged by the reviews of users - owners who have been using it in their homes for a year or more.

One of the advantages is the compact size and ergonomics of the pumping station. There is no hydraulic accumulator that takes up a lot of space, making it much easier to find a small corner to install the pump.

You can use different types of pumps with equal success, including submersible units - then only the pipeline and control devices will appear on the surface.

The cost of a unit without a hydraulic tank is lower, and installation is simpler.

An example of a pumping station that can be used for domestic servicing of a dacha. The pump is equipped with a pressure switch and dry-running protection

There are also disadvantages, the main one being insufficient power. A system without a hydraulic accumulator has minimal performance, and pumping equipment is constantly at risk of failure.

It is not protected from water hammer, and from frequent switching on/off it simply wears out earlier than stated by the manufacturer.

Today, when there are many models on the market with a hydraulic accumulator costing from 8,000 rubles, the system with a storage tank is considered outdated and irrational.

Comparative characteristics of deposit and savings certificates and bonds of one issuer

| Types of risks | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Systemic (market) | ||||||||||

| Country | ||||||||||

| Legislative changes | ||||||||||

| Inflationary | ||||||||||

| Foreign exchange | ||||||||||

| Industry | ||||||||||

| Regional | ||||||||||

| Credit (business) | ||||||||||

| Liquidity | ||||||||||

| Percentage | ||||||||||

| Fraud | ||||||||||

| Capital | ||||||||||

| Selective | ||||||||||

| Temporal | ||||||||||

| Revocable | ||||||||||

| Supplies | ||||||||||

| Operating | ||||||||||

| Settlement of settlements | ||||||||||

| Average risk of a given security |

- personalized deposit or savings certificates

- bearer certificates of deposit or savings certificates

- registered bonds

- bearer bonds

- bonds secured by property collateral

- unsecured bonds

- discount bonds

- coupon bonds that pay interest once a year

- coupon bonds that pay interest more than once a year

- floating rate bonds

2. Analyze the investment qualities of certificates of deposit and savings certificates as types of securities.

Give a comparative description of the investment quality of deposit and savings certificates in comparison with other types of securities traded on the Russian stock market.

How to make the right choice?

Manufacturers provide a wide range of models for a country house. Volume indicators range from 6 liters to 750. The determining criterion for selection is the volume of water consumed. The volume of 50 liters is enough for a family of 2 people, not taking into account the maintenance of the yard area.

If you have flower plantings on your site, then the optimal volume will be 50-100 liters. When choosing a size, consider the number of household appliances that use water and consider the possible purchase of additional ones. But in this case, you can simply replace the tank capacity with a larger one. The process of installing a hydraulic accumulator is quite simple and does not require special skills.

Imported tanks are not suitable for domestic water supply systems. Therefore they do not live up to expectations. The Russian brand Gilex produces products and components of the highest quality at low prices.

Previous articles Next articles

Related Posts

- 25.03.2017.

What is a hydraulic accumulator and how it works

- 25.03.2017.

Replacing the membrane in the hydraulic accumulator

- 25.03.2017.

Why assemble the pumping station yourself.

First of all, it seems to me that you should assemble the pumping station yourself if you already have some of its components, usually the most expensive ones. This is a pump and a hydraulic accumulator. Because the cost of the pump is approximately half the cost of the pumping station, respectively, the hydraulic accumulator is approximately a third. That is, it makes no sense to buy a new pumping station if your accumulator is crushed in winter or the pump burns out for some reason. You can buy both separately and simply replace what is broken; fortunately, the pump fasteners and the hydraulic accumulator mounting platform are, as a rule, standard and you can connect one to the other without much difficulty.

Another reason to assemble a pumping station yourself may be a discrepancy between your requirements and the characteristics of the equipment of the finished pumping station. For example, you need a pump with higher pressure or water flow than the pumping stations offered to you, and what suits you in terms of characteristics does not suit you in terms of cost or reliability. Either the dimensions of the pumping station are too large for the place where you are going, or you are not satisfied with the capacity of the hydraulic accumulator, well, etc. You just need to keep in mind that the final cost of the pumping station may well be much more than what you planned.

The third, most common option is when you are forced to assemble a distributed pumping station due to very... As a rule, in this case, a powerful submersible pump is used, and a hydraulic accumulator with an automation unit is installed somewhere at home.

Installing a pumping station at your dacha with your own hands: choosing a location

In principle, deciding on the location of installation of a pumping station for a summer residence is not so difficult - there are not many options, unless, of course, you reinvent the wheel. In most cases, it is installed either in a pit near a well or well directly in the house, or a separate room is allocated for it. In any case, it is impossible to get rid of laying an underground water supply system. The only option that allows you to do this is to drill a well in the basement of the house - you understand that this cannot be done with the building erected, so we will leave this option alone and deal with the features, or rather, the advantages and disadvantages of the three previous places installation of a pumping station.

In a pit near the well. There are quite a lot of disadvantages of such an installation, compared to other methods of installing a pumping station. And the most important of them lies in the pit itself - despite the fact that it is not difficult to build, it still requires additional money and time. Moreover, when installing a pumping station in pits, you place it on the street, from where all the other shortcomings of this installation site arise. Firstly, it is unsafe (if the dacha is rarely visited, it can simply be stolen); secondly, it is the constant exposure of the pumping station equipment to various weather conditions (even though you equip the pit with a reliable lid, it is still moisture, frost, and heat). And thirdly, it is extremely inconvenient to maintain such a station. Of the advantages, only one point can be highlighted - the noise of the pump unit engine does not cause problems for home owners.

Schemes of pumping stations.

The most common scheme of a pumping station is when all its elements are assembled together, as one reader wrote: “pump on a barrel.” In this case, the automation unit is placed at the pump head, and water is directed to the hydraulic accumulator through a separate pipe or flexible connection. It turns out that you can install a pump and a hydraulic accumulator (HA) in different places by simply replacing the outlet to the HA with a longer one.

But the best option would be to install the automation unit on the GA by connecting the unit’s manifold to the pump with a pipe. Then we get a distributed pumping station, where the pump can be located, for example, in a well (or in a well for a submersible pump), and the HA is located in a warm house.

Continuing to improve our scheme, we can find the most convenient place for the automation unit.

I imagine such a place is the cold water distribution manifold, where the automation unit will maintain constant pressure (after all, this is exactly what we need). The hydraulic accumulator, in this case, can be placed under the bathtub or in any other free place in the bathroom, and a pressure pipeline will be connected to the pump. The pump itself can be placed closer to the source of water supply and away from the house, so as not to hear its noise, or you can buy a submersible pump (again, no noise in the house). Hello, dear readers of “San Samych”. It seems to me that there is no need to repeat the truism that the pump is the “heart” of the water supply system...

Technologies in the field of pumping equipment today allow a private homeowner to completely take on the task of providing water. Models of pumping stations with compact dimensions cover irrigation needs, and powerful units with increased productivity realize the lifting of water to the second floor. To maintain stable pressure in the circuits, developers are increasingly using a hydraulic accumulator. This solution has many obvious advantages, but such power additions are not always appropriate from the point of view of operational rationality. In turn, a properly selected pumping station without a hydraulic accumulator can provide the target facility with water with minimal financial and technological costs.